The subtleties of the choice of voltage regulator for a gas boiler

Gas boilers - good and reliable heating devices. But devices equipped with automation often suffer from improper operation of the electrical network. Special equipment helps to prevent related problems. Voltage stabilizer is one of them.

Appointment and device design

It is worth starting with an important circumstance: after finding out that a voltage regulator for a gas boiler was not used, service center employees almost always refuse warranty repairs. We will have to invest our own funds in the restoration of the heating device.

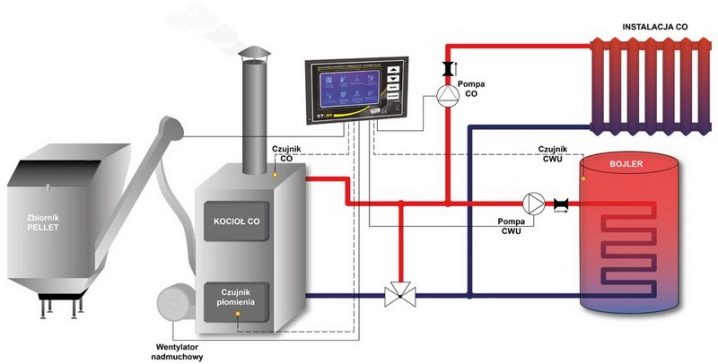

All massively used boilers are equipped with specialized automation, which:

- monitors the action of the burner;

- allows you to change the mode of circulation of water or antifreeze;

- provides a change in operating mode when the situation outside the boiler changes;

- solves a number of other important tasks.

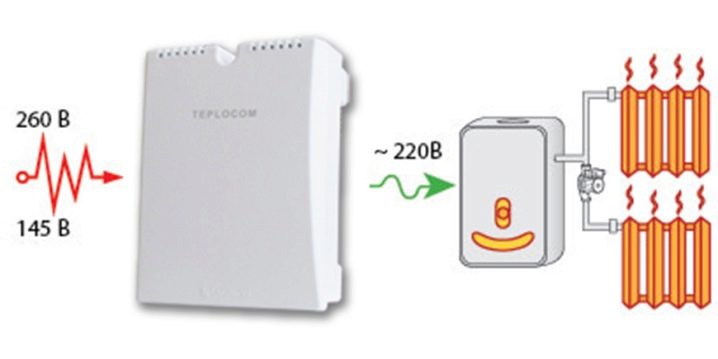

But the high efficiency of automatic systems is ensured by their binding to the electrical network. If a sudden power surge occurs, the highly sensitive boards completely or partially fail. The only solution is to completely replace the control unit. And the cost of such a replacement is quite perceptible - having changed the unit two or three times at power surges, they give about the same amount as when buying a completely new boiler. Therefore, all firms supplying boilers dependent on electricity strongly recommend connecting them through stabilizers.

Permanent electricity passing through the device must be leveled if the input voltage is less or more than the normative limit. In addition to simple devices that simply provide the desired value of voltage, there are stabilizers that change the polarity. Linear circuit devices are also sometimes called dividers. They are capable of making unstable voltage uniform; As a result, the resistance value allows the boiler to provide even power.But the linear option, despite the absence of interference and ease of execution, cannot achieve high efficiency.

Parametric stabilizers are built on semiconductors and gas-discharge elements. The control element is connected in parallel with the electrical load. A current moves through the Zener diode, the force of which is 10 times the current in the resistor. But such a solution is acceptable only in relatively weak aggregates. In successive stabilizers there is a bipolar-type current-boosting transistor and the same parametric stabilizer.

Such a scheme allows to make the voltage at the output independent of the moving current. But here the semiconductor type is of great importance. Walking on the transistor, the current increases its voltage, but sometimes a single transistor is not enough. Compensation performance is based on the feedback effect, when the voltage at the output is compared with the ideal sample. In accordance with this, the controller receives certain signals.

The bottom line is that a certain part of the voltage is taken at the input. It is compared with the fundamental value embedded in the stabilizer settings.Most effectively the similar system works if there is a phase shift. In pulsed stabilizers, a storage device is used - a coil, although sometimes a capacitor is used. Speaking about the organization of the work of the stabilizer, it is necessary to indicate that it can be built by adjusting the pulse length or by comparing the voltage at the output with the lowest values.

Species

To solve this problem, quite a lot of stabilizing systems have been invented.

They differ in a variety of factors, such as:

- market price;

- basic working principle;

- reaction rate to voltage change;

- duration of use;

- provided voltage values at the input and output of the stabilizer.

Thyristor (sometimes also called a triac) type of stabilizers is considered one of the best options. Even in the most simple models, the speed is 20 ms. If you choose more advanced equipment, it will respond to a change in voltage twice as fast. The voltage at the output is set with an accuracy of 1 to 2.5%, which allows you to safely feed even the most “capricious” boilers.Along with the usual systems designed for 220 V, thyristor converters can protect boilers designed for 120-280 V.

What is important, such equipment works without the slightest extraneous sounds and can act for a long time. Registration of the voltage entering the device input is performed with an error of no more than 0.5%. And this means the minimum probability that the system will not work in an emergency situation. The triac stabilizer uses an integrated switched transformer with electronic keys. It is these systems that make it possible to respond to changes in the situation with the highest quality.

There is only one circumstance that can somewhat complicate the use of a thyristor stabilizer. It is about its increased cost. But in reality, not everything is so bad - in many respects the idea of a high price is created by advertising competing products on different principles. Selection of the most suitable model allows to avoid excessively large costs. At the same time, the investment is fully paid off due to technical advantages.

Among thyristor stabilizers, one should first of all choose those that operate according to a stepwise principle. They retain their protective characteristics even in the event of a breakdown of a single thyristor. And because the closure between the windings does not prevent the boiler to work stably. In the opinion of qualified electrical engineers, triac converters are ideal in networks where jerks and voltage changes are permanent. On this familiarity with this kind of stabilizers can be completed.

Electronic, or, in other words, the relay stabilizer is sold somewhat cheaper than its thyristor counterpart. Such a device performs well only when connected to an electrical network with mild voltage surges. Relay protection allows to provide voltages from 135 to 315 V. Its speed is 100 ms. Worse and the accuracy of measuring the voltage at the output, it is equal to only 7.5%.

But at the same time electronic stabilizers eliminate the appearance of distortion in the electric sinusoid. Noise at work, if there is, it is relatively small. Microprocessors are used to control the action of a protective device.All existing relay models can not provide long-term operation. Recently, combined versions have entered the market, to which additional external protection resistors have been added.

Servo-driven devices (otherwise called electromechanical) have a special slider that can move the brushes. As a result, the turns are switched on the winding in turn.

It is recommended to choose such devices because of:

- increased voltage adjustment accuracy;

- smooth setting of current characteristics;

- effective resistance to continuous high loads;

- normal operation in case of overload;

- very affordable prices.

But electromechanical stations have obvious disadvantages:

- usage time is limited to 12 months;

- there is quite a strong noise;

- the design overheats and may even provoke a fire.

An inverter converter (dual conversion device) is considered an almost perfect choice. The only drawback of such a device is the high price, but technically it is flawless. The system effectively corrects all voltage surges in the network.The current indicator at the output is regulated smoothly, which eliminates the appearance of additional problems. First, the alternating current is rectified, and then alternating current is again obtained from the direct current, but its frequency is already stabilized.

As a result, a constant sinusoid is provided, which allows to maximally prolong the operation of the electrical and electronic components of the gas boiler. The occurrence of electromechanical interference is excluded, and the device itself operates for a long time. It is capable of processing input voltage from 120 to 300 V. The system differs in impressive speed and suppresses any voltage changes before they have time to affect the equipment. For your information: an inverter format converter costs from 15 to 60 thousand rubles, and its efficiency is 90%.

As a result, it is often more profitable even to buy an uninterruptible power supply with a battery capable of supplying a 24 kW boiler, rather than a stabilizer. But there are a few more options that should be considered. Pulse width modulation involves the use of a special source of pulses.Their characteristics continuously change according to what the parameters of the current coming from outside are. The result is the same - at the output contact the frequency of the electric pulse is stabilized.

Such devices most effectively adapt to the technique that consumes electricity. As a result, together with the provision of protection against changes in power supply parameters, the highest efficiency of the processor is maintained. Typically, stabilizers based on the PWM principle (pulse width modulation) are used where low voltage is encountered.

Ferroresonant stabilizing device is almost impossible to find in residential buildings. Now such devices are used in high-power boiler houses. The advantage of this method of current conversion is the high specified accuracy of the voltage at the output (the error does not exceed 3%). The system responds fairly quickly. But for the same price, instead of a ferroresonant device, you can buy a backup power supply unit with similar characteristics.

How to choose?

It should be noted that to select a stabilizer for household gas heating boilers, starting only from the principle of its operation,is impossible. It is important to pay attention to the parameters of the power supply at home - it is three-phase or single-phase. In a three-phase power grid, they connect either a suitable stabilizer or a three-phase one (the second option is more complicated, but it allows to get the best current parameters). Single-phase construction is almost always used in the domestic segment. They can rectify the full power of not more than 135 kVA; The variant with the connection of three single-phase apparatuses is practiced mainly on industrial objects.

It is believed that for ordinary gas boilers, which are placed in houses or apartments, three-phase stabilization is excessive. Only rare models of heating equipment are designed for the corresponding nominal voltage - 380 or even 400 V. It is recommended in any case to pay attention to the response time. Of the two units of the same or other technical characteristics, the faster ones are preferable. As for the input voltage variation, the best indicator is from 140 to 260 V.

The fact is that when the actual voltage deviates beyond the upper or lower limit, the system turns off the boiler.This can provoke the freezing of pipes and their failure. Another actual parameter is correction levels. The appropriate factor determines how accurately the specified voltage output is maintained. The elimination of this voltage drop depends on it.

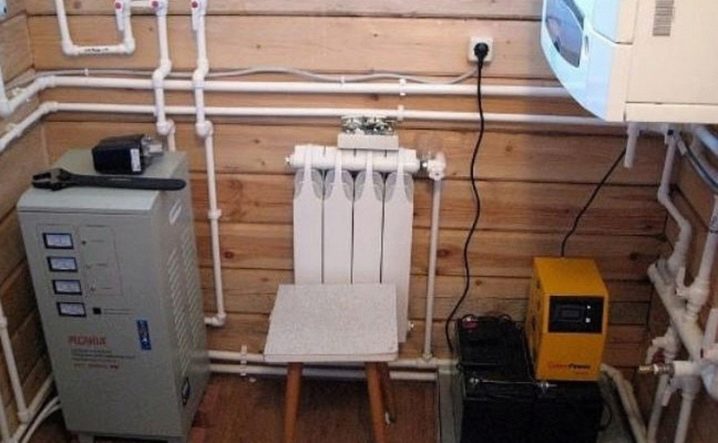

Stabilizers for gas boilers can work in fairly tough conditions. On the territory of Russia, it is worthwhile to use only such equipment options that will be able to preserve the functionality both at +5 and at +40 degrees. For domestic purposes, this range of permissible temperatures is sufficient. Higher requirements are imposed only on industrial grade systems. Voltage stabilization for gas boilers is mainly provided by light mounted models; only three-phase high-power stabilizers are placed on the floor.

Another important point is the power of the stabilizing apparatus (this is important even when selecting it for the Baxi, Viessmann boilers). It is determined primarily by the electrical capacity of the automatic devices inside the boiler and the current that the pump consumes to maintain circulation.Having found out the necessary figures in the documentation attached to the heating equipment, they are summed up and added 30% (to take into account the starting current value). But all such calculations are clearly approximate and give a large error. Where to get professional advice or use online calculators.

Manufacturers Rating

The study of consumer feedback shows that Russian-made voltage regulators are best suited. They are ideal for both time of use and electrical performance. In the presence of free cash, you can choose models of European manufacturers. But stabilizing systems made in China, unlike other household appliances from China, it is better not to take them yet - they are not quite perfect yet. Devices under the brand "Calm" - this is a high-quality and reliable domestic product.

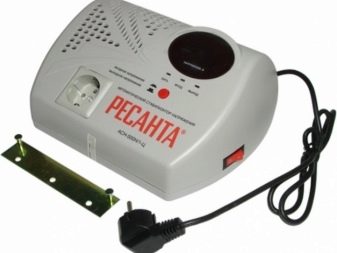

All models of this brand belong to the relay or thyristor format. Equipment "Resanta" manufactured in Latvia and also consistently included in consumer demand ratings. The advantage of such units is their low cost - you can buy a stabilizer for a gas boiler no more than 2 thousand rubles.But you need to beware of fakes coming from the countries of Southeast Asia.

Stabilizing Systems Powercom belong to the electronic version and on the output give an error of only 5%. The company is ready to provide a guarantee for 2 years. Sven relay systems handle input current from 100 to 280 V, speed is 10 ms. Designs are small and sensitive, they can operate very efficiently and without excessive noise. For your information: with frequent shutdowns of boilers do not automatically place all the blame on the stabilizers. It often happens that the real reason is a low level of traction.

Now you can look at individual models. At the most affordable price supplied stabilizer Powerman AVS 500 S, representing a single-phase apparatus capable of working with gas automatics up to 300 watts.

The advantages of the design are as follows:

- insignificant size and weight;

- wall mounting;

- European standard socket included;

- exclusion of the impact of frequency noise.

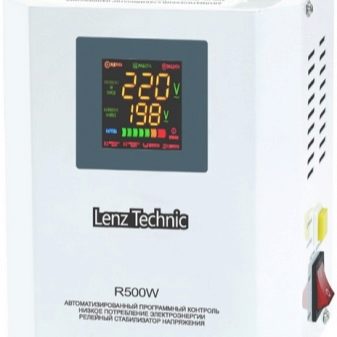

But at the same time consumers complain about the inconvenient placement of the outlet and the lack of a second indicator. According to the balance of accuracy and price the best position is LENZ TECHNIC R500W. The device is reliably protected from overheating, and overloading with excessively intensive work is excluded. But the lack of a system, and an obvious one, is delayed operation. The next line - largely due to its exceptional compactness - managed to occupy "Bastion" Teplocom ST-555.

This device is able to compensate for jerks on the input to the boiler. The designers have specially thought out the optimal parameters for exactly this task. A serious advantage would be a portable outlet type on a flexible cable. The stabilizer can work well even in the basement, where the humidity is very high. The manufacturer claims that its products are not afraid of a lightning strike.

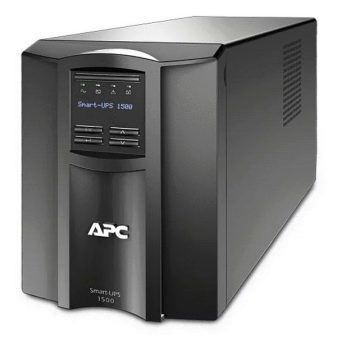

But at the same time, consumers point to individual weaknesses. For example, a similar stabilizer works too loudly. And it can also produce insufficiently adjusted voltage at the output. It is worth looking at such a structure as "Energy" APC-1500 E0101-0109. This system gives an error of maximum 4% and has an efficiency of up to 98%. Triggering occurs a maximum of 10 ms; the disadvantage is the difficulty of fixing on the wall of plasterboard.

In rural areas, it is often recommended “Calm R 600T”. This device interacts well with precision electronics, including microprocessors. The error is very low, but the allowable voltage range is expanded to the limit. The package includes all elements of its attachment to the wall. Deficiencies in the stabilizer is not detected.

If you choose among inexpensive Chinese-made structures, you should pay attention to Rucelf SRFII-4000-L. This stabilizer has the highest active power. The device is mounted on the floor and can insure gas boilers that consume up to 3 kW. The body of the product is highly durable and well ventilated, which allows to reach the optimum temperature.

SVEN AVR 500 it is allocated with the minimum occupied space and the plastic case. Attractive design is supported by indicators with arrows placed on the front panel. The impressive working range (from 100 to 280 V) is somewhat overshadowed by the low stabilization accuracy. The system has the highest speed of action. Only a small part of relay devices has such efficiency.

How to choose a voltage regulator for a gas boiler, see the following video.