Chimney for gas and solid fuel boilers: features of the device and installation

Heat is a necessity for people. In multi-storey buildings, the provision of heat usually becomes an issue that must be addressed by appropriate utility structures. But in a private house, its owner, at the construction stage, must think through exactly how it will provide heat in the building. Most often, the owners of such houses resort to the use of a solid fuel boiler.

This can be judged by the fact that almost every private house has a chimney that brings the products of combustion to the outside, not allowing them to enter the house. The chimney provides the air flow, which is needed for burning fuel.Therefore, we will understand how the chimney is generally arranged, and how to make it yourself.

How does it work?

Any chimney has three important functions.

- It allows the removal of combustion products such as carbon dioxide and carbon monoxide, as well as carbon black.

- It promotes the supply of oxygen to the system, thereby ensuring the combustion of fuel with the subsequent formation of carbon dioxide.

- Carries out a moisture output. This is necessary, because if condensate is collected, it may be the cause of the deformation of the pipes and, accordingly, reduction of thrust.

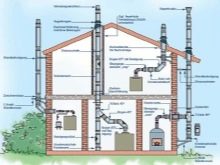

Usually the exhaust pipe is made of bricks or pipes that are installed in the mine or go along the house from the outside.

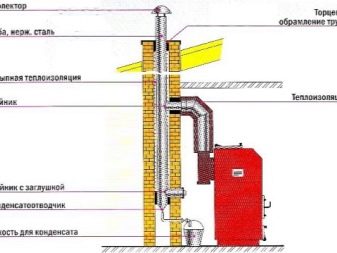

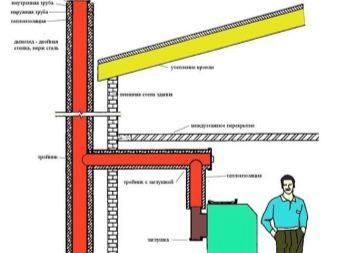

Directly the design of the chimney consists of the following elements:

- withdrawal;

- pipes with a valve;

- tee;

- visible part of the pipe.

The tap is a pipe with an angle, usually 90 degrees, which is connected directly to the boiler using a special adapter. The pipe, equipped with a damper, makes it possible to adjust the inflow of air masses into the system, and also does not allow precipitation and wind to penetrate into the system at the moments when the whole mechanism is not used. The tee is an important part with which the pipe is connected, equipped with a valve.

It is he who allows the hot air masses to go outside., and the condensate that accumulates, cool and drain into a special tank, under which own space is allocated. The top element is a cap with a mushroom in a conical shape, it does not allow precipitation to get into the chimney. There are also a large number of different elements that are fixed to the mine surface or to the wall of the building with a bandage or brackets.

In order for the mechanism to be as effective as possible over a long period of time, it is necessary to ensure that the thrust is good.

It is recommended to use the following recommendations.

- Consider as much as possible the design of the condensate collector so that moisture does not accumulate on the upper parts of the pipe. This can be done if the size of the tee, where the boiler enters, was large — about one and a half times the average size of the structure.

- Calculate the appropriate diameter of the entire chimney structure.

- On a regular basis to carry out cleaning from soot.

A number of experts believe that it is better not to install a mushroom or a deflector on the tube tip.They contribute to the fact that the flow of air is significantly reduced, and this causes the formation of excessive condensate. At the same time, in the absence of deflectors, air is blown into the interior of the pipe, which is also not a very good sign.

Kinds

Structural chimneys for different types of boilers may vary.

We are talking about the following options chimneys.

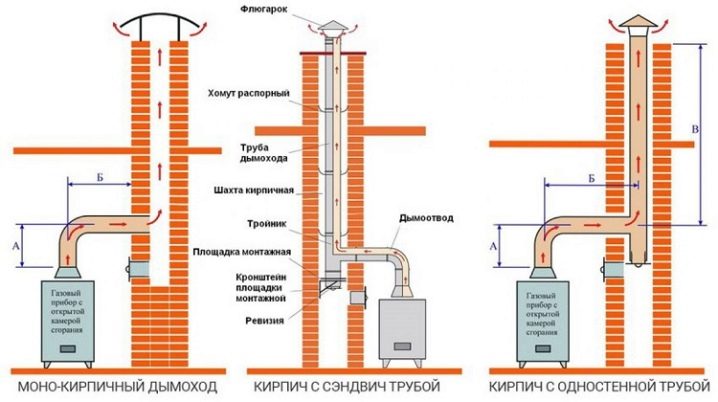

- A vertical channel, usually made of bricks, which is built into the inner wall of the house along with ventilation shafts.

- Vertical pipe made of metal that passes inside the building and goes to the roof. This option can be described as internally attached.

- Additional decisions that are attached from the outside in the house wall. Usually they are made of bricks.

- Steel pipes, which are located on the outside of the house. They can be attached to the wall or attached to a special metal-mast lattice type.

In modern homes, such channels are foreseen by the project in advance. Typically, the chimney is made in the inner wall of the building, which is adjacent to the furnace. There it can be horizontal, and sandwich, and any other.But in old buildings you can find options that are attached to the outer wall and even have a separate foundation.

The house can even be non-chimney, but here everything will depend on the type of boiler.

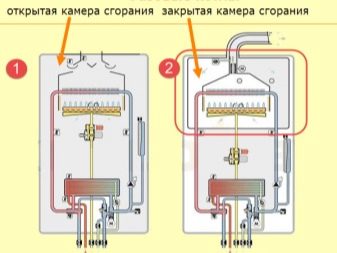

There are two categories of boilers:

- with an open combustion chamber;

- with a closed combustion chamber.

A boiler with an open combustion chamber usually needs a chimney, especially if it runs on solid fuels. Although such a need would be for any boiler equipment, that for solid-fuel, that for gas-fired. True, in the version with the latter, the need for it will not be so great.

For a wall or floor solution with a closed combustion chamber, the chimney is not so much needed because of the tightness of the chamber itself. The same thing will happen if chimney-stoves are used.

Now it is necessary to tell about some characteristics of each variant of chimneys.

Consider the cons of diverting brick devices.

- The inner surface of brick solutions is extremely uneven, which will cause a heavy soot deposits from fuel combustion, especially solid.

- Moisture in the form of condensate that will form on the brick will sooner or later begin to penetrate into the structure of the material, and it will begin to deteriorate due to the temperature difference.

- Typically, brick chimneys are made in the shape of a rectangle, which significantly reduces the aerodynamic characteristics, when compared with the round shape, and significantly increases the resistance to gas flow. The force of natural thrust will also be less.

- If the chimney is attached from the outside of the building, then due to the temperature difference it may begin to separate from the wall and a crack appears between them. And if the chimney was built later than the house itself, then the size of the crack may be significantly larger. Although this pipe is quite suitable for use with a solid fuel boiler, it has a good durability, and it will also look good against the background of a brick house. In general, if you modify this design, then you can fix almost all of these disadvantages.

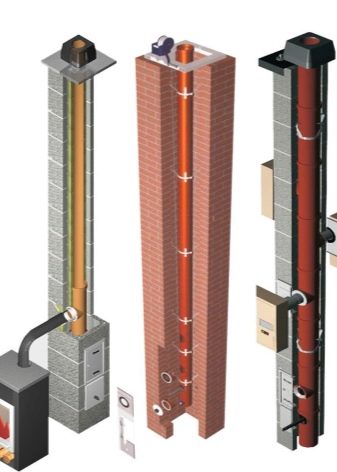

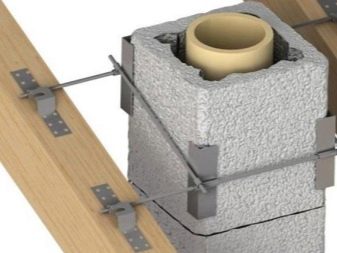

The option of two pipes made of steel or a sandwich with a warming layer is an excellent solution today. A similar chimney is usually created from several sections one to two meters long, which have a small mass. This allows them to be installed even by one person without help.The advantage of this option is that the interior will be smooth, on which there is no soot or any other combustion products, and the condensate will freely flow into a special pipe.

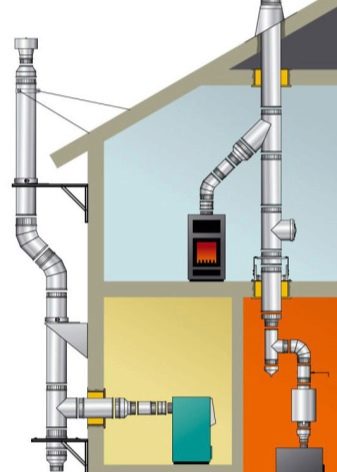

A good solution would be a coaxial chimney made of metal. Through a cross section of the internal type, various products of combustion come out, and between the walls, oxygen enters the combustion compartment from the outside.

Such ducts can even be used with special heating solutions, where such a possibility is provided for in terms of characteristics. Usually these are models with a closed combustion chamber and forced pressure equipment.

Materials

The channel for the removal of combustion products in a private house is easy to make from a variety of materials. The main requirement will be resistance to various aggressive, from a chemical point of view, substances, as well as gas obstruction. Usually, several types of materials are used, the merits and drawbacks of which will be discussed in more detail.

So, the chimney usually happens:

- brick;

- ceramic;

- polymeric;

- stainless steel;

- asbestos cement.

Brick solutions were previously the most popular, but today they are no longer such, due to the fact that they are too heavy and require a foundation with large dimensions. The construction of this option takes quite a long period of time.

If we talk about the disadvantages of this option, it is necessary to name:

- the roughness of the inner walls, which makes them an excellent solution for the accumulation of soot and other combustion products;

- brick hygroscopicity, which may be the cause of its destruction.

Usually, in order to eliminate such defects, a smooth asbestos pipe or stainless steel, suitable in diameter, is installed inside a brick chimney.

When creating such a solution should take into account some points.

- Pipe walls must be leakproof. If they are made of stainless steel or ordinary steel, the chimney must be collected by condensate. If we are talking about an asbestos-cement solution, then the tightness of the joints should also be worried. And in no case should not grease the joint with cement mortar. This will break the seal - moisture will be absorbed and destroy the structure. It is necessary to use various water-repellent substances and tight collars.We must not forget that they must be chemically inert.

- To minimize the formation of moisture pipes can be warmed. But you need to use insulation that is not afraid of moisture.

- At the bottom of the liner to the liner should add capacity to accumulate condensate. It should be so easy to get to it.

Given these characteristics, a chimney for a gas or any other boiler will work perfectly.

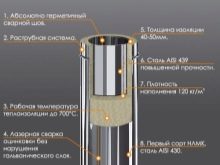

If we talk about stainless steel pipes, then the requirements will be high, namely: they must withstand the long-term exposure to caustic substances. It would be best to use the so-called food stainless steel.

As for the sandwich pipes, due to the presence of thermal insulation, such a chimney can serve for quite a long time. In general, if you compare a sandwich pipe and a conventional stainless steel pipe, then at cost they will be somewhere on the same level. But the reliability of the sandwich variant will be higher due to the fact that it consists of two layers of metal.

The ceramic version will be an excellent solution, as it is durable, reliable and perfectly resists the effects of various aggressive substances.

But he has two minuses:

- high price;

- a large mass, for which reason it is required to install it on the foundation and additionally pay the associated costs.

But to exploit this option can be several decades. Asbestos cement solutions were previously one of the most popular options for the construction of boiler chimneys in their own home. This material is porous with walls of a rough type and non-ideal section. But, on the other hand, this is the most affordable option.

When using this type of chimney should:

- make it as smooth and direct as possible;

- to carry out the complete sealing of the joints, using either hermetic collars and special additives of a hydrophobic character, or coating the dried cement with a sealant;

- make the pipe as long and straight as possible, and also insulate efficiently in order to reduce the amount of condensate formed.

There is also a plastic option, which is also used quite often. But here one should be careful, since ordinary plastic simply will not withstand work with high temperatures, for which reason one should buy goods of this type exclusively in specialized stores.

Before purchase you should be sure to familiarize yourself with the features of the plastic you are interested in and see what operating temperatures are indicated in the manufacturer’s documentation.

Requirements

There are two regulatory documents that regulate all requirements for various types of smoke channels. These are DBN B. 2.5-20-2001 and SNiP 2.04.05-91. Comply with the rules prescribed in these regulations, it is necessary in any case.

If we talk about the basic requirements, we should mention the following rules.

- The size of the chimney can not be less than the size of the outlet nozzle on the boiler. If it has a size of 150 millimeters, then the cross section of the internal type of the chimney should not be less than this value. More is possible, but less is not.

- The product should be straight and go up vertically. It is better that there are no corners in it, but if one cannot do without them, then the greatest allowable slope will be thirty degrees. The length of such a site should not exceed the height of the room.

- At the top of the pipe, you must install an umbrella that will perform a protective function. It will protect the boiler from precipitation and clogging.

- As mentioned above, the joints must be carefully insulated, and they must be sealed so as not to pass gas.

- Height must be such as to provide excellent traction. The design should rise half a meter above the roofing ridge, if it is placed next to it.

- In the lower part, it is necessary to assemble a condensate trap, which looks like a glass made of chemically resistant materials. The best option would be a glass made of stainless steel, and the cheapest - plastic. There are still models of galvanized steel, but they are not recommended because of the rapid destruction.

- The length of branches extending in different directions cannot be more than one meter.

- The chimney system must be made without ledges.

- The largest number of tribes that can be made in the system is three.

- There should be no cross-sectional sections.

- Even small structural deflections are unacceptable.

- All parts must be joined as tightly as possible.

- There should be no gaps between parts of the whole structure.

- The minimum possible slope of the flue pipe in the direction of the heating device is 0.01 degrees.

- It is extremely undesirable to make the inner walls rough.They should have a smooth surface.

- The smallest distance between the surfaces of combustible materials is 25 centimeters, and of non-combustible - 5 centimeters.

- The total length of the horizontal parts of the chimney should be no more than three methods for houses that are built, and 6 meters for already constructed buildings.

- In the corners of the chimney, it will not be superfluous to install inspection hatches that should discharge condensate and facilitate cleaning of the whole mechanism.

- If the chimney is built up, then one link is put on the second one at least by half the pipe diameter.

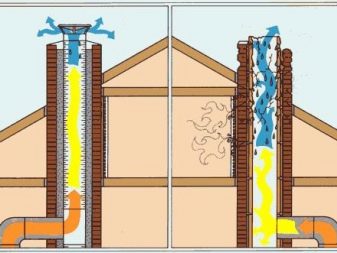

Separately, it is necessary to say about the standards for pipe height of the chimney in relation to the ridge of the roof.

The chimney must be removed beyond the section of the wind backwater and installed at the following heights:

- if the horizontal distance from the ridge is higher than the level of three meters - higher than the approximate level laid down from the roofing ridge to the horizon with a slope of ten degrees;

- if the distance is 1.5 - 3 meters, then on the same level with the ridge;

- if not more than one and a half meters, then not less than 50 centimeters from the ridge.

The flue pipe must be at least half a meter above the adjacent roof. And if the roof is flat, then the distance increases to two meters.

How to install?

The installation of chimneys should be carried out in full compliance with the provisions of the aforementioned regulations and fire safety regulations. The step-by-step instructions for installing the chimney will differ depending on the type of construction and the chosen construction. Before installation, the installation scheme must be carefully considered, because any mistake can cost extra expenses, lost time and additional work. That is, without performing a calculation for a previously chosen construction, it is better not to try to start its installation, otherwise it will be fraught with problems.

If we talk specifically about the list of actions on the example of sandwich pipes, the following nuances should be mentioned.

- Applying the necessary markings, according to the requirements and standards of fire safety.

- Embedding the entrance pipe that will pass through the wall. The pipe must be adjusted to the size of the nozzle so that the whole mechanism is sealed.

- Providing a hole of appropriate size in the wall.

- The implementation of the installation of the tee and the auditing plug. It is installed using a clamp, and the support that will support it is created from various metal holders of different shapes.

Now the chimney from the outside of the house just begins to build up due to the consistent coupling of all elements. Their installation should be done on the brackets that were installed in advance. When all of the above is done, it remains to simply install the cap with the mushroom at the end, and strengthen the structure where necessary. This is done with clamps, which will be drawn in with screws or wire of a large size.

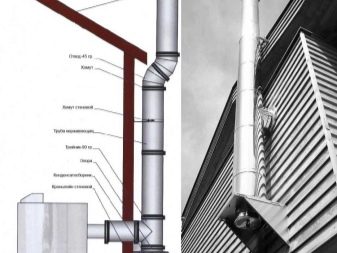

From the inside, the mechanism will be about the same:

- first, we mark the holes for the pipe in the house ceilings and roof;

- check the labels and dimensions of the nozzle to make a chimney opening.

Now you can proceed directly to the installation of the chimney inside the building.

- First, we connect the adapter to the nozzle.

- Mount audit and tee.

- Increase the chimney. If there is a need, then apply for this knee.

- The chimney is wrapped in a stainless steel sheet.

- We carry out the strengthening of the structure using clamps.

- Now you should attach the pipe to the attic beams using clamps and wall brackets.

- We make the installation of a cone-shaped deflector on the output of the chimney.

Upon completion of the installation activities, you should make sure that each seam of the system is tight. This can be done by applying a normal soap solution. If bubbles appear somewhere, it will mean that the tightness of the mechanism is broken.

It is also worth figuring out what requirements are put forward to the chimney from a brick and how to make a solution for it. Before creating this type of boiler chimney, it is necessary to create a foundation with a height of at least 30 centimeters. The base itself should protrude beyond the channel contour by no less than fifteen centimeters. If the chimney is in the elements of the outer wall, the foundation must be clearly at the same level with the base. Laying brick chimney begin even in the construction of the building.

When creating such a chimney, it is important to observe the following requirements.

- Chimney duct must be leak tight. Laying should be carried out with bandaging so that the vertical seam of the last row overlaps with the brick of what was previously.

- Masonry thickness should be such as to exclude the possibility of freezing.

- The flue must not have ledges and any areas - extended or narrowed.

To reduce the cost of construction, it is necessary in the general chimney to provide as many channels as possible. Then the placed channels of ventilation and smoke exhaust next to each other will warm, which will significantly improve the operation of the chimney.

If we talk about the preparation of the mixture for the formation of a brick chimney, then its composition should be selected taking into account which part of the pipe will be laid out: internal or external. To create an external output, the same mixture will be used as for creating the bearing walls of the house. This solution is usually made of water, sand and cement mixture, and can dry in almost any conditions. It is necessary to make the solution in such a volume that in 60 minutes it will be fully used, since it quickly becomes unusable.

So that the mixture does not collapse and does not need repair, it is usually added a number of substances that increase its characteristics of acid resistance, strength and ductility. These additives can improve the quality of the masonry, as well as accelerate the speed of construction and the durability of the actions taken.

Creating a mixture for such a brick chimney that runs inside the house is based on the use of fireclay and clay of refractory type in the ratio of one to one. Such mixtures easily tolerate the effects of high temperatures. They have the highest strength and do not release any harmful substances. To give such a solution strength, add salt in the amount of 130-140 grams per bucket.

Also, for masonry brick chimney, you can buy ready-made mixtures that are resistant to acids and high temperatures. A self-preparation of the mixture, although it will reduce costs, but still ready for the characteristics will be better.

To make sure that the chimney is built correctly and efficiently, simply check the draft. If it is good, then you can almost be sure that you have achieved the goal and built a good chimney for the boiler.

Errors when choosing a chimney

Mistakes in the design, selection of materials and installation of the chimney have a negative effect on the operation of the chimney.

The most frequent manifestations are:

- burning of building materials;

- destruction of chimney walls;

- drop in thrust performance.

The most common mistakes in the selection and creation of the chimney:

- wrong pipe;

- use of wrong materials;

- violation of fire regulations.

The wrong choice of pipes usually causes poor quality traction. Its strength is influenced by aspects of external character: precipitation, wind characteristics, and so on. That is, it is important to ensure the influx of fresh air masses from the outside, for which you can install a separate air channel from the street, which can be regulated.

Inaccuracies in the construction of the pipe may lie in the following aspects:

- wrong choice of section;

- low chimney height;

- the presence of deviations from a flat vertical line - the angle of inclined parts greater than forty-five degrees is not allowed.

It is possible to improve traction using different methods - to increase the height of the chimney or to install a smoke exhauster or a special weather vane on the head.

If we talk about the wrong selection of materials, then in the case of the mediocre characteristics of the brick for the chimney, it quickly begins to collapse, which causes the structure to freeze.

Not all stainless steel models are suitable for creating a chimney. It is better to use steel type AISI 321, which is as resistant to the effects of fire and acids, as well as physical effects. When using enameled pipes, it is necessary to select the appropriate models according to thermal characteristics, since many of these pipes often simply burn through.

Another common mistake is a violation of fire regulations.

The main errors in this case are:

- the absence of fire-fighting and filling high-quality fireproof materials between pipes;

- poor performance of the pipe lining, which causes it to overheat.

As you can see, to create a chimney for boilers of various types will not be difficult, even for an uninitiated person. But it will function qualitatively only when taking into account a large number of various factors.

In the next video you are waiting for the scheme of chimneys for the boiler.