Installation of gas boilers: standards and connection steps

Gas boilers are increasingly becoming the choice of both owners of private houses and residents of ordinary high-rise buildings. In the first case, after the gas supply is carried out to the house, there is a need for gas equipment. In the second case, the decision is made in order to save money and, rejecting the central heating, turn the heating on and off at will. In both situations, it will be necessary to install a gas boiler, which must be carried out exclusively by professionals.

In addition, it is necessary to bring the rooms in order in accordance with the safety requirements, mainly fire.

Required documentation

It all starts with collecting the required documents. This includes the construction plan, the operating conditions of the boiler, that is, its passport, instruction and other valuable data, for example, certificates of conformity. A package of papers is then sent to Gorgaz, where a project is developed on its basis, and it is also checked whether the boiler itself meets the existing requirements. "The project of the heating system" is nothing but a diagram of the installation of the object. Sometimes the project is developed in a third-party company, and then the finished one is coordinated with Gorgaz. In the gas sector, specialists, having studied the information, will give consent to installation. Without it, the installation is considered illegal and unsafe for all inhabitants of the house. In case of refusal, the reasons for such a decision and the time for which it is recommended to eliminate the shortcomings will be indicated.

It will be necessary to conclude an agreement with a company that is ready to provide gas.

Of course, even before the start of this procedure, the owners will have to familiarize themselves with the rules and regulations governing gas distribution systems. All the necessary information is easy to find in SNiP 42-01-2002. Also useful materials are contained in the outdated SNiP 2.04-87, which is responsible for gas supply.Not to ignore and related documents, which contain important information about heating, sewage, boiler plants, plumbing and so on.

To get permission to connect the gas, you need to find out the technical conditions, that is, when such a procedure is possible. The application is sent to a specialized organization, it indicates how much gas approximately tenants need for one hour. After receiving the required document, which can take from 7 to 14 days, it's time to attend to the elaboration of the project. In the latter, the following information is usually indicated: possible pipe layouts, joining the device and the central gas pipeline, crossing their sections of the gas pipeline, as well as the scheme of a gas pipe “falling” into the structure, provided a private dwelling place. It’s not possible to develop a project on your own, it should be handled by specialists who know the provisions of the GOS.

The finished project has to be agreed, and this procedure can last more than 3 months. Together with the project, a package of documents is transmitted, most of which, as a rule, are obtained when buying a boiler.If everything is in order, the document is signed and stamped, and you can proceed with the installation.

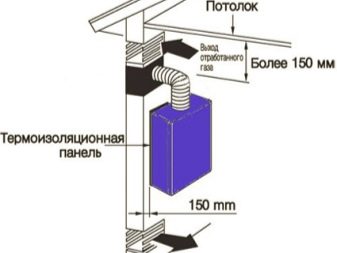

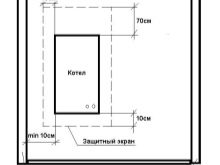

The boiler can be placed only on fireproof walls, and the gap to the surface should be 2 centimeters. If there is a desire to mount it on a dangerous material, for example, in a wooden house, then the surface should be hooked. A sheet of asbestos or mineral wool 3 millimeters thick, covered with a metal sheet, is usually used. Or you can use plaster, but only in the case when its layer is more than 3 centimeters (in this case, the distance to the wall also increases to 3 centimeters).

Fireproof sheet must exceed the size of the boiler itself. Above there should be 70 centimeters, and on the sides - 10 centimeters. The distance between the boiler and the side walls should be from 10 to 25 centimeters. If the object is located on the floor, it is important to take care of the base. Usually make a stand made of non-combustible material, bricks or ceramic tiles on asbestos and metal plates. Such a stand should protrude from under the device for 10 centimeters from all sides and provide the norms of fire resistance for 45 minutes.

What should be the room?

Many recommendations and standards are presented to the area on which the device will be located both in a private house and in a regular apartment.

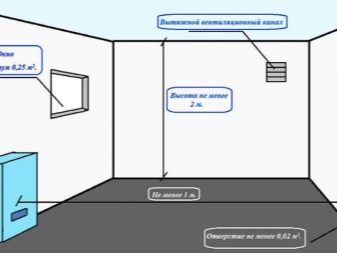

If it is decided to issue a separate boiler room, which, by the way, is the best option, then:

- Ceiling height should reach 2.5 meters.

- The volume of space should not be less than 15 cubic meters.

- Requires a large window that is responsible for natural light, and thoughtful ventilation. The amount of lighting should be sufficient to illuminate the boiler devices. In addition to ventilation, you will also need a chimney, otherwise the tenants of this house may be in danger.

- The door to the boiler room reaches a width of 80 centimeters.

- The walls that lead to the next room should meet the fire resistance standard of 0.75 hours, and also have a zero probability of fire spreading by design, that is, be built from non-combustible materials: concrete, brick or building blocks. If the device is mounted in a wooden house, the walls, ceiling and floor should be further secure.

- You will need to place in the room gas valve, gas meter and gas analyzer.

- It is important to arrange the boiler so that it can be easily approached and reach any part of it if troubleshooting is required.

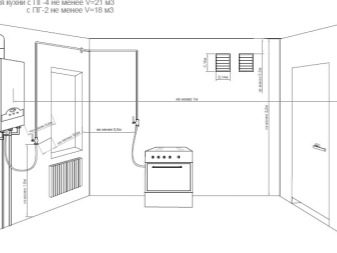

If a boiler with a required capacity of not more than 60 kilowatts will be located in the kitchen, for example, instead of central heating for the inhabitants of an apartment building, the room should be controlled in a certain way:

- the volume of the kitchen can not be less than 15 cubic meters, in addition, plus 1 cubic meter for every kilowatt produced by the device;

- ceiling height should be 2.5 meters or more;

- the performance of the tower can not be less than the volume of the room, multiplied by three;

- additional air for burning will be required;

- the window should be with a window, and its area is determined depending on the surface thickness - the minimum area will be 0.8 square meters, and the maximum - 1.5 square meters;

- in the lower part of the door will have to leave a hole for ventilation, for example, a gap or grating.

There is also a tacit recommendation to place the gas device exclusively in a space with a door., without which permission simply will not be issued.Lovers of arches will have to replace them with sliding or folding versions. If the visual component is important, then you can simply put the glazed doors. They will not “load” the space, but still remain doors.

If the power of the gas boiler will exceed 150 kilowatts, then it will be necessary to organize access to fresh air for security reasons, or the second exit to the non-residential space, corridor or storeroom. Doors themselves will have to install fire.

Installing such equipment in the studio is not recommended. It is strictly forbidden to install the boiler in the bathroom, where there is no natural lighting, in the corridor, which has a small area, and in the closet that does not meet any requirements. Causes certain questions and placement of the boiler under the stairs, which leads to the second floor. In addition, it is prohibited to install gas equipment in dormitories, on balconies and in rooms with combustible materials on the walls.

As for the basement and basement, the installation is permissible, but only in a private house.

Power calculation and equipment selection

Both the place to install the device and the device itself will be selected based on existing regulations. It is allowed to place a heating appliance in the kitchen, whose power does not exceed 60 kilowatts, this indicator can be higher in a separate boiler room. If the power of the boiler does not exceed 150 kilowatts, then it is installed in an individual room on any floor, including the basement. If the power is in the range from 151 to 350 kilowatts, then the boiler can be placed in the individual premises of only the first and ground floors, as well as in the extension. Boilers with high power in residential buildings are prohibited. In general, this parameter should be sufficient, but by no means redundant, especially in the situation with a cast iron boiler. If it is heated, the appearance of condensate droplets will cause cracks. Again, there is the danger of acid dew.

There are a sufficient number of varieties of this equipment, which differ in the method of installation, power, structure of the structure, method of ignition and even the method of output of combustion products. But the main classification is the division of boilers into single and double. The first are responsible only for heating, and for additional hot water will need a boiler.The latter can do both.

According to the method of installation allocate wall and floor appliances. The latter are much larger and more powerful, so they are most often located in separate rooms. Wall-mounted boilers can be seen in ordinary apartments. They do not need a full-fledged chimney, and the products of combustion are output through the wall. The devices are also divided into boilers with a closed combustion chamber and an open one. An open chamber is characterized by a natural burden, and a closed chamber is forced.

Individual attention should be given to outdoor devices, or already street ones. They are often purchased for heating public spaces, such as schools, kindergartens, or hospitals. Their power ranges from 40 to 100 kilowatts. The structure of such a boiler is as follows: inside the insulated metal boxes are placed pipes that heat the water and which wind up inside the room. The device is controlled using a special control panel. Often, such a boiler is complemented by a fire alarm, a chimney, and the ability to transmit a radio signal in an emergency.

Outdoor devices emit little noise, have great power, but are small in size, save space inside the building, are safe, easy to maintain, and are able to serve up to 10 years.

Preparatory activities

The first preparatory event will be the call of specialists, because it is forbidden to install equipment of this type. After that, it is necessary to figure out whether the boiler has the ability to fasten to the wall or it is necessary to purchase fixings. Of course, there is always the likelihood that the choice will be given to the construction, mounted on the floor.

Inside the boiler there are several tubes to be cleaned of dust, which always appears, despite the plugs used during transportation. Then there is the preparation of the wall bordering the boiler. The wallpaper is removed from it, but ceramic tiles are left, and if necessary, non-combustible material is mounted at a certain height.

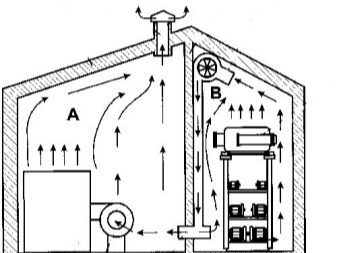

Ventilation

In the room where you plan to place the gas unit, you need to properly consider the ventilation system, including the presence of exhaust. You can do it yourself.

If the boiler is in the kitchen, half of the problems are solved., because such a space in a typical high-rise building is already equipped with a general house ventilation system. If the device is in the boiler room, you will have to figure it out on your own.Typically, the ventilation channel is mounted in the ceiling and out. The door also makes a hole in which the grille is installed. A kilowatt of boiler capacity should account for 10 square centimeters of air outside and 30 square centimeters of air from other rooms - it is easy to calculate the required grid size using these numbers.

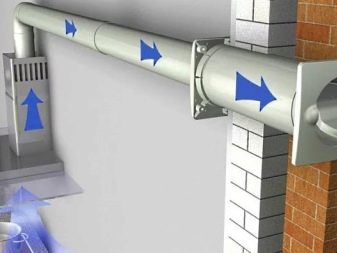

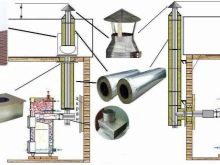

Pay attention to be and chimney. It can be made of a corrugated tube that will follow to the roof of the building, or it can exit through the wall and be different in a compact size. The second version is called coaxial and is suitable for devices of relatively weak power, as well as hinged models. Chimneys are mounted according to fixed rules, but the main thing is that the by-products of the work do not end up inside the room.

The diameter of the chimney should be larger than the pipe that goes out of the boiler.

Mounting technology

Although it is worth recalling once again that the installation of gas boilers is carried out exclusively by experts, knowing the technology is not superfluous. The installation scheme is provided by gas services, it is always unique and suitable for a specific situation.Installation should not be carried out in too cool or too hot weather. The temperature should be in the range of 5 to 35 degrees Celsius.

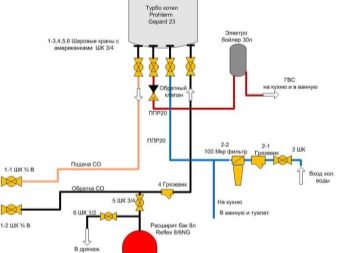

At the first stage, a mark is drawn on the wall for the bracket on which the device is suspended. If a two-circuit device is to be installed, then a filter with a shut-off valve is attached to the return pipe, serving the heat exchanger. On both sides of the filter and on the pipes are installed taps. When connecting the boiler to the general gas supply system, a meter, a gas valve, a thermo-shut-off valve and a special device will be placed next to it, which will report excessive gas contamination.

If the boiler requires energy, the socket must be grounded. Ideally, of course, connect the equipment to the generator to avoid interruptions in operation. After the nozzles are connected to the water supply and gas pipeline, the system is slowly filled with water, and the boiler is disconnected from the mains. At this point, you need to monitor air stagnation - it should not be. Before starting, it is checked whether the pipes are connected with high quality, and whether a gas leak threatens.The test is carried out in a fun way: foam is whipped from soap or dishwashing detergent and applied to the pipes. If there is a leak, bubbles will begin to inflate, and if everything is in order, then the foam will slowly settle. After that, you can start work.

There are also some tips and recommendations for installing different types of boilers:

- Dual-circuit models will require connection to cold water flow under sufficient pressure.

- The boiler is installed so that it is easy to dismantle for any purpose. To simplify the process, a valve must be installed on each pipe attached to it.

- After installation of the boiler is strapping. This term refers to the connection of three systems: electrical, gas and hydraulic. Connection to the propane tank or trunk pipe is always carried out by a specialist, the rest can be done independently.

- If antifreeze with polypropylene was previously poured into the heating system, it must be removed. To do this, the water is drained and the system is washed twice. Otherwise, the chemical may even explode.

- An excellent idea would be to connect a boiler with indirect heating and the boiler itself. The following cycle will occur: hot water from the boiler will heat the walls of the boiler, and they, in turn, will water in the tank. An even better solution would be to buy an electric heater.

- The acquisition of a parapet gas boiler means that it will not have a chimney, which is very suitable for rooms in which equipment of a traditional variety is simply impossible. The chimney is made of just a pair of pipes, which are located in one another. With the help of the external air is in the chamber, and due to the internal output of the combustion products.

- The presence of a room thermostat will save the device from the rapid loss of its performance. Mainly, it provides control and regulation of the temperature in the room.

Safe operation

There are certain rules for the use and maintenance of the heater, that allow you to successfully operate the device for several years:

- The processes occurring inside the gas device are not only complex, but also dangerous for the health and functioning of the individual, but also for the integrity of the equipment.From this it follows that they must be constantly monitored, provided by either a person or an automated device. The boiler protection system is required to turn it off if the process is disturbed in order to eliminate the causes of failure of the normal mode. For example, a thermostat is a security feature.

- The most dangerous situation is the one in which all the burners suddenly die out, and gas accumulates in the room. Among the reasons for the extinction of the igniter, the pressure drop below the norm or the disappearance of thrust. In this case, it is necessary as soon as possible to shut off the gas supply to the burners with your own hands or using a specific device.

- It is important to provide the boiler room with gas analyzers, which will give a signal in case of violation of the norms. In addition, it is worthwhile to install an emergency electronic valve connected with them - it will be able to independently shut off the gas supply.

- Once a year, or even better than two, it is important to check the gas device by the special services. A professional will not only eliminate violations, but also clean the chimney, remove scale and replace the parts that need it.

- Combustible and explosive materials should not be stored near the boiler and in the room itself. These include gasoline with paints and varnishes, as well as firewood and paper that are completely safe at first glance.

- As soon as you feel the smell of gas, immediately need to shut off its flow. At this point, it is also important to ensure that no sparks or open fires arise in the gas-filled room. It should be borne in mind that a spark may occur even with the usual inclusion of electrical appliances. After that, all the windows open, the airing of the room is organized and the gas service is called. Such a situation is especially dangerous in the basement, so if the boiler room is located on the basement floor, vigilance should be doubled.

- Do not lean objects against the working boiler and lean yourself against it. The minimum allowable interval is 200 millimeters.

- Periodically it is recommended to monitor the water pressure in the system.

- Boiler feed is made only when the structure has cooled down, otherwise there is the likelihood of thermal disturbances.

- The protective cover of the viewing window must always be closed.

- Independently it is not necessary to engage in adjusting the sensors and dismantling the boiler.

- Independent opening of the installation is prohibited. Otherwise, the person who did this could get burned, cut, and electrocuted.

- You can not neglect the use of wires that supply electricity. It should not be heated or subject to any other damaging effects.

- You should not climb onto the gas boiler - deformation of the mountings and even failure of the boiler are possible. In particular, this applies to the wall copy.

- If it is necessary to clean the boiler, then the procedure can be carried out only by standing on a stable surface, which does not include stepladders or stools.

- Cleaning is carried out only when the device is disconnected from the mains.

- Solvents and aggressive agents should not be used for cleaning, it is better to use those used in the bathroom for enamel cleaning.

- The boiler should not be accessible to children and people with disabilities.

- Work on the limit is extremely dangerous, as well as overloads and other deviations from the norm.

- If the object is installed in a room where the humidity is high, then you should be prepared tothat metal parts can quickly rust and scale.

- Construction and repair works are prohibited near the installation.

- It is important to regularly clean the pipes, chimney and burner, as well as a tightness check.

How to install a gas boiler, see below.