Floor gas boilers: types, recommendations for selection and rating of manufacturers

To stay in a private house as comfortable as possible, you must pay special attention to the choice of heating equipment. Currently, there are many different types of equipment that can heat rooms of absolutely any size. The most popular for many years are floor boilers running on gas. Today we will take a closer look at such units and find out what types of gas boilers exist in the market of heating equipment.

Special features

Modern private housing or industrial buildings are hard to imagine without a high-quality heating system. Fortunately, in front of modern consumers there is a fairly rich selection of various equipment that works on all types of fuel.If it is possible to connect gas-powered units, people most often choose reliable and efficient boilers of various modifications. Similar products are divided into wall and floor subspecies. If you want to purchase more powerful equipment, then you should buy an aggregate placed on the floor.

Heating systems in which such units are present consist of several elements.

- Boiler room. It is a separate room where the heating apparatus and the control unit are installed. The number of control devices can be increased depending on the specific model purchased.

- Pipeline. This is another important component of such a heating system. This type of communication allows you to transfer heated fluid in different rooms at home. The wiring can be open or closed (this parameter depends on the draft and the immediate preferences of the owners of the dwelling). Often, the pipeline is also used as one of the elements of the “warm floor” system. Connection to communications can be single-circuit or dual-circuit.

- Convectors.Simply put, these are ordinary batteries. When using them, it is possible to expand the area of direct heat transfer.

The pipeline and convectors of such a system are practically no different from the communications that are present in city apartments. But the gas floor unit itself and its regulators are more complex. Connecting such equipment is possible only with appropriate coordination.

The peculiarity of modern floor machines is that they do not differ in their complex principle of operation. Such models can operate on liquefied or natural fuels, which transfer heat to a heat exchanger during their combustion. This component receives water, which further "goes" to the radiators.

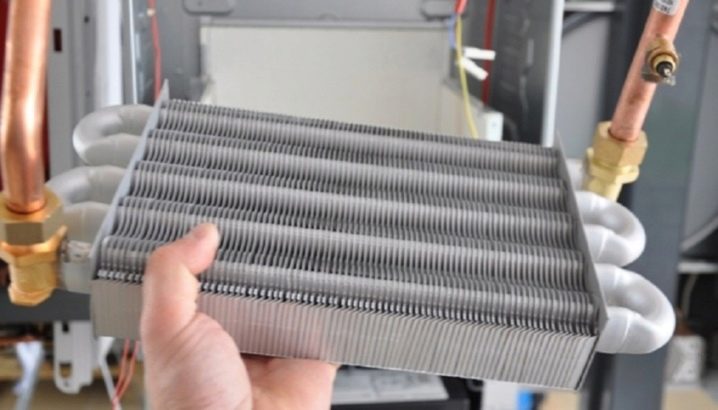

For the floor boiler to work longer it is important that the heat exchanger is made from reliable and high-quality raw materials. Currently, manufacturers use different types of metals in the manufacture of such parts. For example, it may be copper, steel or cast iron. The service life of the device, as well as its performance, depend on it.

The main elements of this technique are.

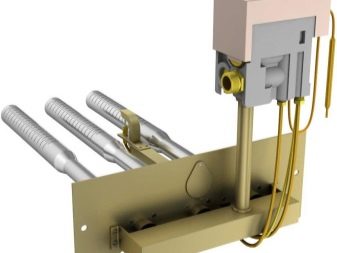

- Burner. Through the gas burner nozzles, the gas enters the combustion chamber. The nozzles themselves participate in the optimal distribution of fuel throughout the burner, ensuring uniform heating of the heat carrier.

- Heat exchanger Thanks to the energy released by the burning fuel, it is directly heated. In the future, the heat passes to the liquid.

- Circulation pump. This element is not available in all heating systems. The main task of the pump is to provide pressure in the event that the gas heating line is of forced circulation.

- Expansion tank. This system node is responsible for the removal of thermal media in the conditions of prolonged heating.

- Technique for removal of combustion products. Quality systems designed to remove smoke can have both natural and forced traction.

- Automatic system. Automation is a control unit of the heating system, which allows you to conveniently set a specific mode of operation of equipment.

- Self Diagnosis This useful and practical system for troubleshooting the system.She analyzes all components of the workflow. If necessary, the system notifies of any faults using special codes that are displayed on the display.

Gas-fired boilers are equipped with built-in temperature sensors, as well as a special electrical power system. There are also models in which there is a very useful function for the Russian climate - protection against freezing, when the equipment works in an energy-saving mode.

Floor gas boilers, like any other heating equipment, have their advantages and disadvantages.

To begin with, let us consider the good results of such devices.

- The similar equipment is distinguished by simplicity of operation. For modern gas boilers do not need to constantly monitor - they do not need control.

- The devices are quite easy to maintain.

- Gas-fired boilers cover a decent area. With this technique you can heat large houses.

- The efficiency of such units is quite high.

- Such devices are also good because the owners of the house do not have to invent where to store the fuel, allocating for it a separate place in the house or on the plot, as is the case with solid-fuel units.

- High-quality devices are durable. For example, a model of cast iron is able to work half a century, and the steel unit - at least 15 years.

- Such units are quite powerful. Modern manufacturers produce models of gas floor boilers, the power of which can be more than 100 kW.

- Additional sensors and devices can be connected to such equipment, thanks to which the temperature regime will be under constant automatic control.

- As a rule, these types of heating equipment work without making any annoying noise.

The advantages of such devices quite a lot. However, it was not without its drawbacks.

It's time to get acquainted with the shortcomings inherent in this equipment.

- To install a gas boiler (both floor and wall), you must obtain a special document in the relevant public service.

- If there are any faults in the gas pipe, the technician may react to this. For example, because of this, ignition can become covered in soot.

- Before installing the machine itself, you must first build a high-quality chimney.

- Installation of gas equipment is permissible to make only in ventilated areas.

- Such models are not allowed to be placed close to the walls or placed between two ceilings, as this prevents the flow of oxygen to the burner.

- In most cases, floor models are large in size, which requires spacious boiler rooms for their placement.

Kinds

There are several types of gas boilers. Each of them has its own nuances and features of work. Such devices are divided according to several signs. Consider them.

By the number of contours

Gas equipment may contain one or two circuits. Thus, the single-circuit unit heats up exclusively the thermal carrier, that is, it functions only as an appliance responsible for the heating of the dwelling. In this technique there is only one heat exchanger, which makes its design simple and low-functional.

Models with a single circuit are usually small in size. The dimensions of the technique also depend on its power level. If you decide to save and purchase a similar model, then to heat the water in the house you will have to buy another unit.In this case, it is permissible to install a boiler of indirect heating or another similar device.

As a rule, units having one circuit buy for heating of such buildings that do not require hot water, or for houses with a large area, where the full potential of the equipment will be directed to direct heating.

More functional and practical are dual-circuit units. Such models today are more in demand and in great demand. The popularity of such a unit is due to the fact that it is capable of heating the heat carrier and warming the water necessary for various household operations.

In these variants of the boilers there are two heat exchangers. This feature affects the complexity of the entire structure as a whole. There are products with bithermic exchangers, which consist of individual segments. According to one of them, there is a heat carrier, and according to the other - a heating fluid. Such devices are reliable and easy to use.

The best are considered to be devices that have two separated heat exchanger.As a rule, much less pernicious scale accumulates in them. In addition, since the circuits are structurally separated, it is not necessary to block the heating segment of the system at the time of hot water supply. In models with a bithermic exchanger, this is necessary.

Dual circuit options are recommended for use in small residential buildings. In conditions of impressive areas, separation of contours is obligatory. This is due to the relevant safety requirements, as well as the required power level.

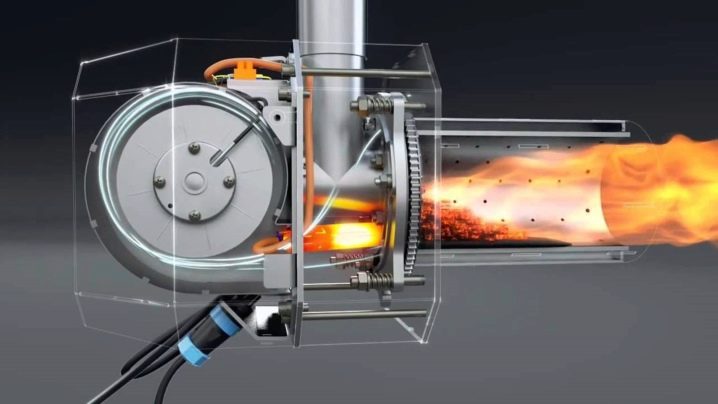

By type of combustion chamber

Gas boilers differ in the type of combustion chambers, which are open and closed. Thus, in the apparatus with an open chamber, natural thrust is applied, when oxygen enters directly into the chamber from the surrounding space, ensuring the combustion process. Therefore, for such units the room should be ventilated.

In addition, in order for such equipment to work properly and efficiently, it is necessary to install a chimney (it is advisable to use vertical variants). This will provide optimal traction. The main advantage of boilers with an open chamber can be considered that they are non-volatile and are inexpensive.

Variants with a closed chamber are distinguished by the fact that they have a special fan, which ensures the flow of air into the system. In addition, this node removes flue gases from the device. Due to its design, the unit does not take oxygen from the room in which it is located. As for the chimney, it is here different from the above option. For such equipment it is necessary to install a coaxial system in which two pipes are nested into each other. The inner part is needed for the discharge of combustion products, and the outer part is designed to supply air from the street.

Coaxial-type flue exhaust is installed not only vertically, but also fixed horizontally. Properly functioning traction provides an integrated fan.

It should be noted that a closed chamber significantly increases the efficiency of heating equipment. This is due to the fact that more fuel is burning. It can be concluded that the main advantage of such equipment can be considered a high efficiency, excellent efficiency, as well as more modest fuel consumption.Models with closed chambers are safer, since the burning process in them is completely closed.

As for the weak sides of the units with a closed combustion chamber, they can be attributed to the fact that they are volatile. If you live in an area where power outages are common, then the equipment will not work stably and efficiently. In addition, such units are noisy operation of the built-in fan. These boilers are more expensive than their counterparts with an open chamber.

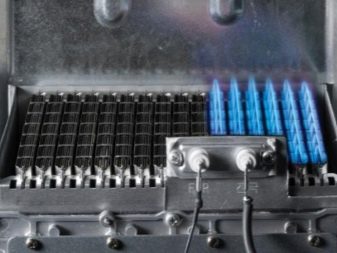

By type of burner

In the floor versions of the boilers there may be burners of the following types:

- single stage;

- two-stage;

- modulation.

The single stage burner provides only one power level. The two-stage unit gives the opportunity to choose from two levels. Modulation - provides smooth adjustment of the power output by the device.

It should be borne in mind that the highest power level of the boiler is not always needed. According to experts, it is necessary only in 15-30% of the time during which the unit operates. The remaining time the boiler produces a lower power level.

If we compare different types of burners, we can conclude that it is the modulation models that are more economically advantageous. Two-stage burners immediately follow. They extend the life of the heating equipment, since it does not need to be constantly turned on and off.

The operation of the equipment in conditions of reduced power can significantly save energy resources. The amount of gases emitted into the air is also reduced. Devices with two-stage burners are permissible to be installed in combination with boilers of different capacities.

On the use of flue gases

Habitual all gas-powered devices are referred to as convection-type devices. They are designed in such a way that the flue gases together with the steam from the water immediately go out. However, their temperature is so high that it is advantageous to use such heat again.

Condensation units accumulate steam, which is released during fuel burning., and then the heat is directed directly into the contours of the system. Thanks to a more efficient use of the energy obtained in the gas processing process, the performance of the circuit as a whole significantly increases.Thus, significant gas savings are achieved, and the efficiency of the boiler increases.

Referring to the drawbacks of condensing units, we note that they have a rather complicated structure, which affects the final cost of the boilers. Convection options are simpler, and therefore cheaper.

Materials

Floor heating units operating on gas are equipped with heat exchangers made from different materials.

Cast iron options have the following positive characteristics:

- they do not corrode;

- not afraid of heat stroke;

- they are not afraid of aggressive acid attacks;

- have a long service life (if you use the equipment carefully, then the heat exchanger in it can last at least 30 years).

The main disadvantage of cast iron parts is their high brittleness. This feature should be considered in the process of transporting such products.

Cast iron heat exchangers are recommended to carefully check before installing equipment. They should not be cracked or chipped. In the course of the boiler application it is extremely important to withstand the required temperature conditions, as well as not to allow differences in temperature values in the processing and feed cycles of 45 degrees (and more).Otherwise, the heat exchanger will crack.

Another disadvantage of cast iron elements is their impressive weight. Because of this, to install such a part and dismantle it if necessary will be quite difficult.

Lighter and stronger are steel heat exchangers. They are not prone to cracking and are rarely deformed. Their main disadvantage is that they are subject to the formation of corrosion, as well as burning. The average service life of such products is 10-15 years. Of course, a lot depends on the quality of the steel. If you do not comply with the requirements for operating conditions, the element will fail very quickly.

Extending the “life” of a steel heat exchanger is not so difficult. For this, it is important to ensure that the temperature in the internal part of the equipment does not drop to the “dew point” for the exhaust gases. If this happens, then condensate will accumulate on the walls of the exchanger - carbonic acid dissolved in water - an aggressive substance that can seriously damage the heat exchanger.

Copper heat exchangers have excellent thermal conductivity, do not rust and are lightweight.However, it should be borne in mind that in the floor products such parts are very rarely put. This is due to the high cost and low strength of the metal. In the course of work of the floor unit, copper wears out in a short time. That is why copper parts are more suitable for wall models.

Dimensions

Currently, gas heating boilers of floor type produce various dimensions. It should be noted that these figures depend on the power and design of the unit. For example, simpler and less functional single-circuit models are more compact and take up little space in the boiler room. If we are talking about a model with a more complex structure and two circuits, then its dimensions will be significantly larger.

Famous Companies

The quality and duration of the life of a gas floor boiler is largely dependent on its brand. In the market of heating equipment today there are many well-known manufacturers whose products are in great demand. Let us consider in more detail the most popular brands.

Aton

Opens the rating of high quality manufacturers of gas boilers firm Aton.

The range of these models is represented by rulers:

- Saab;

- Classic;

- Atmo;

- Nova.

The manufacturer offers the choice of buyers not only expensive, but also very low-end models that have excellent security characteristics.

Lemax

High-quality products of Lemax are very popular among modern consumers. The manufacturer is famous for its flexible model range of gas-fired boilers. Durable and reliable devices "Lemax" can be chosen for any budget.

The main positive qualities possessed by branded units of this brand are:

- high efficiency;

- maximum ease of operation.

In the assortment of this brand there are devices designed to work in conditions of both small and large areas. Here you can find simple single-loop options, and more functional models with two circuits.

The most popular rulers of Russian-made devices from Lemax are:

- "Gazovik" (especially popular economical AOGV 6 and 8);

- Premium;

- "Leader".

"Conord"

Another popular Russian manufacturer that produces high-quality and reliable gas-fired heating units.According to experts, Conord products are not inferior to models of foreign production.

The model range of the company's units is represented by several collections.

The most popular of them today are:

- KSC-G-S;

- KSC-MR;

- KSC-GV-S;

- KSC-GV-N.

In the assortment of the brand there are single-circuit and double-circuit units. In addition, devices can be used both in open and in closed heating systems. Branded devices are equipped with high-quality and accurate Italian and American automation. There are also automatic systems of the domestic type (AGU-TM).

Baxi

Reliable products from Baxi are renowned for unsurpassed quality and long service life. The range of the manufacturer pleases with its diversity - there are not only gas boilers, but also boilers, water heaters and various spare parts / accessories for heating equipment.

The most effective models with high efficiency are presented in the series:

- Slim;

- Slim HPS;

- Slim EF;

In the Baxi assortment, one can meet both volatile and non-volatile boiler versions, equipped with various heat exchangers (including cast iron ones).

Navien

World-famous Korean manufacturer.In the range of Navien there are not only gas, but also diesel heating devices.

The most popular are boilers with the following designations:

- GA;

- GST;

- LST;

- LFA.

The main advantage of Korean boilers from Navien is that they are completely safe. In addition, they contain highly efficient smoke removal systems. Provided in them and protection against freezing.

"Signal"

"Signal" is a group of companies specializing in the production of boilers with one and two circuits of various modifications and power levels.

The main advantages of the manufacturer's branded products are:

- affordable prices;

- profitability in use;

- increased safety;

- ease of use.

"Signal" offers both inexpensive units, and powerful and expensive devices of large sizes. You can choose a suitable model for any budget.

"Danko"

The manufacturer is known for manufactured gas units of the floor type. Its products are able to heat spaces from 70 to 860m2. Branded machines "Danko" equipped with heat exchangers made of iron and steel. As for the automatic systems, in these designs are used Italian and Polish developments.

How to choose?

When choosing a suitable floor standing unit for gas, a number of criteria should be considered.

- Efficiency Choose models in which this indicator is quite high. The largest values have options condensation type.

- Water temperature. Pay attention to the highest water temperature. More often it is 55 degrees.

- Pay attention to fuel consumption. Low-power units - the most economical, as evidenced by consumer reviews. More powerful units can consume up to 24m3 of gas.

- Dependence on energy. It all depends on the conditions in which the equipment will be located. Nevertheless, we recommend buying non-volatile devices.

- Brand Buy only high quality branded products - do not save on the purchase of a gas boiler.

On how to choose the right gas boiler, you will learn from the video.

Tips

If during boiler operation the temperature gradually decreases and gas consumption increases, this may indicate that the device must be cleaned. Usually it is necessary to clean the igniter, burners or jets.

Models with manual control are cheaper, but repeated “turn on / off” operation,for adjusting the temperature in a residential area, harms such aggregates.

Floor boiler can be used in the interior of the kitchen. Typically, this technique is hidden behind the doors of cabinets or in drywall boxes. If you do not want to hide such a unit, then you can find a more modern and stylish model, for example, in the high-tech style.

Experts recommend purchasing varieties of gas boilers that have two levels of power, or the function of its modulation. The use of such products is more economical.