Principles of choice of roofing screws for metal

The modern market of roofing materials is constantly evolving, which leads to the emergence of new substances that can replace conventional slate. But to obtain durable roofs there is not enough of one material - here you also need to take care of fasteners, which also have changed. Increasingly, special screws that differ in shape and quality are used to fasten metal products.

Special features

Roofs today are often covered with metal tile or other similar products. A feature of almost all metals is the high risk of corrosion when exposed to water, which, in turn, affects the quality and durability of the structure.To minimize this effect, professionals recommend using special roofing screws as fasteners.

Metal hardware has several significant advantages over other similar products.

- Highly reliable connection. At the same time, its decorative appearance is much more qualitative, which affects the external characteristics of the entire surface.

- Easy installation. This allows the fastening process to be speeded up several times.

- The self-tapping screw easily gets out. If necessary, it is easy to dismantle without damaging the metal surface. This feature also allows you to apply such hardware again in other systems.

Roof fasteners are almost devoid of flaws. The only disadvantage of such products can be considered poor-quality washers and rubber seals. If these elements do not fit tightly with each other, then water may fall under them. Therefore, such a hardware will not last long, and its use will lead to the formation of corrosion on the roofing material itself.

Make these screws according to GOST. As materials use several types of metals:

- carbon or alloy steel;

- brass.

This product has almost no differences. But steel products are much cheaper than brass hardware.

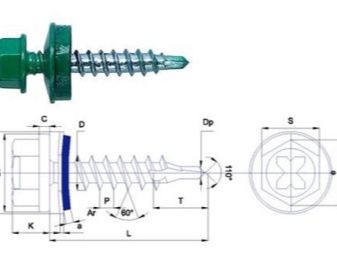

The fixture consists of several basic elements.

- Head. In most cases, it has a hexagonal shape.

- Tip. It is presented in the form of a small threaded rod. At the end of this element there is a special tip in the form of a drill. This allows you to pass thin sheets of metal without the additional application of the classic type of drill.

- Washer and rubber gasket. It is both of these elements that prevent the penetration of moisture under the screw head. They also provide a reliable fixation of the roofing material and prevent the occurrence of movement.

Kinds

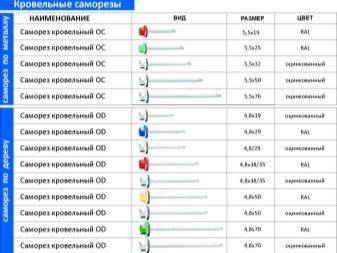

Roofing screws appeared relatively recently: after man began to use metal sheets as materials for roofing. Depending on the environment of use, roofing screws can be divided into the following groups:

- By metal. Products are intended for fastening metal elements. All types of such hardware are equipped at the end with a kind of drill. They also have an increased diameter.This design allows you to apply them to different types of metal products. The self-tapping screw of this kind can drill metal profiles up to 1.2 mm thick.

If a preparatory hole is drilled in the profiled sheet and the supporting metal frame, then fasteners can be used for systems with a thickness of up to 6 mm.

- On a tree. Screws of this type can be called universal - they are very often used for fastening different materials. It can be not only metal and wood, but also metal and plastic. The tip of such a hardware has a sharp end without a drill, so before you mount it in the metal sheet, you must first drill a hole with a classic tool. Another distinctive feature can be considered a thinner diameter than that of metal hardware. Both of these varieties can be complemented by a washer and rubber gasket.

Another criterion for separating screws is the surface treatment method.

- Galvanized. This type of fastener is one of the easiest. Experts use it to fasten materials from zinc. This includes almost all types of skates and wind slats.

- Colored. This type of screws is versatile, as it is suitable for fastening all types of metal roofing products. Moreover, color products are much easier to choose the color of the roof, making the surface uniform. There is also a classification according to the type of cap. Today, screws with a hexagonal surface are considered popular. Their installation is carried out using special bits. But manufacturers also produce classic models for a flat and cross-head screwdriver.

Dimensions

Almost all types of hardware are classified by size. The criterion for this separation is the diameter of the leg and its length, so many manufacturers specify these parameters.

Today, all roofing screws are standard and are available in many sizes.

- Diameter. In almost all types of wood screws, this figure is 4.8 mm. But for metal hardware, the diameter can vary from 4.8 to 6.3 mm, while manufacturers produce them only with a certain step.

- Length. This figure varies already in a very wide range. The smallest products have a length of only 16 mm.There are hardware in which this parameter reaches 150 mm. But such long screws are used only in the case when you need to fix the multi-layer construction. For roofs very often use products with a length of 16-80 mm.

It is worth paying attention to the fact that the thickness of the hardware depends on the length: the longer the screw, the larger the diameter. This allows the structure to withstand high loads arising during installation.

Consumption calculation and installation

Roofing screws are used with different types of materials. Often this may include decking, metal tile and other coatings. But before you start laying the sheets of the roof, it is important to find out the necessary amount of hardware for the entire roofing area.

The algorithm for calculating the volume of screws can be divided into several successive steps.

- First of all, you need to calculate the total area of the entire roof. If the structure has a complex shape, it can be divided into several separate segments.

- After that carry out the calculation of the amount. Initially, the rate of hardware for 1 m2 of a specific roofing material is specified - often all these indicators depend only on the specific type of roof.For example, for constructions of corrugated board you will need from 5 to 8 screws per 1 square. m. If you plan to lay the metal, then this value will increase to 8-10 fasteners per 1 square. m

You can find out the exact value from the manufacturer of the roofing material. Often, it indicates the frequency with which the screws are used. You can also get acquainted with these indicators in special summary tables, which are located on various specialized sites.

The algorithm for working with screws implies compliance with several rules.

- They need to be screwed only at the bottom of the wave. If you use this approach, the profile sheet will not bend, and it will withstand external loads well.

- Screws should be located only at right angles to the roofing. If you tighten them at an angle, then there is no guarantee that the system will be able to withstand the load.

- When screwing, it is necessary to observe a certain effort. It is important not to squeeze the puck, which at the same time forms a hollow. You should also check whether the rubber is pressed to the material - there should be no gaps between it and the surface.

It is desirable that the screw head and washer lay parallel to the sheet, tightly pressing it to the frame.

Tips

The reliability of the roofing depends only on the fasteners used, therefore When buying or working with it, you should follow a few simple recommendations.

- When buying screws you need to check their quality. For good products, the rubber gasket must be flush with the washer. If it is not, then it may be evidence of marriage. As for the washer, then it should be tried to bend with pliers - at the same time, the quality of the products will not crack the paint.

- For roofing, you need to use color modifications of hardware, which will allow not only to match them to the color of the coating, but also to extend its service life.

- Preference should be given only to products of well-known manufacturers - this is a kind of guarantee of quality products.

Roofing screws for metal are unique products, without which installation of many roofs cannot do today. When buying them, it is important to consult with experts who will be able to choose the optimal size of fasteners to solve a specific task.

Details about the roofing screws, see the following video.