Diagnostics and troubleshooting of gas boilers Arderia

Arderia gas heating boilers are manufactured in South Korea. They are manufactured by Daesung under license from Daewoo. This equipment belongs to the innovative generation and already has a lot of positive feedback among users.

The manufacturer offers a wide range of models. Therefore, everyone can choose the most suitable option, based on the area of the heated room.

Specifications

Most of the components of gas boilers Arderia is imported. Most often it is Japanese, Danish and German parts. This particular item is a kind of disadvantage of this equipment, as it complicates the maintenance of the units.

For a more detailed consideration of Arderia boilers, it is necessary to understand their technical characteristics.

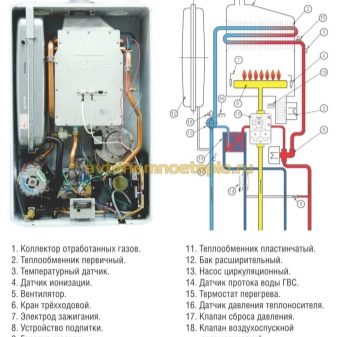

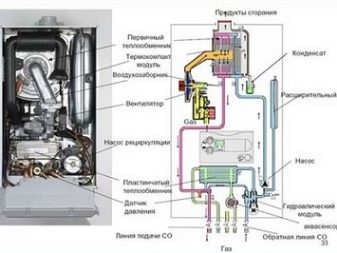

- Heat exchangerThe heating capacity of the boilers under consideration increases due to the fact that copper heat exchangers are used in the primary circuit. As for the data components of the second circuit, they are made of stainless steel.

- Control of the operating voltage in the control circuit. These boilers have a voltage regulator. It supports the correct operation of electronics and enables it to work in large ranges: from 150 V to 290 V and even more. This feature allows you to extend the life of the automation boilers. It is worth noting that all Arderia gas boilers are equipped with a good security system. Special systems monitor excessive heating, the state of the current, the disposal of combustion products, and also control unexpected gas leaks.

- To improve the combustion possibilities and increase the efficiency of the boilers, additional boost is used, achieved by using a fan. It is powered by electrical current. Using a fan helps to increase the life of the device.

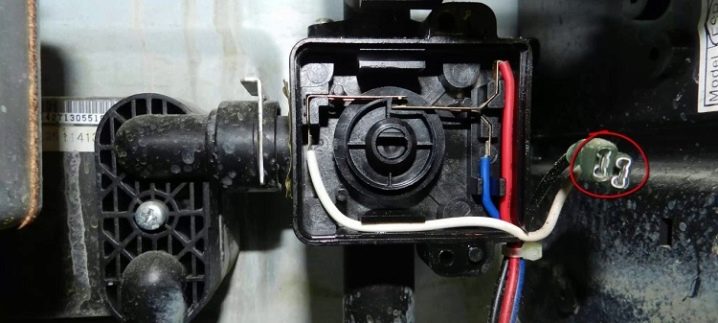

- The use of a Grundfos circulating pump running on a dry rotor reduces the susceptibility to current and also improves the operating conditions of the pump.

It should be noted that many heating boilers are equipped with a remote control. It helps to turn the device on and off without approaching it.

Arderia boilers use a three-way valve. It is installed in order to achieve the optimal level of heating, and the pipes are heated evenly. This part is often made of stainless steel or bronze. These materials are durable and have positive reviews among the owners.

Operating principle

Arderia gas boiler has two types: it can have one bithermic heat exchanger or two radiators. The first type is characterized by the fact that water is simultaneously heated for both water supply and heating.

The second type consists of two nodes. They heat up each separately. One radiator is made of copper, the second - of stainless steel. Water circulation takes place with a pump. Removal of combustion products is also mandatory. It occurs using a special fan.

The control of such gas boilers can be both electronic and remote. A remote control is always sold in the kit.

All gas boilers Arderia heating have a number of features, which include:

- This equipment is fully suitable for Russian heating systems;

- boilers have a special voltage regulator, which helps the device to work smoothly even at voltage surges;

- boilers have a gearbox that stabilizes operation when the gas pressure drops;

- Arderia gas heating boilers are practical, stylish and of high quality.

The principle of operation of these boilers is as follows:

- the first thing you need to set the desired temperature using the remote control;

- the boiler is turned on automatically with the help of a temperature sensor and works until it reaches the set parameters;

- after that, the sensor turns off the boiler;

- as soon as the temperature decreases by 15 degrees Celsius, the sensor switches the boiler on again.

The pressure in the boiler is constantly regulated by the air valve as well as the gas flow sensor.

Error codes

At occurrence of the slightest malfunctions or problems in work of the device on the electronic board a certain error is shown.

In order to properly fix the damage, you need to know the content of all possible equipment errors.

- Error A1 - failure of the air pressure sensor.This is probably due to blockage or icing of the inlet.

- Error A2 - reduced fan speed, in connection with which the boiler does not heat the water well and also makes noise. The reason may be either poor contact, or problems with connecting wires, or getting foreign objects on the fan blade. This may cause noise.

- Error A3 - breakdown of the circulation pump, pressure drops. This problem may occur due to the ingress of dirt into the pressure sensor, as well as if it turned on before the pump.

- Error A4 - increase in the temperature of the device, while simultaneously knocking out both fuses. This can happen if the shut-off valves are screwed down, the heating filter is clogged and the valve is flowing, the pump is out of order, the three-way valve is not working, the water flow sensor is damaged.

- Error A5 - coolant pressure decreases. It may occur due to a decrease in the amount of water in the system, the appearance of air, a pump breakdown or a decrease in its speed, or wear of the pressure sensor.

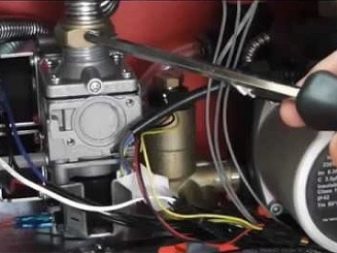

- Error A6 - no ignition, the boiler does not ignite, it goes dead. It occurs in connection with the blocking of the chimney, low gas pressure, inoperability of the gas valve, breakdown of the transformer, clogging of the flue.

- Error A7 - gas valve failure, as a result of which the unit does not start. This breakdown happens due to the closure of the relay, errors in the control system.

- Error A8 - extinction of the flame. It happens due to the presence of residual flame with the gas valve turned off, damage to the diaphragm of the gas valve, failure of the control unit.

- Error A9 - freezing. It occurs as a result of lowering the temperature of the coolant to 5 degrees Celsius.

- AA error - boiling. It happens if the heating circuits are faulty, the filters are clogged, the circulation pump is not working, the three-way valve is damaged or worn, and the hot water supply sensor has failed.

- Error AB, AC - thermostat failure. Possible with an electrical circuit arising in the thermostat, poor contact connections in the device itself.

- Error AE - chimney blocking. Appears due to ingress of foreign bodies into the gas outlet or its deformation.

- Error E0 - problems with anti-freezing. Occurs when the temperature drops to 1 degree Celsius. In this case, the boiler will not work until the temperature rises above this mark.

- Error Е1 - breakdown of the ionizing sensor, no burning. Occurs in the event of flame extinction or poor ignition. Within an hour, the boiler itself will try to correct errors in the system. If this does not happen, then you need to contact the experts.

- Error E2 - the error of the sensor responsible for air pressure. Occurs with a reduced fan or faulty fan. If after the lapse of 15 minutes the device did not work, it is better to contact the customer service center.

- Error E3 - occurs when the thermostat overheats. May occur in the absence or improper circulation of the coolant. It is necessary to drain the hot water, check all the valves, to unlock, press MODE.

- Error E4 - failure or overheating of temperature sensors. May occur in case of breakage of the pump.

There are also cases when the error is not displayed on the board, but the boiler works with complaints.

These cases include the following.

- The fan turned on, but the burner does not burn. The problem may occur due to clogging of the chimney, leakage of combustion products, breakage of the current stabilizer.

- Change the color of the flame to red or yellow.Occurs due to contamination of the burner, failure of the gas valve settings.

- Hot water begins to flow after a long period of time. Rather, it is not an error or breakdown - this phenomenon is associated with the gradual heating of the incoming water.

Repairs

Of course, thanks to the control panel and the display on which the code of the error that occurred in the gas boiler is displayed, it is possible to eliminate it quickly. You can do it yourself or use the help of professionals or a service center.

To get rid of the problem yourself, You can use the following methods to eliminate the most common mistakes in Arderia gas heating boilers.

- When disconnecting the chimney pressure sensor, the outlet must be cleaned.

- If there is a decrease in the number of revolutions of the fan, you need to check for the presence of foreign particles on its blades. After cleaning it, the problem will be solved.

- When turning on the overheating sensor, it is better to replace the DHW heat exchanger.

- In the event of low pressure, it is necessary to check the operation of the pump, as well as the tightness of all valves.You may have to remove the old gaskets and put in new ones, taking into account the dimensions of the sealing rings, and also change the valve. This will help correct the error and increase the pressure in the boiler.

- If an ignition block occurs, it is necessary to remove the parts of the gas valve, to check their operation. You may have to replace them.

- If the boiler is not turned on, and the burner is working, you must check the setting of the electronic control unit: it could break. In this case, it will have to be replaced.

- If sharp changes in water temperature appear, clean the filters and check the pump and the water flow sensor.

Gas boilers heating Arderia equipped with a system of troubleshooting, which allows you to know exactly what happened after the breakdown, as well as quickly solve the problem. It is recommended to use the equipment instruction manual.

As for the reviews of the owners of these units, in addition to all the advantages, they highlight some of the disadvantages, which include:

- the boilers are quite loud;

- hot water comes after a long period of time;

- pump, control unit may become unusable ahead of time;

- simple and uninteresting boiler design.

Gas boilers of the company in question cost an average of 22,000 to 26,000 rubles. They are great for installation in private homes. The manufacturer provides warranty and service for 24 months. These devices are economical, reliable and easy to use, especially thanks to an automated system for finding and displaying faults.

For information on how to do the preventive maintenance of the Arderia boiler with your own hands, see the next video.