Error codes and malfunctions gas Navien boilers

Gas boilers have long been firmly established in the practice of heating homes and even apartments. But even the most reliable and debugged designs can falter. It is very important to recognize the true cause of the problems and to respond correctly to their occurrence.

Special features

Navien boilers occupy ever more significant positions in the Russian market. Against the background of the much appreciated Western European counterparts, they are equally qualitative in terms of technical characteristics, but cheaper solutions.

The characteristic features of such products are:

- canceled build;

- high reliability and stability of action;

- presence in the assortment of only double-circuit models;

- possibility of choice between atmospheric devices and products with the forced plight;

- availability of systems compatible with the coaxial chimney, as well as versions providing for its separate execution.

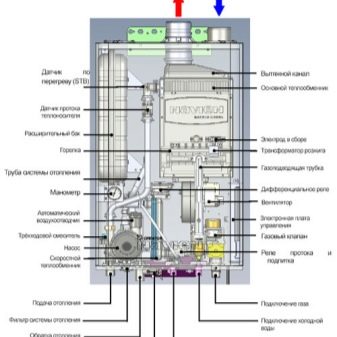

The boilers manufactured in South Korea are equipped with a pair of separate heat exchangers, one of which is responsible for the water circuit and the other for the heating circuit, but both are formed from stainless steel grades. What is important, the firm does all the main components at its own enterprises. Therefore, the problem of incompatibility of components disappears, their stable interaction is guaranteed. Electronics are designed and executed in such a way that sudden voltage spikes do not cause dangerous consequences. Separate German boilers have a similar level of security, but they belong to a completely different price group.

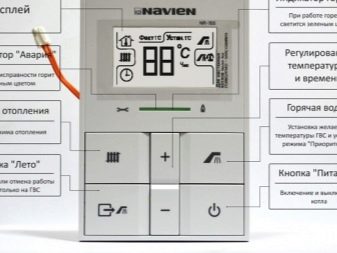

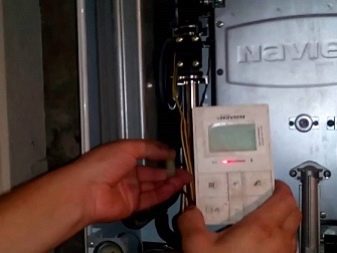

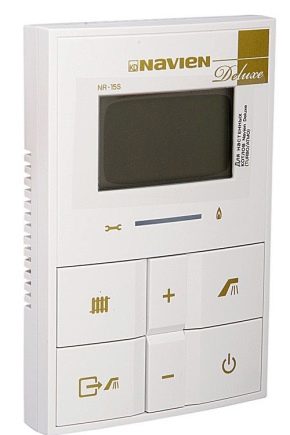

The instability of Russian power grids is too great, and therefore it is better to still connect the South Korean boilers Navien through a voltage regulator. The heaters themselves are equipped with a remote monitor, showing the codes of various failures.

Also, the user will be promptly informed about the temperature settings of the fluid and air, about the modes of operation of the system. A sensor that recognizes the temperature in the room is always used. If you choose a different brand system, almost always such an indicator is delivered only separately and for a separate amount of money.

Models

To know the general characteristics of the system, of course, will not be enough. It is necessary to understand the specifics of its individual versions. So, "Ace K 13", according to the manufacturer, harmoniously combines considerations of convenience and aesthetics. When developing the model, it was taken into account that a variety of people are experiencing the need for it, and thanks to the efforts of specialists it was possible to create a true leader in the price group.

Such a modification is delivered to the most diverse states of Europe and Asia, and everywhere it evokes mostly positive emotions. The basic concept, which the designers adhered to, is to ensure the highest level of reliability possible for modern technology.

The manufacturer indicates that this boiler should be placed only in rooms with a total area of 130 square meters. m

The closed type of the firebox allows you to refuse special boiler rooms by mounting the device:

- in the bathrooms;

- in the kitchens;

- in the bathrooms;

- in other areas of the house of choice.

The boiler will surely warm the house even at very low temperatures outside the window. He will not interfere with either insufficient water quality or voltage surges in the electrical network. In case of any problems the help of the service center does not hesitate to wait. Solved such a typical problem for the Russian climate, as the coolant freezing during the onset of cold weather.

For an hour will be spent 1.33 cubic meters. m of natural or 1.16 kg of liquefied gas, while heating the coolant will reach 30-60 degrees, water will enter the water circuit at a temperature of 40 to 80 degrees.

More powerful option - the floor copper "Ace 24". In the manufacture of all parts of it strictly complies with the requirements of ISO 9001. The boiler is made according to the turbine scheme, as the previous version, does not need a dedicated room.

The installed system of pressurization is modulated, that is, it works strictly as needed. Built-in fan helped to increase efficiency and increase the usefulness of fuel.

Diagnostics

Although boilers manufactured by Navien are designed and assembled very carefully, failures cannot be ruled out during their operation. No technical device can be absolutely reliable, it is contrary to the laws of nature. The designers took care of the creation of automatic systems for internal diagnostics. With their help, the most serious defects are detected and eliminated at an early stage.

If the diagnostic node does not work, it is difficult to understand its readings or a failure has occurred that does not have the installed code, the general principle of finding problems does not change.

Basic encodings

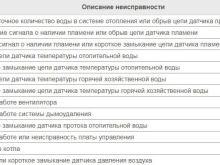

It should be borne in mind that notification itself is not yet a cause for great alarm. Many violations are eliminated by simple actions. Thus, the appearance of the error “01E” indicates the overheating of the gas equipment recorded by a special sensor. The code "02E" means that the electrical circuit of the sensor that monitors the flow of a fluid has broken. If it is intact, it shows an unusual reduction in the level of the coolant.

Code “03E” is issued when the flame signal does not enter the system. Importantly, the fire can be saved, just for some reason the system does not recognize its presence. The opposite state, in which the flame indicator allows false positive operation, is shown on the displays of Korean boilers with the code "04". This code is also issued when the circuit supplying the flame sensor has been short-circuited. If a malfunction occurs in the circuits that transmit a signal about temperature measurement, the notification “05” is displayed on the screen; if there is a short circuit, the conventional signal is 06.

Exactly according to the same principle (“07” and “08”), engineers assigned codes for an unspecified defect in the circuits of the DHW warm-up sensors and for a short circuit. The following errors are unpaired; for example, the code “09” indicates an improper fan action, and “10” indicates that the smoke pumping system is not working well.

Further essence is as follows:

- “12” - the burner is extinguished;

- 13 - closed sensor that determines the flow of the heating circuit;

- "14" - stopped the gas through the pipe;

- “15” - something happened to the electronic board, but the defect cannot be recognized;

- "16" - like the first error, this means excessive heat;

- "18" - overheated sensor that detects the waste of smoke;

- “27” - shortcomings were recorded in the operation of the air pressure meter.

No instructions for the repair of boilers are not included. It is assumed that all maintenance and adjustment should be performed by trained service personnel. But not everything is as bad as it may seem. Recognition of the most common problems and the struggle against them is possible even for poorly trained owners.

You need to be careful and take into account the simplest recommendations. So, if the unit does not heat the hot water, you need to start by cleaning the heat exchanger of the corresponding circuit; if it is very dirty, sometimes it is necessary to change the part itself.

A more serious problem is a quick set of temperature and an equally quick cooling. This is due to the consistently poor state of the heating system or poor-quality design of it. It will be necessary to regulate the speed of the circulating pump, to eliminate the filling of the system with air.

Sometimes, besides these manipulations, it is necessary:

- examine the filter;

- evaluate the lumen of the heat exchanger;

- change the coolant.

In case of error No. 3, it is required:

- make sure that gas is supplied to the boiler;

- evaluate the effect of ignition;

- check the purity of the ionization sensor (it is easily clogged).

If the boiler uses liquefied gas, it is worth inspecting the gearbox. It so happens that no malfunction is detected, but the error still continues to be displayed on the display. Then it remains only to see whether the grounding is done correctly, whether it is not disturbed for some reason. "Navien Ace 24", equipped with a sealed combustion chamber, often suffers from poor smoke removal (error No. 10). The main source of this problem is the defect of the fan, which has to be changed.

Error number 1 does not deserve to panic. If you could not even cope with the problem by dropping air bubbles by standard methods, you need to check whether the pump that provides circulation is intact. Sometimes it does not scroll, or the impeller cannot drive off the coolant. Problems with the pump do not fix it with your own hands, almost always either rewind it with the help of specialists, or even change it to a new unit. It is very important to buy only a well-proven model from leading companies.

Sometimes users are faced with the fact that the pressure drops in the system. Without the normal pressure of the coolant, it is not able to provide heat to the desired parts of the line. In most cases, the pressure should be maintained from 1 to 1.2 atm, while the system should remain empty under technical conditions.

The loss of normal pressure is especially bad if it is filled with antifreeze. It is a fluid with high fluidity, able to find even the slightest holes.

The problem is solved quite simply, you just need to eliminate the leakage channel and pump up the supply of fluid in the expansion tank to the desired value. It should be remembered that a slight drop in pressure inevitably occurs when the liquid cools. When starting the boiler into operation, the parameters should stabilize. There is nothing dangerous in the technical system. If, even with the heating circuit running, the pressure continues to drop, you should immediately contact a specialized organization for assistance.

Even when the boiler does not experience any difficulties in switching on, it often buzzes, and, of course, this worries owners who simply do not understand the reasons for this situation.Not to mention that the constant noise has a negative effect on the mental state.

It is recommended in such situations to wash the primary heat exchanger, and the secondary one also does not hurt to clean. If the reason for the deposition of mineral salts is not eliminated, pollution will soon resume. The prevention of hum and noise is the washing of nodes that exchange heat.

If the source of loud sounds is a gas valve, you should immediately measure the voltage supplied to it by the current. Sometimes it is different from normal - and for technology it is very bad. Sometimes you have to study the state of the electronic board, which sets the wrong modes. Detect a failure in this case helps "ringing" the device with a tester. But all the same, trained professionals should solve the problem.

Sometimes it is possible to eliminate the noise, if we exclude the vibration transmitted from the burner to the body. This is done simply: the lid is removed, the rubber gaskets are put, or the lid itself moves more tightly. The boiler starts up, after which the problem disappears. Many boiler owners complain that the system often shuts down by itself,delivering these many inconveniences and troubles. In some cases this is due to the overpowering of the boiler (in comparison with the rational level).

The situation can be rectified by adjusting the operation of the equipment according to the temperature of the heated liquid and cleaning the water retraction filter. You can also assume that there is no thermostat in the room or there are incorrectly determined temperatures during the adjustment. Sometimes the cause of regular outages is a violation of the piezoelectric element responsible for ignition.

It happens that after the purchase it becomes clear: the power of the boiler is excessively high. The search for a way out of this situation begins with an introduction to the question of how often the boiler should normally be started.

Of course, each model has its own characteristics. But if the system stops for 5 minutes, then it works for about 3 minutes and again makes a 5-minute pause, this is clearly a violation of the rules. Everything should happen rhythmically and measured. If there is free money, you can maintain a stable operation mode of the boiler with excessive capacity due to the installation of four-way mixers. An alternative is sometimes considered to lower the burner, but this will only happen if the burner itself has more than one stage.

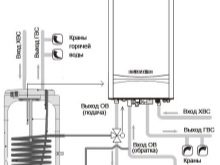

Another attractive way out is to connect the boiler to the boiler. Such a move is attractive because it not only lowers the power delivered to the heating system, but also improves the supply of hot water.

Calculating the real power of single-circuit and double-circuit boilers, it is impossible to apply the same approaches. They necessarily differ, all experts insist on it. Thermo-hydraulic distributors are also occasionally installed instead of mixing valves.

Such a step increases costs, but it will be possible to optimize the power in the boiler in such a way that it not only becomes less frequently switched on and off, but also reduces fuel costs. It happens that all these measures do not give the desired effect, and the boiler stops continue. Then you have to look for the answer in the wrong installation and erroneous setting of the circulation pump. It should be placed only where excess pressure is invariably maintained. Installation of such equipment should be performed only by trained specialists.

When the owners do not know exactly how the heat supply is regulated, they are usually advised to set the mode according to the water temperature.However, such a step very often provokes frequent trips and starts. The fact is that fluids invariably cool rather than air. As a result, an excess amount of gas is consumed and discomfort is created for consumers. Eliminate a similar nuisance can, if you put a carefully selected thermostat. About him already talked, but you need to highlight this in more detail.

Mechanical regulating devices are the cheapest, at the same time they are distinguished by mechanical strength and are very reliable. But the most modern devices are much more difficult to handle, although they have advanced features. They can be programmed, tuned to certain nuances.

But for this very reason, you should clearly understand what is required and how to adjust the system before you take up the setting. Almost always, such manipulations are entrusted to professionals, without risking once again.

Repairs

Even such reliable equipment as the gas boiler Navien, can fail for a variety of reasons. The knowledge of how to repair it is necessary even in the case when the owner will not do anything with his own hands, because control over the work of specialists is also very useful.In addition, many of the shortcomings in the operation of the equipment can be eliminated by simple actions. Some of them have already been discussed before. Those measures that the instruction does not mention should never be taken, even if they are not explicitly prohibited.

When error # 1 occurs, it is assumed:

- inspect the pump carefully and check the impeller;

- assess the condition of the electrical part;

- clean the dirt from the filter;

- remove excess air.

It is sometimes possible to correct the situation with the signal “02” by opening the closed dispensing valve. It is also very useful to clear the box on the sensor. As for the cleaning of a clogged flame sensor, it is produced with sandpaper with a grain of fine fraction. Error "10" is often eliminated after checking and debugging contacts in the tubes of the meter, as well as when cleaning the chimney.

To eliminate the risk when filling the system with coolant, you need to do this:

- disconnect the devices from the current and close the gas before refueling;

- checking the position of the valves, open them all the way;

- open the feed tap to the left;

- close it as soon as the pressure gauge detects a pressure of 1.5-2 bar;

- when emergency devices are triggered, it is required to drain the water and produce everything from scratch.

Strange noise that occurs for no apparent reason and without displaying the code on the screen, for the most part due to a drop in pipeline capacity. Therefore, the best way to solve such a problem is to descale the old coolant and add a new portion of it.

Additionally, it is recommended to reduce the temperature of heating the liquid and find out if the installed boiler is not excessive. Important: in case of any malfunction, even persons with a profile education, it is unacceptable to invade electronic circuits. Spare parts used for replacement, even non-essential ones, such as a three-way valve, should be purchased only from authorized dealers of a South Korean company.

Before opening the lid, it is necessary to stop the supply of not only electricity, but also gas, as well as water.

The fan is replaced in this order:

- the gas supply main is switched off;

- the hose connecting the fan and the air sensor is removed;

- disconnect both connectors that connect the device to the control system;

- unscrew the 3 screws and remove the fan;

- put a new unit (or return the old after maintenance);

- repeat all the operations just described in the opposite sequence.

The main heat exchanger begin to change, removing:

- gas supply pipe;

- transformer, tuning current for ignition;

- fan;

- overheating determinant.

When all of these parts are dismantled, remove the ground, remove the fire chamber and the smoke collector. The next step is to unscrew the screws holding the furnace lid and tie the heat exchanger into one body. After replacing the apparatus, all the manipulations are repeated in the same way, but with the opposite sign, and the boiler is turned on.

Note: cleaned and visually whole heat exchangers can be put back without replacement. The only exceptions are those instances in which the integrity of the ceramic seal is compromised.

Operation Tips

Owners of any heating equipment, of course, are keenly interested in how to extend the period of its use, how to eliminate various problems and delay capital repairs. But even more important is to take care of your own safety. It is categorically unacceptable to open the device and break the sealing of its body, especially when working. Inside there are a lot of hot, sharp and live parts.If it was necessary to dismantle the boiler, this operation, as well as the installation of a new one, must be carried out only by qualified specialists.

During installation and during use, it is necessary to ensure that the wire feeding the boiler does not bend or pass over, does not touch hot surfaces and cutting objects. It is unacceptable to subject the boiler to vibration, to put on it heavy and hot objects. Also, do not use it as a stand or ladder. If it was necessary to clean the device or its part, you need to stand on a stable surface. Neither stools, nor step-ladders, nor kitchen tables can be considered such a surface.

When cleaning any part of the boiler, only sparing compositions are allowed. It is undesirable to use solvents for this purpose. Also, it is not allowed to accumulate or even leave for a short time near a heating installation easily igniting substances, especially liquids. Having noticed the appearance of smoke and burning, emissions of soot, the smell of carbon monoxide, it is necessary in any weather to stop the operation of the system, turn off the power supply with gas and electricity, ventilate the dwelling and call specialists.Failure to comply with at least one of these rules can cause injury, fire and death.

Do not install gas boilers in places with high humidity, especially if it is still hot. In such an environment, even strong metal is easily destroyed, scale accumulates in the pipes and other parts. If possible, you should avoid doing construction and repair work near the heater, any other actions involving dust emission. This not only reduces the efficiency of the system, but can also result in its irreversible breakdown. And even if the “only” central board breaks down, the consequences will still be dire.

Monitoring the operation of the heating circuit implies more than one flushing; It is very important that the contact of water with air is kept to a minimum. Even clean fuel such as natural gas forms various deposits during combustion. Therefore, you should regularly clean the burner, as well as the chimney and ventilation. Inviting specialists for technical control once every 6-12 months is mandatory, even if no reason for alarm is detected.

For your information: in case of any independent repairs and maintenance, there should be someone nearby who will be able to come to the rescue, if the situation gets out of control.

This video presents the maintenance work on the Navien gas wall boiler.