Model range of gas boilers "Lemax"

Gas boilers are supplied to the market by a large number of firms. But not all of them can boast of really high-quality products. One of the exceptions is Lemax products.

Kinds

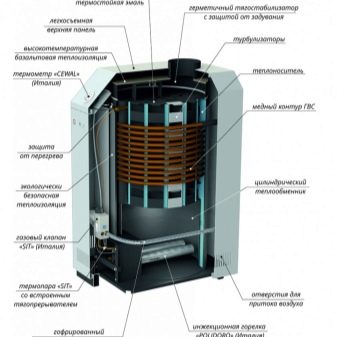

The Premium line is made of high-grade steel, its thickness is 0.2 cm. The grade of steel used is DC01, it fully complies with Russian, European and even North American quality standards.

The main technical characteristics are as follows:

generated power is 7.5-10 kW (for closed systems with a pressure of 1 atm);

generated power from 12.5 to 60 kW (in systems with pressures up to 3 atm);

a special enamel coating with anti-corrosion characteristics that works effectively when heated at 750 degrees;

coating the heat exchanger with a reagent that blocks the action of mineral oil and salts dissolved in water;

autonomy of use;

unique execution of a gas torch and valve;

prevention of overheating and stopping thrust;

convenience when cleaning;

highest efficiency.

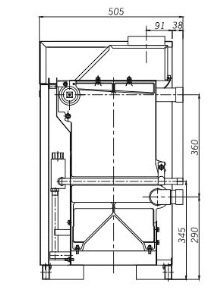

Heating efficiency is enhanced by enhancing the approach of air in the primary and secondary circuits, as well as due to the volumetric heat exchanger and long retention of flue gases. Hot water is provided in systems designed for 12.5 kW minimum. Transfer of equipment to liquefied gas fuel is allowed. Mass varies from 39 to 125 kg. A selection of "Patriot" is made in the calculation of both gravitational and forced circulation of the coolant, connection to the power grid is not necessary.

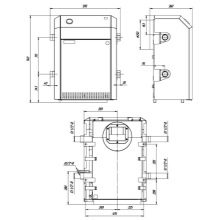

The “Patriotic” series is made of sturdy steel and is used without a chimney. The boiler must receive air from the outside. The shape of the heat exchanger is a rectangle. The generated heat energy ranges from 6 to 20 kW, the fuel burns in a fully closed compartment. To complete the burner used Italian parts, issued by concerns of world renown.

Smoke removal is quite reliable. A viewing window is provided to monitor the main and initiating burners. Facing the boiler is easy to clean, which greatly simplifies the service. Smoke removal provided structures of stainless steel. Branded warranty - 36 months. The efficiency of the device is 87%, the exhaust gases are heated to at least 110 degrees.

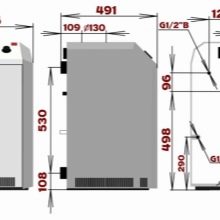

The nominal gas pressure is 1.3 kPa, and the working pressure in the water line is limited to 0.2 MPa. Depending on the modification, the hourly gas consumption is from 0.38 to 1.2 cubic meters. m. All boilers of the series heat up the water to 90 degrees, the size of the coaxial chimney is 25 or 31 cm in diameter, 33-80 cm in length. The connection is made through the gas connections of 0.5 inches; connectable connections can be 1-1.5 inches larger. If there is a need for a cast iron boiler, you should pay attention to the “Leader” compilation, in which heat exchangers are made from gray cast iron of Czech production.

The manufacturer promises that the boiler will exhibit excellent anti-corrosion characteristics and provide decent heat recovery. It is not necessary to connect it to the electrical network. Typical power range includes 16-50 kW. Allowable pressure at work - 4 bar, coefficient of performance - 0.91. Provides measures against the occurrence of soot and excessive heat.

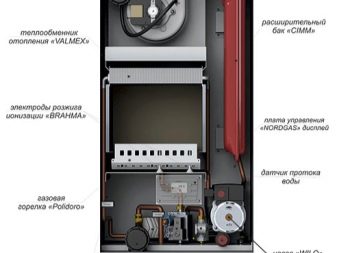

AOGV of this series is always equipped with a thermomanometer, which allows you to control the pressure in the system as comfortably as possible. The design, as in other models, allows you to switch to liquefied gas, and the total warranty - 3 years. Automation at the expense of the components Novosit means that the thermostat is displayed on the front panel. All temperatures there are provided clearly, because the choice of the appropriate mode is extremely simplified.

It is possible to connect room thermostats for the most effective control of room heating.

The category of outdoor boilers includes "Gazovik"; This compilation works great when receiving heat energy from 6 to 29 kW. Removable top panel facilitates cleaning, and even the developers have taken care of such an important option as an attractive design. The warranty period is 3 years from the date of purchase.

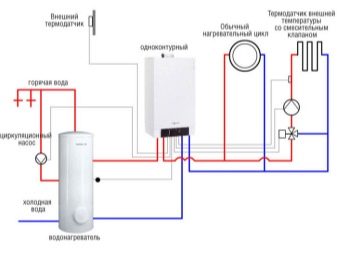

Single-circuit boiler "Lemax" can be equipped with a cast iron heat exchanger (in the collections of "Leader" and Wise), and steel - this is "Premium", "Gazovik", "Forward".The simplicity of the design and the ability to significantly save will please all responsible consumers. The parapet type of boilers is represented by all modifications “Patriot” - these are models 6, 7.5, 10, 12.5, 16, 20. The efficiency of all these structures is 87%, they are able to heat water up to 90 degrees. The mass of products varies from 42 to 67 kg, depending on the modification.

An important feature is compatibility with the Lemax turbine nozzle, which provides compulsory maintenance of exhaust gas. But it should be borne in mind that normal work is guaranteed only when using nozzles made not earlier than September 2016.

Special features

Heating gas boilers "Lemax" are distinguished by decent thermal efficiency. They are launched using piezoelectric ignition, which makes it possible not to depend on power supply. Useful is the thrust sensor, which reacts to interruptions in the ventilation of the firebox. The company has mastered the production of double-circuit boilers along with single-circuit ones. The flame ignites, if you press and hold the special knob after turning and hold it recessed for 60 seconds.

Advantages and disadvantages

Judging by the reviews of the owners, gas boilers "Lemax" are economical, but they are quite expensive.The difference in comparison with similar devices of comparable power reaches 30 or even 40%. Taganrog development is ideally adapted for Russian conditions and is distinguished by ease of maintenance. The entire automatic system and display are translated into Russian, which drastically simplifies use. Some problems may be caused by errors when tying boilers, but a comparison of characteristics with competitors' products shows that these disadvantages are not very significant.

All floor constructions from Lemax are independent of power supply, but wall models cannot do without it. What is important, with the extinction of the fire will have to kindle it yourself. The choice of attachments is more meager than those installed on the floor, and they are also strictly dependent on the power supply. But at least, the automation works stably, and when receiving a normal, stable voltage, it manifests all its possibilities.

Lemax boilers are not equipped with devices that block freezing or prevent the pump from seizing up; suspended devices better cope with the heating of the water.

Recommendations for use

The boiler can be ignited only after the water pressure in the system has been accurately measured and it is not higher or lower than the permissible values. Do not feed the circuit with water if the main burner is working or the line is heated to 50 degrees and above. The use of a boiler with a coolant heated to less than 50 degrees should be discarded. As practice shows, this quickly provokes significant faults in various parts of the system. It is forbidden to include boilers in operation without connecting to chimneys.

Before starting, make sure that the channels for the exhaust smoke are not blocked and that they develop normal traction. According to technical standards it is forbidden to use hot water from the heating system for any extraneous needs, as well as to check gas mains and parts of the boiler with the help of an open fire. A very dangerous decision is to turn on the gas burner if there is no necessary air dilution in the firebox. Of course, if the boiler suddenly goes dead, independent adjustments to the thrust sensor and other components of the device are unacceptable.

The formation of condensate in the initial period after ignition is completely normal and does not require any special actions.It is strictly forbidden to raise the temperature of the coolant to more than 95 degrees. Upon detecting this, you should immediately stop the heating operation and not turn it on until the problem has been fixed by professionals. Preparation for operation implies placing the boiler on a sheet of metal. This is mandatory even in rooms with non-combustible floors.

How much to fill the coolant in the heating system is determined by the individual project. The accompanying materials provide indicative data that can be adjusted in one direction or another. It is advisable to install a fuse that discharges water from the heating system when the normal operating pressure is exceeded. Adjustment and verification of the performance of automatic safety equipment is the prerogative of workers in the gas industry or other authorized, certified organizations.

It is possible to start the burner ignition only after the corresponding knob is set to the “off” position.

It is undesirable to drain water from the boiler and the heating system at the end of the heating period. Only the need for repair, dismantling, reconstruction or alteration of the system justifies this. The return pipe in the area in front of the boiler must be equipped with a device that collects dirt from the water and prevents its penetration into other parts of the system. It is recommended to annually call for inspection and testing of the boiler by employees of the gas territorial service or an organization equivalent to it. Pipeline filling is allowed only with water; the use of fluid with properties different from it means the user's automatic rejection of all claims to warranty service.

If the boiler can supply hot water to the faucet, the highest efficiency of this mode is ensured by bringing the thermostat to the maximum value and turning off the circulating pump. Traction in the chimney and the health of its circuits are checked annually. A special mixer helps prevent burns. But if it is not there, it is necessary to first open the “cold” faucet, and only then gradually add hot water.

Compatibility with obsolete chimneys is limited.Since, with an estimated efficiency of 90% and higher, the flue gas temperature does not exceed 120 degrees, problems may arise. According to statistics from authorized service centers, only 6% of cases of excessively low productivity are not associated with the removal of gaseous combustion products. In the room where the boiler is located, it is unacceptable to block the ventilation grilles.

Only in strict compliance with these requirements and special instructions of the instructions for a particular model, the manufacturer will fulfill its warranty.

Review of gas boilers "Lemax", see the video below.