Gas burners for the boiler: types, selection, device and cleaning

Today, when choosing a heating system for their own homes, more and more home owners prefer solutions based on the boiler. We are talking about gas boilers, although some people prefer electricity or wood. And the gas version is popular due to the fact that this type of fuel is one of the most affordable. And its consumption will be significantly lower than that of similar options. But the effectiveness of the described device will largely depend on the good operation of such an element as a burner.

Device and principle of operation

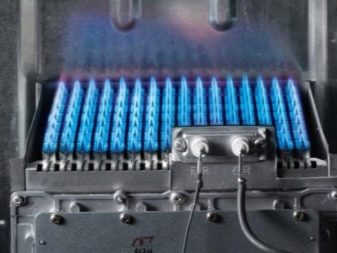

In order to completely burn the gas and get the maximum amount of heat from it, it should be mixed with an air mass having a certain oxygen content, which is an oxidizing agent. The perfect blend in the final should burn with an almost colorless fire with a hue of blue and maximum temperature. The gas burner will be responsible for this whole process. If we talk about its device, then it can not be called complex.

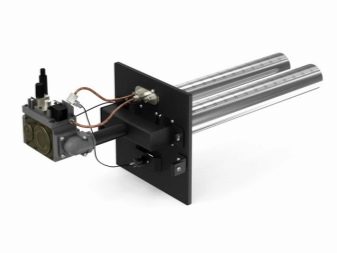

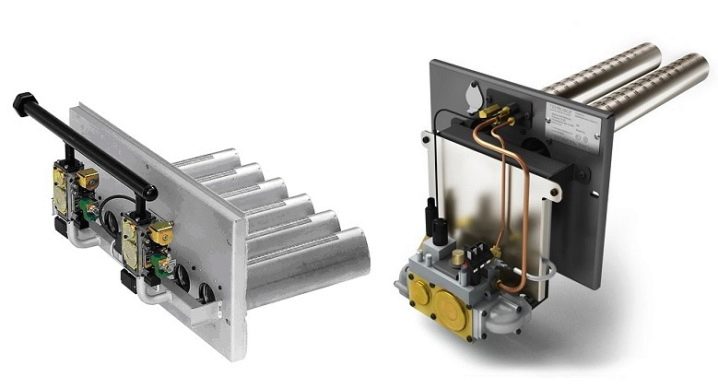

Any burner consists of the following elements:

- nozzles;

- ignition mechanism;

- a sensor that monitors the presence of a flame;

- automatic temperature monitoring system.

It should be noted that modern designs must meet certain requirements:

- long period of use;

- silent operation;

- complete burnout of gas.

In the old models of the burner boilers were used for a long time, since then the quality of the materials and the elements themselves were quite high. Now many technologies and materials are not used, and the quality of the burners has fallen somewhat. Experts recommend buying products that are manufactured by well-known companies that use high-quality parts.

If we talk about silent operation, this is a really important point. Many people remember the flow heaters for Soviet-made water, where the noise of the flame was great. And the models produced now work quite quietly.

When selecting the boiler, it is necessary to pay attention to the ignition. It should be carried out without claps and other noise. This is a very important point, because there is no possibility to adjust it. Therefore, if the burner behaves in this way, you should not buy it. The noise level will also be affected by the design of the combustion chamber.

The third point about which it is necessary to say is complete gas combustion. This is also important and it should not be neglected, because the burner must burn gas in full with the lowest release of combustion products and other compounds, including carbon monoxide. At this point will affect other parts of the gas equipment. It is also necessary to equip a good exhaust gas with an excellent chimney.

The essence of the burners is simple - the fuel gets inside through the ejector. The fuel feed rate will be very high and for this reason low pressure is formed, which allows the air to mix with the gas.Through the tubes, the resulting mixture goes to the holes, due to which it turns out to be in a special firebox, where it is ignited using electric ignition.

Species

Now let's talk about the categories of burners. It is better to apply the model, which is indicated by the manufacturer in the regulatory documentation. The heat exchanger, as well as the design of the boiler, is usually created with the expectation of installing a specific burner device.

If you take a destination, then there are two categories of burners.

- For industrial boilers high power. In this category, injection burner fans are usually installed. Their performance will be from 120 to 250 kW.

- Household options. In this case, the power will not be more than 120 kW. This includes the atmospheric boiler burner. Its disadvantages are large fuel consumption and the serious requirements associated with installation.

If we talk about the type of fuel as classification criteria, then there are two types of burners:

- working on liquefied gas;

- on a natural counterpart.

The difference between the types of burners will be in gas working pressure and nozzle sizes.In domestic constructions from European brands, universal options are usually installed that can work with both types of gas.

There are also injection diffusion and other solutions with preliminary partial or one hundred percent mixing. But such options are used only in industrial models. It should be noted here that the type of burner will affect the structural features of the heat exchanger, the combustion chamber, the variant of the gas outlet, the exhaust system.

The type of regulation of the burner are:

- 1-step;

- 2-speed;

- 2-stage with modulation of the gas version;

- modulated.

Depends on adjusting type, the open or closed torch will be applied. The device category will have an impact on the standards that will be imposed on the installation and operation of such a boiler.

Now we will tell more about each of the categories. Single-stage solutions are the most common option. Their principle of operation is that they are switched on and off. The frequency of change of operating modes will depend on how quickly the thermal medium cools,as well as on the mode of operation.

The features of such burners are:

- work regardless of the availability of electricity;

- high gas consumption;

- excellent reliability;

- availability of the ignition mechanism.

If we talk about two-stage burners, they are suitable for boilers, where there is a precise regulation of gas flows. By name you can understand that such a device can work in two modes. Usually it is about 30 percent and about 100 percent of power.

The features of this solution will be:

- constant burning;

- heat carrier heat one hundred percent;

- models with automatic control of the transition from one mode to another.

If we talk about the third category, here the working principle is identical to the previous version. The only difference is that the switch is performed without quick jerks.

The features of this type of burners are:

- low fuel burning;

- universality;

- electrical dependence;

- adjustment of temperature of heating of the heat carrier.

The last type is modulated burners. They are considered the most economical. Changing the power of the burner is usually carried out in auto mode.

The features of the modulated burner are:

- availability of control automation;

- universality;

- high profitability.

Choice of burners for different types and models of boilers

When selecting a burner, one should pay attention to its various characteristics - the model of fuel supply, the option of mixing gas with air, compatibility with various categories of devices. We will talk about the most interesting models.

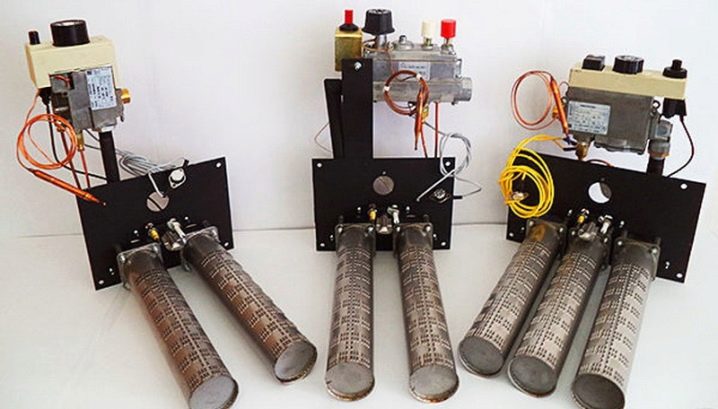

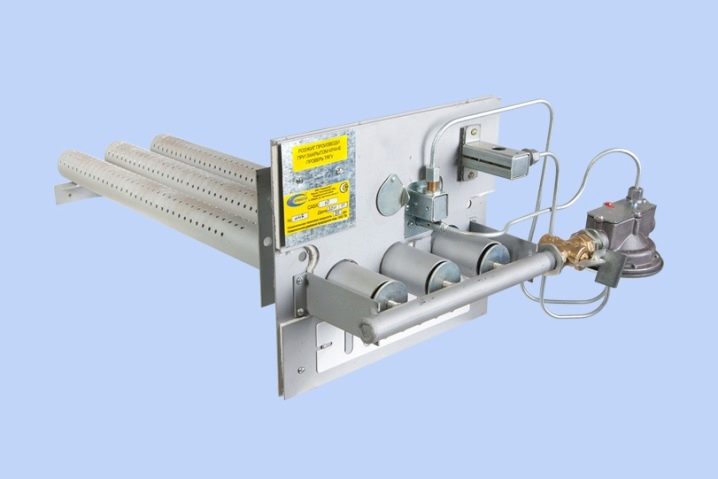

- KCM burner. It is used in boiler units, converted from conventional fuel to LNG or ordinary gas. It is usually present automation, and there are three nozzles. It is used in boiler units of the “Contour” model or similar variants.

- Burner "Hearth". It is a device of the pneumomechanical type, which has an automatic mode of operation. It turns off by itself if:

- the fire went out;

- gas supply stopped;

- missing required traction.

This model has a gas pressure controller. This makes it possible to achieve equal burning of fire, even if there are any malfunctions in the mechanism. Such solutions are easy to maintain due to the fact that no soot accumulates in the convection part.

- Another burner that I would like to mention is the model. "Kupper". This option is universal and suitable for combined boilers, solid fuel-fired constructions from Kiturami or models of Russian production of the Konord brand. The advantage of this torch will also be the possibility of its installation without plumbing or welding.

- Another very popular solution is DKVR burner. Such a block device is used where there is a forced air supply. This solution is used for steam boilers for industrial use and having the appropriate capacity. Their efficiency is about 94-95 percent. This design works either in diffusion or in inflatable version. To increase its efficiency often use powerful Italian fans.

- Another category is burners for FAC. They are used for domestic needs and are solid fuel. Considering that there is no need to use too powerful equipment for space heating, atmospheric or injection solutions are used. When selecting a burner element, you should pay attention to the power and safety in use.

How to do it yourself?

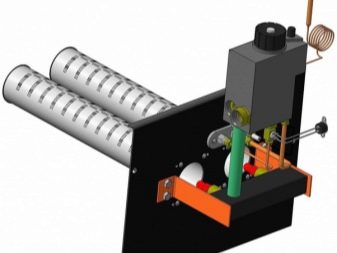

Consider the example of the manufacture of a gas burner for a solid fuel boiler unit. It is better to use a valve from an oxygen cylinder made in accordance with the standard VK-74.

To create a burner, you must perform the following steps.

- Equip the outlet at the outlet with a nozzle that will be connected to the reactor with a hose.

- At the entrance patrol part connected to the cylinder, we mount the cap, where there is a small hole for connection with the nozzle. It can be found on the stove or in a blowtorch.

- Now a steel pipe with a length of one hundred millimeters and a wall thickness of two millimeters is welded to the cap.

- Between the nozzle and the cap should be a distance of one and a half centimeters, through which access to oxygen will be carried out. For this reason, you first need to attach 3 small pieces of wire to the cap, and then the pipe itself.

The burner is ready. It remains only to make the base on which the device will be located for installation in the combustion chamber.

In addition to the manufacture of the burner itself, you should follow certain recommendations when firing it:

- first open the gas supply;

- bring the match to the nozzle;

- open the main valve.

It should be said that the power of a homemade burner is easy to adjust with the use of a valve.

How to clean?

Now let's talk about how to clean the gas burner, because it, like any other equipment, needs care and maintenance. If you take the legislative norms, they are expressly prohibited to carry out outside interference in the work of gas equipment, for which reason you have to contact certified specialists who have all the necessary permits for this type of work.

However, the furnace and burner can still be cleaned independently, but only at your own peril and risk.

The main stages of such work will be:

- shutting off the gas main and disconnecting the heating boiler from the power supply;

- dismantling the device;

- decontamination, which could be formed on the incendiary electrodes;

- cleaning the chamber for the firebox;

- replacing the filter on the gas valve.

After the cleaning process, the device should be assembled with the presence of all the corresponding gaps, which are in the technical manual for the device.After the assembly is carried out adjustment and adjustment. All these works are carried out using a special device - a gas analyzer. It is installed in the chimney, and it examines the chemical composition of the gases that are waste.

In general, as can be seen, there is nothing difficult in the design and selection of gas burners for boilers. When working with them, the most important thing to remember is to strictly observe the safety requirements, as well as the rules set forth in the relevant regulatory documentation. And it will not be superfluous to contact specialists if for some reason you are not sure that you will be able to carry out certain works with them clearly and correctly.

How to improve the gas burner for the boiler with your own hands, see the following video.