Gas floor single-circuit boilers: types and technical characteristics

The most popular heating equipment in our country is a gas single-boiler installed on the floor. Floor products have always been and still remain the replaceable leaders in the market of heating devices, as they are favorably distinguished by ease of installation and operation, without taking up space on the wall of the dwelling. The choice of buyers by various manufacturers offered a huge range of various models of boilers, so there will obviously be no problems with buying a product.

Device and purpose

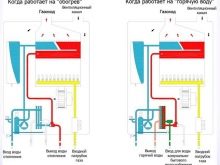

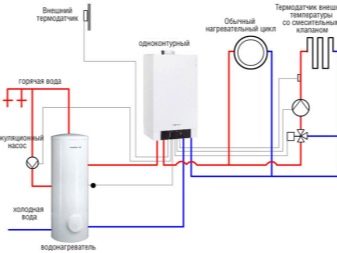

A single-boiler boiler installed on the floor is a device that is equipped with only one heat exchanger. This product is used only to warm the room, but there is no function to provide the owners with hot water.If you need a liquid warmed up for domestic needs, then you will have to purchase an additional device for the equipment. Of course, you can immediately purchase a dual-circuit gas boiler, but it has an extremely complex device. Therefore, single-circuit devices are in a more advantageous position and are most often selected for heating a private house.

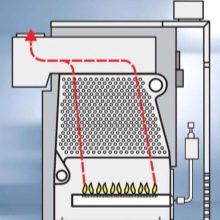

At the bottom of the product with a single circuit, you can see the gas burner. A grate is visible under it, air is flowing through its openings. The heated gas begins to circulate inside the body of the product and goes between the “heat” “pockets” - this is a subspecies of the radiator, consisting of flat containers, and the heat carrier itself is located in them. There is a large number of such tanks, the heat removal area is large, and the gas that has spent its life gives up its heat to the maximum. The tanks are combined into one collector, from which the heat carrier goes into the system. In these boilers is often present automation, designed to monitor the performance of the entire system.

Principle of operation

The heat wave begins to appear when gas is ignited in a special chamber, thus the heat carrier itself is heated.Heat exchange is carried out in a heat exchanger. This, by the way, is the two main nodes of all gas-type heating devices.

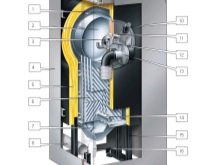

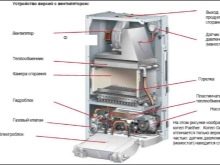

All products have components such as:

- housing;

- the combustion chamber;

- chimney;

- burner;

- heat exchanger;

- control unit.

Through a special valve, the fuel in a metered quantity enters the burner, where it is first mixed with the air there, then goes through the nozzles into the chamber for subsequent combustion. Using a igniter or spark gap, the gas is ignited. The control unit controls the entire combustion process, setting the required thermal power of the device. Products from combustion with most of the heat go gradually to the place of heat exchange, where the resulting heat is transferred to its walls. It will be necessary to keep the water in the heat exchanger in motion to prevent its boiling up and thereby continuously transfer it to the batteries placed throughout the building.

The gas floor single-circuit boiler is often bought only for heating a home. Not only the well-known water, but also other effective liquids can become a carrier of heat in them. The absence of heated water can be easily corrected.For this, the boiler is supplemented with a special tank in which water is heated or a water heater is installed. This option is considered the most convenient for use in the cottages. Floor models usually have larger parameters than products for walls, but their weight does not exceed 100 kg. The pipe of a similar boiler should go strictly upwards.

Advantages and disadvantages

The main positive features of single-circuit gas domestic boilers are as follows:

- equipment efficiency - the best boilers with one circuit are extremely economical and they will need a minimum amount of fuel; they give the received energy as efficiently as possible due to high efficiency (up to 93%);

- the strength of the devices and their long service life — products with high-quality cast iron heat exchangers are selected for installation on the floor, for this reason they are not fixed to the wall, because cast iron is a very heavy metal; but a cast-iron gas boiler can operate for many decades without interruption;

- long work without constant control of the owner of the dwelling;

- high power;

- easy to maintain and easy to use;

- completely autonomous device which does not depend on jumps of the electric power;

- these devices regulate the production and supply of heat, taking into account the parameters set by the owner of the housing, while monitoring the safety of the boiler operation;

- democratic price.

There is talk about the negative aspects of single-circuit products, the minus is only one - they can take a lot of space. For an oversized home, this option is 100% not suitable. But for a large house in the form of a two-story cottage - it is quite suitable. In this case, the parameters will recede into the background, excellent performance characteristics will come to the first.

Species

Single-circuit gas units have many varieties, among which everyone will definitely find the one that is perfectly suitable for a particular dwelling.

Depending on whether the boiler is connected to electricity or not, there are two types of boilers.

- Energy independent devices. The boiler, selected for a private building and working on an independent scheme, experts call the ideal device. The light, it happens, often goes out as the wires may break, emergency situations at substations constantly occur.Gas is supplied to the house more stably, the outages can only be planned - and then in the summer, and not in the winter season of the year. Therefore, devices independent of electricity are in great demand among the population.

- Volatile products. The boiler that is connected to the network has a number of advantages - the best combustion of fuel (it can be in products with any combustion chambers), there is a quick ignition, comfortable and easy control, which can be performed using the remote control. Ignition, you can choose electric or manual.

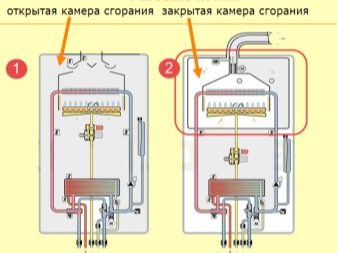

Depending on the type of combustion chambers, there are two more varieties.

- The most uncomplicated gas devices for home heating are open-type combustion chambers (with a special burner). The flame burns at the expense of the usual oxygen supply that comes from the room. The device is placed in rooms with excellent ventilation - it may well be even an ordinary boiler room with a window. These products can easily operate without electricity.

- Gas boiler with a closed combustion chamber (it is also called turbocharged) has such advantages as:

- temperature control, which provides gas savings;

- Smooth ignition and flame force control reduce the serious load on the device;

- high efficiency;

- to accommodate the turbo boiler will not have to equip a separate room;

- Turbocharged products are the most efficient, but they are very noisy, since they have fans built in, which are responsible for weathering the products of combustion and provide a flow of clean air.

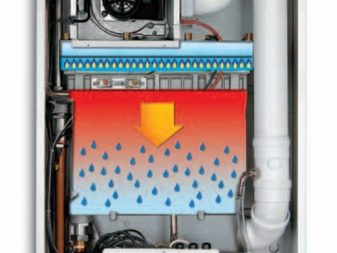

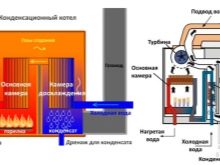

According to the efficiency of fuel combustion, gas boilers are further divided into two types.

- Condensation devices. The efficiency of condensing boilers manages to achieve parameters of 90% and even much more. Enough heat can remain in the combustion products, which is best transferred to the home heating system. For this process, condensation products were invented, which make it possible to take into the system for heating a dwelling almost all the heat wave generated by the burner. They are operated only when connected to the mains.

- Convection products. Traditional single-circuit floor boilers are manufactured according to the convection principle - only the heat exchanger and the burner itself are present.Their efficiency is not too high, like that of other units, but they are much easier to manage, and they are cheaper.

Depending on the types of heat exchanger, boilers are divided into several varieties. The duration of the boiler operation depends directly on the type of its heat exchanger.

He, in turn, can be made from any modern materials.

- Copper structures can be seen extremely rarely. Despite the high thermal conductivity of copper - it is an expensive material that wears out pretty quickly in serious devices with high power.

- Gas boilers with a cast-iron heat exchanger design last as long as possible, and therefore are quite popular. Cast iron is not afraid of corrosion, acid attacks and temperature shocks. The life of high-quality cast iron products can be even 30 years. Cast iron has only one drawback - this is brittleness, which will have to be taken into account when choosing and not to allow temperature differences between the supply of more than +45 degrees. After purchasing a cast iron gas product and bringing it to the site, experts advise to carefully check the heat exchanger for cracks.

- Steel structures are crack resistant and have much less weight. But they can quickly rust or burn out, which will shorten their life to 15 years.

It is also worth highlighting the parapet-type boilers, which are represented by structures that are selected for heating in their own houses and apartments. They combine the best properties of gas boilers and convectors. Parapet boilers are non-volatile products that are in great demand.

Overview of models and manufacturers

A fairly large number of companies today produces boilers of this kind both abroad and in domestic production facilities. It is worth considering in more detail the most popular manufacturers.

- Siberia Company produces inexpensive, but excellent gas appliances, the efficiency of which reaches 90%. They can quickly heat a building that has an area of up to 600 m². The heat exchanger from steel or a design from cast iron is included in the package of a product. Independent of electric power, single-circuit Siberia boilers with an atmospheric burner include automatics of Italian production, equipped with a manometer and a thermometer.Siberia boilers are the best choice for houses that are built far from the city.

- Baxi can be called one of the most famous brands in our country. Popularity gave him the excellent characteristics of modern equipment for high-quality heating. Buyers leave only positive feedback on all models of the manufacturer.

The Baxi product line for floor installation consists of the following models, each of which has its own functional set:

- Luna 3 with self-diagnosis;

- Luna 3 Cmfort with control from anywhere in the room;

- Ec Four with the choice of any combustion chamber;

- Main Fur with the ability to check the product in two modes and an LCD screen.

- Very popular products and from the well-known gefest companies, which produces a popular gas convection boiler with a capacity of 14 kW, which can easily heat a house of 120 square meters. m. independent of energy type. "GEFEST VPR KSG-12,5S" is the best model, because it is presented with a closed combustion chamber and an efficiency of 92%.

- Gas boiler called AOGV 29 MOT from Victory connects to additional equipment if it is necessary to heat the water. Such a boiler can heat almost 270 m².AOGV 29 TO is a boiler with one circuit and a closed combustion chamber, a three-way valve, a number of sensors, convenient control, and an excellent degree of protection.

- Aton gas products - These are designs of excellent quality at affordable prices of Ukrainian production. These boilers are suitable for heating any buildings that have both large and small areas.

- Gas floor products "Zhytomyr" from the company "Atem" - These are products of decent quality from Ukraine. Characteristic features of Zhytomyr boilers are an affordable price in the market of high-quality gas products and independence from electricity.

Demanded boilers made in Russia dramatically increase their rating compared to more expensive foreign counterparts.

- With the release of domestic gas product "hearth" the most innovative technologies are used. Specialists of the manufacturer have on hand 6 patents for inventions in the field of gas equipment and 11 certificates. The most modern equipment is installed on the production and qualified specialists work. Ochag gas devices will last for many years, will not require specific maintenance, and at the same time also have a quality certificate of the state standard level.

- Gas products "Signal" - This is a single-circuit boilers series, which belong to the budget series of floor products. They are available with a minimum power of 7 kW and a maximum - 40 kW.

The most popular devices in this series are the following:

- gas boiler "Signal" S-term 7 - this model is made with control on the front panel;

- boilers of the previous version "Signal" KOV 16 STPS.

- Boilers "Conord" produced in Russia. The manufacturing plant produces heating boilers for over 50 years. Recently, production has been modernized, so the boilers of this famous brand began to actively compete with imported counterparts. Floor boilers from "Conord", despite their size and judging by the customer reviews - this is one of the most reliable.

Criterias of choice

If there is a desire to choose a household gas boiler with its installation on the floor, then It is worth paying attention to the features of his choice.

- Power of the unit. It is calculated by the area of the room that needs to be heated, and by heat loss. In small houses more compact, not very powerful devices can be found, and in large houses more productive and heavy ones.You can calculate the power of the product yourself. Approximately 1 kW of energy will be needed per 10 m² of housing. But you do not need to go to buy the unit with a power that is calculated accurately. In each building there will be unaccounted heat losses, and the unit efficiency will not be all 100%, and sometimes significantly less, so it’s better to add 20% for conditional catching up of possible heat losses. If, according to calculations, a power of 30 kW is obtained, it is better to choose a boiler of 35–40 kW, so the room will heat up as evenly as possible. Devices of 12 kW are highly demanded, they are suitable for a heating area of up to 120 m².

- Heat exchanger material. Experts recommend purchasing gas boilers with a solid cast-iron construction. For thrifty consumers in stores, you can find models with steel structures.

- The possibility of operation on liquefied gas, which is especially important in rural areas where gas has not yet been conducted.

- Availability of self-diagnostics, which allows you to quickly determine the various faults of the device. If suddenly there is a malfunction in the system, the error code will be displayed or the indicator of a certain color will light up.

- Existence of function of shutdown of a torch in the emergency mode. This useful feature is a guarantee of peace of mind.

- Automatic control. If the product is controlled by automation, then this will significantly save gas consumption in accordance with the existing characteristics. For the period when no one is at home, you can put reduced fuel consumption.

- Domestic and imported products. Floor boilers made in Russia are in no way inferior to prototypes produced by foreign brands. Many buyers choose equipment from well-known Russian companies, while noting the simplicity of the units and their uninterrupted operation, even in difficult conditions. Foreign companies are also trying to provide the best equipment to the market, so they manufacture devices that take into account our climatic conditions.

An overview on the gas single-circuit cast iron boiler BAXI Slim in the video below.