Pressostats of gas boilers: purpose and principle of operation

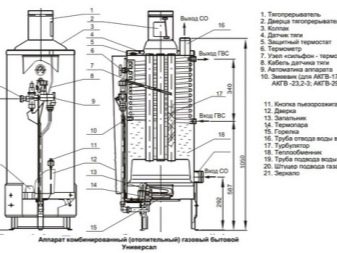

Modern type gas boilers are complex units that help to heat residential premises by heating water. They work with the use of explosive gas, so the design of such equipment requires the presence of special elements that control the operation of all mechanisms. They call such control devices - pressostats of gas boilers.

What it is?

Pressostat, monostat, smoke sensor, differential smoke pressure switch, pneumorele are all different names for the same device. An important detail controls the operation of the boiler fan, as well as the process of smoke removal, protects the heating apparatus from overheating during a sudden pressure drop of gas or at the time of reducing the amount of water supplied.In addition, the smoke detector allows the burner to function or, conversely, to turn it off.

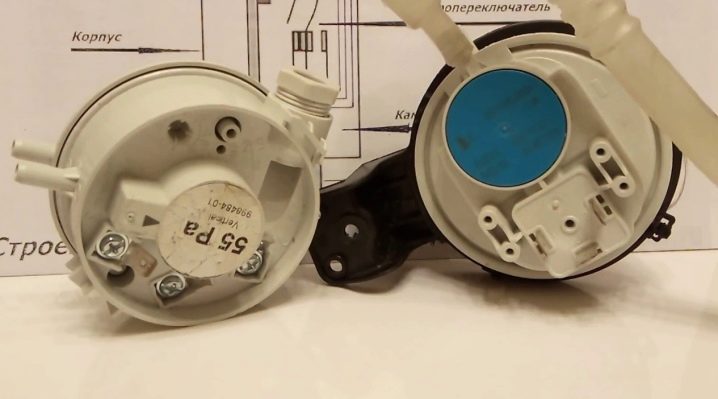

Visually, the pressure switch is a small flat plastic box.In which the sensitive membrane is placed and the three-contact microswitch connected to it. It is these details that control the work of a complex heating apparatus.

How does it work?

The differential relay has a pair of contacts interconnected by two control circuits. During normal (normal) operation of the heating device, one block of contacts is closed, with the duty officer - the second one.

In more detail the operation of the device can be described as follows.

- The first mode is operation at normal pressure. At this time, the thermostatic membrane of the controller does not change its position, and one pair of contacts is closed. The boiler operates normally by passing current through the circuit described.

- The second mode is activated when any of the mechanisms of the system fails: the relay moves inside and the diaphragm bends. The first block of contacts of the smoke sensor is disconnected, and the second, on the contrary, closes.Heating equipment stops its operation.

The pressure switch is triggered by the slightest change in temperature in the combustion chamber, it records the appearance of condensate, monitors all pressure indicators in the boiler.

Functional check

Finding out whether everything is in order with the pressostat at home and finding out the principle of operation of the device is quite simple. To do this, slowly turn the water supply valve in order to reduce the volume of fluid entering the apparatus. In this case, the value of the pressure received at the moment will appear on the control panel.

The minimum pressure indicator (critical number) is considered to be 0.5 bar. That is, if the water pressure decreases, the temperature of the flue gases will increase, and the contacts will overheat. As a result, the gas supply to the boiler will stop, the device will stop working. The values given in the instructions for the device indicate in what mode the heating device is operated.

Another important parameter for gas boilers is the upper (maximum allowable) pressure indicator. If the permissible value is exceeded, the relay sends a command to turn off the automatic power supply of the dual-circuit device.Otherwise (for example, the monostat has failed) the expansion tank may overflow and burst.

Thus, following the indications of the pressure switch, and comparing them with the tabular data in the explanatory book for the gas boiler, one can understand whether the heating unit is working correctly or not.

Symptoms

Evidence that the pressure switch for the gas boiler has become unusable are the following factors.

- The fan in the monostat is switched on silently. The absence of a sound signal indicates that the device has malfunctioned and needs immediate repair or complete replacement. Important! When you start the fan must be heard click.

- The boiler does not turn on, and when you try to turn it on, the device gives an error signal (most often the red indicator lights up).

If the pressure switch does not work for any reason, it is better to suspend further operation of the gas boiler in order to avoid serious problems.

Causes of failure

Under the conditions of continuous operation of a double-circuit boiler, breakdowns or inaccurate information supply by a smoke detector are possible.

The following negative points can lead to similar consequences.

- Contact oxidation. When the fan is turned on, the audible signal of the switch is heard, however, due to oxidation processes on its current-carrying elements, the circuit cannot close.

- Wear membrane. The operation of the pressure switch can significantly deteriorate if the technical properties of its moving element (membrane) deteriorate.

- Cork from debris, damage to the condensate tube. If the tube has cracks, tears, or it is clogged, flooded with water, the smoke sensor may begin to produce an error in the readings.

- Reduced fan performance. The deterioration of the fan operation entails the deterioration of the work and the pressure switch.

Repairs

If the pressure switch stopped working, you can determine the failed node in this way:

- disconnect the boiler from the power supply;

- open the decorative part of the unit housing (its front panel);

- conduct a visual inspection of all mechanisms of the heating device;

- if no visible damage is found, reset the error and restart the boiler by connecting it to the power supply.

The boiler turned on without any problems - this is a sign that the damage is located in the pressostat.

To diagnose and repair it, you should check the status of some parts.

- Tube condensate. This device must be inspected to exclude or confirm thermal wear. It is also necessary to check if there are foreign agents inside the tube. Since this part of the condensate collector is in a place of high temperatures, the material of its performance gradually loses its original physical properties from constant thermal influence, and through holes can also appear.

In addition, the permeability of the channels of the tube may impede dirt or fluid formed on the inner walls due to sudden temperature changes. If defects have been identified, the damaged tube should be replaced or try to repair or clean the worn product. For example, clogged areas can be carefully cleaned with wire, and deep cracks on the surface to cover with thermal paste or tape.

- Internal camera differential relay. When the liquid enters the body, the oxidation process begins to occur at the contacts of the microswitch (they begin to become covered with rust).Consequently, if condensate is present in the monostat for a long time, the gas boiler's pressure switch can start to work intermittently, so it is better to move it to another place, away from the place of possible condensation.

- Electrical contacts. You can check these items can be a multimeter. If the tester emits a piercing sound, this means that the conductive parts of the relay are not oxidized, and the relay is working properly. If a unit appears on the display of the measuring device, it means that the sensor has broken. Many models of pressure switches have a solid body, so it is rather difficult to inspect their internal contents. To separate the parts of the box, you need to gently peel off the solder. Then open the case and clean the conductive elements. Inspect the diaphragm for damage. If there are none, assemble the device or replace the diaphragm and then return the case to its original position.

- Fan power. When the exhauster power deteriorates as a result of a decrease in voltage in the power grid, severe contamination of the turbine blades or the bearing service life is long over, the relay membrane will not adjoin the switch to the required degree.And, despite the fact that the relay has screws for manual adjustment, you shouldn’t change anything, because you can knock down the primary settings and put them in the required position will not work. Thus, it is necessary to scrupulously inspect all of the listed elements, it is possible that a breakdown occurred in the smoke exhauster of the gas boiler.

How to choose?

The pressostat works in harsh conditions for any equipment, so its warranty period has time limits.

To select and buy a really high-quality device, you need to find out:

- trademark of the heating device;

- monostat manufacturer;

- availability of a quality certificate for the purchased goods.

Before buying, it is also important to know that there are two types of pressure switches available: the GW series - for controlling flue gases and the LGW - for monitoring the permeability of liquid and gas.

The second type of controllers is considered more useful.

The cost of the pressostat depends on who produced the device. Sensors of Chinese firms are much cheaper than European counterparts.

The device, malfunction and repair pressostat for the boiler, see the video below.