Types and advantages of gas boilers Viessmann

Gas boilers Viessmann are widely represented in the Russian market of heating equipment and enjoy well-deserved demand. The production of devices engaged in the eponymous German company that has been operating for a hundred years. Using years of experience and taking into account modern trends, the company produces reliable and high-quality models and is rightfully one of the world leaders in the gas boiler market.

Special features

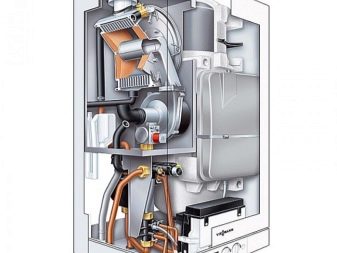

Gas boilers manufactured by Viessmann are a high-tech type of gas equipment. The devices are equipped with innovative technology and full process automation. In their design, the models of each series are somewhat different from each other, but in general they are structures represented by a pipe,primary heat exchanger, combustion chamber with modulating type gas burner, AquaBloc hydronic module, control unit and expansion tank. The units are equipped with a Grundfos three-speed pump (Wilo pump was installed in earlier versions), and appliances with a closed combustion chamber are additionally equipped with an electric fan. The boilers operate on natural and liquefied gas, and some models have a combined performance and, if necessary, can easily switch to diesel fuel.

In the manufacture of gas boilers Viessmann uses a unique technology «MatriX», providing equipment of the burner with a flame net made of a heat-resistant alloy. Thanks to this design, the burner is able to consistently maintain its main functions regardless of thermo-effects. Another distinctive feature of the German boilers is their appearance and design. The model range is presented as a small wall-mounted devices that do not clutter the space and do not spoil the interior, and overall, but at the same time very neat models of floor performance, capable of just as organically fit into the space, as well as attachments. The power range of gas boilers is 2-1400 kW.All products meet the strict requirements of ISO 9001 Tuv Cert, which speaks of its high quality and guarantees the safe operation of equipment. Fuel consumption ranges from 3 to 8 cubic meters of gas per hour, which is an average indicator of the efficiency of instruments of this class.

Many models of gas boilers are equipped with a built-in boiler for hot water supply, the capacity of which can reach 90 liters. A medium sized boiler can provide hot water from 12 to 18 liters per minute. The tank functions on the principle of a heat accumulator and is equipped with a programming function, thanks to which it is possible to organize the water supply at a specific time. All boilers are equipped with a safety valve, which, in the event of a pressure increase above 3 Bar, will automatically open and release air. For all Viessmann boilers, the critical pressure in the DHW circuit is considered to be 10 bar.

The temperature setting is carried out using a control unit equipped with a liquid crystal display. If problems occur in the nodes and units of the device, a digital code appears on the screen, the numerical value of which corresponds to a specific fault.The cost of gas equipment Viessmann starts from 50 000 rubles and depends on the type of installation, power and type of burner.

Species

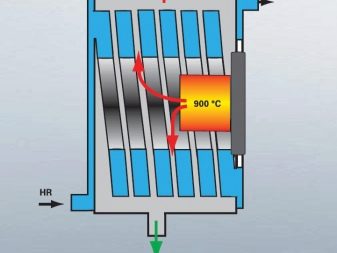

The range of gas heating equipment of the Viessmann concern is represented by wall and floor models, which, in turn, are divided into condensation and traditional types. The first ones are represented by the “Vitodens” series and, by the method of heating the heat carrier, are fundamentally different from the traditional ones. Such models are much more efficient in operation and have a higher efficiency. The principle of operation of these units is that when burning gas, water vapor is generated, which in traditional models is simply removed to the outside through the chimney system. The condensing boiler is equipped with a Matrix modulating gas burner made of stainless steel and having a cylindrical shape.

A coil, also made in the shape of a cylinder and wound on pipes with a square cross section, is located around the burner. Hot steam generated from the combustion of gas passes through this coil and, settling on its surface, gives up its thermal energy to the coolant inside.After that, the cooled drops flow into the receiver and are collected in a specially designated container.

Viessmann gas boilers are available with open and closed combustion chambers. The open ones are characterized by the intake of oxygen from the room and are considered less environmentally friendly devices. In closed oxygen, to maintain combustion, it is taken from the street through the coaxial chimney system, and exhaust gas is discharged through it.

Condensing devices have high efficiency, which is 100 percent or more, and are in high demand in European countries. In Russia, these models are not so popular. This is due to the relatively high cost, which is 100 or more thousand rubles. Condensation models are dual-circuit, thereby providing the consumer with not only heat but also hot water, the consumption of which can reach 14 l / min. Power devices varies from 17 to 150 kW.

Viessmann gas boilers with the traditional heating system are represented by dual-circuit models of the Vitopend series. Due to the low cost, wide model range and a large range of capacities, these devices are much more popular than condensing.The principle of operation of traditional units is quite simple: the water in the heat exchanger is heated by the combustion of gas and is fed into the heating and hot water systems. The efficiency of the devices is 90-99% and depends on the type of combustion chamber and the power of the unit. Models equipped with a closed camera have a slightly higher efficiency than boilers with an open system. This is due to the lack of heat loss in closed models and more powerful heat transfer. All traditional models are equipped with modulation burners that are able to automatically increase or decrease the intensity of fire burning in a given range.

The control of the burner in all models is carried out using the Vitotronic 100 controller. The device monitors the temperature conditions of the coolant, controls the boiler security system, regularly diagnoses all units of the device, and in boilers with a closed combustion chamber ensures synchronous operation of the modulation burner and electric fan.

All Viessmann models have the ability to connect Vitotrol remote temperature controllers, with which you can maintain a certain thermal regime of the coolant, taking into account the ambient temperature.Depending on the modification, traditional devices can be equipped with two heat exchangers, one of which is made of copper and is the main one, and the second one is made of steel and is designed to heat the running water. The performance of the devices ranges from 10 to 14 liters of hot water per minute and depends on the power of the device. The boilers are volatile and operate at a voltage of 120-220 V.

Among the devices with a traditional heat exchanger, there are also single-loop models. The power of such devices ranges from 24 to 30 kW. The boilers are designed for space heating and, due to the lack of a second circuit, they are not suitable for organizing hot water.

Advantages and disadvantages

High customer demand and a large number of approving reviews of Viessmann gas boilers due to several important advantages of these devices:

- Silent operation allows you to place equipment in residential areas.

- A neat design and compactness make it possible to install units in smaller rooms, for example, in kitchens and bathrooms.

- Equipping a boiler with a fuel economy system significantly reduces its consumption and reduces heating costs.

- High quality components ensures trouble-free operation and long service life of the equipment. The manufacturer provides a guarantee for all types of gas boilers for a period of 2 years.

- A large range of models allows you to choose a boiler for heating a country house, and for heating a large shopping center.

- The possibility of organizing hot water.

- The presence of a modern control system and full automation of the process make the operation of the device convenient and completely safe.

The disadvantages of boilers include frequent failure of parts of the pipeline, due to poor water quality, the high cost of some models, costly repairs and difficulty in purchasing spare parts.

Models

The range of Viessmann gas boilers is quite diverse. In the line there are floor and wall models of different power, made in both single-circuit and 2-circuit design.

The Vitopend modification is represented by dual-circuit devices, the power of which varies from 10.5 to 30 kW. A distinctive feature of the models in this series is efficiency and compactness.The chimney of the units is made according to the improved technology, which excludes the freezing of pipes in the winter period. The efficiency of the device is 90-93%, the performance is equal to 14 liters of hot water per minute. An atmospheric sensor can be installed on all devices, independently monitoring the heating temperature and allowing significant savings on heating.

The “Vitogas” modification is represented by one floor model 100-F, produced in two power options: in household boilers, this figure varies from 29 to 60 kW, and in industrial it can reach 140 kW. A distinctive feature of the devices of this series is the high efficiency and minimum amount of exhaust gases. Due to the fact that for the manufacture of heat exchangers used gray cast iron with graphite coating, this type of equipment is considered the most durable and safe. The devices are a single-circuit unit and are well suited for heating a private house. If the organization of hot water supply is required, in addition to the appliance, an indirect heating boiler is purchased.

The Vitodens modification is represented by Viessmann 100 / 200W condensation wall models. The devices are characterized by a beautiful design, high reliability and efficiency, and their efficiency reaches 109%. The boilers are equipped with a MatriX cylindrical burner capable of electronically modulating the intensity of combustion depending on the degree of heating of the coolant. This avoids excessive fuel consumption and saves money. The models have a double-circuit design and are manufactured using the “Inox-Radial” technology, with the help of which the heated surfaces are independently cleaned of soot and soot. The boiler is completely volatile and in the event of a power outage suspends its operation. For the DHW system, a plate-type heat exchanger is used, which significantly reduces the time for heating water and increases productivity.

The “Vitocrossal 300” modification is presented by floor condensation models with capacity from 29 to 60 kW. with efficiency exceeding 100%. The heating elements are made of high-alloy steel, and the MatriX gas burner runs silently and ensures the environmental safety of the process. At installation of coppers of this type arrangement of a coaxial system of a flue is required.

Useful tips

The manufacturer guarantees uninterrupted operation of gas equipment for 10 years. However, minor breakdowns and faults do occur. In the process of using the device, it is recommended to pay attention to the electrodes, which wear out quickly, as a result of which, when turned on, a spark can pierce the casing. You should also pay attention to the work of the three-way valves, which are also a weak point of some models and due to the development of the thread often fail. As a result of this failure, one of the circuits stops and paralyzes the system.

Judging by the reviews of the owners, there are also frequent failures in the automation of the device. This is due to the poor quality of water and gas, which causes clogging of the sensors by products of combustion of fuel and rust.

In general, the products of the Viessmann company fully meet the strict European requirements for gas equipment, and with proper connection and careful operation can serve for many years.

For the history of Viessmann and its products, see the following video.