Ariston dual-circuit gas boiler: advantages and disadvantages

When carrying out major repairs in cottages and private houses, residents often face the need to replace the existing heating system with a new, more modern and energy efficient one. Nowadays, the market offers a large selection of various options for gas equipment, which differ in power, as well as fuel used, manufacturer's brand, construction features, etc.

For many years, Ariston double-circuit boilers have enjoyed consistently high demand, which are characterized by exceptional operating parameters and affordability.

Special features

Gas boilers Italian production Ariston are presented in a wide variety of models, however, regardless of the modification, the equipment of this brand is focused on the installation of heating systems on an area of no more than 500 m2.Some versions of boilers work only for heating, while others are used not only to supply heat to the house, but also for hot water supply.

Speaking about the indispensable options for gas boilers of this manufacturer, it is possible to distinguish the following characteristics.

- The presence of a multilingual menu - this allows users to choose a language familiar to them to effectively manage the operation of the boiler.

- The “auto” function allows you to adjust the required power parameters in the autonomous mode based on monitoring the actual temperature values in the room, as well as inside the boiler.

- Heat and noise insulation - ensures silent operation of the equipment, and in addition, it helps to keep the coolant at a given temperature for a long time even after stopping the work.

- The warranty on all of its equipment, for standard boilers, it is 2 years, and for condensation models it lasts longer - for 3 years.

- Ease and ease of use - the menu is thought out very well, thanks to which even beginners who have not dealt with gas installations can manage the boiler effectively.

- A safety system that prevents breakdowns caused by power outages.

- Built-in electrified elements that maintain the efficiency and performance of the unit even in conditions of low pressure of water or fuel.

A characteristic feature of all Ariston models is a well thought out and deeply technological protection system, which determines the long and uninterrupted operation of the gas installation.

It includes:

- mechanisms for feeding the boiler with water;

- built-in system of timely pumping of accumulated air;

- blocking the circulation pump;

- protection mechanism against the occurrence of scale and freezing.

The overall parameters of all Ariston models are small dimensions and the ability to supply hot water. The basic package includes: a double-type heat exchanger, a burner control module, a system for monitoring the content of carbon monoxide, a mechanism for maintaining a normal microclimate in the room, a device responsible for controlling the freezing of water inside the heating system.

Characteristic

Ariston gas equipment is produced in two basic versions - floor and wall.In private homes, as a rule, wall models are used.

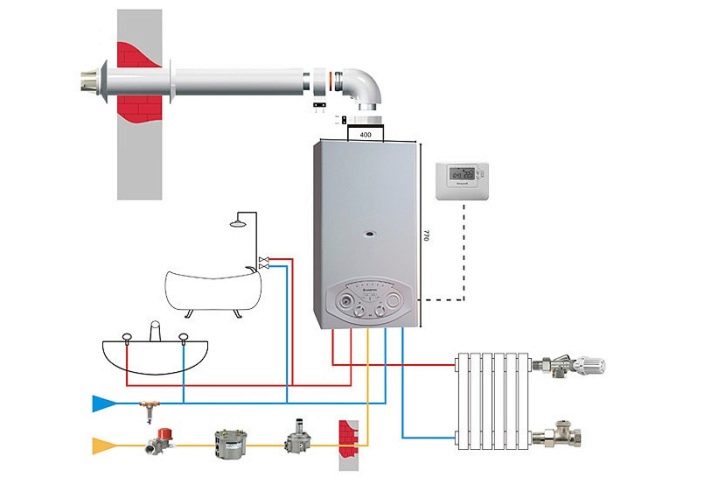

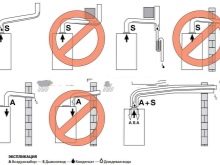

Depending on the parameters of the model, the unit may have an open and closed combustion chamber. In the first case, combustion products are discharged from the boiler in a natural way, in the second case, the forced exhaust system works. Usually, installations with a closed chamber are connected to a coaxial chimney. A coaxial pipeline implies the presence of two structural layers, so that you can simultaneously remove carbon monoxide and ensure the flow of fresh air into the furnace.

In addition, the camera has a built-in fan, which is responsible for the timely removal of burnt gas and hot air. These models are more secure than devices with an open camera.

In addition, they take the air necessary to maintain combustion, from outside the living space, this is another advantage in comparison with closed-type cameras, because they take the oxygen inside the house, thereby reducing the microclimate in the building.

Floor boilers have quite high powertherefore, they are used for industrial purposes or in residential buildings with a large area.Usually they are designed only for the supply of heat to the batteries and radiators, so if necessary, water heating should be additionally purchased boilers.

The main element of any boiler equipment is the burner, which is responsible for burning fuel and the flow of heat into the heating system. Burners can be conventional and modulation. Modulation is more modern and technologically advanced, since they allow you to automatically adjust the power of the device depending on the results of internal control over the temperature level.

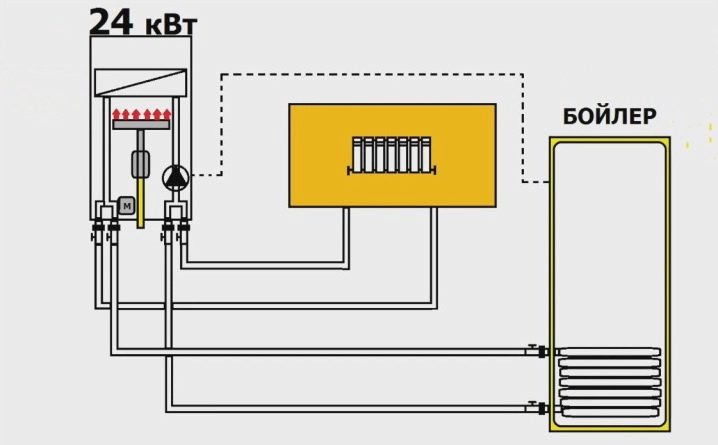

Ariston double-circuit boilers have 2 heat exchangers: the first is needed to provide hot water, and the second - directly to heat the main coolant. Their production can be carried out in three versions: they are separate, bithermic or with a boiler.

In the general case of the boiler two autonomous circuits are simultaneously placed:

- heating - he is responsible for the supply of heated water to the radiators;

- water - this mechanism is connected to the water pipes.

Water heating can be done in several ways:

- flow-through - this option only works when using hot water: after passing through the burner, it goes to the final consumer in a heated form;

- boiler room - such a device implies the presence of an additional reservoir in which water heated to a predetermined temperature accumulates and from there it enters the tap.

The double-circuit boiler operating in the boiler mode is more economical.

At the location of the contours of the boilers are divided into 2 types.

- Bitermicheskie - in such installations the water pipe is located inside the heating system. In this case, the heating circuit heats up more actively and transfers some of its heat to the water supply.

- Duothermal - include two tubular heat exchangers that evenly transfer heat to both systems. In this case, the energy is used most efficiently, however, and the heating rate is significantly reduced. In addition, this principle of operation creates prerequisites for the appearance of lime deposits, so these devices need regular cleaning.

Depending on the method of combustion, Ariston boilers are conventionally divided into ones that work on the principle of turbocharging and under natural draft.Turbocharged boiler has a rather high heating rate, however, the gas is consumed in a large volume. The second type of model heats the water rather slowly, but fuel consumption is more economical.

Gas boilers of this manufacturer are most often produced with a capacity of 15, 18, as well as 24 and 28 kW, the most purchased modification is a unit with a capacity of 24 kW, it can provide heat for living rooms of up to 230 m2.

Advantages and disadvantages

Ariston gas boilers are popular all over the world. This is due to their exceptional performance:

- effective built-in protection system against voltage surges in the network - devices can operate in the voltage range from 150 to 260 V;

- the ability to effectively control the heating rate of water: in the case when the flow parameter does not exceed 6 l / minute, the temperature can reach 37 degrees, so that the water heats up faster, you just need to increase the boiler power;

- simultaneous work in the mode of a water heater and an effective heating device;

- the ability to automatically shut off the gas in case of attenuation of the flame, regardless of its causes;

- automatic termination of the heater in the event of a decrease in water pressure in the system to a critical level;

- the presence of two heat exchangers;

- wide product range of models;

- excellent adaptation to use in the Russian conditions;

- Italian assembly;

- European quality control system.

However, there are also disadvantages, among them it is necessary to highlight the following:

- very high cost in comparison with analogues;

- use of components produced in China.

Russian users distinguish boilers of this brand as high-quality, reliable and practical. Reviews of owners of private homes indicate Ariston's advantages such as compact dimensions, energy-efficient gas consumption and ease of operation of the mechanism. Among the shortcomings, the dependence of its work on electricity supply is highlighted, but this feature concerns not only Ariston - almost no gas equipment operates without connection to the AC network.

The boilers have an aesthetic appearance, thanks to which they fit into any interiors.

User's manual

The first thing to remember before proceeding with the installation of a gas boiler is that only certified specialists should install and connect the device.Self-installation is not recognized by the gas services as legal, in this situation the inspection company has the right to cut off the gas supply to the house and impose a fine on the owner of the dwelling. And this is at best, and at worst - the cauldron can fail or even explode and cause harm to life, health and property.

Before use, check the level of ventilation. - the room where gas equipment is installed must be well ventilated. During the entire period of operation of the boiler it is necessary to constantly monitor the water pressure in the heating system. Normally, it is 1.5-2 bar, if the pressure drops, the boiler shuts off, and the control display shows an error. In this case, you should ensure that there are no leaks and “feed” the installation.

Even if the installation and connection were made by professionals, and the use of the boiler was carried out strictly according to the instructions, there is always the likelihood of damage to the device.

The reasons for which the unit can fail are many, but the most common are the following.

- Failure control board.This problem is usually associated with frequent power surges or power outages. To avoid problems at the installation stage, you should think about installing a voltage regulator, and for the cottage a backup generator, which is equipped with a circuit breaker and grounded, can be an excellent option.

- Low efficiency or underheating of water. Such a breakdown often accompanies excessive hardness of the water or the presence of contaminants in it, so experts recommend using water filters.

- Stops due to lack of oxygen. Such a defect occurs if the room is not equipped with a ventilation system.

- The discrepancy between the actual parameters of the coolant declared. This problem is a direct consequence of improper installation of equipment and illiterate boiler settings.

And finally, a few recommendations:

- you should not neglect regular preventive inspections of the boiler and its quality service;

- in the event that a fault recurs too often, you should contact the service company;

- Repairs should be trusted only to a certified organization whose specialists have all the suitable spare parts and necessary tools, and in addition, have the required permissions to work with gas equipment.

With proper installation and operation of the 2-loop boiler from Ariston will serve at least 20 years.

An overview of the Ariston gas boiler is in the next video.