The process of washing the gas boiler heat exchanger

Comfortable living in a private house depends on the state and efficiency of the heating system. Every homeowner knows that this parameter is related to the quality of the boiler. There are often cases when this unit functions incorrectly. The banal contamination of the boiler, or more precisely, some of its important parts - a heat exchanger or column can lead to such unpleasant consequences. Today we will look at how to properly flush the heat exchanger of a gas heating device.

The need and frequency of cleaning

Currently, a gas boiler installed in a private house is not something outlandish and rare. This technique is famous for trouble-free and durable service, which attracts homeowners.In addition, these devices are characterized by their effectiveness. Thanks to a well-chosen gas boiler, it is possible to provide ideal living conditions for households, even if there is a bitter cold outside the window.

Gas powered devices do not require special attention or costly maintenance. It is enough to clean the equipment from time to time so that it works smoothly and as efficiently as possible. Conducting such activities can not be called time-consuming and costly in terms of free time process, so cleaning the boilers does not cause most homeowners much difficulty. Before proceeding to a detailed review of the washing process of such a detail of the boiler as a heat exchanger, you should understand why this is so important.

During the year in the heating system there is a constant circulation of water. After some time, saline or lime deposits are deposited on various parts. Such impurities can get into an important part of the boiler - the coolant. It should be remembered - the higher the water hardness, the more mineral accumulations will remain on different components in the system.They remain in the heat exchanger, which has a negative effect on the equipment itself.

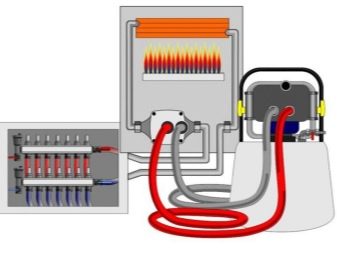

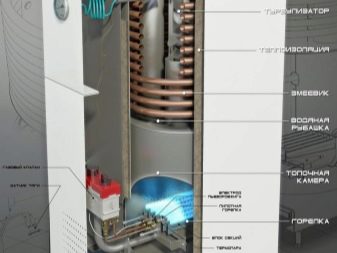

The principle of operation of such heating units is based on the fact that the thermal medium is heated when moving along the curved channels of the coil. Special plates are used to raise the temperature of the water. Thanks to these details, the coil and the fluid are evenly heated optimally. When assembled, such a practical system resembles a car radiator.

The efficiency of the operation of such equipment depends largely on the degree of thermal conductivity of the materials from which it is made.

Most often, copper or other alloys with the addition of this metal are used for this. Absolutely any deposits and growths appearing on the inner surfaces of the coil pipes have a negative effect on their level of thermal conductivity. In addition, in general, the whole system at the same time ceases to operate properly.

And now let us consider more specifically what the neglect of preventive measures for washing the heat exchanger in the boiler can lead to.

- The heat exchanger in the technique can begin to overheat regularly, which eventually provokes its breakdown.It should be borne in mind that the repair of such parts can cost owners a large amount. In addition, while the unit will be in the process of repair, residents will have to choose alternative options for heating their home. As a rule, at this time, people run electric heaters that consume quite a lot of electricity.

- The coolant will not pass the quality of the system, if it contains a raid. The larger the drops, the more impressive will be the load on such an element as a circulation pump. In such a situation, the equipment will have to constantly work in difficult conditions, which will lead to the rapid deterioration of "vital" parts, and then the failure of the boiler.

- A clogged heat exchanger will not work efficiently enough. The heating of this component usually requires more energy, which increases the fuel consumption (in this case gas). From this we can conclude that the owners will overpay for heating their home if the boiler is not served on time, and during this period the house will not be heated properly, which is especially critical if there is a cold winter outside the window.

As you can see, flushing the gas boiler heat exchanger is very important if the owners want to live in a comfortable and cozy environment. As for the frequency of cleaning the heat exchanger, then everything depends on its specific type and design features. As rarely as possible, you have to maintain simple single-circuit options, in which clean water often acts as a heat exchanger. To keep these units in working condition, you can clean it once every 4 years.

In cases where water that has not been cleaned passes through the system, it is recommended that the boiler be flushed at least once every 2-3 years. When a fluid circulating in the system is distinguished by high rigidity, cleaning is required every 2 years. The secondary heat exchanger of the gas heating unit should also be flushed frequently, as water rich in various impurities passes through it.

Frequent and regular maintenance is required by gas boilers in which antifreeze acts as a coolant. Such instances, it is important to clean at least 1 time in 2 years. It is also necessary to control the shelf life of antifreeze and change it in time.If you ignore these simple rules, the efficiency of the heating system will begin to decline, and the cost of heating will increase significantly.

In the process of cleaning heat exchangers, the appearance of the boiler itself and the nozzles should be inspected. If it is necessary, it is necessary to carry out repair work on time. In addition, experts strongly recommend monitoring the condition of the chimneys - they must be cleaned of soot.

Ways

There are several ways to clean a gas boiler.

They are conventionally divided into two main options:

- demountable;

- not folding.

The name of the collapsible method speaks for itself. In this case, it implies disassembly of the heating unit. In this case, contaminated elements are dismantled and placed in a separate container with reagents (another option of cleaning parts can be used). In the selected container, parts must lie for several hours, after which they are mechanically cleaned. Further, all parts are installed back into place.

With a collapsible cleaning method, it is not necessary to remove parts from the boiler. Washing is carried out directly on the place.Such works are carried out with the help of a booster. And now let's take a closer look at what methods can be used to clean the heat exchanger in the gas boiler.

Manual cleaning

To carry out manual cleaning, you must carefully remove the heat exchanger, otherwise you simply will not have open access to untreated surfaces. After that it is necessary to choose either mechanical cleaning or washing with special solutions. For mechanical decontamination you need to use a scraper, a stiff brush and a vacuum cleaner. If you turned to the flushing, which is most often used in relation to the double-circuit unit, it is better to use a special liquid to dissolve the salts.

With the manual method of cleaning the heat exchangers, it is important to be extremely careful and careful. Putting the exchanger in its place, be sure to verify the complete tightness of all connections.

Chemical solution through a booster

In this case, it is supposed to use a special technique called a booster. Thanks to such a device, a special acid composition for washing is pumped into the heat exchanger.For a long time, it passes through the pipes many times, because of which the deposit simply dissolves and leaves the system along with the washing itself. As a result of this operation, the throughput and thermal conductivity of the unit increase significantly.

The acidic composition is capable of destroying even the oldest and most persistent contaminants, such as carbonate or trivalent iron. The acid residues in the pipes are neutralized thanks to a specialized solution — it is simply run into the heat exchanger at the end of its cleaning.

Hydrodynamic method

There is another popular variant of flushing the heat exchanger in gas equipment - hydrodynamic. If you decide to carry out cleaning by this method, then you should know that in this case water is pumped (sometimes an abrasive filler is used instead of water), and then pressure is generated. The very rapid movement of fluid in this situation contributes to the removal of excess deposits outside the system. However, when using the hydrodynamic method of washing there is a risk of exceeding the maximum pressure parameters.This can lead to negative consequences - pipe rupture.

Experts do not recommend washing the heat exchangers on their own, especially if you have never encountered such processes and have little idea of their principle of operation. It is advisable to turn to experienced craftsmen who have appropriate approvals for working with gas equipment.

Facilities

For cleaning the heat exchanger using various means - from natural to aggressive, based on chemical compounds. Consider the most popular and effective components that allow high-quality cleaning.

Lemon acid

Currently, many owners of houses and cottages choose citric acid for cleaning boilers. A similar substance is available commercially and is found in many stores. A solution is prepared from citric acid having a concentration of 0.5-1.5%. Density depends on the complexity and duration of pollution. The liquid, heated to a mark of 60 degrees, seamlessly destroys scale and oxidation. You should not worry about the metal coating technology - it does not suffer from this.

Citric acid is often used when cleaning aggregates made from materials such as brass, stainless steel and copper. Such an effective remedy is distinguished by the fact that it does not cause any harm to human health.

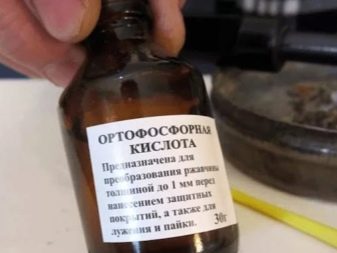

Orthophosphoric

This known chemical compound is most often used in agriculture. You can find it just as easily. Orthophosphoric acid is used to clean heat exchangers of absolutely any kind. To carry out the washing technique, it is recommended to prepare a 13% solution. Such a concentration will provide an opportunity to easily and easily remove scale and almost any type of pollution. In addition, when using such a tool on the metal, a reliable protective layer is formed.

Many people are afraid of contacting orthophosphoric acid, considering it dangerous to health. In fact, this tool does not need to be avoided - it does not harm the human body.

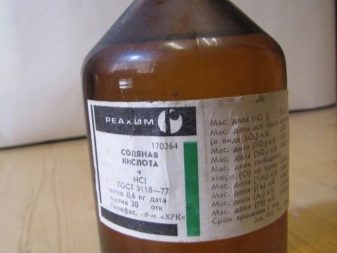

Salt water

Hydrochloric acid on the territory of the Russian Federation is a precursor (a substance used in the preparation of narcotic substances). For this reason, to get a similar composition for cleaning equipment can be problematic.Despite this, in pharmacies you can find affordable solutions of hydrochloric acid - they are sold under the name of gastric juice.

When cleaning aggregates from copper and stainless steel, usually 2-5% hydrochloric acid solutions are used. This fluid contains inhibitors that provide additional protection for the metal. In addition, this popular tool is capable of dissolving various carbonates and oxidation products.

Sulfamic

Sulfamic acid is realized by organizations that are directly related to the chemical industry. This reagent freely dissolves various defects, if their chemical composition allows. For this reason, before cleaning the equipment, it is desirable to study in detail the structure of the pollution that is planned to be removed.

The following tools are also used to clean the heat exchangers.

- Detex. This is a special tool that effectively helps dissolve scale, salt and oxidation products from heat exchangers made of materials such as cast iron, copper or steel. Detex is mixed with water to obtain a 10-17% solution.

- GEL Boiler Cleaner DE. This concentrated product contains inorganic acids and inhibitors.Such components can even fight with rust. GEL Boiler Cleaner DE is used to clean parts from copper and steel.

Experts say that working with sulfamic acid is better at a temperature of 55-65 degrees. As for the direct concentration of the solution, it should be only 2-3%. If you adhere to this "recipe", the cleaner does not harm human health.

How to disassemble the boiler?

If you have chosen a collapsible method of washing the heat exchanger, then You should follow the following action plan:

- it is important to shut off the gas supply at the very beginning;

- after that you need to disconnect the wires from the gas valve;

- now you can unscrew and remove the unit door to the side;

- disconnect the thermocouple and nozzles (experts recommend setting the depth of immersion of the last parts in the burner);

- Now you need to disconnect the outlet pipe;

- Remove the burner, unscrew the nuts and remove the back cover.

After that, you can proceed to the cleaning of contaminated elements.

Cleaning details

It is possible to wash the heat exchanger of the boiler on gas at home and with your own hands.Of course, such works should be treated very carefully and carefully in order to prevent serious mistakes.

Before self-cleaning gas heating unit, you should familiarize yourself with some of the subtleties of this process.

- In the chemical method of cleaning the aggregate, plaque and other particles are removed using a vacuum cleaner, brush or brush. Some people take for this not a ruff, but an old toothbrush.

- For washing the necessary parts are soaked in special solutions. As mentioned above, this method is recommended to apply if we are talking about a double-circuit boiler.

- When manual cleaning should be very careful not to damage any part.

- For chemical cleaning use a booster. With it, an acid wash solution is pumped into the system. It passes through the heat exchanger and cleans it for several hours.

- For hydrodynamic cleaning does not need to disassemble the heating unit. Water is pumped into the main line (sometimes with abrasives), and then pressure is injected. After this, the circulation of the fluid is accelerated, impurities are removed.

To clean the heat exchanger from soot, use a soft brush on the metal.Inside the canals of the apparatus are vacuum cleaned. The burner in this case is usually cleaned with a brush or a needle, the diameter of which is less than the hole in the burner.

Useful tips

Of course, it is a little easier to use and flush gas boilers than solid-fuel units, which often have to be cleaned of tar or tar. However, gas models still require careful handling and timely flushing.

Experts do not advise to take up this matter, if you are not confident in your abilities, because mistakes in this case should not be allowed.

- Pay attention to your kettle, which usually boil water. If a bloom is visible on it, which reappears after each new cleaning, this means that the heat exchanger in your boiler must be cleaned at least once every 2 years. If there are no deposits on the teapot, then you can get by with one cleaning every 3 years.

- In the process of cleaning the boiler in any case, do not rub the plate with pressure or extra effort. Do not use cloths, brushes or sponges. This is due to the softness of the plates - they can be easily damaged.

- Experts and more experienced users in these cases advise beginners to remove the entire disassembly process (if you disassemble the unit) and clean up on video or take a photo.Based on the footage, it will be easier for you to collect the equipment back, and most likely there will be no extra parts left.

- During cleaning of the heat exchanger, it is not recommended to use tools that have pointed edges. Such items can damage important parts of the heater.

- It is recommended to wear rubber gloves and a mask when working with acids that clean the heat exchanger from deposits. Observe safety precautions. Do not allow chemicals to come into contact with skin or mucous membranes.

- If you decide to perform a hydrostatic cleaning of the heat exchanger, then you should take into account that in no case can you exceed the critical pressure level. Otherwise, pipe rupture may occur.

- Do not attempt to make the torch hole wider using a thick needle. Of course, after that it will be easier to clean this element, but the work of the equipment itself may deteriorate.

- The brush is perfect for cleaning internal surfaces that have any shape. It is recommended to use a tool with a longer handle - with such a device it will be much easier to reach all contaminated sites.

- When assembling a pilot burner, it is important to remember one important rule: the tip of the thermal paste should be located opposite the area where the flame burns.

- If you decide to clean the heat exchanger in a chemical way, then you should consider that high-quality reagents, as a rule, have a high cost.

- If a turbocharged boiler is installed in your home, then at its bottom you will see garbage pulled into the inside of the duct. It also needs to be removed. It is enough to use a vacuum cleaner.

- Some experts argue that regular use of hydrochloric acid to clean the exchanger can lead to brittleness and serious wear of the metal. This should be taken into account when choosing the appropriate washing method.

- A common signal to clean the heat exchanger is to reduce the water pressure. If you notice this change, you should start flushing the equipment as soon as possible.

- Also, it is necessary to start cleaning the equipment even if the circulation pump began to work too noisy. This will indicate that the part is under heavy load.

- The non-separable method of washing can be contacted only if your heating equipment does not have too serious and old pollution.In addition, this method is not suitable for the removal of dirt, which appeared due to corrosion.

- After washing the unit, which you have not disassembled before, you should neutralize and dispose of the cleaning solution immediately after carrying out all the necessary procedures.

If the water passes freely, it will say that the inside of the pipe is free of debris. After completing the cleaning of the necessary parts, collect everything in the reverse order. Be sure to remove any contamination from the inside of the boiler. Then run the equipment at full capacity - this must be done to ensure that there are no leaks and that the equipment is working properly.

To learn how to flush the heat exchanger of a gas boiler, see the following video.