Soft roof of the company "TehnoNIKOL": characteristics and features of laying

High-quality roofing - a pledge of safety and durability of the structure, as well as all communications, equipment and things inside. The modern built-up roof of the TekhnoNIKOL brand gained popularity due to its special characteristics, as well as the ability to operate it in any climatic conditions.

Advantages and disadvantages

The advantages of a soft roof include the following features:

- Long service life. Properly installed roof from "TechnoNIKOL" can be operated for 30 years.

- Many types of roofsFrom economy class to soft tile premium segment. This undoubted advantage will allow you to choose the material for your wallet to every customer.

- The coating is not afraid of water. The high rate of moisture resistance and water resistance allows the roof to withstand heavy rain and snow.

- Nice appearance. This is especially true of soft tiles, which are in no way inferior to models from world leaders in the production of roofing materials.

- Easy installation. Just need to follow a certain algorithm, and also have on hand all the necessary materials, then installation will take place quickly and without difficulty.

- Low weight. This parameter greatly facilitates both the work and the transportation of the material.

- Resistant to sunlight. Soft roof "TekhnoNIKOL" does not fade under the influence of ultraviolet radiation and retains the original color and appearance throughout the entire period of operation.

- Resistance to mechanical and chemical stress. "TechnoNIKOL" - the coating for which you should not worry.

- Wide temperature regime. The material of the soft roof can withstand a temperature range from +1100 C to -600 degrees Celsius. The coating can be used in the conditions of a sharply continental climate and even in the regions of the Far North.

- Fireproof. The material is incombustible, does not spread a flame and emits very little smoke when in contact with fire.

It is worth noting that despite the resistance to damage, sometimes a soft-coated roof may still need repair. It may be necessary to replace the failed segment without dismantling the entire row.

Despite all the advantages, there are some disadvantages that owners of such a coating have to face, but they can be easily avoided if the installation is carried out correctly. So, damage to the waterproofing layer is often encountered, which can later lead to cracks and deformation of the soft roof. Also difficulties may arise with vapor barrier. If it is incorrectly installed or the selection of inappropriate materials, moisture begins to accumulate in the roof layers and leads to an increase in humidity inside the room, destruction of the soft coating, as well as leaks.

Kinds

Guided roof "TechnoNIKOL" consists of fiberglass, which is covered on both sides with a material based on bitumen, which is applied to the main outer coating. The manufacturer very competently shares its line of roll products,which makes it easier for the buyer to choose the appropriate roof.

By species can be divided into the following categories:

- "Economy";

- "standard";

- "Premium";

- "business".

Economy

In a line 2 types of a roof - "Stekloizol" and "Bikrost" are presented. Economy class has the smallest thickness of all TechnoNICOL roll materials. "Stekloizol" consists of fiberglass, bitumen and special filler. The top layer is made of polymer film.

"Bikrost" - roll material, made on the basis of fiberglass. The top layer is oxidized bitumen.

Standard

In this category there are the following types:

- "Linokrom" - consists of bitumen fiber with the addition of a polyolefin component;

- "Bikroelast" - similar to "Linokrom", but the knitting layer is arranged in such a way that high heat resistance is achieved;

- "Bipol" - the top layer is represented by a polymer film, which is additionally covered with mineral composition.

Business

In this line are presented only two types of soft roof - “Uniflex” and “Ecoflex”. The first is polyester, which is coated with a bitumen-based polymeric material, and the second has a particular elastomeric composition,allowing to use this roof as an independent waterproofing.

Premium

The segment is represented by the following products:

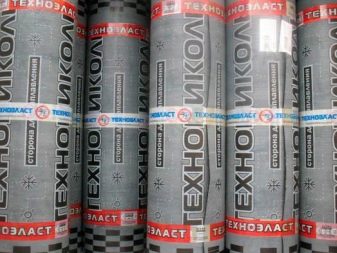

- "Technoelast" - has an additional protective layer of artificial rubber;

- "Vestoplast" - a roof with the addition of special polypropylene, which gives it increased reliability.

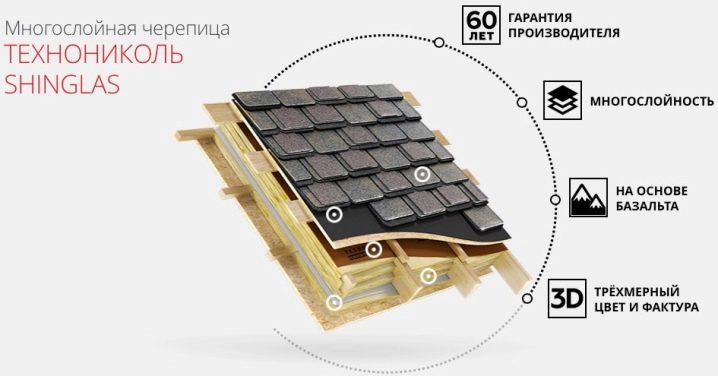

Soft tile is also divided into several types:

- single layer;

- two-layer;

- three-layer.

The three-layer tile, according to the manufacturer, is capable of serving 60 years or more. Also, the tile has a different pattern and type of cutting, while the main materials of manufacture do not differ from roll models.

Sequence of work

The technology of installation of a soft roof varies depending on the selected material, as well as the design of the roof itself.

Laying roll rolled roof occurs in the following scenario:

- Roof preparation. It is necessary to thoroughly clean the surface from debris, dust and dry. If moss has formed in some areas, it should be removed with a brush. If the roll roof will be stacked on the old roof material, then it is necessary to remove the existing bubbles by cutting them crosswise.If the soft roof is laid on a concrete base, then it is also necessary to clean it from dust and litter, and cover the cracks with a solution of cement.

- Next is applied bitumen mastic, and the place of processing is pressed.

- Insulation should be laid on the non-insulated roof. As a rule, mineral wool or polystyrene foam is used. Extruded PP overlaps in two layers.

- After that, primer should be applied - bitumen mastic or bitumen mixed with kerosene.

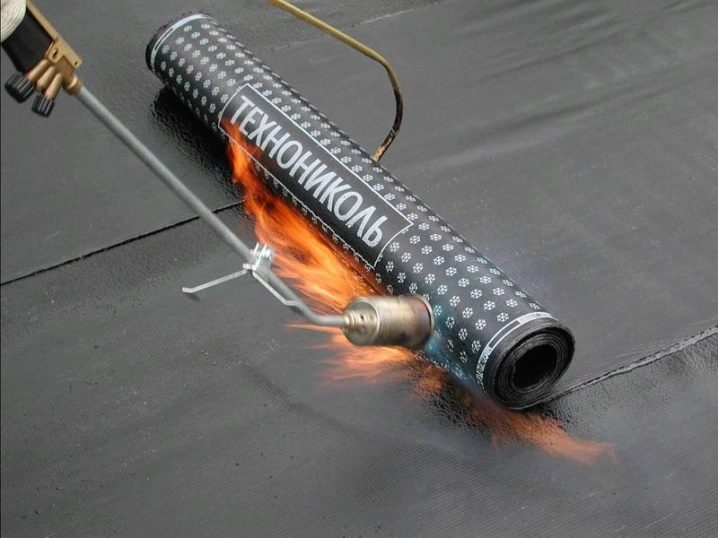

- After that, you can proceed to the installation of soft roll roofing. This will require a gas burner, a holder, a construction knife and a metal roller.

- The material is rolled out on the roof and trimmed with a margin that depends on the topography of the roof, as well as elements that should also be covered with the roof of TechnoNICOL. The installation of the material starts from the middle of the roof, as this allows it to be laid easily and without any problems.

- The burner warms up the bottom layer of the roll to the state when the substrate becomes soft. Further, with the help of the holder, the roll is unwound and gradually warms up along the entire required length.

- With the help of a roller, the soft roof is compacted for better adhesion to the roof surface.

- The following layers are stacked with overlap.For this purpose, TekhnoNIKOL rolls have one side surface without special bedding. It must be placed inside and the next layer of soft roof should lie on it.

As can be seen, the installation process of the overlayed roof presents no particular difficulties and can be performed independently in a short time. It is only important to observe the sequence of actions, because without proper preparation it is impossible to achieve high-quality and durable coating.

It is already more difficult to cope with the installation of soft tiles, since the preparation process and the installation itself are more labor-intensive.

For the flooring of this material perform the following steps:

- The rafter system and obreshetka is established. Rafters are installed at an angle that depends on the surrounding terrain.

- After mounted waterproofing layer. The membrane material is attached to the roof with a special stapler.

- On top of the waterproofing layer is lathing. It is designed to simplify the installation of insulation.

- After laying the insulation layer (usually using mineral wool), the vapor barrier is installed.

- Next, the roof is sewn with plywood sheets or other selected material.

- After you can begin to lay a soft tile. At first the eaves lath is mounted. It is attached with nails. It is desirable to have them at a distance of 13-15 cm in a staggered manner.

- After put lining. It is laid across the roof over the eaves strip and fixed with nails.

It is important to observe several conditions:

- the overlap of the substrate sheets must be at least 10 cm;

- the entire roof is covered completely, there should be no “bald patches”.

Installation of a soft roof begins with mounting the starting strip at the eaves. You can use both prefabricated elements and trim the existing tile yourself. It is fastened with nails.

Each next sheet of soft tile overlaps with the previous one.

Installation of soft tile is very laborious and requires special care and attention, especially when processing chimney and ventilation units.

Subtleties of installation

When installing a build-up roof there are some peculiarities that need to be known and used in order to get a good result and avoid reworking the coating. So, professionals recommend using only a gas burner and in no case do not replace it with a gasoline burner.It's all about the difference in temperature of these units. Gasoline burner can easily damage the soft roof, which will increase the consumption of material.

Also, when constructing a batten, special attention should be paid to the gap between the elements. It should be 4-5 mm. Boards necessarily have annual rings up, which will avoid the destructive effect on the roof.

When constructing a plywood roofing, they retain a 3 mm gap between the canvases in order to compensate for the expansion in the spring and summer period. When mounting them use nails or screws. They are placed in a checkerboard pattern.

Soft roof "TechnoNIKOL" - a great alternative to other types of coatings. It is durable, resistant to external factors, its installation can be done with your own hands. It is only important to follow the instructions of the manufacturer’s production line and building codes.

Below is a detailed video tutorial for laying self-adhesive roll tiles brand "TechnoNIKOL".