Vaillant gas boilers: variations and recommendations for use

Germany is the birthplace of heating equipment, and the German concern Vaillant is the leading structure in the global production of heating appliances and the company that first adapted gas appliances for their use in the special climatic conditions of Russia. Today, Vaillant appliances are prestigious, reliable, top quality and, of course, homely comfort.

Special features

By their capabilities, Vaillant gas boilers are used both as heating systems and for the production of hot water. All products of the company are subject to detailed verification and have certificates. Some models are even assembled by hand.The mechanisms of the devices are constantly being upgraded and their quality is increasing.

It is worth noting the following obvious features of the instruments of the German company:

- constructively, the boilers provide for work in conditions of uneven (spasmodic) pressure, they can quite effectively be used in Russian water pipelines and gas systems;

- Vaillant boilers consume a minimum of gas (economical);

- they are easy to operate and give a “smart” signal in case of a malfunction;

- the guarantee of the device’s proper operation is 20 years;

- many models are equipped with gas leakage prevention and self-diagnostic systems;

- high power level, almost independent of the dimensions of the device;

- boilers are distinguished by a high level of adaptation to the conditions of Russia - they are safe and durable;

- devices are environmentally friendly - the degree of emission of harmful substances into the environment is minimal;

- availability of nodes and various components to them.

Vaillant boilers are quite a suitable and necessary product for Russia. The price range of equipment manufactured by the concern is 29000-47000 rubles. However, the high price is compensated by the fact that when buying, for example, a two-circuit model, the owner receives a device that performs two functions - heating and hot water supply of the room.Some time ago, the concern organized the assembly of devices in Slovakia, where devices are now being manufactured for the east of Europe and the Russian Federation. The abbreviation of these products contains the label Int.

In Germany, only condensing units are manufactured, for example, the EcoTec Plus model range.

Advantages and disadvantages

German Vaillant devices have the following advantages:

- high quality products;

- almost all nodes, for example, TEC Pro and TEC Plus, are performed in copper versions;

- apply the most innovative technologies;

- prestige brand;

- profitability;

- silent work of devices;

- availability of two thrust sensors (patent);

- availability of necessary connectors and adapters for connecting water and gas;

- Excellent reviews from both experts and owners.

Of course, these products have disadvantages, such as:

- high price tag;

- high cost of spare parts;

- in some cases, large dimensions;

- non-freezing fluid is not recommended for individual models;

- the installation of after-production chimneys on apparatuses with a closed combustion system is not allowed;

- sometimes when working devices are noisy.

Kinds

The line of equipment from Vaillant includes the following types:

- condensing units;

- capacitive heaters;

- boilers with one or two circuits in the floor and mounted versions.

Technical characteristics of the products are as follows:

- power - in the range of 9.60–36.0 kW;

- execution - two-circuit or single-circuit;

- installation method - wall or floor (in both cases installation of a refractory sheet is required);

- electric ignition system;

- Efficiency - up to 98%.

Vaillant VU single-circuit boilers are used exclusively for heating purposes. If it is necessary to provide hot water, it is possible to connect the boiler. The complex of such equipment is sold by the company at a discount of 10% with full guarantee of compatibility of components and accessories of the units. VUW dual circuit devices provide full system functionality and uninterrupted hot water supply.

That is why the dual circuit is more preferable for users than the single circuit.

In addition, there are types of open and closed combustion options, equipped with coaxial chimneys or a conventional smoke removal system.Condensation varieties of Vaillant boilers are usually equipped with a special modulating device that provides a modulation level of 22–100%. Outdoor equipment options are less popular than wall (wall), because they are more used in buildings with large areas and are expensive. In addition, their placement requires a separate room with certain characteristics (heat point).

For example, you should look at such atmospheric, outdoor models, such as:

- AtmoVIT - 1656 kW;

- AtmoVIT Exclusive - up to 47 kW;

- Atmo CRAFT - 65–157 kW.

The Vaillant company lets out a wide choice of hinged heating devices.

Condensation

The main advantage of this type of apparatus is its economy. The principle of their work is based on the use of waste gases (condensate) in order to generate additional heat. The temperature of exhaust gases at the exit of such devices is from +50 to + 60 ° С, and for ordinary ones - from +120 to + 180 ° С. The effect gives you up to 15% savings in consumables. They are stable during operation, even when there is a shortage of pressure in the system, they perfectly regulate the power of the boiler (up to 20%) and have good noise insulation.

It is noteworthy that back in 2015, the sale of non-condensation heating equipment in Europe was banned.

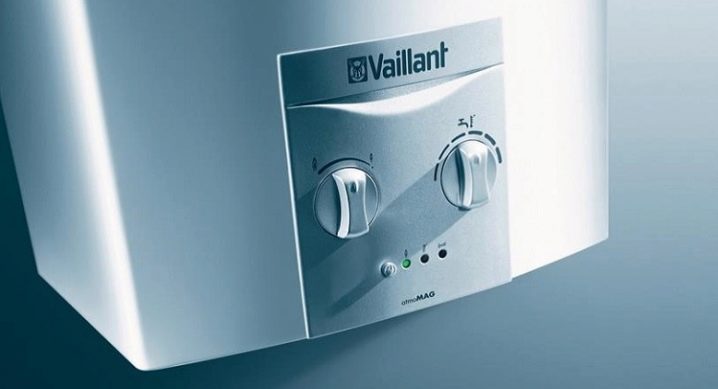

Traditional

Traditional heaters are available in the following types:

- with two circuits (VUW);

- with one circuit and boiler connection (VU).

These devices may vary according to the methods of removal of combustion products, namely:

- with a closed combustion system (TurboTec and TurboFit);

- with an open combustion system (AtmoTec).

Single-circuit devices manufactured by 12, 20, 24, 28 and 36 kW can heat up to 360 m². This type of boiler has been labeled VU Plus. For example, the Vaillant VU TurboTec 242 / 5-5 is considered a turbocharged boiler with a capacity of 24 kW, belongs to the fifth generation, is single-circuit, is represented by the Plus modification.

Double-circuit German devices for Russia, which are produced in Slovakia, are represented by such types as:

- VUW Tes Plus;

- VUW TurboFit;

- VUW Tes Pro.

Relatively inexpensive are the products of the VUW Pro line with a power of 24 kW. The devices of the VUW Plus range are distinguished by an expanded model variety and a convenient power range for selection: 20, 24, 28, 32 and 36 kW. The difference between the Plus models and the Pro is contained in the functionality - in the first version, the products are supplied with a “hot start” device that ensures a stable temperature condition in the heat exchanger.The latest level devices are equipped with an Atmo Guard device with several high-speed temperature sensors (NTC). Atmo Guard, being innovative, has a security function in the operation of the device. There are innovations in devices collected in Turkey. So, in the Vaillant TurboFit VUW 242 / 5-2 (24 kW) double-circuit heater, the hydraulic unit is not made in a copper version, but from composites, which made it possible to significantly reduce the price level of apparatuses.

It is also significant that the dimensions of the boiler have decreased significantly.

Vaillant products are sold throughout Russia, it is worth considering especially popular models.

- Among the double-mounted devices worth noting the following options:

- Turbtec Pro - is simple and reliable;

- The Vaillant 32 kW is a dual-circuit device suitable for an area of approximately 320 m²;

- Turbtec Plus is a suspension type option;

- Ectec Plus is environmentally friendly, easy to repair and reliable in operation.

- Floor-mounted appliances with one circuit and forced pitch, for example, Vaillant 24 kW.

Operation Tips

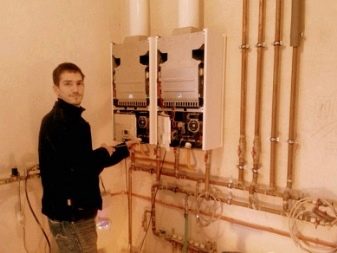

The general requirements for installation and operation of devices from Vaillant are:

- Mandatory connection to the mains through an uninterruptible power supply and a voltage regulator, since the electronics used in the devices react extremely sensitively to power surges;

- grounding installation is obligatory for any model of a copper.

In order to save gas, it is important to avoid overheating of the room. To do this, install special thermostats, allowing you to set a program to maintain the temperature of the room at different times of day. With the help of the Vaillant regulator, you can adjust the temperature schedule in the house, setting a reasonable temperature for a day or even a week. The accuracy of such automation systems is up to 0.5 degrees.

The advantages of installing thermostats are as follows:

- savings up to 15% due to the absence of overheating;

- convenient process of management, during which changes are made using an external control unit, placed at the request of the client in any place convenient for him.

The professional examination and maintenance of the apparatus significantly prolongs the period of its service and must be carried out at least 1 time per year, regardless of whether the equipment is used for a private house or an apartment. Installation of boilers is important to trust only licensed professionals. In the case of purchasing a device with an open combustion system, regular ventilation is necessary - the devices use oxygen that circulates indoors.Otherwise, oxygen deficiency will negatively affect the well-being of the household, and the boiler will not function to its full capacity. Before using the boiler, it is advisable to carefully read the instructions and verify that the system contains the recommended amount of fluid, the proper operation of the safety valve and the quality of combustion. If there is a shortage of fluid, it should be replenished by topping up to the expansion tank according to the instructions.

If the device is not equipped with an anti-overheating device, air must be removed from the system using a special bypass valve.

From the point of view of safety and proper operation of the boiler, it must be placed in a room of at least 4 m² and a height of at least 2.5 m, with lighting, a steady flow of fresh air and a ventilation system. The doorway must be at least 80 cm wide. The cross section of the chimney and the exit section must be the same size. When choosing a boiler, it is worthwhile to give preference to devices equipped with automatic trigger systems for instantaneous gas shutdown in case of leaks. During operation, it is important to control the presence of good traction, the possible appearance of unpleasant odors, debris. It is important to clean the burner regularly.

Temperatures reflected by the display should not show values greater than +90 degrees.

Experts recommend to follow such additional tips as:

- the product must comply with the parameters of the heating system;

- connection must be made in strict accordance with the instructions;

- any, even small deviations from the parameters of the operating mode, should be immediately checked;

- initial work start must be preceded by thorough diagnostic measures;

- It is important to know that the factory settings are often set to maximum values, therefore at smaller areas it is necessary to reduce the power level, which can be done after connecting during the first diagnostics.

Possible faults

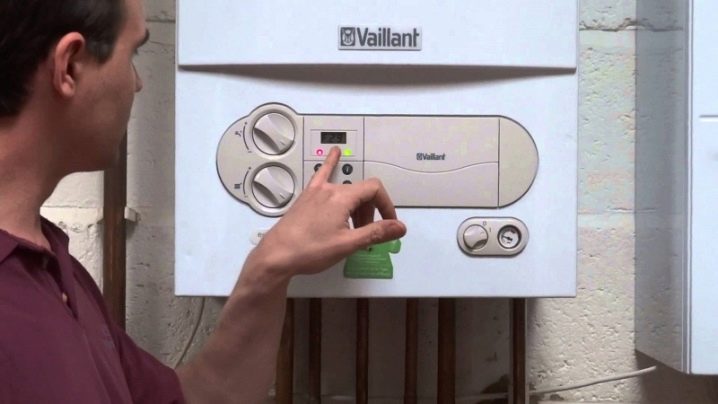

Vaillant boilers, equipped with an electronic unit with memory, are equipped with an automatic diagnostic system. Data on the current state of the device are displayed on the display in the form of an alphanumeric code (past errors are also recorded).

Therefore, before the repair by a maintenance technician, it is possible to assess the condition of the boiler, namely:

- check the degree of tightness of the inlet and outlet paths (carbon monoxide, hot water supply, condensate);

- check for the presence of various types of mud deposits in the chamber of reduced pressure;

- inspect the wiring - the quality of the connections in the connectors and plugs;

- inspect the condensate as well as the siphon for the occurrence of salt deposits or limestone, which should be cleaned;

- in the presence of soot, clean the burner, as well as the walls of the chambers and the chimney from the inside.

In cases of malfunction, the display shows various error codes which are indicated in the instructions. Commonly occurring errors are complex, but the display will show the one that prevents the device from moving to the operating mode.

The most common are several faults.

- F22 - lack of fluid in the apparatus. It is necessary to check the operation of the pump, the quality of its connections with the sensors, as well as the nature of the circulation of water.

- F28 - the boiler does not turn on. The main reasons are: connection error in the zero-phase pair; a glut of air has occurred; insufficient gas pressure; control board faulty; error in the boiler grounding; cable broken. Separate, but not all faults are solved independently according to the instructions.

- F29 - the flame in the burner dies out, ignition is unproductive.Causes: incorrect equipment grounding, gas supply interruption, failure of the ignition transformer or valve. It is advisable to check the pressure in the gas system, because it can be low, or check the air deficit to ensure the combustion process.

- F36 (Atmo) - leakage of combustion products from the system. Causes: lack of ventilation system or broken chimney draft.

- F75 - pressure does not correspond to the norm when the pump is running. Causes: malfunction in the water pressure sensor, air penetration into the system, violation of the expansion tank connection, low water pressure. The water pressure sensor should be put in order or the necessary elements should be replaced with spare parts designed for a higher power level.

Often, owners complain about excessive noise in the Vaillant Atmo Tec Pro device. The most likely version is the failure or incorrect operation of the three-way valve of the hydraulic unit of the device. Valve repair or replacement is required.

You should not try to understand and troubleshoot yourself, it is better to immediately call the servicing master if the following codes appear on the display:

- F0, F - NTC sensor malfunction;

- F2, F3, F - failure of the NTC sensors;

- F5, F6 (Atmo) - sensor of safe removal of combustion products is faulty;

- F10, F - the temperature sensor has shortened in the leading (F10) or in the outgoing lines (F11);

- F13, F - closes the sensor "hot start";

- F15, F16 - fault sensors output products of combustion;

- F - the device has overheated, coolant deficiency or emergency shutdown of the device due to excessively high temperature of the exhaust gases;

- F32 (for condensing units) - fan failure;

- F33 (TurboTec) - pressure switch malfunction.

You can learn how to install the heating system on the Vaillant gas boiler from the video below.