Baxi gas bypass boilers: device, assortment overview and troubleshooting

Double-circuit boilers Baxi Italian manufacturer distributed in 70 countries. In the domestic market, they are also presented in a wide range. Such fame is ensured by the fact that dual-circuit devices are adapted for use in our conditions. These devices function even with reduced fuel pressure, they are completed with an electronics system designed to provide self-diagnosis of the device.

Design features and principle of operation

The main purpose of Baxi double-circuit gas boilers is the organization of hot water, as well as the heating of a private house. The design of a double-circuit boiler provides one or two heat exchangers.

Baxi boilers have the following features:

- a wide range of products, thanks to which it is possible to choose a boiler for any design;

- simple and reliable modern technologies combined with high-quality assembly;

- the possibility of repair;

- affordable cost.

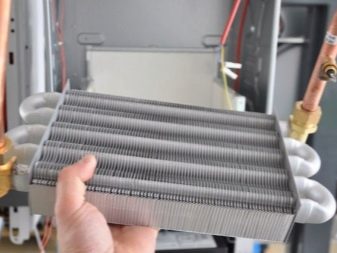

It should be noted that even in low-cost boilers, components are not inferior to more expensive models. The presence of weather-dependent automatic system allows you to install a simple water temperature sensor. Most often double-circuit boilers are equipped with two heat exchangers, one of which is the main one and is installed above the burner device, the second - plate-type, provides hot water supply. The main heat exchanger is made of high quality copper and covered with a protective film, the second - from the "stainless steel". As well as a double-circuit heating apparatus can be equipped with one heat exchanger, where the heating circuit and the circuit for hot water supply are combined.

Such devices are much cheaper, however, during operation may require significant costs due to water hardness.On the inner walls of the boiler scale is formed, which leads to breakdown of the boiler unit and to significant costs.

Each Baxi double-circuit boiler in its configuration has a circulation pump unit of the popular worldwide manufacturer Grundfos and Wilo. The pump power is sometimes enough to heat a private house of a small area. It works silently, equipped with an automatic air vent. With regards to gas automation, the boiler can be equipped with reliable and wear-resistant Honeywell and SIT valves. The sensor for switching the temperature and the hot water circuit is called a three-valve valve, which is made of brass.

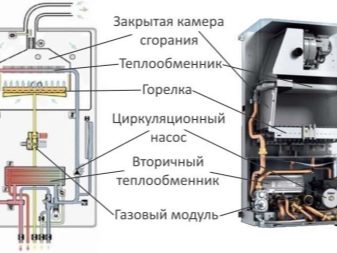

The main structural elements of Baxi double-circuit gas boilers are the combustion chamber, the burner, as well as the expansion tank and the heat exchanger, manufactured in the following two variations:

- dual - in one unit two heat exchangers are combined; the first is made of copper and provides thermal energy, and the second heats the water for domestic needs;

- bithermic heat exchanger consists of two tubes, differing in their diameters; smaller tubeIt is located inside a tube with a large diameter, the inner tube is designed to provide hot water, and the outer tube is designed to provide heat.

Heating equipment Baxi has the principle of work in two directions. The first heating circuit operates due to the heated coolant, which gives off heat and heats the room. The second heats the water for domestic use. Dual fuel boilers fuel is gas. The circulating agent for the heat exchanger is water.

Fuel, burning, heats the heat exchanger. At this time, the pump is connected to pump the liquid. Water that goes to the boiler has a temperature of at least +35 and no more than +80 degrees. Such equipment binding is called mini-boiler rooms. When a certain temperature is reached, the fuel begins to flow with less fuel. As a result, the heating radiator goes into standby mode, the heat agent gradually begins to heat up with minimal power. After 60 seconds, the power rating reaches its highest value.

Baxi double-circuit boilers of floor-standing version are equipped with electric ignition.Its feature is that the fire is regulated by the automation system. This allows you to maintain optimal temperature values in the room.

Experts recommend installing a filter element in the heating system in cases where the water is hard. This will avoid scaling.

Advantages and disadvantages

According to customers, using boilers known manufacturer, Baxi gas boilers with two circuits have the following advantages:

- long life due to the use of modern high-quality materials;

- lack of equipment breakdown in case of overheating;

- ease of control parameters of the boiler;

- fast supply of hot water thanks to the built-in boilers;

- high efficiency;

- availability of models with different power ratings, which allows the buyer to choose the boiler of the optimal cost.

Disadvantages of Baxi heating equipment are as follows:

- weak electronic unit;

- sensitivity to water containing salts and mechanical impurities;

- it is difficult to purchase replacement parts in case of replacement.

Kinds

The classification according to the type of combustion chamber includes the following types:

- boilers with an open combustion chamber are distinguished by a low price, at the same time they require caution during operation and compliance with sanitary standards and fire safety rules;

- boilers with a closed combustion chamber are quite simple to use, but they are much more expensive than previous boilers.

Classification by installation method includes two more types of boilers.

- Wall mounted boilers can be mounted on the wall in any free area of the room. They do not require special boiler rooms, for the proper functioning of all the elements are located inside the case. Power of wall boilers can be 14, 18, 24 kW.

- The mounted heating boiler meets all safety requirements, and customer reviews indicate the ease of operation of the boiler and its reliability. Each wall-mounted heater is equipped with a monitoring system, thanks to which the device can self-diagnose depending on changes in weather conditions.

Wall mounted gas boilers are presented in the following range:

- gas boiler with one circuit;

- double-circuit household heating boiler;

- double-circuit turbocharged boiler;

- gas boiler condensation type.

Gas floor heating devices work smoothly thanks to high-quality assembly. They are equipped with an electronic unit that provides self-diagnosis of equipment and, if necessary, optimizes the operating parameters in the highway.

Heat generated in the heat exchanger is consumed in a double-circuit boiler to maintain heat transfer stability. With a constant supply of cold water is provided the intensity of heating.

Popular models

Baxi boilers with two circuits are represented by several models, each of which differs in properties, a complete set, advantages and disadvantages.

Main four

Main Four is the most common model equipped with a bithermic heat exchanger. The device has such a positive feature as instantaneous heating of water as a result of the flow principle of operation due to local heating of the equipment coil with a burner flame. And also particularly noteworthy is the simple design of this heating equipment, which ensures reliability in operation.Experts say that bithermic heat exchangers are easier to maintain than lamellar heat exchangers, since their internal part can be cleaned of the formed scale. It should be noted that heating devices with bithermic circuits cost up to 15% cheaper than with lamellar circuits. This advantage especially attracts the attention of buyers. The Main Four boilers can heat up 11 liters of water per minute with the option of smooth flame adjustment, which ensures the support of the optimum temperature of the liquid and avoids sudden drops. Even in the boilers of Main Four there is an automatic cooling function of the heat exchanger and a magnesium anode that prevents the occurrence of scale.

Main 5

Turbocharged boilers of Main 5 are equipped with a gas burner, a heat-exchanger of copper-type bithermic type, a circulation pump with an automatic air vent, an electronics unit and an expansion tank. They are available with a maximum capacity of up to 24 kW, and for smaller houses there are models for 14 and 18 kW. These modifications are the same in the device, purpose, differ only in performance.

Fourtech

Wall-mounted boilers Fourtech are made of composite raw materials. Unlike other models, they are equipped with turbine regulators of hot water consumption. The flow meter sends a signal to the electronics unit, which allows you to control the flow of water and change the parameters of the thermal media.

The main advantage of Fourtech is the possibility of self-assembly and quick response to any changes in the system.

Eco four

Eco Four boilers are equipped with a copper heat exchanger. The internal surface of the device is treated with a protective layer from corrosion. The maximum power of the heating equipment is 24 kW. The boiler is equipped with an open-type combustion chamber. A distinctive feature of the Eco Four is its large height, which is 73 cm. The weight of the equipment is about 30 kg.

Luna

The main series of Luna boilers is available in the medium price range. The devices are equipped with an electronic unit, LCD screen. The maximum power of the device - 28 kW. Gas consumption per hour is 3.2 m³. Water heats up from +35 to +65 degrees. The weight of the device is about 37 kg.

Luna-3 Comfort

Heating equipment Luna-3 Comfort are produced since 2007.A distinctive feature is the ability to control with cable and cable-free unit, which allows you to control the parameters of the equipment at a distance. The cable-free panel can function as a programmed thermostat, which allows you to adjust the parameters of the boiler for several days in advance. This option provides adjustment of the flow, gas, electric energy.

Panel type mounted on the wall. Inside the device there are modern engineering technologies, so the boiler with two circuits has an electronic sensor for measuring flow, flow and flame control. Heating equipment capacity - up to 31 kW. Each boiler is equipped with a plate-type heat exchanger in which a thermal agent moves through copper pipes. These tubes can be made with steel fins, which minimizes hydraulic resistance.

Luna-3 Silver Space

Luna-3 Silver Space boilers are designed to operate in open areas at temperatures down to -15 degrees. The unit is equipped with a continuous flame adjustment and can be operated with an excess fuel pressure of up to 5 atmospheres.The heating unit consists of a three-code valve, a circulation pump unit, a pressure gauge, an automation unit and a filter for cleaning water from salts and mechanical impurities. Water can heat from 35+ to +80 degrees.

NUVOLA-3 Comfort

Heating equipment NUVOLA-3 Comfort is equipped with a built-in boiler of 60 liters. The boiler is designed for consumers in large quantities using hot water. The boiler unit heats up for half an hour the water of about 500 liters with a temperature of +80 degrees. The boiler is also equipped with a magnesium anode, which provides reliable protection of the walls of the apparatus from the damaging effects of corrosion. It is mounted on the inside of the flange joint. When heating up, the magnesium anode begins to react with water, so that no scale forms on the wall of the boiler.

However, during long-term service, the magnesium anode gradually wears out, so it needs to be changed. In the absence of this part, the duration of operation of the boiler will be reduced to two times.

Repair and service

Before installing a double-circuit boiler, you must make sure that it can work on the gas that is supplied to a private house.This can be found on the packaging of the heating equipment. You should also check the chimney for any restrictions and precipitations.

To ensure long life when connecting a heating device, follow the instructions below:

- with increased water hardness, installation is carried out using a polyphosphate dispenser or other filter element;

- between installation and operation, the heat exchanger must be thoroughly washed at home from possible contamination; for these purposes, special liquids are used to wash equipment, which do not contain concentrated alkalis and acids, which destroy the material of the product;

- Heat exchanger material for hot water supply must comply with Directive 98/83 EC.

Before the initial start-up, the correctness of the connection of all units is checked, as well as the compliance of the fuel and water parameters with the boiler parameters.

The start-up process includes the following actions:

- the heating apparatus is connected to a power source;

- fuel is started by opening the corresponding crane;

- switching on and setting the optimal mode - winter, summer, heating;

- setting the desired temperature setting buttons +/-;

- wait for the ignition of the symbol in the form of a flame on the screen; in the summer mode, the symbol is different.

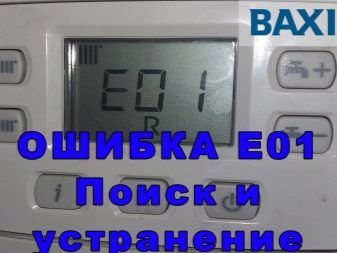

During the initial start-up of a double-circuit boiler, you may encounter such a problem as the accumulation of air with the formation of a gas plug, while the pressure in the system increases significantly (error E01). In this situation, there is no ignition of the burner, and the boiler does not heat. To restart the heating apparatus, press the "reset" button.

Then it is necessary to reconnect and disconnect the device for gas supply to the burner, as a result of which the pressure in the system drops. To completely turn off the heating apparatus, it is disconnected from the power source.

When choosing a boiler, it is necessary to take into account possible malfunctions of the device.

- Bithermic heat exchangers are often scaled. Therefore, they are mounted in systems where there is a small amount of salt in the water. The heat exchanger must be descaled annually.

- With a weak chimney also the boiler will start to malfunction. During operation of the heating device, the chimney clogs up, so it must be regularly cleaned of soot.

- In that case, when opening both taps, warm water begins to flow, and when opening only one - very hot, it is recommended to install a pump unit of the post-circulation type. This pump is a thermostat designed to regulate the parameters of the boiler.

Overview of the gas boiler Baxi - in the next video.