Features of heat exchangers for gas boilers

Nowadays in many homes there is such a heating unit as a gas boiler. Such equipment perfectly copes with its main task thanks to a well-thought-out device. One of the most important parts of the boiler is a heat exchanger. Today we will get acquainted with the features of this part.

Purpose

This component of the equipment acting on gas is designed to perform the heating function. It is the design of this part that determines the functional characteristics of the boiler itself.

A heat exchanger is designed to transfer heat between heat carriers. So, the heat is transferred from the hot source to the cold one, after which it passes directly to the liquid that needs to be heated in the system.

Through this item passes the heat generated by the combustion of gas. Further, it is transmitted directly to the thermal carrier.

You should not think that the heat exchanger is a simple detail, represented by one simple structure. In fact, there are several varieties of these elements. Their type affects the final cost of the equipment, as well as its technical characteristics.

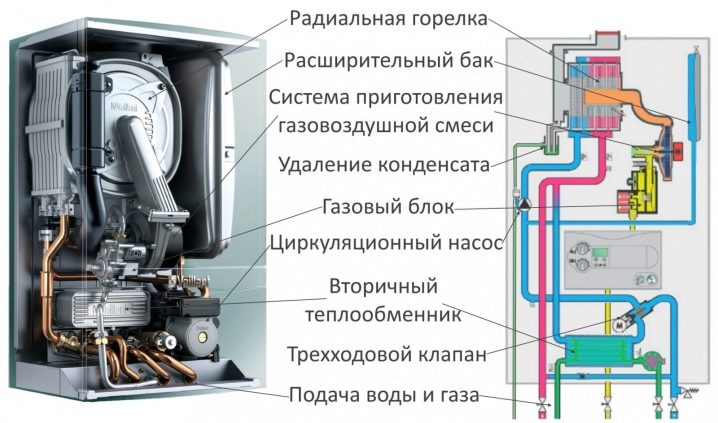

Classification and principle of operation

As mentioned earlier, today there are several types of heat exchangers. They differ in their design and device. Consider their properties and features in detail.

Primary

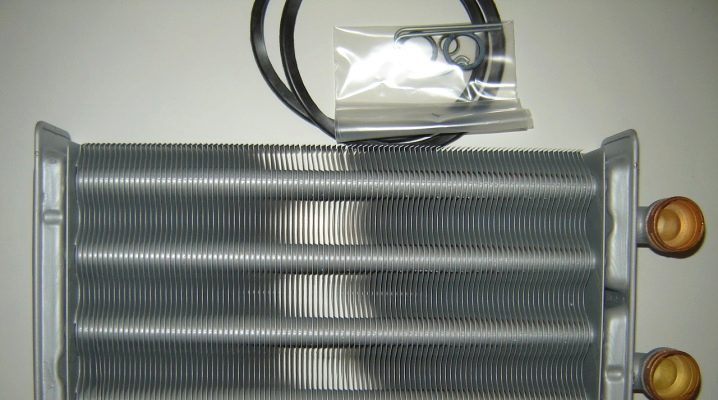

The primary type of exchanger is made in the form of a large and curved tube, similar to a coil. As a rule, this item is made of metal that is not susceptible to the corrosive effect of corrosion. In addition, in the plane of this element there are special plates having different sizes.

Usually, the surfaces of primary heat exchangers are treated with special paints that protect the bases from negative external effects and the appearance of rust.

As for the principle of operation of such an exchanger, it consists in sending energy from gas to a heat carrier. The power level of the exchanger is dependent on the length of the pipe and the number of edges.

Often, the primary heat exchanger fails due to dirt and soot or active internal accumulation of salt deposits. If such contaminants affect the part, then over time it may begin to malfunction during circulation. In addition, the level of thermal conductivity of the walls of the unit from this can also significantly decrease.

Experts strongly recommend to pay due attention to the maintenance of such items. It is imperative that work be done on time to clean and flush the primary exchangers. Otherwise, they will not last long, and the boiler efficiency from this will significantly decrease.

Heating equipment with such a detail, as a rule, is cheaper and has a simple design. Such models are not subject to breakage, especially if they are serviced in time. However, it should be noted that the primary heat exchanger is less functional, since it performs only one task.In addition, it is very important to consider the fact that such products it is recommended to add special filters. These components will reliably protect the exchanger from negative external influences and various kinds of deposits.

Secondary

The secondary, or heat exchanger of hot water supply, differs from the primary instance in that its design contains special plates that are interconnected. The most common are secondary heat exchangers made from steel.

In such models, heat is transferred from liquid to liquid. They are more reliable and durable. As for the rate of heat exchange, it is higher in such models. Due to this feature, various contaminants / salts are not deposited on the surface of components. Because of this, the exchangers serve much longer, and also they do not have to be constantly cleaned. The more plates in such products, the higher are their power parameters, as well as the efficiency of the task being performed.

Similar details are distinguished by the fact that they have a rather large area for heat exchange.In addition, these heat exchangers almost do not accumulate traces of corrosion.

Such types of heat exchangers are good for their versatility - they are responsible not only for heating the home, but also for providing hot water (HWS). Usually boilers with these elements are more expensive, but they are bought more due to practicality and the necessary functionality.

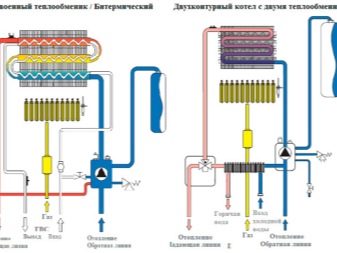

Combined (bithermic)

Such a heat exchanger differs from the other options in that it has a double exchange of heat - from the coolant to water and from the gas to the heat carrier. The water in the heating pipe is heated from the outside, and at this time the internal compartment prepares hot water.

These parts are a pipe with copper ribs plates soldered to it. At the same time the pipe itself is double (with two separate compartments). Its internal part is responsible for hot water, and the external one is intended for the thermal carrier itself.

The combined type of heat exchanger has one important advantage - it is characterized by a very simple design, not subject to breakage. In this case, the secondary heat exchanger is not needed, as well as the three-code valve.Thanks to these characteristic features, boilers with similar elements are inexpensive, and their dimensions are compact.

Of course, such options exchangers have their drawbacks. For example, they can not boast of large capacity in hot water mode. In addition, these varieties are prone to salt deposits. Salts that are contained in the water, in a short time, settle on such details, which negatively affects the operation of the boiler as a whole.

Also need to take into account that repair of bithermic exchangers is not a simple matter. According to experts, in 90% of cases the repair of these models is not possible. In addition, not every master agrees to work with such a detail, and those who do take on such work do not always have sufficient qualifications. In addition, the combined elements are subject to leakage due to the large number of internal joints and connections.

Materials

Modern heat exchangers are made from various materials. Many parameters of these details, as well as their pros and cons, depend on this parameter. Let us consider in more detail, from which heat exchangers for gas boilers are usually produced.

Steel

Most often in the gas heating equipment there are heat exchangers made of steel. Their prevalence is explained by the democratic cost of steel and the simplicity of its processing. Steel parts have their own distinctive characteristics, for example, such a heat exchanger is quite plastic. In addition, these options have a long service life, which attracts many consumers.

It should be noted that the plasticity of steel specimens plays one of the most important roles when it comes to the contact of the exchanger with high temperatures. Due to this characteristic, no cracks are formed on the boiler components when a serious thermal stress is formed in the internal part of the metal near the burner.

However, the steel options have one serious disadvantage - they are prone to corrosion. Of course, the appearance of rust reduces the service life of the exchanger. In addition, it must be borne in mind that defects of this kind can appear both on the inner and on the outer half of the device.

Another disadvantage of steel exchangers is their large size and weight. In addition, with such details will increase gas consumption.This happens because most modern manufacturers seek to achieve a high level of inertia and expand the volume of the internal cavities of the heat exchanger.

Cast iron

The second most popular is heat exchanger made of cast iron. This model differs from the steel that in contact with the liquid does not become susceptible to the appearance of corrosion. Thanks to this distinctive feature, we can safely talk about the durability of cast-iron options.

However, we must not forget that the pig-iron exchangers require regular maintenance and attentive attitude. In addition, these options are distinguished by their fragility. If scale builds up on the heat exchanger from cast iron, the heating in the system may become uneven, which will cause the exchanger to crack. In order to extend the life of this element, it is necessary to carry out periodic washing. In most cases, if running water is used, then washing is carried out once a year. If antifreeze is used as a heat carrier, then such work will need to be carried out once every 2 years.

Less often, the purification of the heat exchanger should be done,if purified water is used as a heat carrier, it will be enough once per 4 years.

Copper

Copper specimens are practical and durable. They have more pluses than minuses. The following should be highlighted Characteristics inherent in such exchangers:

- copper parts are lightweight;

- differ in small dimensions;

- not covered by destructive rust;

- they need quite a bit of fuel to warm up well.

Thanks to these advantages, the copper heat exchanger is recognized as one of the most sought after. However, it is expensive, so buy it less often. In addition, these elements become less robust and reliable in heating conditions. Copper heat exchangers burn out very quickly, and then fail.

Aluminum

In many proprietary models of gas boilers there are heat exchangers made of aluminum. This material is distinguished by high plasticity; therefore, exchangers of any form and complexity are obtained from it. In addition, it is necessary to take into account the fact that the thermal conductivity of aluminum is 9 times higher than that of other popular raw materials - stainless steel. Aluminum heat exchangers have a very modest weight.Due to such positive characteristics, we can safely talk about the practicality of such components, as well as their reliability and functionality.

Such devices are also good because they are usually free from vulnerabilities. For example, in the construction of stainless steel there are welds, bends and other similar areas. They are very vulnerable, so they endure significant loads in the course of equipment operation. In the aluminum versions, there are simply no such problems. The aluminum parts are distinguished by powerful chemical resistance, which is excellent for condensation.

However, aluminum exchangers can serve less if they accumulate scale from hard water. These options require good water treatment.

Manufacturers and reviews

Nowadays, it is difficult to make a choice in favor of a specific model of a gas boiler and its component parts solely because of its rich assortment. There are many large manufacturers on the market whose products are in great demand. Let's get acquainted with some of them.

Thermona

The large company Thermona offers the choice of consumers not only gas and electric boilers of various modifications,but also accessories for such a technique. Heat exchangers of this company are made of copper. These elements are coated with a silumin compound, which makes them fire-resistant and not subject to the formation of rust. In the assortment of Thermona there are both models with an average price, as well as more expensive items.

Most consumers were satisfied with the purchase of Thermona heat exchangers. According to people, such products serve for a long time and are practical. However, not all buyers are satisfied with the price of Thermona brand exchangers.

In addition to heat exchangers, This brand produces good boilers (floor and wall). This product is very popular. Consumers mark trouble-free and long service life of branded models, as well as their high efficiency. The downside is that some people are faced with a number of errors that are issued by the technique. Not every user eliminates them immediately. For example, some people have observed an error with the code “01” for several years. As a result, most consumers turn to specialists to solve the problem.

Hydrosta

Hydrosta is the world's largest manufacturer of water and heating systems. It has been operating since 1995. Hydrosta offers consumers the following products of unsurpassed quality:

- relay relays;

- heat exchangers;

- expansion tanks;

- fans;

- valves;

- sensors;

- floor and wall mounted boilers for gas and diesel.

Heat exchangers of this brand are made with different number of fins. The South Korean brand offers a choice of copper (more expensive) and steel products (cheap). The range of the company is rich and diverse, therefore Hydrosta products are extremely popular today.

According to numerous consumer reviews, we can conclude that Hydrosta's branded machinery has a long service life. The only common problem faced by many users is the fast clogging of the telplo exchanger, but it is solved very easily - the part should be cleaned periodically so that deposits do not accumulate on it.

Master gas

The Master Gas range has a huge variety of components for gas boilers. These are not only heat exchangers, but also three-code taps, pumps, sets of seal rings, various sensors, filters, air vent valves and even remote controls.

The main advantages of Master Gas branded products are:

- all products belong to the average price segment;

- the manufacturer has adapted the manufactured products for operation in Russia;

- in terms of their functionality, branded equipment can be attributed to the premium class.

Products of this brand has a good reputation among consumers, not only because of the affordable cost, but also due to the large number of service centers. In addition, consumers are pleased that the exchangers for gas boilers Master Gas are presented in many retail outlets and online stores. In most cases, people are satisfied with the quality of branded products.

Some consumers are not satisfied with the boilers of this company. In some cases, the equipment allowed to flow after a couple of months of use. As a result, the unit had to be repaired, although he had not yet had a year.

Arderia

This large company has in its range a variety of spare parts for gas boilers, as well as AOGV. Arderia heat exchangers are represented by both primary and secondary plate models that are suitable for both wall and floor heating units.Many consumers opt for the products of this company, as it has a democratic value with high quality.

The lion's share of buyers did not notice for themselves the serious shortcomings of heat exchangers and boilers of this brand. Many people won the functionality, efficiency, cost and durability of branded products.

Fondital Victoria Compact

The company Fondital Victoria Compact known in the modern market is rightfully recognized as the real benchmark for excellence in home heating. There is a brand since 1970. Today, Fondital Victoria Compact products are in high demand, as they are characterized by excellent quality and a large assortment. The company offers a choice of customers not only various components and accessories for heating equipment, but also high-power boilers, boilers, chimneys and traditional floor and suspended type units.

Any product of the Fondital Victoria Compact boasts excellent quality and many positive reviews. Buyers like the durability and power of branded goods brand. So, the most popular product is a wall dual circuit. gas boiler Fondital Victoria Compact CTFS 24 AF with electronic ignition and frost protection.

There are also those buyers who were served by the company’s accessories and boilers for a very short time, after which they demanded repairs, but people who associated with a factory marriage or unscrupulous sellers usually face such troubles.

Saunier duval

Saunier Duval is a French brand that produces wall mounted heating boilers, chimneys and various programmers. The main advantages possessed by branded products are:

- kit with remote, designed for weekly programming;

- reliable components of boilers;

- lamellar steel heat exchangers;

- primary exchangers are made of copper;

- units are supplemented with special pressure sensors.

Consumers positively assessed the branded products of this brand from France. The primary advantages that people have noticed for themselves are:

- efficiency of equipment;

- easy installation and use;

- high efficiency;

- reliability (for some consumers, branded boilers and components for them have been used for more than 10 years).

Of the downsides, users note the costly maintenance of Saunier Duval branded products.

Demrad

Heating units, as well as spare parts for boilers from this company are in great demand due to excellent quality, wide range of products and affordable prices.

Original Demrad components are purchased for the following brands of boilers:

- Arderia;

- Vaillant;

- Ariston;

- Chaffoteaux;

- Junkers;

- Thermona;

- Baxi;

- Mora Top;

- Ferroli;

- Bosch;

- Protherm;

- Saunier Duval;

- Beretta;

- "Danko" (in the range there are both gas and solid fuel models).

Consumers are attracted by the efficiency and ease of use of the Demrad brand boilers. However, many people claim that the products of this brand breaks down very often, and its repair is expensive.

AEG

This German company produces wall-mounted water heaters of storage type, wall-mounted boilers with two circuits, as well as components for them. Branded products are renowned for their trouble-free work, excellent build quality, and attractive design.

Modern buyers are satisfied with the quality of AEG products. Branded boilers, as well as spare parts for them, are characterized by brilliant quality and trouble-free operation. However, many are repelled by the acquisition of such products for their high cost and rather expensive maintenance.

"Beleto"

Tula heating equipment "Beleto" differ by such characteristics:

- environmental friendliness;

- safety of use;

- beautiful design of boilers;

- availability in the range of nonvolatile models.

Product reviews "Beleto" are ambiguous. Some boilers and components manufactured in Tula are satisfied, while others declare their unreliability. In addition, many users note that the equipment of this brand is often sold understaffed.

Faults and repair

Consider what faults are typical for heat exchangers of gas boilers, and also understand how to fix them with your own hands:

- There may be a crack on the heat exchanger. You can solder it yourself. Solder must be selected depending on the material from which the part is made.

- When THAT burns through, it can be “stuck” with a copper or tin patch. Less often, people use lids from cans and other homemade items. Fix patches with zaklepochnik.

- If the unit has dripped, you can turn to cold welding to seal the damage.

- THAT must be periodically cleaned of scale in order not to provoke a malfunction of the unit. Apply hydrochemical cleaning method, manual or chemical.Before cleaning the heat exchanger will need to be removed from the equipment.

- To completely replace the heat exchanger, it is recommended to contact an experienced technician.

Video review of the boiler with cast iron heat exchanger, see the video below.