Self-adhesive insulation: what is it and where is it used?

For insulation of buildings and structures of various types and purposes, as well as preventing the penetration of drafts into residential premises, manufacturers of modern building materials offer buyers insulators with an adhesive base. Self-adhesive insulation is a unique building material that allows you to reduce heat loss and increase the level of insulation of the room. A wide range of products of different widths, reasonable price, ease of installation and reliable fixation of the product to the working surface made insulation a popular and popular building material.

Features and benefits

The unique properties of self-adhesive heaters make it possible to carry out work on the insulation of walls, ceilings, pipes, windows, doors, basements and attics.The material is used to perform work on finishing the premises both inside and outside. For the production of self-adhesive insulation using rubber, polyethylene foam, PVC, foam rubber sheets. ProfessionalThe general builders note the following advantages of this building material:

- environmental Safety;

- universal technical characteristics;

- high level of fire safety;

- small weight and thickness;

- the presence of waterproofing and moisture-proof properties;

- resistance to negative environmental influences;

- affordable price;

- wide range of colors;

- ability to fill gaps and cracks;

- mobility;

- resistance to low temperatures;

- reliable compaction and noise insulation;

- production of insulation of different widths and purpose;

- ease of installation work.

But also highlight the disadvantages of self-adhesive insulants, such as:

- rapid contamination and deformation;

- fragility and low resistance to mechanical damage of foam rubber insulation;

- special care for rubber insulation;

- fast drying adhesive;

- replacement of insulation on plastic windows is carried out by professional service organizations;

- complex process of cleaning the adhesive tape removed from the tape.

Kinds

Professional builders advise to use self-adhesive insulation to insulate air ducts, ventilation ducts, window and door openings. On the shelves of hardware stores you can buy several types of self-adhesive insulation.

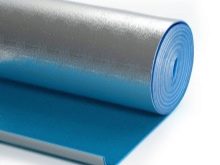

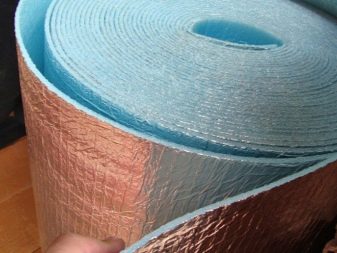

- Rolled - It is an indispensable material for warming balconies, loggias and other residential premises, having a small weight and thickness. The basis is low density polyethylene. The front side is coated with a high-temperature aluminum foil that provides reflections of infrared radiation and reduces heat loss. The wrong side of the canvas is coated with polymer glue, protected from drying out with a special material.

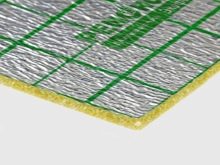

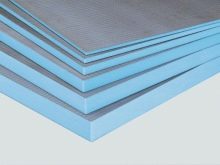

- Tiled - these are decorative panels with narrow scope of application. The basis is cork or foamed polymers. The underside is covered with construction glue and a protective film. It has high energy-saving parameters and pores for ventilation. For effective isolation this type is used together with other materials.

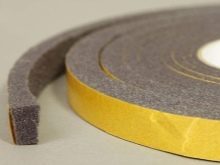

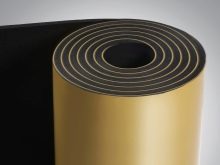

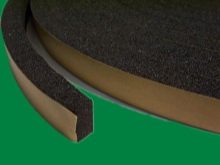

- Tape - this demanded heat-insulating material. It is available in two types: tape for direct insulation and tape for sealing windows and frames. Strips of insulation tape have high heat transfer resistance. A wide range of materials with different widths and slow-drying adhesive makes insulation ideal for insulation of pipelines and joints between the plates. The base is polypropylene or rubber. Air chambers in the design reduce the thermal conductivity of the material and increase the percentage of energy saving. They have an affordable price range.

The most popular foil foam is 10 mm thick. This material has the following advantages:

- high waterproofing and noise absorbing performance;

- preservation of all properties throughout the entire period of operation;

- the ability to reflect thermal radiation;

- cellular structure;

- prevents the appearance and multiplication of mold and fungi;

- wide scope.

For work on the sealing of the premises used foam rubber or rubber insulation, laid on the perimeter of the working surface.This type of material has unique properties of compression and rapid recovery of its shape.

How to choose?

The right choice of building material is the key to quality finishing work. Before buying self-adhesive insulation novice masters It is necessary to study the recommendations of experienced builders, such as:

- insulation of interior doors should be carried out on the basis of foam or silicone materials;

- for the entrance doors used rubber insulation;

- When buying, you need to check the labeling of products, the quality of the adhesive base, its shelf life and rigidity;

- use quality products without deformed elements of well-known manufacturers.

When choosing a material for insulation, it is necessary to take into account a huge amount of goods with different technical characteristics and properties. Of great importance is the material from which the insulation is made:

- PVC has wide application and reasonable price. Short life and instability to temperature changes are the main disadvantages of the product.

- Rubber has a long period of operation.Its advantages include resistance to temperature changes, moisture resistance, elasticity, no cracking and shrinkage. Disadvantages include unpleasant odor and high price range.

- Foam rubber - This is an old type of insulation. The advantage is low price and elasticity. The disadvantages are represented by a short service life, a porous structure that absorbs moisture.

- Rubber - This is a modern type of insulation. Advantages are elasticity and resistance to temperature changes. The disadvantages include the high price.

- PES - it is the made foam polyethylene which has high heat-insulating rates. The main advantage is elasticity.

- Silicone - It is a versatile material for the production of insulation. Advantages are resistant to mechanical damage, the action of ozone, ultraviolet radiation and temperature changes, a high level of elasticity, durability. Among the shortcomings worth highlighting the high price.

Installation Tips

Installation of heat-insulating materials with an adhesive base will not cause difficulties even for beginners.Manufacturers of this type of building material provide a complete description of all stages of fixation on the protective film of the product. For high-quality installation of insulation professional builders advise to use the following simple rules in their work:

- before fixing the insulation, it is necessary to clean the working surface from debris, dust and grease stains;

- repair cracks and chips;

- To cover the concrete surface with primers, plaster and clean the brick wall with emery paper; clean wooden structures from dust and sawdust;

- cutting insulation should be carried out with a special construction knife or scissors along the lines of a dimensional grid applied on the wrong side of the tape;

- thin sheets of tape or roll insulators must be mounted with overlap, and dense butt-and-butt;

- remove the protective film;

- Attach the insulation to the planned place and press tightly;

- heat insulation should be glued with one whole strip and not cut it into separate elements;

- full fixation will occur in 120 minutes.

Particular attention should be paid to the installation of foiled insulation.For the work you need to purchase a construction stapler, hammer, nails and building tape. The material is laid foil side into the room.

The method of attachment depends on the type of work surface, namely:

- nails and staples are used for wood;

- for a concrete and brick surface - construction glue;

- for insulation of water supply systems - building tape.

Useful recommendations

Tips and recommendations of experienced builders and workers of building stores will help to make the right choice when buying the material, to avoid mistakes during the installation and operation of insulation. Current recommendations for novice builders are as follows:

- for reliable fixation of the insulation joints should be glued with construction tape on the basis of foil;

- To slow down the process of fixing the insulation, you must sprinkle with talcum powder;

- if the adhesive base is dry and does not stick to the working surface, it must be wetted with water;

- It is prohibited to re-mount the roll insulation;

- additional fastening of the cloth with staples will increase the level of fixation of the insulation;

- safety precautions and personal protective equipment should be followed;

- for insulation of premises it is worth using only foamed polyethylene with foil;

- to increase the operational life of rubber insulation they must be treated with warm water with the addition of soda;

- for work on the warming of the premises it is desirable to use soft and flexible types of material;

- it is necessary to comply with the rules and technical rules of installation, specified by the manufacturer on the package;

- for the insulation of wooden structures it is necessary to use foam with two adhesive sides;

- acquiring large-sized foam rubber, it is possible to seal cracks and cracks with high quality;

- tubular heaters have a longer service life than foam rubber products;

- re-use of foam rubber insulation is prohibited;

- adhesive layer dries quickly in contact with air.

On the shelves of hardware stores you can find a huge range of material for insulation. Modern manufacturers of building materials offer a new product for this type of work. Before buying the necessary material, novice masters need to carefully study the properties and technicalcharacteristics of self-adhesive insulants or contact professional consultants of specialized stores for help. Only the use of high-quality insulation material will create a comfortable microclimate in the house and help to avoid the penetration of drafts and cold air flows.

On how to insulate doors and windows with self-adhesive insulation, see below.