Condensation gas boilers: technical characteristics, advantages and principle of operation

Today, condensing gas boilers are the most popular models of equipment for heating systems due to their positive operational features that distinguish them from other types of heating equipment.

Device and purpose

The main purpose of the condensation heaters is the arrangement of the heating system in private houses.

Among the main elements of the condensing gas heating boiler should be noted:

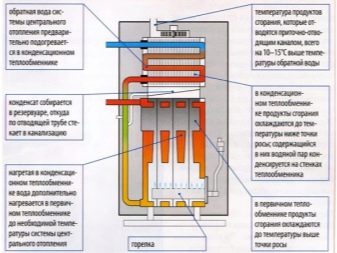

- A device that is designed to collect the condensing liquid, which receives the coolant after cooling exhaust air masses. Thus, steam is condensed and gives off thermal energy to water.Then the condensate is discharged into a special container through the drain device.

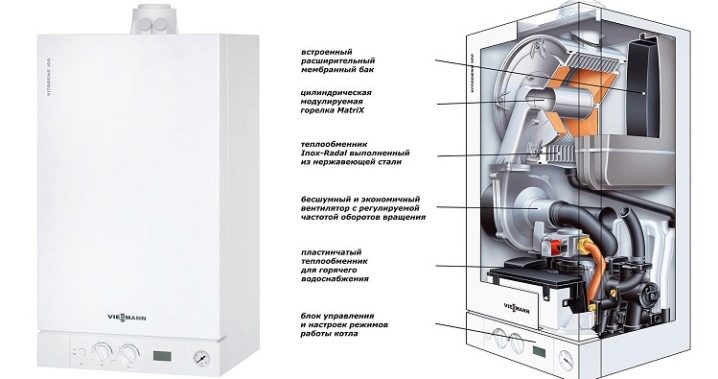

- The heat exchanger is cylindrical in shape with a large heat exchange surface. This device is made of materials that are resistant to acids: "stainless steel" and aluminum alloys with silicon. High power boilers have a pair of heat exchangers.

- Gas burner with a closed combustion chamber. It is possible to automatically change the flow rate of supplied gas and air masses.

- Control and management system.

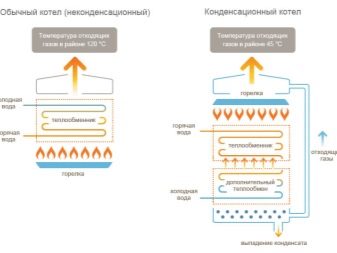

For a more detailed study of the principle of operation of condensing boilers, you need to have some idea of conventional boilers. Traditional boilers produce heat energy by heating the coolant using the heat accumulated in the combustion products. The temperature of the gases entering the combustion chamber is not more than 200 degrees. This is justified by the fact that with a decrease in temperature, the thrust decreases, and active condensate is formed, leading to the corrosion destruction of heating equipment.

As mentioned above, condensation heaters have one two-stage or two separate heat exchangers.The initial stage works on the same principle as in the heat exchangers of classical heating units. The decomposition gases enter the heat exchange unit, called condensation.

In this case, the vapor present in the decomposition gases is cooled and condensed until the onset of the liquid phase. The heat released in the process is transferred to the coolant. Thus, in the condensation apparatus, a certain part of the expended energy is returned for the possibility of its reuse.

Heat, which is usually removed by classical units into the atmosphere, is used in the condensing unit to increase their efficiency. Condensation gas boilers are available in two versions: floor standing and wall mounted apparatuses, however, they are similar in design features.

In condensation-type apparatus, the condensate is usually sent to a special container provided for by the construction of the equipment, and then to the sewer.

Since condensing type heating units are equipped with closed combustion chambers, the exhaust gases from them are removed by force.This is explained by the fact that the exhaust gases have a relatively low temperature, and an additional heat exchange unit will increase the resistance to transporting the output products. As a result, natural thrust is not enough for the output of products, for which the forced method is used.

Air into the combustion chamber is supplied under increased pressure by means of a turbine.that ensures complete removal of exhaust gases from the chamber. As a result, there is no need to equip the boilers with chimneys, since the products are removed from the room through the supply and exhaust duct. Condensing boilers can be installed in rooms without chimneys, as well as in buildings with short chimneys to form a certain traction.

Condensation equipment is considered to be more fireproof, since combustion is carried out in complete isolation from the building where the apparatus is located.

Advantages and disadvantages

Positive characteristics of condensing equipment:

- There is no need for a chimney, which has a complex structure. Since the temperature of the combustion products is low, there is the possibility of arranging the chimney made of aluminum and plastic pipes.It is also allowed to install coaxial chimneys, where the air mass is supplied and discharged using the “small pipe in a large pipe” method, that is, the products of combustion are removed through the wall to the atmosphere.

- Compactness combined with high performance. The line of condensing units with a capacity of 120 kW is made in wall variations. Traditional gas appliances take up much more space and are only outdoor.

- Intake of air mass for optimal functioning from the building in which they are located. Thus, there is no need to arrange special boiler rooms for equipment with a capacity of less than 60 kW.

- Reducing the release of harmful gases and vapors into the atmosphere.

- Significant gas savings. With a high-quality installation of a 60 kW unit, over 2000 m3 of fuel can be saved over the winter.

Negative characteristics of condensing equipment:

- High cost. On average, the price of standard boilers of the same capacity is up to 40% lower than the cost of convection boilers.

- Condensate should not be drained into a septic tank, so a special tank is needed to collect condensate,where it is neutralized with the help of neutralizing components, and only then it can be sent to the tank for draining. The condensate tank should be of sufficiently large capacity, since the equipment, even with low power, produces a high volume of condensate.

- The need for a heating system that operates at low temperatures.

- Inefficient operation at too low temperatures, as there is a need to increase the temperature of the thermal medium.

- Volatility.

Based on feedback from owners of private houses who installed gas condensing boilers, taking into account all the pros and cons, you can make the right choice of apparatus for the heating system.

Features of operation

Condensation equipment uses natural or liquefied gas as fuel. The first is widely used in everyday life, and the second - in industry. The basis of the functioning of the condensing device are the laws of physics. Fuel burns with the release of water and carbon dioxide. In this case, the liquid evaporates and a certain amount of heat is released.The formation of condensate ensures the return of the lost thermal energy to the system, which leads to an increase in the efficiency in the system. In standard boilers, condensate is considered an undesirable phenomenon that must be disposed of.

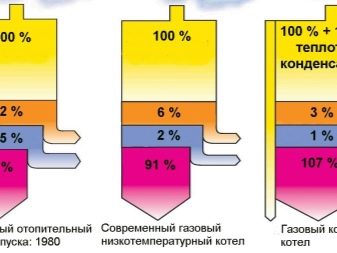

The main difference between condensing boilers and convection boilers is that the latest models are considered obsolete. Also, the efficiency of condensing equipment differs from conventional and convection up to 15%.

Most buyers note that the cost of purchasing condensing equipment is offset by the high efficiency of the device.that is provided by the condensation of vapors that are contained in flue gases. After cooling of the flue gases in the heat exchanger to 55 degrees, condensation of water vapor begins with the release of additional heat, due to which the efficiency increases.

Condensation formation is possible only if the temperature of the coolant is not more than 57 degrees and the greatest effect is achieved at 35 degrees of coolant in the return line.

Installation of condensation equipment is relevant in heating systems with low temperatures.

Criterias of choice

When choosing a condensing device, it is recommended to give preference to a manufacturer with a good reputation among customers and manufacture products using innovative technologies with increased comfort during operation.

With regards to the technical characteristics of the boilers, you need to pay attention to the following points:

- Performance. Too high power may not always be a good option, and the operation of half a power in the near future will lead to the failure of the equipment. Therefore, before buying the device, it is necessary to calculate the optimal power for heating the house. To do this, calculate the area of the building, the height and the level of insulation. You can even use special tools to research a private house. By means of them the available thermal losses will come to light. The optimal power of condensing devices depends on the climate zone. For example, for Moscow on 10 m2 of a house, the equipment capacity should lie in the range of 1-1.5 kW. Thus, for a privately owned heating system of 200 m2, equipment with a capacity of at least 20 kW is needed.

- The number of contours. Dual-circuit devices for liquefied gas work as follows: the first heat exchanger heats the thermal medium for the heating system,and the second - for hot water. The single-circuit turbocharged boiler heats only the thermal agent. For many buyers, the second option is not very convenient, but when organizing a hot water system, you can simply install an additional boiler. With intensive use of hot water can be purchased and double-boiler with a boiler. Thus, opinions about which condensation equipment is better converge.

Dual-circuit devices often have a small capacity - up to 24 W, and are installed in rooms with a good level of insulation or with an autonomous heating system. In other cases, the most optimal options with a single circuit.

- Gas consumption rate depends on the performance of the boiler, efficiency, and the load of the heating system. - Material of which the heat exchanger is made.

The speed of heating response to external factors largely depends on it:

- Silumin, or an alloy of silicon and aluminum, is designed to combat aggressive condensate. In this case, the heat exchanger must be seamless, since the presence of seams increases the risk of corrosion.

- "Stainless steel" is considered an inexpensive material compared to silumin. The advantages of stainless steel include corrosion resistance, lack of inertness and resistance to thermal shock. Therefore, the rating of materials for the manufacture of heat exchangers is headed by “stainless steel”.

- Environmental friendliness. Conventional turbocharged boilers emit fumes with acidic impurities into the atmosphere during the combustion of fuel, and in condensation devices the vapors dissolve in the condensate and undergo neutralization.

- Operating temperature affects the efficiency of the equipment. With a decrease in temperature, the intensity of condensate formation increases. So, at temperature conditions of vapors from 30 to 40 degrees the highest rate of formation of condensate. In this case, condensation occurs in constant mode.

- Control. Modern condensing devices are equipped with an automated control system. Automation allows you to monitor and control the temperature, flow and pressure in the circuits. The most advanced models of boilers are regulated through a special application on the smartphone.

- Installation method: on the floor or on the wall. Floor models with a single circuit are available with a capacity of more than 100 kW and are easily connected to the boiler equipment by means of pumping units. With intensive use of hot water floor boiler will be a great solution. If the area of the house is small, and water is consumed much less, it is recommended to give preference to wall models with two contours. They are compact and have low power - up to 100 kW, easily mounted and do not require a special chimney.

- Pricing policy gas condensing boilers.

All equipment models are divided into the following classes:

- Premium class boilers are usually manufactured under German brands. They are easy to use, safe in all respects, quiet, made of high quality materials, effective in operation and meet environmental requirements. However, they have one drawback - the high cost.

- The boilers of average cost are manufactured by the Baxi trademark and are distinguished by comfort, economy, environmental friendliness and a variety of models. Devices of this class also comply with European requirements.

- Economy class boilers are produced by Slovak and Korean manufacturers. A distinctive feature is their price, which is several times lower than that of German-made boilers, as well as adaptability to our operating conditions. Inexpensive equipment with simple functionality has a small number of options, which allows them to be used with frequent pressure drops and power failures.

When selecting equipment of condensation type, experts recommend taking into account not only personal tastes and technical features, but also the maintainability of the product, the availability of spare parts in stores. The equipment of the middle class in this case is considered a leader.

In the next video you will find a review of the Vaillant EcoTec condensing boiler from the ABC of Heat.