Technical characteristics of Bosch double-circuit gas boilers

Gas equipment for heating a private house is practiced very widely. And an important place in the assortment of this product is occupied by Bosch double-circuit gas boilers. For many decades, they are in demand among consumers.

Special features

A company from Germany can offer its customers such undeniable advantages as:

- excellent quality of all parts and their connections among themselves;

- a variety of manufactured devices (they are adapted either to residential buildings or to conditions in industrial complexes);

- prolonged use;

- excellent environmental properties;

- reasonable and justified by technical parameters price.

Models

Bosch double-circuit boilers supply hot water to consumers with the same German thoroughness as the coolant in the heating system.Except wall, there is a wide range and floor designs. The second helps to heat a significant area, and the first allows you to save space in the house. Devices with a pair of circuits are divided into convection (when water is heated from burning fuel) and condensation (in which the condensation energy of steam from exhaust gases is additionally used). There is also a division into boilers with an open and closed scheme of the gas combustion chamber.

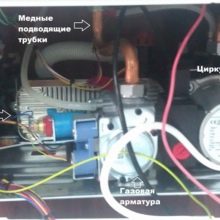

Attention is drawn to Bosch Gaz 6000 W WBN 6000. This is a modern mounted boiler of convection execution, the power of which varies depending on the settings and ranges from 7.2 to 24 kW. At the same time, the level of heat load that a closed combustion chamber is able to withstand varies from 8 to 26.7 kW. The developers took care of modern electronic control, the primary heat exchanger is consciously made of high quality copper. Connect the device to a single-phase electrical network, inside it there is a proprietary pump that provides circulation.

The capacity of the built-in expander reaches 8 liters. Not only natural gas, but also liquefied gas is suitable as a fuel. Its consumption is 60 minutes, respectively, 2.8 cu.m and 2 kg. The system will be able to deliver water heated to 82 degrees to the heating system (with a minimum value of 40). For the hot tap sector, these figures will be 60 and 35 degrees.

For 60 seconds, the boiler will give up to 11.4 liters of water heated to 30 degrees. If it needs to be warmed up to 50 degrees, the output is reduced to 6.8 kg. An alternative is the "Bosch Gaz 4000 W ZWA 24-22 K". This is also a convection unit with a difference in power from 7.8 to 22 kW. The system is able to warm hot water from 40 to 60 degrees. Enough hot water (50 degrees) can be obtained in a volume of 6.84 liters per minute; There are still models for 18 kW and 35 kW.

From condensing boilers, pay attention to the “Bosch Condens 7000 W ZWBR 35-3 A”. This unit is capable of generating from 10 to 35.3 kW of heat energy. Designers chose to equip it with a closed combustion chamber and single-phase electrical wiring. Electronics are used to control the operation of the boiler. Inside can burn both natural and liquefied gas (consumption will be, respectively, 3.7 m3 and 3.1 kg in 60 minutes).

Tthe fan in this condensing boiler is heated to 90 degrees, hot water up to 60 (minimum value in both cases - 40 degrees). Water can be supplied to a hot water system under pressure up to 10 bar, and into heating pipes up to 3 bar.For the convenience of users, pressure and temperature meters, automatic ignition, modulation of the burner flame are provided. It is allowed to connect not only a warm floor, but even external automation. The developers took care of gas control and prevention of overheating, the minimum risk of freezing and blocking the pump.

Other options are:

- the flow of gas and heating water is provided through the pipes ¾;

- hot water circuit connected through the entrance ½;

- coaxial execution of the chimney is achieved by pipes with a cross section of 8 and 12.5 cm;

- mass of the boiler 50 kg (permissible wall installation).

An alternative is Bosch Condens 5000 FM ZBS 30 / 150-3. This is a heavier device, designed for floor mounting. But still it will have to be connected to a single-phase network or through a transformer. The capacity of the boiler inside reaches 150 liters, and the expansion tank has an internal volume of 12 liters. The provided power is in the corridor from 6.5 to 30 kW; only natural gas can be used to generate heat.

Possible problems

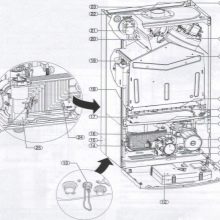

An important aspect when using dual-circuit gas boilers from Bosch is the timely detection and elimination of their faults. Even such advanced and technically competent devices have weak points.But enough complete information about the failures provide messages displayed on the display. A comprehensive analysis of the data is difficult to imagine without a clear understanding of the system design. The transition from one mode to another is performed using a valve equipped with three “strokes”.

Faults are indicated by special codes of letters and numbers. Thus, the message "A2" according to the instructions means that the heat exchanger overflows with soot and mineral deposits. The problem is reliably eliminated by mechanical cleaning, and citric acid solution successfully copes with alkaline substances. Instead, you can apply and specialized compositions for removing scale.

Otherwise, you need to act when you receive the signal "A3". It indicates that the system cannot receive data from the flue gas sensor. Wired communications should be examined and problem contacts tightened up. If visible defects are not detected or their elimination was unsuccessful, you will have to change the part. Only replacement will help when receiving the signal "A7", which shows the malfunction of the water temperature meter.When the system gives an error "C7", this means that you have to try to turn off and turn on the power of the fan, in case of failure to repair it.

Very serious problems can be associated with the error "EA", which indicates the absence of flame in the burner. The first step is to open the common gas valve until it stops and check the pressure on the line (in the cylinder). If such obvious measures have failed, you should check the stability of the voltage in the power grid. Other actions are also applied: tightening the contacts, preventive installation of the stabilizer, cleaning the ignition electrode. If you save the problem, you should give up your attempts and immediately seek help from a specialized organization.

It is important to bear in mind that some of the problems in Bosch boilers, judging by the reviews, are not documented in any way and are not displayed on displays. So, the inoperability of the burner means that it is necessary to assess its state, to start the emergency and proactive modes. Often it is required to repair safety automats, even change them for completely new parts. Additionally, it is recommended to diagnose temperature meters and combustion gases relay,cleaning of fire chambers and burners, chimney channels.

The absence of a spark during gas ignition may be due to:

- ignition electrode (pollution, too far from the gas flow);

- burner condition;

- transformer responsible for preparing the ignition current.

Sometimes users are faced with the fact that the system is growing pressure and even reaches unnecessarily large quantities. This is mainly due to the fact that water somehow seeps from the hot water circuit into the heating segment. It can do this through a loosely closed supply tap. If it is tightly closed, the problem is more serious - almost certainly there is a hole in the heat exchanger, you can also assume membrane deformation in the expansion tank.

The pressure may increase excessively if the expander is chosen incorrectly (it is too small, or it is designed for a different pressure than arising in the system). Hydraulic shocks are another source of trouble. When the boiler makes a lot of noise when it starts up, it buzzes, you need to immediately clean its parts from scale. A plaque not removed in a timely manner can cause overheating and breakdown even of the most stable mechanism.The reason for the lack of hot water in the faucet is consistently searched for in a three-way valve, in the mixer itself, pipelines and filters.

An overview of the Bosch wall boiler is waiting for you in the video below.