Reinforcement of brickwork: technology and details of the process

At present, the reinforcement of brickwork is not mandatory, as the building material is produced according to modern technologies, using various components and additives that improve the brick structure, providing a reliable connection between the elements.

The strength of concrete is also increased, eliminating the need to use mesh to reinforce rows of bricks. But to ensure improved stability for certain types of structures according to SNiPs, the use of reinforcing mesh is recommended.

Special features

Before you determine why you need a grid, you need to consider the different types of this product, which are used in the construction of buildings.All of them have their advantages and disadvantages, and therefore you need to know where the grid will be best applied.

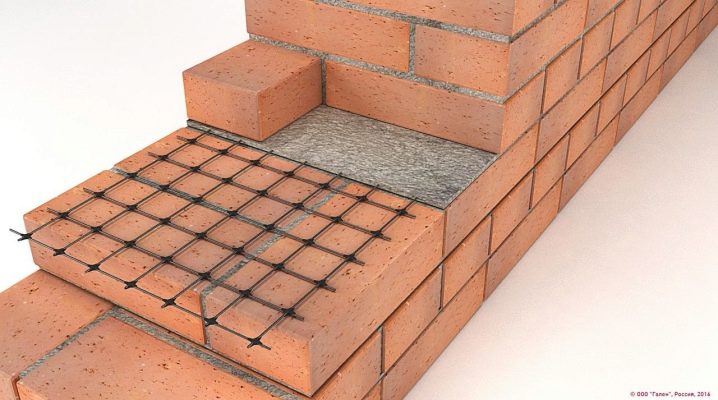

Reinforcement is carried out in order to improve the strength of the entire structure. Also, it does not allow the walls to crack when the foundation shrinks, which occurs during the first three to four months after the construction of the structure. The use of reinforcing mesh allows you to remove all loads from the masonry, but it is necessary to use only metal or basalt products.

To reinforce the building and eliminate shrinkage, various reinforcement options can be selected, no matter what material they are made of. The reinforcing mesh helps to build walls with higher quality, it is recommended to lay it at a distance of 5-6 rows of bricks.

Also, the fixtures are made of half-brick walls. For this you need to put the grid through 3 rows. In any case, the step of its installation is determined by the strength class of the structure, the grid itself and the basement.

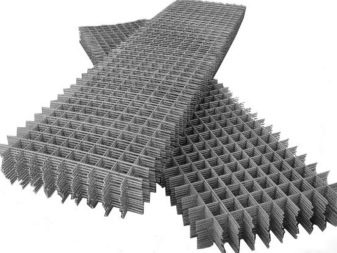

Most often, BP-1 mesh is used to reinforce brick walls. It can also be used for other types of construction work and can be laid on various mortars, including glue for ceramic tiles.Such a grid has a cell size in the range from 50 to 100 mm and a wire thickness of 4-5 mm. Cells can be square or rectangular.

The product is durable and resistant to aggressive substances or moisture. It has increased impact strength and can maintain its integrity in the masonry even with partial damage to the base, which makes it possible to quickly restore it. The grid does not contribute to the deterioration of the insulation of the masonry and can last up to 100 years. Its installation allows to reduce the level of vibration of the structure, it perfectly adheres to the concrete. Sold in rolls, which provides ease of transportation.

Mesh properties

Depending on the material used, the reinforcement mesh is:

- basalt;

- metal;

- fiberglass.

The production material is selected based on the design features of the structure where reinforcement will be applied. The last mesh has the lowest strength, and the first and second drawback is that they can corrode during operation. Metal mesh is often used for vertical reinforcement.It is quite strong, but can cause some difficulties when laying in a wall, and therefore it is necessary to work with such material very carefully.

The best option for reinforcing bricks is considered to be basalt mesh.which differs in durability and surpasses metal products in the parameters. Also, polymer components are added to this mesh during production, which prevents corrosion and increases resistance to harmful factors.

Advantages and disadvantages

All grids that are sold today are produced in accordance with the requirements of SNiPs, and therefore, to ensure their durability, it is necessary to observe only the norms for laying bricks and walls. Such a grid can withstand a substantial breaking load, which is an important factor for brick walls. It is also lightweight and can easily fit into walls.

Other advantages also include:

- good stretching;

- small weight;

- low cost;

- the convenience of use.

The downside is only that it is necessary to properly lay the grid, determining their consumption depending on the type of wall and the characteristics of the foundation.Therefore, specialists should work with such materials to ensure maximum effect from the construction. If it is illiterate and wrong to lay reinforcing material, then this will only increase the cost of work, but will not bring the expected result and will not enhance the strength of the wall.

Kinds

Reinforcement can be performed in the following variants.

Transverse

This type of wall reinforcement involves the use of reinforcement elements on the surface of a brick in order to increase its compressive strength. It is recommended to choose special types of wire mesh with a diameter of 2 to 3 mm. Or conventional fittings that are cut into rods (6-8 mm) can be used. If necessary, use the usual steel wire, if the height of the wall is not very large.

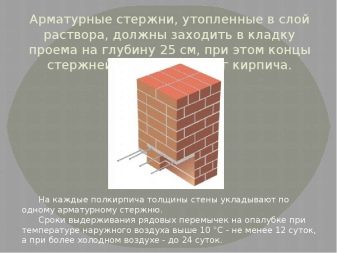

Lateral reinforcement is usually carried out in the construction of columns or partitions, and all elements of the reinforcement material are installed at a distance depending on the type of construction. It is necessary to lay them through a small number of rows of bricks and at the same time reinforce them with concrete on top. In order for the steel to not corrode during the period of use, the thickness of the solution should be 1-1.5 cm.

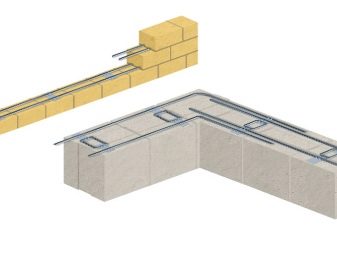

Rod

For this type of surface reinforcement, reinforcement is used, which is made of metal rods cut into a length of 50-100 cm. Such reinforcement is laid into the wall in 3-5 rows. This option is used only for ordinary laying brick and place the rods at a distance of 60-120 mm from each other in a vertical or horizontal position.

In this case, the reinforcement material should enter the joint between the bricks to a depth of 20 mm. The diameter of the rods is determined based on the thickness of the seam. If it is necessary to reinforce the laying, then it is possible, in addition to the rods, to additionally use steel strips.

Longitudinal

This reinforcement is divided into internal and external, and the elements inside the masonry are located depending on the location of reinforcing parts. Often, rods with a diameter of 2-3 mm are also additionally used for this type of reinforcement; they are installed at a distance of 25 cm from each other. You can also use the usual steel corner.

To protect such elements from the effects of negative factors, it is recommended to cover them with a layer of mortar 10-12 mm thick. Installation of reinforcing elements is made every 5 rows of bricks or according to another scheme, depending on the characteristics of the masonry.To prevent the displacement and deformation of the rods, they must be additionally attached to the bricks. If a substantial mechanical load is assumed on the structure during its operation, then it is possible to install reinforcing components every 2-3 rows.

Useful tips

- For the front masonry today you can use different types of grids and at the same time lay them in different variations, which will help to revet the walls with decorative materials if necessary. To do this, you can additionally leave a small amount of mesh outside the masonry for the installation of thermal insulation.

- It is mandatory to link the individual elements of the reinforcing mesh to each other in the masonry.

- Experts note that when reinforcing, you can choose any shape of the grid with square, rectangular or trapezoidal cells.

- Sometimes the mesh can be made independently by changing the size of the cells and the wire cross section.

- When installing such a reinforcing element, it is necessary to immerse it very well in the solution so that it is coated on both sides with a composition of at least 2 mm thickness.

- Usually the reinforcing element is mounted through 5 rows of bricks, but if it is a non-standard structure, the reinforcement is made more often, depending on the thickness of the wall.

- All work on the reinforcement are made together, and the material is laid with overlap. After that, it is fixed with a mortar and bricks are put on top of it. During the work it is necessary to observe that the material does not shift and does not deform, since the strength of the reinforcement will decrease.

- All products for reinforcement are made in accordance with GOST 23279-85. It regulates not only the quality of these products, but also their strength and the content of polymer fibers in the composition.

- If necessary, the reinforcement can be laid using a cement composition, but this reduces the thermal conductivity of the structure itself and its noise insulation.

- If it is necessary to use the reinforcement mesh when laying decorative bricks, it is recommended to use products of small thickness (up to 1 cm), which can be drowned in a small layer of mortar. This will ensure an attractive view of the wall and increase the duration of operation of the entire structure, improving its stability with a minimum layer of mortar.

As you can see, in spite of the fact that the laying process is rather complicated and requires the participation of specialists, the reinforcement of the walls can be performed independently, while observing the necessary rules and regulations.When implementing measures, it must be remembered that the strengthening of structures during the construction of structures also applies to construction work. Therefore, all actions must be carried out taking into account the requirements of SNiP and GOST, which will help extend the life of the building, despite the increase in the cost of its construction.

More information about the reinforcement of brickwork can be found in the video.