Paint on metal: characteristics and subtleties of choice

Our time is marked by the emergence of new materials based on synthetic, but this does not negate the widespread use of metal. Constructions from it are an integral part of apartment buildings, as for suburban construction - there is even more active use.

The popularity of the metal is due to its properties, such as the ratio "price-quality", strength, resistance to temperature extremes. However, this material also has its “Achilles heel” - susceptibility to corrosion, as a result of which it needs to be painted.

Surface features

When carrying out repairs, it must be remembered that any iron construction needs to be protected with anti-corrosion agents.To do this, a primer must be applied, creating an invisible layer on the coating, due to which moisture does not get to the surface.

The surface of the metal can be as complete as it may contain traces of destruction. Evaluation of the outer layer determines the choice of paint - on metal or rust. In addition, the product can be from black, colored, galvanized and any other type of metal. This is also of great importance when choosing a protective coating. For example, non-ferrous metals are dyed with a special single-component enamel.

Its peculiarity is that after painting the structure is protected from burnout, as well as from corrosion under the influence of precipitation.

In addition, the surface may vary in size: be large and small, may be figured, such as a fence, and may require a mirror coating, such as a car's wing. Products can be placed both outside and indoors, which will also require different types of coatings and methods of their application.

The radiator of the central heating battery and the “bronze” handle on the front door need different types of paints and completely different ways.staining.

Types of paint: advantages and disadvantages

The main types of paints are:

- alkyd;

- acrylic;

- epoxy;

- oil

Epoxy enamel is extremely toxic because of the components that make up it. Therefore used very rarely. It is designed to protect the metal from heating to high temperatures.

AT oil paints The main components are natural oils and linseed oil. They do not withstand temperature changes, because used mostly for interior decoration. Another disadvantage is that they do not protect the metal structure from corrosion.

Alkyd species (enamel) extremely flammable. However, this category of paints is quick-drying and has good adherence. Enamels are well suited for dyeing galvanized metal, and also prevent the structure from rusting..

Acrylic can withstand high temperatures, coatings of this type can be painted, for example, central heating batteries. It is wear-resistant, not subject to cracking and fading, provides protection against corrosion. Does not lose gloss, does not turn yellow and is not oxidized.

Also acrylic paints are eco-friendly, they are washed from hands and tools with water before they dry. After drying, the acrylic becomes water resistant.. It is not surprising that this type of dyes is gaining increasing popularity in the market, despite its high price compared to other types.

Of the minuses, apart from the high cost, it is also necessary to note the need for thorough surface preparation before painting.

Great for metal constructions water paint. She has good adhesive ability and elasticity, it is not flammable, does not emit harmful substances. It can be used on industrial facilities.

Zinc mineral paints provide better corrosion protection - up to 25 years. Polyurethane paint is also good for this purpose. For example, a two-component primer enamel is a symbiosis of such properties as wear resistance and rust prevention.

In addition, it is frost resistant, immune to the effects of sea and fresh water, with a glossy shine. There are also semi-gloss polyurethane paints.

If need mirror paint under chrome, it also exists. There are two types, but only two-component will be suitable for painting metal construction.

The application process is a bit more complicated, since it requires careful surface preparation before painting and creating a protective varnish layer after, but the result is indistinguishable from real chrome. For work with such paints the spray is used, paint rollers and brushes are not suitable.

Suitable for printing on a metallized surface of any degree of contamination or wear. metal marker. It uses safe highly pigmented inks, they are water and heat resistant, lightproof, do not lose brightness for a long time, and are convenient to use.

Nitrokraska (nitro enamel, nitrocellulose) - Another type of coating, which is obtained by treating cellulose with nitric acid. Sold ready to use, does not require dilution. Differs in ultrafast speed of drying, therefore, it is most often applied by spraying. Inexpensive. Very attractive lookresulting from dyeing is another plus for nitro-enamel. But it should be noted that a beautiful coating is obtained only with a long and thorough preparation of the surface before painting.

Other cons:

- combustibility;

- high toxicity;

- volatility;

- the requirement to work only in a dry room (whitish leaks may form on the surface of structures in a raw building);

- fragility - can fly away from the coating upon impact.

In addition, nitrocellulose is incompatible with other types of paints: it cannot be applied over any coatings, only independently.

Colors

Modern industry allows to paint metal surfaces in almost any suitable color to the owner. Basically, of course, these are simple colors: blue, red, white. What to do if you need a complex shade?

You can get it yourself or by resorting to the help of professionals. Three options:

- tinting;

- mixing different colors of the same type of paint;

- adding a special powder.

Coloring is the addition to the base white of the dye of the desired color - color scheme. If the shade is very complex, it is possible to add several colors. Best for tinting suitable water-based formulations - silicone, acrylic.

There are two ways - computer tinting and manual. Both are not easy. In the first case, the selection of the composition performs the computer, it is convenient for cases when you need to repeat the tinting (not enough mixed coverage, for example).

However, the accuracy of this option can limp, and the pleasure is not cheap.As for hand-tinting, almost any shade can be achieved here, but there is a risk of not being able to repeat it exactly the second time if needed.

When mixing several colors, the principle of operation is the same; only white is taken as the basis, but a different color. For example, for get orange mix red and yellow.

It is possible to achieve more complex color solutions. The method is suitable for coatings that tinting is not suitable.

As for the powder method, it is best suited when you need to create an imitation of a metal - silver, bronze. For example, using copper powder, you can get paint "under the copper." The more in the composition of the main paint powder, the more believable effect of a valuable metal is obtained in the end. The optimal ratio is 20% to 80%.

For example, chrome-plated paints with a mirror coating will put on any piece of metal in gold or silver, will give the surface any tint - copper, bronze, iridescent. By the way, these dyes are quite affordable.

Black and gray are suitable for non-residential premises, and for living space it is better to choose brighter colors: green, blue, red, orange.

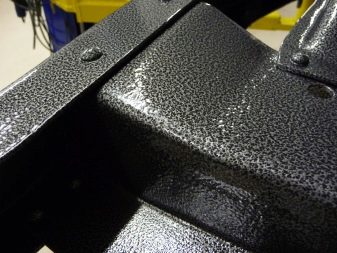

If a paint with a hammer effect is chosen, similar to the prints of a blacksmith's hammer, its color range is modest. It consists of standard black, white, and several other simple colors. But they can paint the product in gold, copper or bronze. The advantage is that such paints are sold ready for use. They do not need to be mixed and dissolved as powder, but you just open the lid and mix thoroughly.

Each manufacturer of paints for metal has its own color palette, for someone it is very wide, for someone - only basic colors. The consumer has the opportunity to choose a product to your taste and wallet.

How to choose?

What paint on metal should be chosen by the consumer depends on a number of factors. If the design is planned to be exposed to high temperatures, oil and alkyd types will do, they can withstand heating up to 80 degrees Celsius. Acrylic paint is suitable for painting central heating batteries, some types of epoxy and alkyd paints that easily tolerate 120 degrees.

The most heat resistant are:

- polyurethane paint - up to 150 degrees;

- epoxy bitumen - up to 400 degrees;

- paints based on silicone resin - up to 600 degrees, such are suitable, for example, for painting the furnace.

If important to paint was not toxic, the best choice would be oil or acrylic. Acrylic paint in many cases is the most preferred, as it is durable and non-flammable. It can be used not only in the production of interior finishing works, but also for painting metal, other iron roof elements, if the original paint has burnt out or signs of corrosion have appeared.

Alkyd paints are toxic, but their popularity is based on high adhesive properties. If the structure needs protection against corrosion, then primer-enamel will do., they are not inferior in quality to the usual compositions in the work of rust. Polyurethane compounds are suitable for use in sub-zero temperatures.

For staining entrance doors suitable coating with a hammer effect. And to paint the metal fence traditionally used alkyd, oil, polyvinyl chloride paint, as well as enamel on the basis of chlorinated rubber.

For painting parts of the product that should be seen in the dark, a reflective paint (also called retroreflective) paint is suitable. It can be on acrylic, polyurethane, alkyd basis.

If the fence is galvanized or aluminum, then the only option is dispersion acrylic paints. According to consumers, Cyclole paint is the most popular in this segment. Packaging is made in cans with an aerosol dispenser, in buckets, cans.

In case it is necessary to paint and at the same time insulate metal pipes or pipelines, thin liquid ceramic heat insulation for metal will do.

It is a single component, made on the basis of water, protects steel structures from corrosion, can be applied to scale or rust.

For decorating metal products best suited acrylic paints, they can even be used for allergies. On such types of coatings should always be marked "decorative". They come in many different shades, but gold and silver are best for decorating metal.

When buying materials of domestic manufacturers, it is better to choose those of them that are made in accordance with GOST. Then you can count on better quality, higher performance properties.

For interior work

In these cases oil and acrylic types are used. They are non-toxic, dry quickly, retain color if there are no permanent external effects on the painted surface. Nitroemal is also often used because it is incompatible with a moist environment.

The use of toxic paints such as acrylic or epoxy, it is better to avoid for interior decoration, despite their durability and better adhesion to the surface.

The choice of a specific type of coating is made taking into account the characteristics of the product that require painting, as well as the impact of factors that the painted surface will be exposed to during operation: high temperatures, humidity, direct sunlight, etc.

For exterior finish

For the production of outdoor works, it makes sense to buy paint marked “weatherproof”, since its composition is designed specifically for the street, taking into account all types of environmental influences.This type of coating is composed of high-molecular silicones.

In order to paint a galvanized surface, not every dye is suitable. For her, there is a separate group of materials. They can be in the form of a powder that must be diluted or in the form of a finished mixture.

To prepare the metal structure for exterior finishing, its surface is cleaned of plaque, dust, dirt, and also rust, if the paint is not painted with rust. If necessary, the surface is also degreased.

Best for outdoor work dyes with hammer effect. Their quality scores are highest.. However, due to the high consumption and high price, they are better to choose when you want to paint a small surface. You also need to know that this type of dye requires applying a primer of the same brand. If the consumer is not limited in expenses, this coating is suitable for painting any surface in air.

Famous manufacturers and reviews

The leading manufacturer of decorative paints in Finland, Sweden and Russia is the company Tikkurila. The company has been operating in the Russian market for more than 10 years, which is why it’s known even to people who are far from repair work.Products that are manufactured under its brand, has always been popular with the consumer, as it has high quality and is represented in all price segments: economy, medium and premium.

Tikkurila coating is wear-resistant, not affected by lubricating oils and various types of fats.. The company produces types of paints for interior and exterior. Heat-resistant paints are also in the range. Feedback on the products of this company in the overwhelming majority of extremely positive. A variety of products and the ability to choose to your taste and wallet only contributes to this.

"Novbythim" - domestic manufacturer. The company produces primer-enamel "3 in 1", which is not only decorative, but also a protective coating. Suitable for interior and exterior, for glossy and matte coatings. Plus is that it the coating is resistant to temperature fluctuations and to the manifestation of environmental influences: it can be applied at temperatures up to - 10 degrees Celsius. Customer reviews on Novbythima products are mostly good. It is noted as the ratio "price-quality" and the low price, availability of goods in principle.

Another brand - Hammerite (manufacturer Akzo Nobel) - The founder of the production of anti-corrosion paints, as well as painting technology directly on rust. The coating has a scaly structure, and this is an additional barrier in the path of moisture and air to the metal surface. Coatings are distinguished by high adhesiveness, even if applied over corrosion.. Constancy of appearance - at least up to 5 years. Also these colors are distinguished by an interesting and unusual texture. Consumer reviews on the coverage of this brand are mostly positive, the only negative is the high cost of Hammerite products.

Of course, there are still a very large number of products from various manufacturers on the market, you just need to choose.

Useful tips

- Paint should be stored at temperatures from - 15 to +25 degrees Celsius. Before applying most coatings, they must be heated to room temperature. Shelf life without loss of quality - no more than 6 months. Then it should be thrown away.

- It is necessary to paint the heating system only when the equipment is turned off. Best of all, when the heating season is over, that is, in the summer time.A dye capable of withstanding at temperatures up to 150 degrees Celsius is used in this case.

- For coloring non-ferrous metals only special type primers are used.

- In order to paint the oven, you need to use paint that can withstand temperatures of more than 500 degrees Celsius.

- For exterior painting of metal structures, organic solvents should be used.

- If the area that needs to be painted, there are spoiled by the fate of fate that depart from the surface, they must be removed before painting.

- Before starting work, it is worth checking the temperature characteristics of the paint for compliance with their thermal resistance of the object.

- If the coating of a metal structure occurs in a period of low temperatures, it is better to take a winter quick-drying paint, for example, a Fast Metro. Compounds of this type can be applied at temperatures up to - 20 degrees Celsius.

- Metal coating is prohibited to apply to surfaces that come in contact with drinking water.

How to choose paint for metal you will learn from the video below.