Coaxial chimneys for gas boilers: design features, types and installation steps

Today, coaxial boilers have become very popular with owners of gas boilers. This device allows you to solve the rather acute problem of heat loss that occurs when using standard chimney systems. Also, such a chimney is able to provide a good flow of air into the heating equipment. Therefore, a coaxial chimney is an efficient and expedient device for diverting boiler combustion products.

Device and purpose

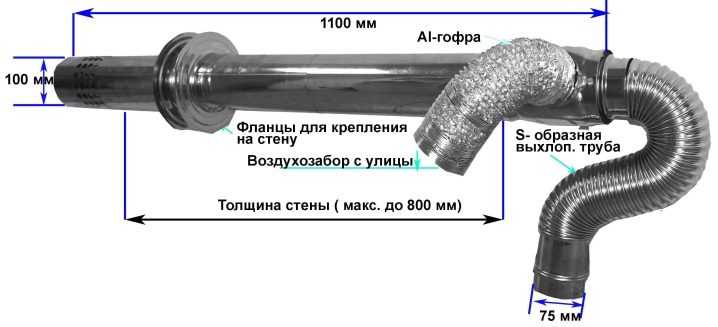

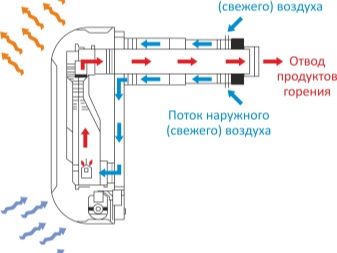

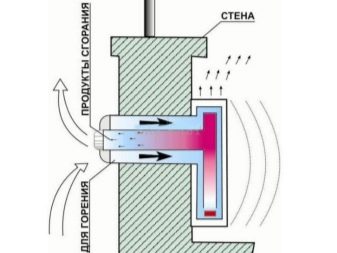

Such a chimney consists of two pipes having different diameters.It is made of pipes, which is smaller, inserted into the other, so that there is a gap of several centimeters between them. Such a device chimney system and allows you to remove the products of combustion, and at the same time collect the required amount of air from the street. That is, a constant circulation is ensured. Also in the construction of coaxial systems is used "knee", which is a transition element, and a clamp, which securely holds all parts of the structure.

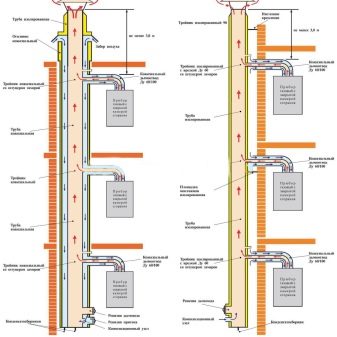

It is also worth highlighting two main types of systems, depending on the design features in which you can install such chimneys:

- Collective systems. These types of chimneys are installed during the construction of large high-rise buildings.

- Individual systems. This type of system is used for installation in private houses where one heating device is used.

Principle of operation

The pipe, which has a larger volume, is designed to draw air from the external environment of the house. The smaller pipe is used to remove the combustion products. The great advantage of such a device is that the air entering through the outer tube is already heated from the inner tube, which removes waste.That is, the air already heated to a certain temperature enters the boiler, and this reduces the gas consumption in the boiler. Thanks to such a system, the productivity and efficiency of gas heating equipment is increased.

Also, a wider serves as a kind of cooling system for the internal, so that the design does not heat up, thereby reducing the level of fire danger.

Advantages and disadvantages

These types of chimneys have their positive and negative sides.

Among the main advantages of coaxial systems, the following should be noted:

- There are no great requirements for ventilation. This is explained by the fact that this type of air is taking in air not from the room, but from the street.

- Simplicity and high speed installation work.

- These types of chimneys can be used not only for wall mounted gas boilers.

- Use both in private, and in multi-storey buildings.

Among the shortcomings are two main disadvantages:

- The operation of such a chimney involves the release of condensate. It is quite toxic, so the installation requires careful insulation of pipes. Even small errors in isolation can lead to unpleasant consequences.

- The second minus directly follows from the first. Since toxic condensates are emitted in such chimney systems, a set of permits from the relevant authorities will be required when installed in a collective heating system.

Kinds

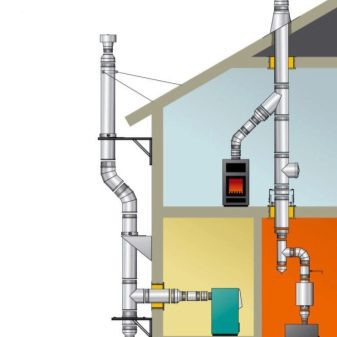

According to their location, coaxial systems are divided into internal and external. Internal systems are more complex, because for their use special mines are necessary, separated from the premises. This type of chimney is used infrequently. Outdoor systems are standard and easy to install.

Depending on the type of output distinguish horizontal and vertical systems. Horizontal are more complex. To install this variant of the chimney, it is necessary to take into account the characteristics of the building. It is worth remembering that the maximum length of the pipe coaxial horizontal chimney should not be more than 5 meters. For vertical systems, two connection options are used. This can be a cascade connection type or an individual one. The cascade system is used in high-rise buildings, where there are several heating systems.Accordingly, the individual system is used in private one- and two-story houses.

Here it is also worth considering the length of the pipe to calculate the load that will fall on the wall of the house.

Also for the materials used emit stainless steel chimneys and plastic boilers:

- Stainless steel systems are able to withstand much higher temperature loads, unlike plastic ones. Also, stainless steel pipes have a high level of resistance to acids. In general, stainless steel chimneys are very reliable and have a long service life. They can also be insulated or without insulation.

- The main advantage of plastic systems is their low cost. Also, these pipes have a small weight, which facilitates the installation process. And in general, the installation of such a system is quite simple. The service life of plastic systems is lower than that of stainless steel constructions, besides, it is impractical to use plastic in boilers where the temperature is high.

Normative base

To install coaxial chimneys, legal requirements are imposed and certain permits are required.The state has established standards in accordance with SNiP 2.04.08-87 and 2.04.05-91, which stipulate the rules for installing chimneys.

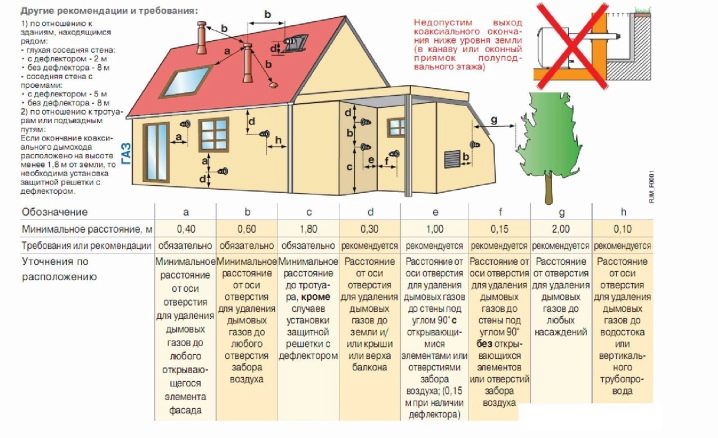

In particular, these acts state that when establishing a coaxial chimney in a collective heating system, it is necessary to obtain a special permit from the gas service. Also in collective systems there is a minimum length of up to half a meter to windows and doors. On the facade of the building chimney should be located at least two meters from the ground.

In accordance with fire safety, it is stipulated that the gap between the wooden walls of the house and the chimney pipe must be at least 5 cm. In the brick walls, the hole for the pipe must be one centimeter larger than the diameter of the pipe itself.

Normative acts also indicate that there should be no obstacles in the immediate vicinity of the chimney. This design should not exceed 30 cm.

A diagram of the horizontal coaxial chimney is shown below.

The slope of the horizontal chimney relative to the boiler should be approximately 3 degrees. With individual installation of the chimney in a private house, the maximum length of the documents should not be more than 7 meters.

Installation

In the implementation of the installation of a coaxial system with their own hands, a number of preparatory work must be done. In particular, it is worthwhile to carry out a careful calculation of the dimensions, prepare holes in the wall and provide for a slight slope of the pipe. A slope of 2–3 degrees will allow condensate to drain. Next, you need to bring the chimney through the wall of the house. It is quite simple, the main thing is to comply with all requirements of regulatory documents.

Then you can proceed to the installation of coaxial equipment to the boiler. To do this, you must use a special connection adapter. Then a tee is installed with a condensate collector, after which the chimney construction is discharged through the wall.

In some cases during installation it is necessary to increase the length of the coaxial chimney pipe. For this purpose, swivel couplings are used to fasten the joints between the pipes. It is worth noting that it is not recommended to seal the pipes with silicone. It can not withstand high temperatures. It is also recommended to minimize the number of turns of the pipe, so that the draft design is higher.

Many users of this type of chimney are faced with the problem of icing of the extracted pipe. If this happened and there is ice on the pipe, then most likely the installation of the system was carried out incorrectly. To avoid the appearance of icicles on the pipe, you can use a special nozzle. Such an anti-icing device will eliminate the problem of ice on the pipe. In particular, when using this type of chimney in collective systems, the use of a nozzle is a mandatory item.

Also, when ice appears on the pipe, you can increase its slope for complete drainage of condensate towards the boiler.

To protect the pipe from windy blowing it is necessary to calculate in advance where the chimney will be installed. Here it is necessary to take into account the structure of the building. Also, a special windscreen and diaphragm are used for this.

If you are not confident in your own abilities, then you should contact the experts who will help you install the coaxial chimney correctly. Otherwise, you can allow gross errors, because of which the system will work inefficiently.

Among the most common mistakes during installation are the following:

- Rough errors in the calculation.It is necessary to carry out measurements and calculations strictly according to the established regulatory legal acts.

- Violation of fire safety regulations. For such systems, gaps must be provided to reduce the level of risk of fire. Failure to comply with such requirements can be very disastrous.

- Incorrect connection to the heating equipment.

- Error in the choice of material. Above said that the chimney system can be made of stainless steel or plastic. When choosing, it is necessary to take into account the individual characteristics of the heating system so that the material can withstand the necessary temperatures.

Tips and tricks

When choosing a coaxial chimney should pay attention to the manufacturer. In the market there are certain brands that have proven themselves from the best side, producing high-quality and reliable products.

Among such firms are the following:

- Navien. This is a Korean manufacturer, which presents on the market convenient and high-quality chimneys at reasonable prices. The company produces coaxial chimneys for low power boilers.

- Baxi. This company has long been engaged in the production and supply of coaxial chimneys on the world market. Basically, this manufacturer specializes in the production of stainless steel chimneys for gas types of heating systems. The composition of the products of this company contains the best quality polymers and high-strength steel.

- Valliant. This German company is engaged in the production of heating equipment, as well as coaxial chimneys. This product has a long service life, stylish appearance and ease of maintenance. Often, to many boilers of this manufacturer goes in addition and coaxial smoke exhaust system.

Installation of chimney pipes should be done carefully. It was mentioned above that in such systems toxic condensation is formed, therefore, the leakage of pipes can lead to negative consequences.

It is extremely important to familiarize yourself with the established regulations. Errors can lead to inefficient operation of the device. If necessary, you can make additional insulation of pipes. True, for coaxial chimneys this is done extremely rarely.

Usually chimneys of this type do not require cleaning. It is established by norms. In extremely rare cases, the chimney pipe can be further cleaned.

So, coaxial chimney today is the actual device. This design increases the efficiency of the boilers, does not require much effort during operation, and the installation of such a system is quite realistic to do it yourself.

In more detail about the device of a koaksimalny chimney the following video will tell.