Expansion tanks for gas boilers: device and pressure control

Heating equipment is always calculated for a certain pressure and pressure in the system. Gas boilers are no exception to this rule. Expansion tanks for gas boilers help them to maintain the stability of the parameters.

Special features

The question of how these tanks should normally work is associated either with operational disturbances or with the need for maintenance. The main purpose of using the tank is to eliminate the effect of expansion of the heating water. It is becoming more and more, but the volume of pipes, radiators and storage tanks is finite. In closed heating circuits, it is necessary to fill 100%, and this means that the excess mass of the coolant needs to be dumped somewhere.The tank becomes the right place.

If suddenly there is no way out, the liquid will certainly find a path through which surplus will burst out. Safety valves usually become such a place, but still they are rather emergency equipment. Even if they work out exactly as they should, they will have to eliminate the spilled water, re-fill (refill) the system. Installing tanks in advance helps prevent this development. And even with boiling coolant to keep everything in order.

How does the system work?

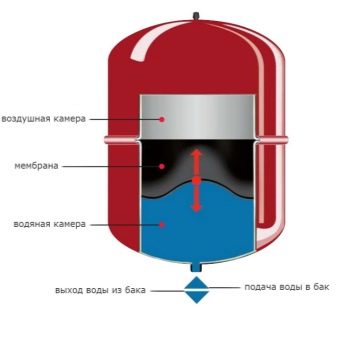

Expansion tanks - dull closed vessels, which are divided into two fragments using rubber membranes. This is not a simple rubber, because it must carry a significant heat, while remaining flexible and not losing strength.

Important: the pressure must be determined inside the air cavity entering the empty container, strictly at a temperature of 20 degrees. It is equal to the static pressure of the full heating system. This condition allows to achieve the equilibrium state of the membrane and to compensate the pressure exerted by the coolant.

That is, by the time of launching the tank will be completely empty, and its entire volume can be used to correct thermal expansion of water or antifreeze. If the gas boiler sensor detects that the pressure in the heating system has dropped to 0.7 bar or less, it gives the command to turn off the heater. And the average value, ensuring normal operation - 1.2 bar. Since going from a non-equilibrium position to an equilibrium, the membrane can raise the pressure even more, its initial level for an empty tank is taken to be 0.3 bar (on average) higher than the standard for the heating system.

Conclusion: with the closed heating circuit of a gas boiler, the pressure should be from 0.8 to 1 bar; parameters of any deviating system standards are calculated individually, taking into account:

- estimated volume of water or antifreeze;

- Tank efficiency;

- its required size;

- initial pressure at start up.

Tanks on double-circuit boilers Baxi, as follows from the instructions, must operate at a pressure of 0.5 bar. However, in fact, this figure is minimal, and to ensure the normal functioning of the device allows all the same pressure of 0.8 - 1 bar.The built-in expander with a capacity of 6 liters stably works with heating systems with a capacity of 75 liters (on water). Or 50 l (on antifreeze).

Whether it is necessary to use an additional expansion tank, or enough regular equipment, only experts decide at the time of project preparation.

How to control the system and work with it?

It is very important to check the actual pressure in the expansion tanks. Manual gauges are almost always used for this purpose, since most air chambers are equipped with type nipples, like automobile or bicycle tires. The problem may occur if the boiler is wall-mounted. Compensating devices are often located on its rear wall, and it can be difficult to use them. The output is the use of a compact mobile pressure gauge.

As soon as the deviation of the indicator downward is detected, the air should be pumped correctly. Leaving everything as it is, you can encounter emergency stops of the boiler. It is even difficult to say whether such an outcome is worse or that of excess fluid is released. Each manufacturer of gas boilers advises consumers to measure the pressure in the tank annually.There will be no harm, of course, if you do it twice as often.

It must be remembered that pumping is performed only when the tank is completely empty; to do this, drain the water from the boiler. The easiest way is to use a bicycle pump when monitoring the result through a hand pressure gauge.

The sequence of actions is as follows:

- taps on the heating system;

- water comes down from the boiler;

- pumped tank to the desired pressure;

- the crane for discharge is blocked;

- the heating circuit is saturated to the desired level through the provided tap;

- taps connecting the tank with heating are opened.

Possible problems

It is not always possible to download the expansion tank to the desired number of atmospheres. Strictly following the serviceability of technology people rarely encounter, of course, problems. But negligence or irresponsible approach can bring a number of troubles. Often, the pressure gradually decreases, and after a series of feeds to the boiler, the tank fails. Even before it comes that the membrane from being pressed to the wall is deformed by the spool.

Repair in this case is impossible, the expander will only be able to be replaced completely. It happens otherwise: the pressure in the heating circuit is at the maximum allowable level, but the tank was not serviced and remained without pressure. As soon as the heating system stops and begins to cool, the fluid will shrink, the change in pressure will not be corrected. As a result, the boiler gets into an “accident”. Problems of this kind can be triggered by prolonged use of the heater for hot water supply or power outages.

Another likely scenario is that it is necessary to systematically and without obvious reasons supply new water. For example, the hot water circuit works, and the pressure gauge shows the pressure drop, the boiler stops working. Since thermal expansion is not compensated, heating the coolant will reset its excess by the safety valves. If you do not notice this situation in time, you can face serious troubles. Therefore, it is required to pay maximum attention to the state of the expansion tank, to regularly measure the pressure inside it.

Additional Information

The expander helps to extinguish the hydraulic shocks created by air closures and abrupt closure of the reinforcement.Tanks will be able to perform this function, if you put them on the reverse course of the coolant directly in front of the boiler. You should not assume that the pressure exhibited at the factory will be ideal for practical needs. Its adjustment is made by a zolotnik.

Important: when measuring the pressure in the expander, any manometer registers only the excess value, to obtain the absolute figure, add 1 bar.

The pumped tank does not work well, since the air will push the coolant out. If everything is set up correctly, but the fuses continue to discharge water intermittently, the problem is most likely in an excessively small volume of the expander. Therefore it is worth choosing tanks that can hold 10% of the total coolant circulating in the system, or even more. Since the tank does not provide for fittings for pressure gauges, they must be connected to the nipple. It is placed on the side opposite to the filling coolant circuit.

Since automobile and bicycle manometers measure pressure in MPa, it is necessary to compare their readings with the pressure in the heating system (expressed in bar or kgf / sq. Cm). One bar equates to 100 kPa.When using a car meter, it is recommended to wait 10 minutes after turning off the boiler so that the circulation stops. When the tank is built into the boiler itself, it is necessary to shut off not only the shut-off valves, but also the flow of coolant and its return stroke. By following these recommendations, you can significantly simplify your life.

For information on how to check the serviceability of the expansion tank, see the following video.