Dual-circuit floor gas boilers: types and design features

Equipping a private house, it is very important to pay special attention to the choice and installation of the heating system. Fortunately, modern consumers have a chic selection of a variety of units designed to keep a home warm. Today we will talk about the popular double-circuit gas boilers of the floor construction, consider their positive and negative sides, and also take a closer look at their varieties.

Special features

Currently, there are a large number of well-known manufacturers on the market of heating systems, producing a variety of units that are responsible for heating a home. However, the most common and sought-after over the years remain double-circuit gas boilers.Such devices are famous for ease of installation, efficient operation and absolute cost-effectiveness.

A distinctive feature of such devices is that they represent a whole mini-boiler room, in which there are all the necessary details: a burner, heat exchangers, a pump, a control panel. Thanks to their clever design, these products are easy to use - anyone can handle them.

Floor boilers with two circuits are the best models, which are responsible not only for heating in a residential area, but also for hot water supply. Such equipment combines two different devices at once - a gas boiler and a flow-through water heater, also acting on gas.

Many consumers believe that outdoor units have massive dimensionstherefore they are not suitable for small rooms. In fact, this opinion is wrong. Outdoor equipment can be both large and very compact. Thanks to the choice of sizes, it will be possible to choose a suitable model for housing of any size and layout.

Floor boilers running on gas, have a good level of power, since they are not limited in size and design options, such as wall-mounted units.Today, homeowners have the opportunity to pick up equipment of suitable capacity for a building of any type.

Advantages and disadvantages

Modern double-circuit boilers designed for installation on the floor, like any other heating units, have both advantages and disadvantages.

Let's start with the good - let's see the advantages of such equipment:

- First of all, you should pay attention to the fact that in such devices there is a second heat exchanger, so they are responsible not only for the heating in the house, but also for providing hot water.

- Most of these devices have an automatic sensor installed directly in the case. Such a detail will ensure the reliability of the equipment and will also be responsible for its safe operation. Thus, during the extinction of the flame in the burner, the thermostat stops the flow of fuel.

- These types of boilers are very convenient and easy to operate.

- Gas double-circuit boilers are distinguished by their efficiency.

- Often in the cases of such devices there is a special filter designed to clean the heated water.Thanks to this useful detail, the unit can last much longer without causing any problems.

- Similar devices differ in effective work. Most floor boilers with two circuits have a sufficient level of power, so with such units in the house always remains the optimum and comfortable temperature.

- These types of gas boilers are distinguished by rapid heating. To warm the water you do not have to purchase an additional boiler.

- Double-circuit floor units are presented in the most different price categories. You can choose the right product for any budget.

- These heating systems are environmentally friendly, since they emit an insignificant amount of harmful substances into the atmosphere.

- In the shops you can find non-volatile boilers acting on gas. Such products will continue to work even if electricity has been cut off in your street or in the house.

- According to experts, floor devices are more practical and reliable than wall. This is explained by the fact that in their design there is a heat exchanger made of steel with thick walls or cast iron.

- Dual devices can boast a long service life, especially if you treat them responsibly.

It can be concluded that double-circuit gas fired boilers are reliable and practical. Of course, much depends on the specific model and its manufacturer.

Now it is worth considering what disadvantages these heating devices carry:

- Such equipment repels buyers by the fact that it is recommended to allocate a separate room for it - a boiler room, boiler room or "furnace". This requirement is due to the fact that such a unit should be located as far as possible from any sources of fire. In addition, there should be free access to it from absolutely any side.

- The cost of installing a gas floor boiler can cost a pretty penny. The high price is due to the considerable weight of the units, as well as the need to install automatic parts.

- Such an apparatus will need to install the supplement in the form of a high-quality and full-fledged chimney that does not have ledges.

- To put such equipment, it is very important to pre-level the floor.

The most important disadvantage, which is noted by many users, is that to install and run this equipment, you need to get special permissions. Having such an apparatus, one should not forget about the risk of gas leakage.

Device and purpose

All types of heating devices have single main units. Different units can differ from each other only in certain details.

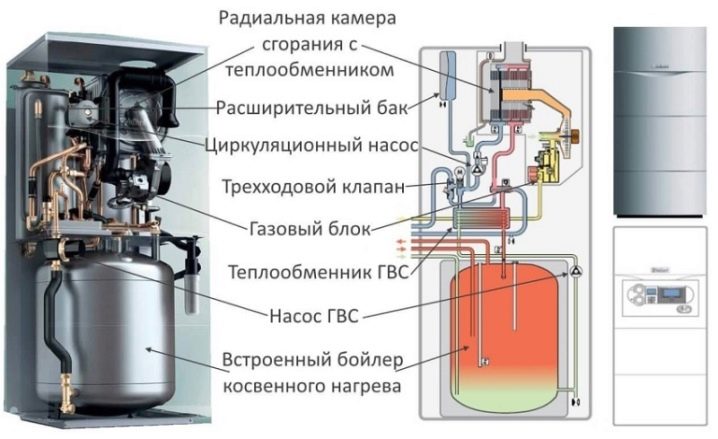

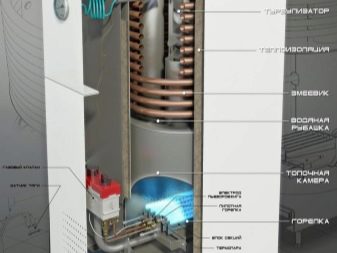

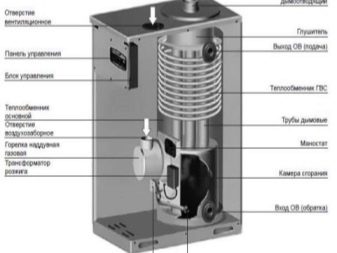

If you look inside the insulated casing of such equipment, then you can find the following components:

- heat exchanger;

- burner;

- combustion chamber;

- automatics;

- three code valve;

- main and secondary heat exchangers.

The shape of the burner, as well as its direct structure, may differ based on the fuel from which the unit operates. In gas samples, this part is a camera. In its internal part, the combustion of fuel takes place, entailing the release of heat and oxidizing products.

The main task of the burner is to release the energy required for sufficient heating of the coolant. Above the burner is usually a heat exchanger - a container in which there is a coolant.Following its walls, the products of combustion give up their heat to the water, which is then sent to the pipes of the heating system. It is important to know that the already cooled products of combustion pass straight into the chimney, and then are brought outside.

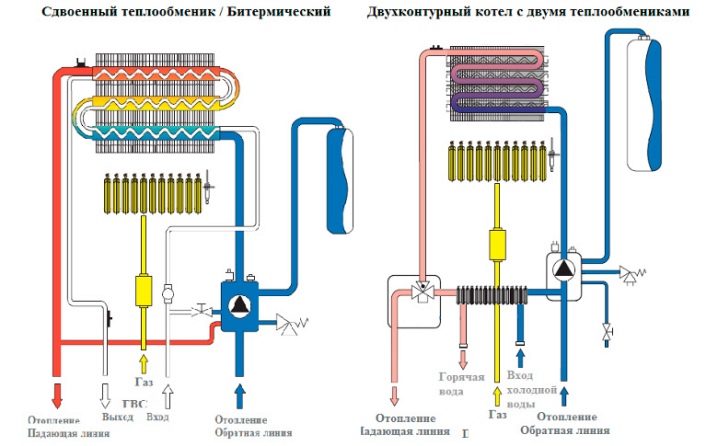

Depending on the specific configuration of the device designed to transfer heat, distinguish such models:

- with double;

- with bithermic heat exchanger.

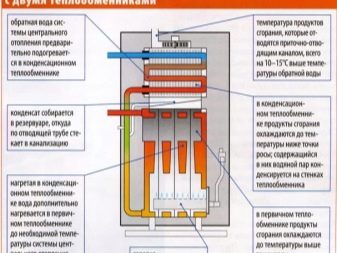

So, dual variants have two heat exchangers in their structure. One of them is responsible for the heating circuit. Usually it is assembled from copper tubes and plates with surfaces covered by a protective layer, protecting them from the formation of destructive corrosion. The main function of this part is heat transfer.

With regard to the second heat exchanger, he is responsible for hot water. This element consists of plates that transfer heat directly to a heated aqueous medium. Due to its structure, these types of gas boilers with two circuits are called lamellar.

As for the bithermic specimens, they are the “pipe in pipe” structure. In them, the inside is responsible for preparing the hot liquid, and the outside is for heating the living space.

An important role for outdoor gas equipment is played by the type of ignition.This part is responsible for the combustion of gas.

Ignition is divided into 2 main types:

- electric;

- pieza.

The device with two circuits, operating from the gas supply, is necessary to achieve two main goals - heating the room and heating the water.

Principle of operation

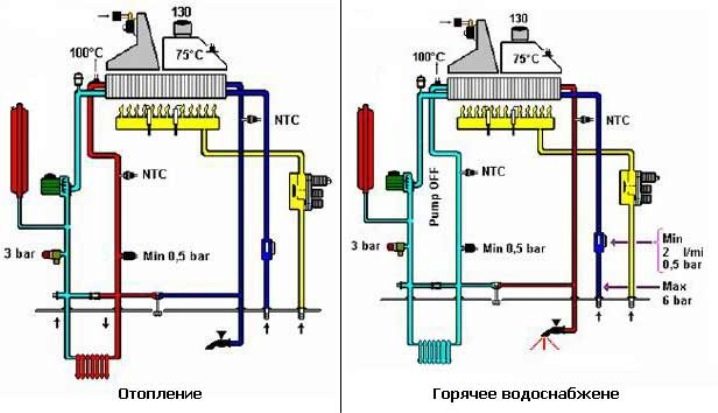

Thanks to its device, equipment for heating can function in 2 formats:

- heating;

- hot water supply.

In the first embodiment, the heat carrier is heated, which is stored in a heat exchanger. In his role serves simple water. Based on how hot it should be in the end, it is heated. It can range from 35 to 80 degrees.

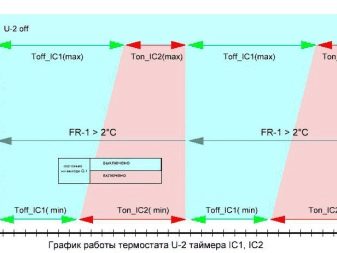

The heating mode is activated due to the thermostat. It responds to changes in temperature values in the living space. In case of its decrease, the thermostat signals the activation of the pump, which further forms a vacuum in the return pipe. This process is completed by the fact that the fluid in the heat exchanger is heated and the liquid is sent straight to the heating system, taking into account the pressure.

So, if this indicator is above 0.45 bar, then the relay contacts are closed and the burner controlled by a special microscopic processor is ignited.

After that, the device starts to work at the lowest power. Then it rises to the maximum level. If at a certain stage the heating of the heat carrier happens to the required temperature value, the equipment will automatically switch to the modulation mode. When at the very beginning the power level is high, the electronic system turns off the burner and starts its re-ignition after 3 minutes.

The combustion chamber is a container made of metal, decorated with a heat-insulating layer. A copper heat exchanger found its place above it. The burner itself is placed below. Its ignition is carried out automatically when you need to heat the liquid. Together with the burner, the pump is also activated, which is necessary to ensure the circulation of the thermal carrier through the pipeline.

When the required values are reached, the fuel supply is reduced automatically and the device goes into standby mode. Under conditions of further temperature reduction, the thermal sensor signals the valve, which opens and releases gas in a significant amount, thereby triggering a burner to ignite.

To prevent the water from passing into the 2nd circuit, a special three-code valve is used. The heated heat carrier is fed into the system from the equipment through the supply line, and the return is done through the reverse. Since the liquid in the primary heat exchanger moves closed, it does not leave a raid. In the second heat exchanger, water is supplied from pipes that have impurities in a large volume. Such elements can cause breakage of the unit.

As for the operation of the unit in the warm season, for example, in the summer, here the need for heating the dwelling simply disappears. In such a situation, only the circuit that responds to the heating of the water should act.

Dual-circuit boilers operate in a similar format as follows:

- a three-valve valve deactivates the heating line;

- heat carrier is fed from the primary heat exchanger to the secondary;

- moving on it, the low-temperature water gradually warms up and goes to the circuit responsible for hot water supply;

This process is activated by means of a pressure switch that closes when the flow of fluid exceeds 2.5 liters.

First, the automatic system gives the signal for the ignition of the burner, and then the gas valve opens, and the power gradually increases to the highest value. The device operates in a predetermined mode until the liquid warms up. After that, the equipment goes into process control mode.

Kinds

Double-circuit gas boilers of the floor structure are different. Let's get acquainted with the varieties of such units.

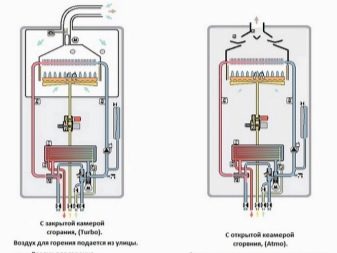

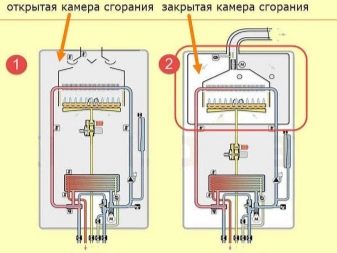

With closed type combustion chamber

Heating boilers with closed-type combustion chamber (turbocharged) possess such distinctive characteristics:

- They present air intake by force, working thanks to a fan (turbine). This component ejects carbon dioxide and produces fresh air. The turbine operates all the time, so these units work quite noisy.

- In such models there is a burner built-in type. It is a modulated device. Automation adjusts the power level of the burner to the specific requirements of the area in the heat, as well as indicators of the gas supply / heating system.

- Similar types of boilers work in two main directions - “winter” and “summer”.

- The equipment of the closed type can be mounted not only in private houses, but also apartments in apartment buildings. They are closed with a box and embedded in the furniture ensemble.

With open camera

Such units have a rather simple design. In them, the burner is located directly under the heat exchanger. In the course of burning fuel fresh air is taken from the room.

Equipment with an open burner is otherwise called atmospheric and has the following features:

- In it the air intake is carried out in the course of gas combustion. In this work, air masses are used that come directly from the space of the boiler room, because of which large demands are placed on the location of the apparatus.

- Such types of boilers are characterized by high efficiency (about 92%). Currently, there are quite strict standards that limit the possibility of installation and location of these units. For example, you should know that it is impossible to close an atmospheric device with a decorative stone or panels, and its installation is permissible only in a room with an area of at least 9 square meters. m

- In such units there are two burners - the main and pilot.Thus, the pilot burner operates continuously. The intensity of combustion of the main element is regulated by turning on / off the burner.

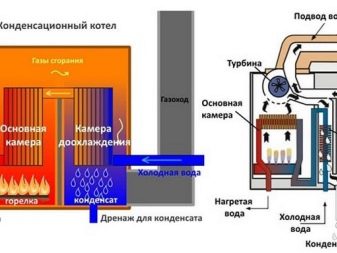

Condensation

Such boilers are the most economical among the huge range of heating equipment operating from gas. Such units are characterized by a very high efficiency indicator - 108 and 109%. A similar device works by using heat from gases.

Burnt gases leave such a device like this:

- In the course of fuel combustion, dew temperature is constantly maintained. Because of this, the heating of the heat carrier varies from 60 to 70 degrees. Maintaining the temperature at the dew point provokes the active formation of moisture that is contained in the flue gas.

- Smoke, which contains a lot of moisture, is sent to the condenser, which is necessary for the accumulation of heat stored in the heated steam.

- Condensation leads to additional heat (about 15-16%).

- After heat transfer, the smoke is sent directly to the chimney.

Gas floor boilers are also divided into volatile and independent of electricity.

Volatile devices have a special piezo ignition that must be started manually. The mechanical automatic system is connected to the thermal pair, which is responsible for the generation of low potential voltage. In this case, the power regulator is based on the principle of thermal expansion of metals. Such work of thermal equipment is completely non-volatile - it does not need to be connected to the network.

Devices that depend on electricity, most often have a closed-type combustion chamber. In them, the burner is equipped with electric ignition, and the launch takes place thanks to a special key. Automation in such models operates on the basis of a microprocessor, which gives a signal to turn the burner on or off, as well as fire modulation. In addition, the automatic system of volatile units is responsible for controlling the intensity of rotation of the fan.

Overview of models and manufacturers

Consider the rating of the most popular manufacturers producing the demanded models of gas double-circuit boilers of floor modification.

Protherm

Protherm is a popular brand in Russia that produces gas boilers in an ideal price-performance ratio.The range of the company includes not only floor-standing, but also wall-mounted units, as well as models working from electricity and solid fuels.

Protherm floor heating equipment is equipped with an electric ignition function, a built-in boiler of various sizes and stable heat sources. The company’s product range includes both volatile and independent devices.

Protherm floor gas boilers are presented in the following collections:

- Bear - KLOM, SLZ17, PLO, TLO;

- "KLO Grizzly";

- "Wolf";

- "Bison NL".

Baxi

Baxi company produces heating equipment of unsurpassed quality. A representative office of this company was opened in Russia in 2002. In the Baxi assortment there are not only boilers, but also boilers for them, autonomous water heaters (AGW), accessories, remote control systems. Floor heating units of this company are produced by condensation and with atmospheric burner. The category of condensing units is represented by the models “Power HT 45-150” and “Power HT 230-650”.

In the arsenal of samples with an atmospheric burner there are highly effective collections:

- "Slim" with a cast iron heat exchanger;

- "Slim HPS" - a series of gas boilers of the highest efficiency;

- "Slim EF" - a line of non-volatile units made of cast iron.

Buderus

Good reviews are left by consumers about the products of the German brand Buderus. The range of this manufacturer is very rich and diverse. Here you can find not only floor-standing boilers of excellent quality, but also control systems, water heaters, equipment burners, radiators, gas-fired power plants, solar collectors and various components for engineering systems.

The company offers a choice of consumers units for gas “Logano” from cast iron with a capacity of from 20-24 kW to 270 kW. All models of the brand Buderus have certificates of quality.

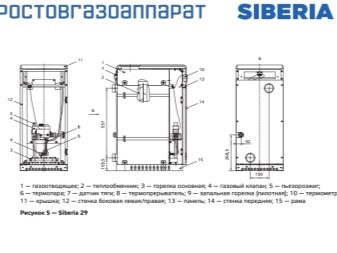

"Rostovgazoapparat"

A domestic company called Rostovgazoapparat is famous for its popular series of gas boilers - Siberia, RGA, AOGV. So, the latest generation floor equipment is presented in the Siberia series. It is distinguished by its affordable cost, cost effectiveness, the presence of automation and modern design. In the RGA collection there are devices for water heating and hot water for residential areas. They are great for small spaces. The AOGV series is represented by classic gas-powered devices.

They are designed for hot water and water heating.Work both at natural, and at the liquefied gas. Non-volatile.

Navien

Navien is the best boiler manufacturer in Korea. The company has in its product range floor gas and diesel powered units. These products are represented by high-quality models with the abbreviations GA, GST, LST, LFA. Korean brand branded units boast excellent safety features, efficient smoke removal systems, high-quality steel heat exchangers and an anti-freeze protection system.

"Signal"

The Signal group of companies produces single-circuit and double-circuit boilers of various capacities and modifications, as well as stoves for baths and saunas.

The main advantages of branded heating units from Signal are:

- affordable cost;

- profitability;

- security;

- usability.

In the assortment of this brand, you can find inexpensive units, ranging from 9 to 15 thousand rubles, and more expensive copies for 47-50 thousand rubles. You can choose the best option for any wallet.

"Conord"

This manufacturer is the largest manufacturer of heating equipment in Russia.Its range includes more than 50 units of modern gas and solid fuel heating units. The double-contour floor models “Conord” are notable for their brilliant quality, individual design and energy efficiency.

Heating devices of this brand are equipped with cast iron and steel heat exchangers. In addition, the range of "Condor" and there are products of increased heat output and even industrial boilers of appropriate capacity and dimensions.

"Danko"

The large company “Danko” is famous for its high-quality floor gas boilers, the cost of which varies from 20 to 80 thousand rubles. They can heat the area of 70-860 square meters. m. In branded units there are steel and cast iron heat exchangers.

In different products there are different automation systems:

- Sit (Italy);

- Kape (Poland).

Tips for choosing

Picking up the boiler on gas, need to rely on the following criteria:

- Efficiency The higher is the better. The maximum values have condensation models (102-109%).

- The volume of water warmed up by the device in a minute. As a rule, this indicator makes 2,5-17 l / min. More powerful products give more than 30 liters.

- Maximum water temperature. Usually it is 55 degrees.

- Maximum fluid pressure. Usually it is 6 bar.

- The temperature in the heating circuit. As a rule, does not exceed 80-90 degrees.

- Volume of the tank. Often make 17 l. But you can find more roomy options, if you want it.

- Gas consumption. Small boilers of small capacity consume 0.78 cubic meters / hour. More powerful options for a large area will consume about 24 m3 of fuel per hour.

- Volatility. It is advisable not to buy volatile models if you experience frequent power outages.

For more information on Baxy gas boilers, see the video.