Gas boilers Ariston: the types and subtleties of installation

Despite the standardization of heating equipment, each manufacturer offers a few, but different solutions. The Italian manufacturer of boilers - the firm Ariston - also does just that. It’s time to figure out how perfect its products are and how it differs from products promoted by competitors.

Special features

Gas boiler is considered the most practical and economical source of heat in any locality where pipes of gas mains are stretched. It is precisely this equipment that largely determines how consumers will feel the advantages of heating with “blue” or liquefied fuel. Although the Ariston boilers were created by Italian engineers, the specific Russian conditions were taken into account as follows.

Created systems were originally designed with the expectation of:

- unstable and often low gas pressure;

- insufficient stress;

- ingress of contaminated water;

- extremely cold winters with heavy rainfall and lush winds.

The functional parameters of the systems are approximately the same.neither the type nor the charge for a particular model is of any particular importance. The main difference concerns the external perception, the size of the boiler. Of course, one cannot help but mention that, like other manufacturers, there is a clear distinction between single-circuit and double-circuit models. A useful option is the auto function, which, when used, automatically adjusts to the required parameters. In addition, any boiler of the Italian concern is equipped with an embedded automated unit for the discharge of excess air, protected from freezing and accumulation of scale, other dirt.

Kinds

To evaluate the characteristics of wall-mounted boilers, you need to refer to individual models. And a special place among them occupies the dual-circuit Alteas X. This device is classified as a premium heating equipment, designed for the highest possible thermal performance.The designers took care of the possibility of remote control via the Wi-Fi module. If you have mobile Internet, you can track the operation of the device anywhere in the world

Information is displayed through a matrix display. What exactly they will be - depends on the consumer (everything is flexibly configured). The boiler menu is 100% Russified. The system uses a modulated pump that consumes 30% less electricity compared to simpler counterparts. The device develops efficiency of 93.6% under favorable operating conditions. In addition to purely technical and consumer advantages, the stylish appearance of the boiler is also important.

A solid competition of this model can make the mechanism Cares. It is also mounted on the wall and also works with two circuits at the same time. But at the same time, it ensures the effectiveness of work in 93.8%. Heating can be programmed, for this purpose usually use compatible two-position control devices. In the production of the primary heat exchanger, premium grade aluminum is used with excellent corrosion resistance and thermal efficiency.

The secondary circuit in contact with tap water is very durable and lasts a long time. At the same time, he is able to give the required heat in 13.6 liters of water in 60 seconds. Both in the heating circuit and in the hot water supply system, and in the boiler feed channel, filters are installed to prevent ingress of mechanical impurities. With all its perfection, Cares is indifferent to harsh operating conditions. Even if the water pressure drops to 5 mbar, and the temperature in the street drops to minus 52 degrees, this will not affect the quality of work.

In some cases, there is no need for hot water, you only need to heat the house (or vice versa). Such situations make the Ariston Clas X System single-circuit boiler quite relevant. The efficiency when burning high-quality gas in this boiler reaches 93.6%. It is equipped with a two-speed pump and a liquid-crystal information screen. In the external appearance of the boiler all the undoubted advantages of the Italian design school appear.

The production uses the best construction materials., and special functions minimize the number of stops and starts of the boiler. You can connect an external boiler to get consistently hot water.As in the Cares model, the initial heat exchanger is made from aluminum of the highest metallurgical grades. Depending on the specific subspecies, the gas burning compartment can be either open or closed. Heat production for the heating circuit sometimes reaches 28, and for the water supply - 31.8 kW.

Clas One is a business category double-circuit condensing boiler. As the manufacturer says, it is made with innovative additions. In particular, a specially designed heat exchanger of the latest generation, featuring an increased diameter of pipes, was used. If street and room sensors are used, the system reaches the efficiency group A +. Updated device responsible for the suppression of working noise; a storage tank for a 24 kW mounted boiler or other power must for the most part be purchased separately.

Connection

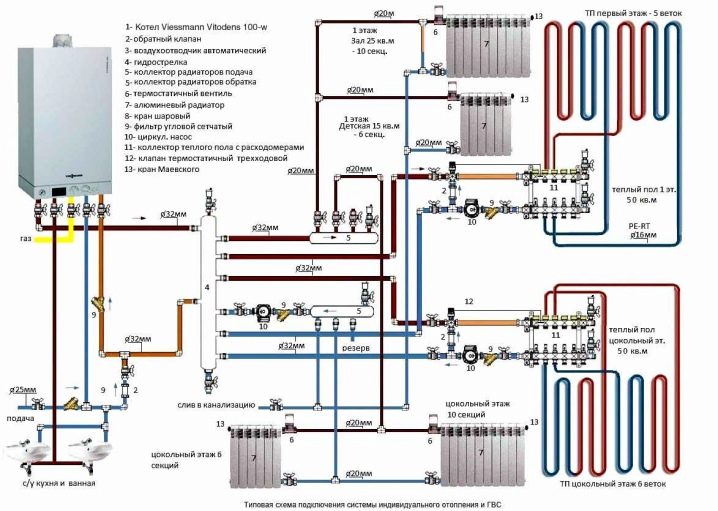

Knowing the wiring diagram for Ariston mounted boilers is very useful. Yes, the company prescribes that such work should be carried out exclusively by trained professionals. But behind them need a thorough all-round control. The work is carried out in strict accordance with the instructions of the SNiP.The draft prepared is coordinated with the territorial authorities overseeing gas security.

The project should indicate:

- what are the real parameters of the equipment;

- where it will rise;

- how the rest of the heating infrastructure will be completed.

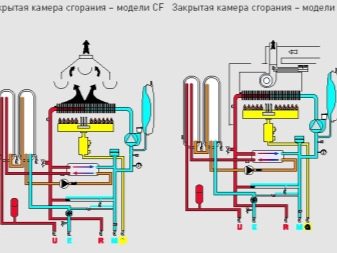

Important: even if these conditions are observed, the installation itself must be carried out only by representatives of authorized service centers. It is possible to use mounted gas boilers only when placed in separate rooms (furnace or boiler rooms). The exact list of requirements depends on the capacity of the boiler and the type of working compartment. In the case of an open chamber, the approach is approximately the same as when using a conventional furnace, that is, a chimney is used to remove gases. The window facing the street should have an area of at least 0.5 square meters. m, should also provide an adequate platform for maintenance.

Based on practical experience, you can turn on the boiler without risk in a room:

- volume up to 8 cu. m (with a furnace power of 30 kW maximum);

- up to 13-14 cub. m (if you get up to 60 kW of heat);

- from 15 m3 and above (if 60-200 kW are generated).

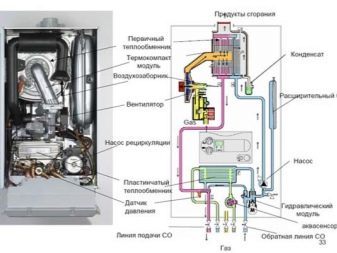

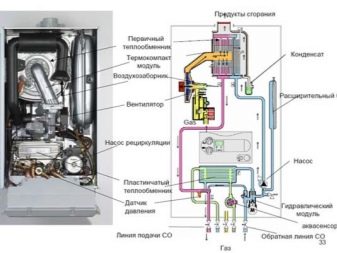

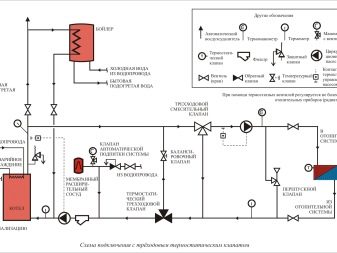

Differs approach to closed combustion chambers.It uses a coaxial type of chimney, that is, a twin pipe. On the outer side, the outside air moves into the firebox, and on the inner side, gaseous products of combustion escape. In any case, such devices are equipped with fans connected to the electrical network. It is the closed type of the flue compartment that is optimal in sanitary and environmental terms, therefore it is recommended for kitchens, bathrooms.

It is critical to choose the mounting height on the wall and the method of such connection. Not always proper fasteners are added to the supplied bracket. Because sometimes they are chosen individually, focusing on the wall material and its parameters. It is necessary to take into account that the bracket must transfer the load from the installed device and at the same time maintain it in an even position. For floor systems, the requirements are noticeably softer.

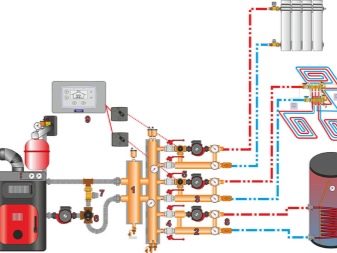

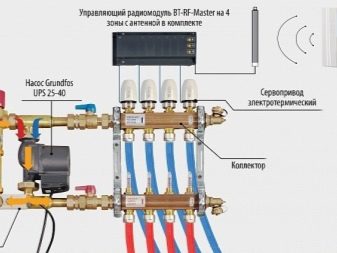

The entire surface of the wall adjacent to the heat generator, even being at a considerable distance from it, must be covered with a fireproof layer. The lowest point of the suspended device rises 0.8 m above the floor, the distance from the wall to the back line of the boiler is at least 50 mm.Next, connect the main heating circuit. How many pipes need to be attached depends on the one-pipe or two-pipe performance of the system. Before connecting, do not forget about dismantling the plugs covering the boiler nozzles.

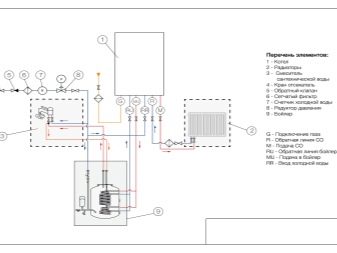

It is advisable to mount on the input filter. Even if filtering is provided in the boiler itself, it is still best to avoid overloading it. Only a boiler connected to the water supply can be included in the gas supply circuit. Attention: this information is for reference only. Only professionally trained and officially authorized specialists have the right to connect gas boilers to gas pipelines!

Initially, a ball-type valve is inserted into the device. A meter consumes fuel and a leak indicator. Next comes the turn of the thermal alarm valve. If the temperature rises excessively, it will block the flow of natural or liquefied gas further. The next step is (for some boilers) connecting to the electrical network.

Most often choose the scheme, implying the use of three wires. Regardless of the scheme chosen, all wiring and devices connected to it are subject to grounding. It is very good when the boiler is connected to the mains through a voltage regulator. Connecting it to the electrical network, then they are engaged in the formation of the output in the chimney. Atmospheric boilers should have a separate channel for the discharge of combustion products.

At the time of installation inside the chimney should not be the slightest dirt and traces of soot or soot. The vertical block after withdrawal from the device in length to the nearest turn is equal to at least two diameters. Then begins the section where the pipe bends in the direction of the boiler. It is recommended to shorten the length of the segment connected directly to the chimney as much as possible. Before filling the heater with water, they invite a specialist who personally adjusts the equipment and makes sure that it works correctly.

An important role in the piping of the gas boiler is played by the thermostat. It simultaneously provides savings of resources and optimum level of comfort in the room (thanks to competent settings). Reducing the load of the boiler itself and the circulating pump also turns out to be quite a good deal.Even the most expensive device justifies investments already in the first heating season. For your information: when it comes time to turn off the boiler at the end of this season, it is undesirable to drain water.

Tips and tricks

The maintenance of Ariston boilers designed for heating a private house is quite simple and does not cause any problems. The thermostat valve can handle different gases with the replacement of only the nozzles. The maximum pressure cannot exceed 60 mbar. Judging by the reviews of the owners, it is enough to periodically check the gas pressure and power in the hot water mode to ensure stable operation. How exactly to do this is stated in the instructions for a specific device.

Tests for minimum power and soft ignition are also useful. If a bypass is installed in the boiler, its operation is switched automatically and does not require adjustment. In the event of alerts about faults, further use of the boiler until they are eliminated is unacceptable. If any problem occurs systematically, even with the successful elimination of private cases on their own, it is advisable to turn to professionals.All repairs, as well as the supply of replacement parts, must be carried out by specialized organizations.

Look at the following video on the types and subtleties of installing Ariston gas boilers.