Features of wall gas single-circuit boilers with a closed combustion chamber

Wall-mounted single-circuit gas boilers with a closed combustion chamber are very popular among the owners of residential buildings, warehouses and production plants. Devices allow you to quickly and effectively solve the problem of heating buildings and at the same time save a lot.

Technical characteristics of devices

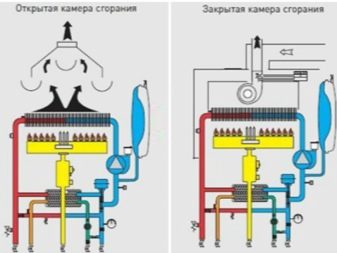

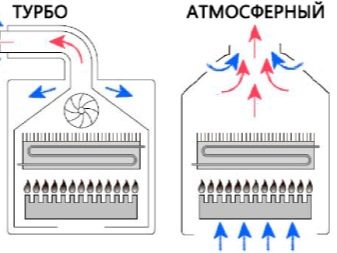

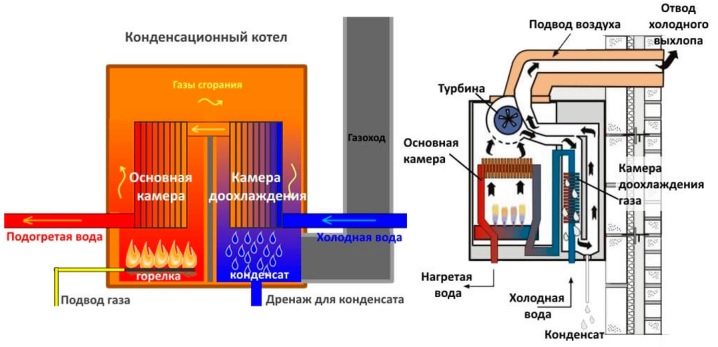

The main feature of gas appliances with closed chambers is the method of oxygen absorption during the combustion of fuel. Unlike open-type units, where the inflow of oxygen and the discharge of exhaust gas are provided as a result of natural draft, the technology of their forced injection and removal is used in closed systems.

During the operation of the unit with a closed combustion chamber, the air that is needed to support the combustion process is absorbed from the street through the coaxial chimney pipe, and the waste products of combustion are removed through it. Such a device completely eliminates the intake of air from the room and makes it possible not to worry about regular ventilation of the dwelling and arrangement of an additional ventilation system.

The combustion chamber in such models is completely separated from the room and is connected only with the coaxial chimney system. Such a device ensures the impossibility of gas leakage in the building and completely eliminates the risk of an emergency. Air supply and discharge into the system are carried out by force with the help of an integrated electric fan.

The coaxial chimney pipe can be installed horizontally, which eliminates the need to build a vertical outlet. Structurally, the coaxial chimney is made in the form of two pipes of different diameter, one of which is inside the other. Through a pipe of a larger cross section, air is drawn in from the outside, and through the internal one - the exhaust gases are discharged to the outside.

Design features

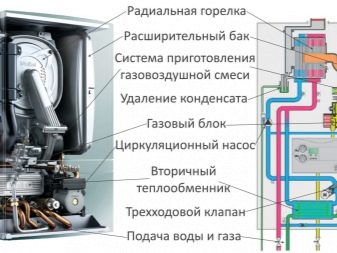

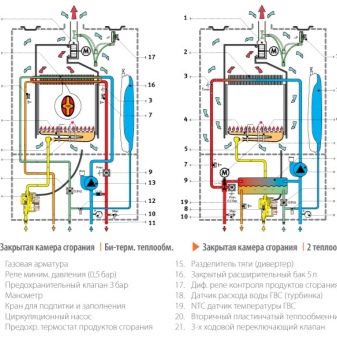

The range of modern gas equipment is represented by single and double circuit models. The former provide only space heating, and the latter, in addition to the heating function, are able to organize uninterrupted supply of hot water. The disadvantages of dual-circuit devices include the inability to use any other liquids, except water, as a coolant.

Single-circuit models in this sense are more versatile and able to function on any fluid, including antifreeze. The absence of the 2nd circuit can be easily compensated by connecting a water heater, which will ensure the complete autonomy of the DHW system and make it always an available resource.

Gas boilers are available in floor and wall versions. Wall types have compact dimensions, low weight and have an aesthetic design. The disadvantages include lower, in comparison with floor models, power, which makes it impossible to use them for heating large industrial buildings and warehouses.

All versions of wall-mounted single-circuit gas boilers of the closed type carry out the heating of the coolant flow method, there are no storage tanks in them.Thanks to this device models have a neat appearance and small dimensions. This allows you to place them in small rooms, without fear of visually cluttering up the space and ruining the interior.

For comparison, floor models often require the presence of additional space, due to their increased power, and, consequently, large size. The advantage of outdoor types is the presence of a cast-iron heat exchanger, characterized by high heat dissipation and long service life, which reaches 30 years or more. The disadvantages include a large weight of the product and the need to equip the strapping system.

According to the principle of operation, single-loop wall gas boilers of a closed type are turbocharged and condensing. The first type requires the presence of a coaxial chimney and operates by forcing air into the system. The heating medium is heated in a heat exchanger, after which the hot liquid enters the heating pipes. Condensation models are more advanced devices and work by condensation of the heat generated during combustion.The role of the heat exchanger in such devices is assigned to a cylindrical coil, surrounding the burner from all sides.

The coolant moves inside the coil, as a result of which condensate formed during the combustion of methane falls on its surface. It is with the help of condensate that the heat energy is transferred to the coolant. The main advantage of condensing boilers is a higher efficiency, reaching 99% in some models, while in turbo devices this indicator is 95%. In addition, condensation models are very economical and can reduce fuel consumption by 40%

Advantages and disadvantages

High consumer demand and popularity of wall-mounted single-circuit gas boilers with a closed-type combustion chamber due to a number of indisputable advantages of these devices:

- excellent heat dissipation and higher efficiency in comparison with open-type units;

- no need to build a vertical chimney and equip an additional ventilation system to simplify installation and provide the ability to install boilers in the premises of any purpose, including residential apartment buildings of various heights;

- compact size and modern design allow you to install the device in any, even the smallest room;

- due to the complete isolation of the combustion chamber and the absence of any contact of gas and its combustion products with the air environment of the room, the devices are absolutely safe and approved for use in all types of buildings without restriction.

The disadvantages of a closed system include the dependence of the models: in the event of a power outage, the boiler operation will be stopped. When the power supply is turned on, the device will automatically resume operation. The absence of a second circuit and the need to install additional equipment for the provision of hot water supply are also referred to as disadvantages of this type. The cost of boilers with a closed combustion chamber slightly exceeds the cost of open-type devices and is often regarded by consumers as a minus.

Popular manufacturers

The most well-known companies that produce single-circuit gas appliances wall mounted with a closed-type combustion chamber are domestic Siberia and Neva and a number of European concerns such as Vaillant, Lemax, Protherm and Viessmann.

Among the models, the Vaillant Turbo Tec Plus VU 122 version 3-5 is very popular. The device is able to provide efficient space heating up to 120 square meters. m. Power adjustment is carried out using a modulation burner. Due to the presence of a stabilizer, the boiler can function even in the case of a decrease in gas pressure in the network, and there is no loss of performance. The disadvantages of the model include the high cost of the device, which is fully explained by its high quality and long service life.

Baxi boilers are also in high demand. Among them, the most popular is the model Fourtech version 1.24 F. The device is equipped with a modulation burner that allows you to change the heating power, and a copper heat exchanger, thanks to which the water is heated almost instantly. The efficiency of the boiler is 93%. The weak point of the model is the gas valve, which sometimes breaks and requires replacement.

Korean Navien device is also quite popular in the domestic market of heating equipment. The boilers are perfectly adapted to Russian fuel and gas communication networks.Models of this brand are optimal in terms of price-quality ratio and, despite the low cost, they are capable of power up to 13 kW. The minuses of the series are a weak thermostat and automatic failures.

Criterias of choice

- Before proceeding to the choice of the device, it is necessary to determine the power of the future boiler. To do this, the total area of the room should be multiplied by a factor of 0.1. The resulting numerical value in kilowatts will be the desired value. This calculation system is based on the fact that heating one square of a room requires 0.1 kW of thermal energy. For example, for efficient heating of a house of 120 square meters. m, you must purchase a boiler with a capacity of 12 kW.

- The next criterion should be the cost of the device. When choosing a value that is comfortable for oneself, one should take into account that the more high-tech the device is, the higher its final price.

- The material of manufacture of the heat exchanger is also an important factor when choosing a model. Copper heat exchangers conduct heat well and have a low melting point. Cast iron differ in long service life and cool for a long time,and steel is an intermediate option between copper and cast iron and have average thermal conductivity and service life.

- When choosing a model, it is necessary to pay attention to the manufacturer of the devices. It is better to opt for boilers of well-known, proven companies that provide a guarantee for their products and have a network of service centers in our country.

A wall mounted gas single-circuit boiler with a closed-type combustion chamber is an economical and reliable device that allows quickly and for little money to equip the heating system at home and make it comfortable and comfortable to stay.

An overview of a single-circuit gas wall boiler awaits you in the video below.