Characteristics of modern roofing materials

A variety of modern roofing materials can capture the imagination. They not only ensure the reliability of the coating, but also delight in their appearance. Among them are “long-livers” with a lifetime of about 200 years and relatively short-lived, but very inexpensive options. And there are also highly functional, providing status and the title of "smart home".

Special features

Roofing materials are the outer part of the complex structure of the roof, and the roof itself may consist of one or several layers.The degree of protection against atmospheric phenomena and heat preservation depend on its structure.

Coatings of private homes can be made of natural materials, organic, mineral and synthetic options. The production of many products, their dimensions and characteristics are governed by the State Standards and SNIPs. Classical shingles, for example, do not have a production schedule, its quality is determined only by the raw materials and the firing temperature conditions.

Duration, quality of operation and difference in the properties of products largely depend on the composition. Thus, polymers last more than twice as long as their organic bitumen classmate. Minerals beat them both for safety, because they are not flammable. Ceramics and slate easily absorb moisture, so their weight after rain can increase significantly. And the metal roof noisily reacts to rainfall.

Classification: Pros and Cons of Varieties

All roofing materials for the roof are divided into four types: piece, soft, sheet, liquid (mastic). It is simply impossible to find out what structures of various purposes are covering today without familiarizing with the main species.

Sheets

This large group includes rectangular or square metal sheets having sufficient rigidity. The method of attachment of such a roof is overlapped or special seams - folds.

Sheet species include smooth coverings, metal roofing, roof with seam seams, ondulin, decking and slate.

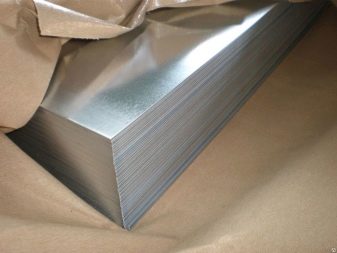

Flat

Produced from steel (not to be confused with corrugated board) and aluminum. The metal may have a protective coating of zinc or polymers - polyester.

For galvanized metal there is no strict size limits. The width can vary from 750 to 1800 mm, length - 2000-2500 mm, thickness - 0.45-1.2 mm. For polyester, the standard size of a flat sheet is 2000x1250 mm. The length can be higher - from 3 to 10 meters (depending on the length of the mill).

Thickness is 0.45-0.7 mm. Unlike galvanized varieties, there is a large color choice. The warranty period is 10 years.

Advantages:

- when laying there is little waste;

- with sufficient thickness withstands heavy loads;

- flexible, relatively inexpensive.

Disadvantages:

- galvanization is not very beautiful;

- metal makes noise when precipitation falls;

- requires sound insulation;

- thermal insulation for residential buildings and lightning rod.

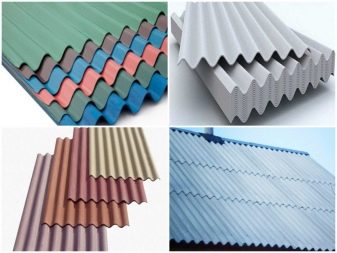

Slate

Under this concept hides almost the entire group of sheet materials. The fact is that since the times of the Middle Ages such a type, then exclusively natural coatings, had a wavy shape. Nowadays, corrugation is made from different materials, and slate can be based on metal, plastic or rubber.

The classic is considered to be an option of asbestos cement, and it can be both flat and wave - from 5 to 8 amplitudes. Forms differ in height and width of a profile, in the way of laying. Produced according to the norms of SNiP. Thickness is 6, 8, 10 and 12 mm.

There are three types of standard sizes of corrugated sheets:

- ordinary (VO) - 1200х680 mm;

- reinforced (WU) - up to 2800 mm;

- unified (HC) - 1750х1125 mm.

The parameters of flat slate are from 2500x1200 to 3600x1500 mm. Modern models may have soft colors - traditional gray, green, red. It is used for laying on the roofs of household buildings, less often residential, as it is considered not quite safe for human health.

Advantages:

- ease of installation;

- does not burn, frost-resistant;

- has low thermal conductivity;

- does not produce noise during precipitation;

- small price;

- the actual service life without loss of quality - from 10 to 30 years.

Disadvantages:

- fragility;

- burnout;

- susceptibility to mold and moss formation.

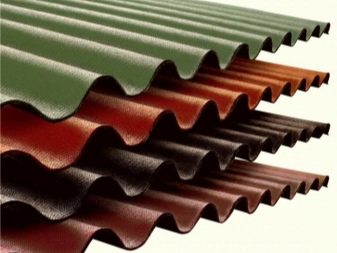

Ondulin

It has a lot of names and varieties: euro-slate, asbestos-free, soft, bituminous, wavy sheet. You can find analogues - aqualine, nulin, ondur, gutta.

It is made of multilayer pulp (cardboard) impregnated with bitumen with the addition of resins and polymers. Painted with acrylic. The surface is glossy or matte. In the second version has a rough top layer.

Designed for registration of economic extensions. The maximum lifetime of an ondulin is up to 50 years. The height of the ridge - 36 mm, weight - 6-8 kg / m2. Dimensions of standard sheet - 950x2000 mm, thickness - 3 mm.

Advantages:

- can withstand heavy snow loads;

- flexible;

- waterproof;

- plastic;

- belongs to the category of noiseless;

- has a beautiful appearance.

Disadvantages:

- softens at high temperatures, and when negative becomes brittle;

- burns out unevenly;

- combustible;

- high price

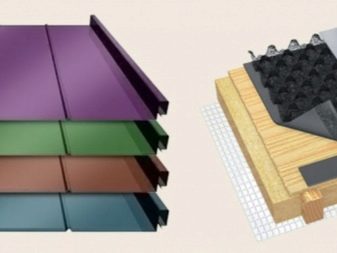

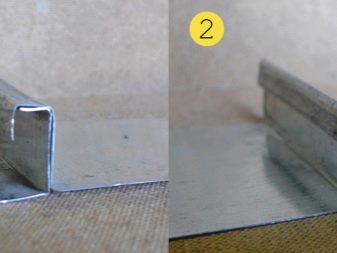

Faltsevy roof

Available in steel (galvanized), aluminum, copper or zinc-titanium alloy. All options, except copper, may have a protective coating of polymers.The weight of one product depends on the metal: for steel - from 5 to 10 kg / m2, aluminum - 2-5 kg / m2.

Sheet options:

- thickness - from 0.45 to 0.55 mm;

- reinforced thickness - from 0.63 to 0.7 mm;

- width - from 510 to 1250 mm;

- length - from 710 to 3000 mm.

For copper:

- thickness - 0.3 mm;

- length - 1100 mm;

- width 700 mm.

A distinctive feature - the elements of the roof are interconnected by means of folds (vertical and horizontal), which provide reliable sealing of the coating. Operation - from 25 to 30 years.

Advantages:

- ease;

- strength;

- durability;

- wide range of colors;

- for copper and aluminum - patinated;

- materials are suitable for installation at any angle of the slope of the roof;

- The most popular type of roofing for private houses.

Disadvantages:

- makes a loud noise when it rains;

- requires additional thermal insulation, sound insulation and installation of protection against lightning strikes.

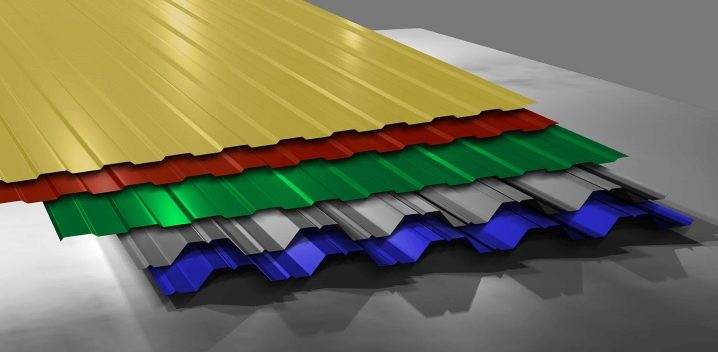

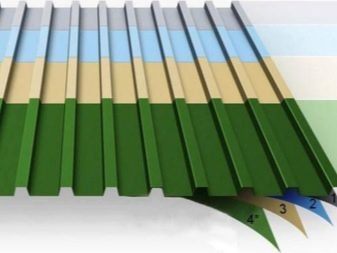

Decking

He is a corrugated sheet, professional sheet, profiled flooring, having a rectangular, trapezoidal or wavy cut. For metal sheets, production is carried out according to GOST 24045-94, which establishes the dimensions and parameters of products, including the thickness of the protective layer (galvanization).

The length of roofing materials is from 0.5 to 14 m, in half-meter increments. Thickness - from 0.45 to 1.2 mm. The width that can be measured with a tape measure depends on the height and frequency of the profile waves: the higher and more often, the narrower, but stronger the sheet. There are brands C8, C21, HC35, C44, H57, H60.

For comparison width:

- C8 - 1200 mm;

- H75 - 800 mm.

The professional flooring has a useful or working width. It is calculated taking into account the overlap, which is recommended when laying. For example, the linear width of the C8 is 1200 mm, and the working width is 1150 mm. Most often, the material is used to cover industrial and household objects, such as facade panels. The lifetime of the roof is up to 50 years.

Advantages:

- strength;

- flexibility;

- affordable price.

Disadvantages:

- like all metal types, it makes noise when it rains;

- requires heat insulation and lightning discharge system.

Metal tile

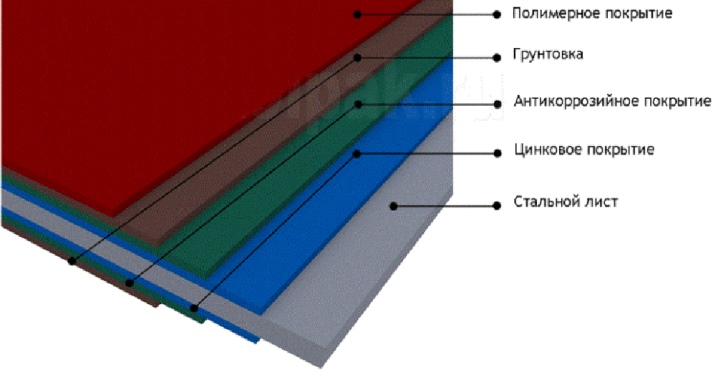

Sheet tiles are based on metal profiles made of galvanized steel, aluminum or copper. The shape of the metal imitates all types of natural tile: steps, waves, scales. The coating can serve as polymers - on one or two sides.

The most common products with the outer polymer layer and the inner part of the plate, treated with paint.In the case of composite materials, the working surface is decorated with stone chips. The characteristics, quality and price of the material depend on the characteristics of the protective layer.

It is used for all types of residential and technical buildings. The length of the finished sheet is from 50 to 800 cm. The thickness of the base is at least 0.5 mm.

Benefits:

- small weight;

- strength;

- resistance to precipitation and deformation;

- wide color palette;

- simple installation.

Disadvantages:

- when precipitation makes noise;

- when laying gives a large percentage of waste;

- additional expenditures are necessary on the arrangement of the heat-insulating, noise-absorbing layer, installation of a lightning rod and grounding.

Piece roofing

Pieces are small in size coating elements. Presented by a wide selection of various forms of tiles from natural and artificial materials. There are ordinary - for the main coating and special - for the design of the ends, windows, elements of ventilation, antennas or chimney (walk-through).

There are products:

- small pieces - no more than 15 pcs / m2;

- standard - usually do not exceed the size of 30x30 cm;

- large-format - 9.5 pcs / m2.

This roof has a beautiful appearance and high price.Fastening is carried out on special locks.

Laying:

- parallel - creates clear horizontal lines of coverage;

- with offset - scales effect, more reliable protection against precipitation

Ceramic

Such a tile is made of baked clay (red-brown) and painted in a variety of colors. Sometimes it is coated with glaze on top, which increases the moisture resistance and durability of the material, while the upper layer acquires a bright gloss or dullness. Some manufacturers make materials with dirt-repellent properties and self-cleaning effect.

According to the profile and method of laying pottery happens:

- stamped;

- flat tape;

- grooving;

- with one wave;

- two wave;

- grooved.

The parameters are not regulated, the thickness of the element varies, depending on the manufacturer, from 10 to 15 mm. The material is heavy, one tile measuring 30x24.5 cm weighs about 2 kg. Apply to cover the roofs of country houses. The real term of operation is from 25 to 150 years.

Among the undoubted advantages:

- naturalness;

- frost resistance and fire resistance;

- beautiful appearance.

The disadvantages include:

- with the strength of the entire roof fragility of individual tiles;

- long installation;

- strengthening truss system and high price.

Cement and sand (CHR)

More rough analog of a tile which is created without roasting. The composition includes quartz sand, cement, coloring and other additives that increase the strength of products. In some cases, the material is coated with icing. Profile - wave or flat.

Scope of application, size, thickness are similar to ceramic samples. Service life - 50 years.

Benefits: in comparison with natural ceramics has a lower price.

Disadvantages: a large percentage of losses during transportation - up to 10%, rough appearance.

Polimerpeschanaya

It is made from river sand with the addition of plastic waste, binders and dye. Compared with the previous types of tiles easier, weight often does not exceed 2 kg. Somewhat stronger, the percentage of combat is small.

Provides full moisture impermeability and low heat conductivity. The tile is capricious for sudden temperature changes, otherwise it has all the advantages and disadvantages of a piece roofing. Operation - no more than 30 years.

Metallic

The vast majority is a composite material, based on steel, aluminum, titanium-zinc alloy. The exception is copper, it is always used only in the form of pure metal.

The profile repeats natural tile. Available in rectangular or diamond shape, which allows for the laying of all kinds.

Benefits:

- wide color palette due to the polymer layer;

- small weight of the roof;

- easy installation

Disadvantages:

- noisy;

- the need for additional thermal insulation;

- the need for anti-lightning systems and high cost.

Shingles

Wooden tiles (chipped and sawn) are made by hand from extremely durable and relatively inexpensive wood: oak, aspen, spruce, larch or Canadian cedar. Over time, the coating darkens significantly, acquiring natural shades of dark brown and deep green - antique. Sometimes shingles are covered with paint. Unlike other types, it does not have a longitudinal cut for fastening.

Popular sizes:

- length - from 200 to 800 mm;

- width - from 60 to 250 mm;

- thickness - from 60 to 150 mm.

Benefits:

- environmental friendliness;

- resistance to external atmospheric phenomena;

- absolute tightness;

- easy installation;

- relatively low price.

Disadvantages:

- fire hazard;

- susceptibility to rotting, the formation of moss and mold, which requires constant treatment with special impregnations.

Slate

It is the most expensive type of tile roof, has a maximum service life - from 70 to 200 years. It is produced from a mountain stone (slate) in several forms: square, rectangular, with one rounded end - “beaver tail”. In the profile - flat or with a light wave, that is slightly convex. The thickness of one element - from 4 to 9 mm, weight - 45-50 kg / m2.

Benefits:

- respectability;

- the uniqueness of the laying;

- water tightness;

- incombustibility;

- deadline life.

Disadvantages:

- fragility - up to 15-20% loss during installation;

- the color palette is limited by the color of the stone;

- great weight.

Soft

Such roofs are distinguished by flexibility and plasticity, which makes them very convenient when laying on structures of complex shape. The basis can be cardboard, synthetic fabric, impregnated with bitumen. The resulting materials have absolute water resistance and demonstrate high thermal insulation properties.

They do not make noise during a rain, on them the mold or a moss is not formed. Rafter system does not require amplification. Laying does not make special work and the waste practically does not remain.

There are three subspecies:

- tiled;

- roll;

- membrane materials.

Roof tiles

Its other name is shingles. It is made with sheets with figured cuts in the form of rectangles, squares or other shapes imitating a classic tile covering. Used as a cover on economy class homes or outbuildings.

The basis of the material - fiberglass (stekloizol), which is impregnated with bitumen, tar composition with reinforcing additives. The outer layer - with basalt, rarely shale, sand or copper tapes. The inner side is covered with a protective polymer film. The real life is about 40-50 years.

Benefits:

- snow retention, which ensures the presence of crumbs;

- nice appearance.

Disadvantages:

- softening under the influence of high temperatures;

- combustibility;

- loss of ductility at negative values;

- fragility.

Roll roofing

From the title it is clear that the material is produced not in the form of sheets, but in rolls. The production method and composition are no different from roofing tiles. The material is used to cover private houses, good for flat or low-angle roofs. Often used as a waterproofing layer.

The subgroup is big enough. Differences between species may be at the base or additional layers that provide improved performance. The average specific weight is 7-10 kg / m2.

Subspecies:

- on a cardboard (from 1 to 5 layers) and mastic - roofing material;

- with a layer of foil - metalloisol, folgoizol;

- based on cellulose or PVC - can be molded, resemble asbestos cement sheets covered with paint layers;

- with an additional outer layer - rubber, stone chips or thermoplastic elastomers, may have a soft color gradient;

- on a non-woven basis - fiberglass, polyester, rubemast, glass fiber, rubestek, bikrost, hydroglass glass, self-adhesive rizolin, uniflex, etc.

Membrane material

It creates a seamless coating with a thickness of 1.14 to 2 mm, which ensures complete tightness of the roof. Available in rolls with an average width of 1000 to 2000 mm. Weight - 1.4-2.0 kg / m2.

Different substances are used as the basis for these insulation materials.

Ethylene propylene diene monomer

EPDM - based on synthetic rubber. Safe, do not emit harmful substances. Rolls up to 12 m wide and up to 60 m long.

There are several options:

- unreinforced;

- reinforced;

- composite.

TPO and PVC

- Thermoplastic polyolefins - contains ethylene (50-70%) and propylene (30-50%).

- Plasticized polyvinyl chloride - has a small proportion of volatile plasticizers that are hazardous to health.

Benefits:

- creates a durable and seamless moisture-proof layer;

- flexibility and elasticity;

- simple installation;

- resistance to mechanical damage.

Disadvantages:

- requires perfect condition of the base of the roof before laying;

- chemical susceptibility.

Self-leveling roof

Bulk materials are in the initial state of the mastic. The composition is applied to the prepared surface, where it freezes. In finished form, in terms of their appearance and properties, self-leveling roofs are similar to roll roofs. For example, there is a liquid roofing material.

Like membrane, there are three types:

- unreinforced - applied in one continuous layer;

- reinforced - with fiberglass or fiberglass;

- composite - from several layers, no more than 2 mm each, including additional protective ones, with powder of stone powder and a layer of paint.

Benefits:

- resistance to elevated temperatures;

- simple installation.

Disadvantages:

- uneven thickness;

- has dangerous volatile compounds;

- the inability to apply when the slope of the roof more than 25 degrees.

For smart home

Reasonable savings and heat preservation in country houses dictate new standards for roofing materials. Self-leveling, membrane and rolled types of coating, for example, fiberglass impregnated with bitumen, are capable of providing absolute hydro- and thermal insulation. Their characteristics are especially important when building a thermos house. Such a roof is quite affordable and justifies itself during construction in the difficult climatic conditions of Russia.

The category of premium for the decoration of the roofs of smart homes is glass tile. It is made of tempered glass, equipped with technical capabilities for the accumulation of light energy. In fact, the entire roof becomes one solar battery. While forces are enough for lighting at night near the territory or heated water for a large family, but the developers do not intend to stop there. The guaranteed service life of such a roof today is about 40 years.

Protective layer

Composite roofing materials imply the presence of a polymer layer, which provides a wide color palette and increases resistance to external influences.Metal, film often have a similar shell or only a coating on the outside.

Overview of the main types

- Polyester RE glossy - the cheapest covering material, 25 microns thick. The main substance is polyester, the coating is scratch-resistant. Such materials are intended most often for summer houses and garden houses.

- Polyester MPE Matte - 35 microns, does not limit the flexibility of the base, does not respond to mechanical stress. It has a small selection of colors. The cost of MPE is lower than that of plastisol.

- Plastisol PVC200 - up to 200 microns, created on the basis of PVC with the addition of plasticizers. Stronger and more plastic than previous versions, resistant to chemical reagents.

- Pural PU - 50 microns, from modified polyurethane with polyamide. Durable and durable coating with a wide choice of colors that do not fade with time.

- Polydifluorite (PVF2) - 25-35 microns, from a mixture of polydifluoride with acrylic. It is glossy and matte. Has the highest performance of all film coatings. The price is also the highest.

Subtleties of choice

Modern diversity allows you to choose the only option that meets all the requirements of both the roof itself and the capabilities of each individual wallet.First of all, they are guided by the features of the main construction in order to provide an ideal technological and operational combination. Then you should pay attention to durability, flame retardant properties, appearance.

Warranty terms for roofing materials:

- soft tile - 20 years;

- membranes, ondulin and metal tile - 15;

- ceramics - 30-50, slate - 40;

- slate - 10-12;

- metal - 40, for copper - from 70 to 100 years

In determining the service life for which the manufacturer is responsible, the type and thickness of the polymer layer is important. Before choosing, it is necessary to determine the angle of the roof.

Each niche has its own particular pricing policy. Thus, in the period of economic crises, the cost of slate and ondulin is the least fluctuating and insignificant increase. This phenomenon is typical for all countries of the world, so planning does not cause difficulties.

Useful recommendations

- Prices for Euro-slate are about the same for all manufacturers, so the main focus is on design and definition of ease of installation.

- The cheapest material on the market is plain unpainted slate.

- Professionals do not advise to choose a metal tile at the lowest prices, as this is evidence of its low quality. Reinsure can only be enlisted with a properly issued guarantee.

- It is worth remembering that the roof of the alloys and composites is always much more expensive than analogue of pure metal.

- A significant price gap is typical for a roll roof, depending on the manufacturer and the quality of the product, it can vary by 6 times.

- Make a purchase only from vendors with official certificates: a fake can cost more than money saved.

The well-known brand, which values its reputation, in addition to the quality of its products, offers a complete set of fasteners and additional elements. When buying instruction is issued. All leading brands test their product, often at every stage of the process.

Installation

Each type of roofing has its own method, and sometimes several options for installation. Roof systems of different design, density of lathing, are used, various special tools are used.

Ceramic tiles

- The system of rafters necessarily strengthens - the step decreases and the section of beams increases.A continuous crate is made.

- Work begins from the eaves to the ridge, for fastening apply wire, staples and nails.

- Elements with grooves are stacked in one layer, the “beaver tail” joints are treated with lime or other protective solution.

Slate roof

Requires reinforced truss system and solid crate.

Installation is carried out by three methods:

- English - as for ordinary ceramic tiles;

- German - scales;

- French - double overlap

The following actions:

- It is fastened with nails. To keep one angle of inclination, a fixing rail is laid under the bottom row.

- At the ridge, the protruding part of the roof of one slope must be higher than the other.

- The joints are treated with a special waterproofing solution.

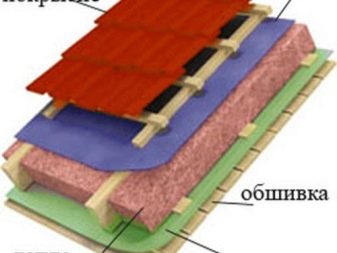

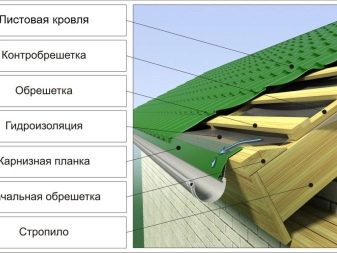

Metal tile

- In some cases, reinforcement of the truss structure is required.

- Requires a clean base and cleaning after all the work. Special conditions for the storage of elements before installation: the room must be unheated, without direct sunlight and protected from precipitation.

- In order to protect the roofing pie from the inevitable appearance of condensate, enhanced ventilation and waterproofing must be installed.It is necessary to be careful in determining the front and seamy sides of the membrane, as in case of an error, the effect may be the opposite.

- For residential buildings require noise and heat protection. When calculating the noise insulation insulation is taken into account.

- The first sheet is laid after alignment on the end of the roof. The following parts are overlapped or overlapped. Fastening screws. Daily and seasonal size changes due to temperature are taken into account.

Euro slate and slate

- With a large roof area and a slope of 20-35 degrees, it is recommended to cover the sheet in several slopes so that snow does not accumulate in winter.

- The crate is made with small cells or solid.

- Sheets are laid from the eaves to the ridge with an overlap of up to 140 mm, minimum - 100. Fasteners - screws and nails through a rubber gasket, which should ensure tightness.

Decking

- The first sheet is laid from the bottom corner, the next in rows are moving up to the ridge. The sheet connects with each subsequent one or two waves.

- It is fixed in each lower profile amplitude on the batten (step - not less than 50 cm) or steel purlins with self-tapping screws with a gasket.

Faltsevy roof

- Before starting work, edges for seam seams are cut and prepared. Collect strips in the entire length of the slope.

- The cake is necessarily protected by a waterproofing membrane, provide for increased ventilation, as condensate forms on the inside of all metal products due to the temperature difference.

- Fastening to a continuous crate spend klyammery. They are laid in such a way that the mounting clamp of the previous strip remains under the lock of the next one.

- Make stand-up folds, which includes the plate plate. Fasteners do not tighten tightly, providing for average daily and seasonal expansion and shrinkage of the sheets. In some cases, seam treated sealant.

Membranes

- The joints are sewn with hot air using special equipment.

- For fastening around the perimeter of the ramp, special fasteners are used, after which the entire cut is sealed.

There are three types of styling:

- ballast - for small slopes, not more than 10 degrees;

- mechanical - for flat roofs;

- glue - for a complex geometry of the base.

Roll Coating

- For coating used single or double layer base. For the first variant, thicker and wider boards are used.

- The blades are fixed from the ridge to the overhang, fixing takes place with the help of vertical slats.

- The finished roof, for example, isol, is subjected to mastic treatment (for the budgetary options, tar-like compositions are used) and covered with clean, sifted sand. Or opened with varnish, and after drying, covered with paint.

- For flat roofs, the deposited material and the corresponding technologies are used.

Bituminous tile is fixed to a continuous crate with waterproofing nails.

Manufacturers

In the building stores today are widely represented both domestic and foreign roofing materials. Enterprises that do not stop at what they have achieved and introduce new, improved coatings, including innovative ones, deserve high marks.

Rating of market leaders:

- metal tile - Coversys, Weckman, Stinergy, Mera Sistem, Metal Profile, Ruukki, Grand Line, AkzoNobel, Monterrey, Cascade;

- ceramic tiles - Nelskamp, Meyer-Holsen, Laumans, Erlus, Tondach, Roben, Koramic, Creation, Braas;

- faltsevy roof - Ruukki, Rautaruukki;

- decking - Metal Profile, Mitten, Ruukki, Grand Line;

- roofing slate - Theis-Boger, Rathscheck, Schiefer;

- copper tiles - Tegola, Copper Roof Company with the Eurasia product;

- membranes - Tyvek, TechnoNICOL, Ruvitex Industry Corp., Renolit SE, Sure-Weld, FTD, Alkorplan, Aqua100P, Logicroof, Fatra;

- waterproofing membrane - Tyvek, Firestone Building Products;

- soft roof (rolled) - “Ryazan Cardboard-Ruberoid Factory”, “TekhnoNIKOL”, Icopal.

Among the popular roll materials is the bipole, created by the Russian company TekhnoNIKOL. The development is a durable and reliable waterproofing, perfectly suitable for the arrangement of soft roofs. The basis is fiberglass or polyester.

Examples

The metal tile - excellent option for a country house.

- Roof decorated tile.

- Membrane cover is perfect for high-tech style.

- House with a folded roof.

All about popular roofing materials, see the video below.