Types and properties of insulation materials

Insulating materials (MI) - this is something that no construction or repair work can do without. The scope of their use is so wide that it is sometimes difficult to determine which and where material to use.

general characteristics

In all variety of insulating materials It is customary to distinguish several basic types:

- heat insulation;

- insulation;

- waterproofing;

- steam and air insulation;

- windscreen.

Construction materials are subject to the construction regulations and building codes. So, work on the installation of roofing and insulation is recommended to be carried out at a temperature of from +60 to -30 degrees Celsius. When working with hot mastic, the lowest possible air temperature should not be below -20 degrees, and for water-based compositions without special additives up to -5 degrees.

According to the requirements, the course of action for the insulation of the room should be as follows:

- smearing seams between the plates;

- application of temperature-shrinkable compositions;

- installation of embedded elements;

- plastering of the treated parts to the required height.

IM and paint and varnish compositions are superimposed in a uniform layer. The more even layer (without large overlaps and uncovered spots), the higher the operational properties.

After the work is done, you should check the quality, guided by the following criteria.

- For waterproofing. Examine the joints and holes in the building on the subject of fullness of the material, assess the quality of the caulking. It is necessary that there are no leaks and interruptions in the seams, especially in the metallized waterproofing.

- For roofing materials. Tie angles should not be with sharp, protruding angles. You should inspect the bowls of drains - their level should not be above the surface of the roof. Visible gaps in the structure, chips, cracks are unacceptable.

- For thermal insulation. Evaluated the continuity of the seams, the quality of processing fasteners, equipment, various parts.There should be no damage, sagging of the material and a loose fit to the roof or wall.

Following the rules and regulations will allow to avoid mistakes and correctly, from a technical point of view, to do all the work.

Production Development Trends

The building materials market is growing by tens of percent every year. The increasing pace of housing construction dictates a high need for equipment, materials, including insulation.

The Russian market of insulating materials is one of the most dynamically developing markets in the European part of the world. IM are in high demand due to the following factors:

- the growth rate of construction in the country as a whole;

- growth in the share of commercial real estate;

- increase in prices for energy and utilities;

- the increase in the volume of housing requiring repair (old housing stock);

- increase in repair of heat networks of the old sample;

- toughening SNiP in the Russian Federation.

The current situation on the market of insulation materials dictates its own rules. In order to remain competitive, enterprises increase production volumes and increase production capacity.

Experts suggest that the most reliable position in the near future will be taken by those companies that produce IM in ready-made building structures, for example, sandwich panels. The production of integrated systems for the insulation of houses from the outside is also promising.

The warming of the situation on the insulating materials market is also associated with the modernization of old equipment and the improvement of investment in this industry.

Kinds

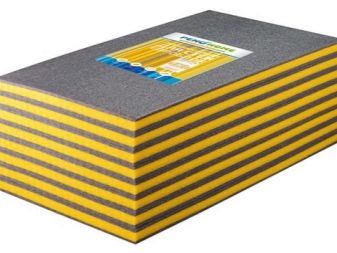

Insulating materials are divided into several types, among which there are their next row.

- Organic They are made from waste after woodworking, as well as substandard wood, peat, some crops and gas-filled plastics. Organic MIs have a very low fire safety and are not used at temperatures above +150 degrees.

- Inorganic. These are mineral wool and slabs of it, cellular concrete, fiberglass, foam, and others. Often made of asbestos and foamed mineral rocks (vermiculite, perlite). Possess high-temperature properties.

- Mixed. Such MIs are produced from minerals with the addition of organic matter (wood).Have higher fire resistance and durability, especially in comparison with natural materials.

Currently, inorganic and mixed materials are the most common, as they have higher technical characteristics and durability.

Purpose

Materials for thermal insulation reduce heat loss, and therefore reduce energy costs for heating the room.

By type they are:

- solid;

- powdered or granular;

- fibrous.

They allow you to reduce the thickness of the walls of a building without heat loss, thereby reducing the financial costs of construction. In addition, they have a high density, with high porosity, which only slightly reduces the strength of this insulating material.

For sound insulation are used to reduce penetrating noise.

Were widely used both in production and in the repair and construction of residential facilities.

Divided into 2 types.

- Sound absorbing. Apply in the device of ventilation, conditioners to normalize noise level. In concert halls and studios they create perfect audibility.They are made of mineral wool and fiberglass. Soft insulation is made in mats and rolls, one side of which is covered with a thin layer of aluminum, polyvinyl chloride or asbestos. Semi-solid insulation is made from the same materials as soft, and is a plate. Solid MIs use suspended minvata and paste as a binder.

- Gasket. Silenced sound waves and do not let them inside the premises. Available in rolls and plates of fiberglass and mineral wool, as well as plastic filled with special gas.

Waterproofing is necessary to protect objects from moisture and rain. Prevents condensation.

Divided into several types, depending on the material of manufacture.

- Asphalt. Presented in the form of paints and varnishes and paints. They are made both in cold and hot ways from bitumen, concrete and asphalt.

- Plastic. Available in several forms: varnish, film and paint from polyvinyl.

- Mineral compounds. They are made of silicates, are a paint.

- Metal. Apply aluminum foil and sheets of various metals, including galvanized steel.Can be used for pipelines.

Particularly valuable IM penetrating action (paints, varnishes and mastics). They fill the voids with water-insoluble compounds in the concrete, while not violating vapor permeability.

Vapor barrier eliminates the formation of excess moisture and allows you to effectively remove the steam. It includes: PVC membranes, some polymers, foil.

A huge amount of insulating materials is being produced, and new ones are constantly being produced, with improved technical indicators.

Tips for choosing

The use of insulation materials must be thoughtful and individual. On this will depend not only the final cost of construction and repair work, but also the correct functioning of the building, as well as the period of its trouble-free operation. It should be at the planning stage and drawing up the drawings to determine the type and type of insulation. In case of individual construction, it is possible to seek professional help from construction experts, however, it is quite possible to cope with this task independently.

In order to choose the right insulation, you should follow these guidelines.

- To determine what insulation is necessary for, then its type is selected (heat, hydro, or other). At the same time, it is necessary to pay attention to the technical characteristics of a particular manufacturer indicated on the material packaging: thermal conductivity, stability, strength, fire resistance (burning or incombustible), service life and environmental safety.

- Consider how the work will be done. If you need to perform waterproofing in a small area, it is better to give preference to liquid formulations that can be applied with a brush or roller. But for a large area, for installing underfloor heating, to insulate water pipes, it will be more convenient to use a film - so both time and labor costs will be significantly lower.

- To approach the issue of isolation should be a complex. It is necessary to consider not only the type of material (sheet, mats, paintwork materials), but also take into account the features of the building. For example, at the device of thermal insulation the number of doors and windows is always taken into account, since the main amount of heat is lost through them.

- It is better to choose materials that can be mounted outside the room.So the useful area is not lost, and the subsequent work by finishing coverings is simpler to make outside, than inside.

Insulation materials are experiencing a real boom. A large number of organic and synthetic materials on the construction market allow you to choose the best option for any kind of work.

About modern insulation described in the next video.