Technology insulation of the roof of a country house

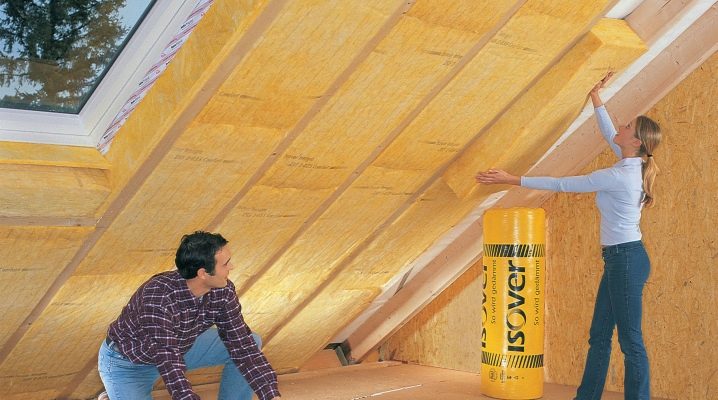

To properly insulate the roof in such a way as to significantly reduce heat loss, first of all, it is necessary to select the optimum materials and get acquainted with the installation technology. Competently insulated roof increases the thermal efficiency of the house by 15-20%, and also allows you to convert the attic into a room suitable for living.

Special features

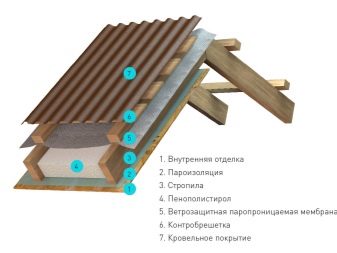

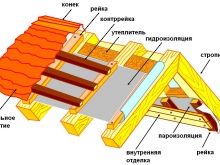

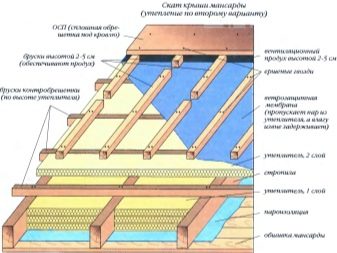

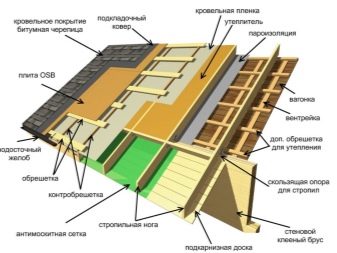

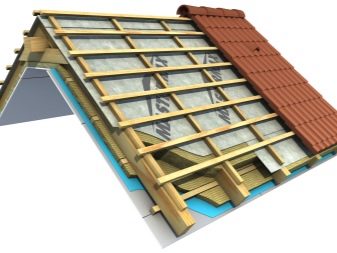

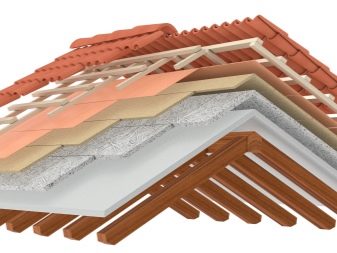

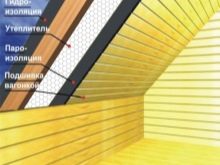

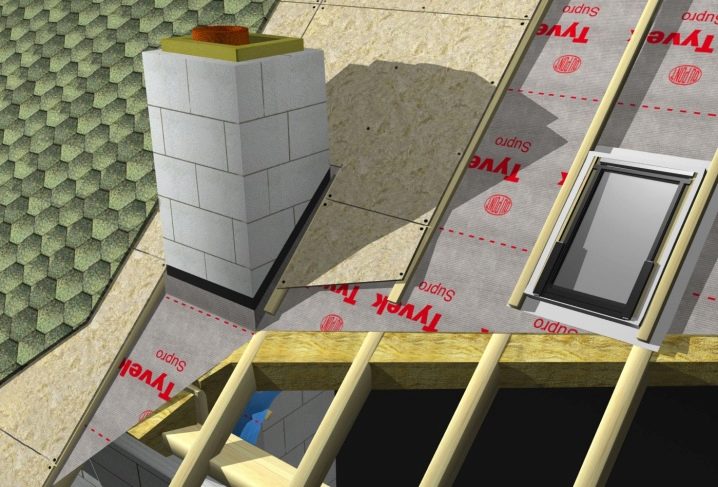

The roofing system of houses and cottages is reminiscent of a layer cake - it includes directly roofing material, a crate for mounting a structure, hydro and vapor insulating films, thermal insulation, a framework for installing insulation and an inner covering.

Properly laid roofing "pie" is necessary to create an optimal temperature in the room and maintain a healthy microclimate.

The roof protects the house from rain and snow, as well as from other adverse environmental factors. In order for the house to stand for many decades and it always has a healthy atmosphere, it is very important to correctly calculate, install and insulate the roof.

In principle, it is possible to do without insulation, but it can significantly reduce the cost of heating the house, improves the performance characteristics of the roof and extends its service life.

All these tasks are solved with the help of thermal insulation materials., which are mounted directly under the roof and do not allow moisture to penetrate inside. Otherwise, the wooden rafters and beams will very quickly become unusable and begin to rot. All this will lead to additional costs, which will be much higher than laying a layer of insulation.

If we are talking about the attic floor, then the question of the feasibility of warming the roof should not even rise - in such structures it should be laid in a mandatory manner.

In order for the thermal insulation to be practical and functional, you should purchase the highest quality insulating material, as well as properly lay a layer of insulation.

Types and device

A few points related to the roof that you need to know before planning work on the insulation of the roof:

- The enclosing structures of the roof are characterized by increased requirements of thermal resistance. For example, in a number of European countries, this parameter for walls is 5.88 m2 * C / W, and for the roof it is much higher - 11.11. This is almost a twofold difference.

- The material that is used for the arrangement of the roof, more than any other is exposed to moisture, and it is well known that it is the fluid that is the main enemy of thermal insulation.

- Insulating layers are laid according to the principle of ventilated facades, that is, concrete and brick elements do not protect it from fire, which means that a quality insulation for the roof must necessarily be fire resistant.

Regardless of the type of roof, its area is in any case significant, so the cost of the material must fit into the total cost of construction.

Fortunately, nowadays there is a wide variety of materials for insulation, the prices of which vary in a wide range, so everyone can choose insulation for every taste and budget.When choosing materials suitable for insulation, it is necessary to take into account the peculiarities of the roof itself.

There are three schemes of roofing structures:

- flat;

- pitched;

- mansard

These options are presented in a variety of modifications - the roof can be gable and broken, it can be equipped with overhangs, etc. Each of these types requires its own variant of using heat-insulating materials.

Flat roof in the majority of cases is operated, therefore, the insulation must be tough. In this case, it is worthwhile to give preference to a dense mineral wool or foam. Most manufacturers have their own product line for the roof of this type. Materials with cuts make it possible to impart the required inclination and equip special chutes for water withdrawal.

The sloping roof most often assumes an uninhabited attic, so insulation in most cases is done on the floor. However, if you wish, you can lay a heater between the rafters, in this case elastic materials, such as mineral wool, are used.

The mansard construction assumes that the walls of the room are not made of brick or concrete, but of roofing material.Attic is a living room, therefore, special requirements for its insulation are made to the environmental and fire safety of materials.

Materials

Before starting work on roof insulation, it is necessary to choose the right material.

Its choice depends on a variety of operational parameters.

- Density. This indicator directly affects the degree of heat transfer coating: the lower it is, the greater the porosity of the insulation, and the higher the porosity, the better the thermal conductivity of the substance.

- Heat transfer. This parameter affects not only the porosity, but also the degree of moisture of the material.

- Hygroscopicity. High-quality insulation should not absorb and absorb the liquid, so the material is pre-treated with special hydrophobic components. This fact should certainly be clarified when making a purchase decision.

- Fire resistance and flammability class.

- Resistance to temperature extremes.

- Resistance to acid-base solutions.

- Environmental friendliness.

- Predisposition to the formation of mold and fungal reproduction.

- The possibility of "attack" rodents.

When the question arises about the choice of insulation for a cottage or a private house, it is important not to make mistakes that can significantly affect the quality of installation work.

- Saving on quality. Miser pays twice, so give preference to materials from manufacturers, well-proven in the market. Remember that the purchase of cheap insulation can lead to rapid decay of the wooden elements of the roofing structure, as well as an increase in the cost of heating the room in the winter.

- Installation of a layer of insulation insufficient thickness.

- Non-observance of technological features of roofing works.

The materials used in roof insulation can be divided into several categories:

- in the form of plates and plates;

- roll;

- bulk;

- sprayed.

Each of them has its own advantages and disadvantages.

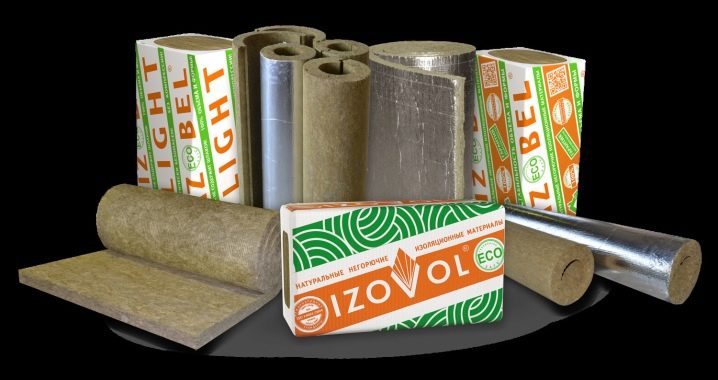

Mineral wool

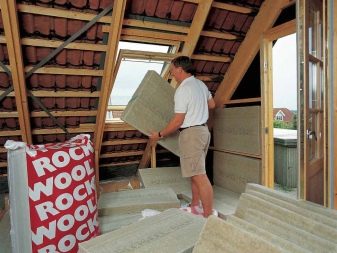

In thinking about how to insulate the roof of a private house from the inside, most consumers prefer mineral wool. It has found wide application in the arrangement of warming flat and pitched roofs. Mineralovate is a material with a fibrous structure, produced from melts of rocks.In stores, the product is presented in the form of rolls and plates.

The undoubted advantages of the material include:

- high thermal insulation characteristics;

- resistance to burning, non-flammability;

- ecological purity, absence of harmful and toxic substances;

- the invariance of the main physical and technical parameters in different operating conditions;

- ease of installation;

- low cost;

- good sound absorption and sound insulation;

- environment unfavorable for reproduction of rodents and dangerous microorganisms.

Slabs of mineral wool are quite strong and dense, so in most cases they are used for thermal insulation of a flat roof. Rolled versions have a smaller thickness and density, so they are optimal for arranging pitched and mansard roof structures.

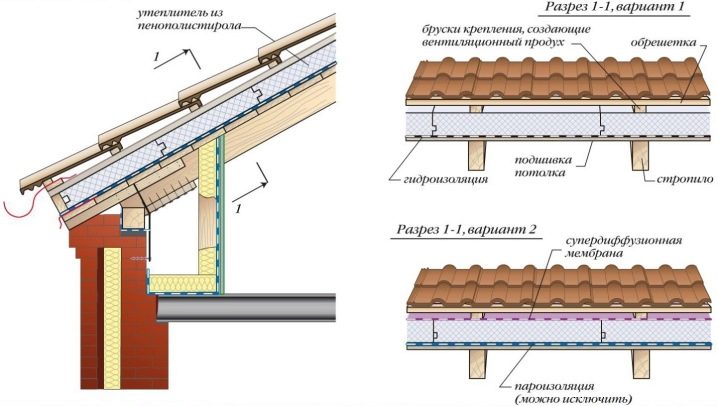

When using a heater of this type, additional laying of steam and waterproofing materials is required., as well as the installation of ventilation gaps. If we neglect this requirement, then moisture will collect in the insulation, as a result, the operating parameters of the mineral wool will significantly decrease, and the wooden rafters will begin to rot and collapse.

Glass wool has similar characteristics to mineral wool. This heat insulator for a long time used in the construction and decoration and has established itself as a high quality product. Glass wool is produced from molten glass and sold in the form of plates.

Insulation on hot days does not allow heat to penetrate inside the house, and in winter prevents it from going outside. In addition, the material has good sound absorption. However, the work requires the use of special protective suits, otherwise glass wool may be harmful to health.

Glass wool, like mineral wool, requires an obligatory vapor barrier layer. However, in recent years, many manufacturers produce glass wool, which already has a foil layer on the outside, which prevents the accumulation of condensate. Its presence greatly facilitates the laying of insulation.

Styrofoam

One of the most popular materials is extruded polystyrene foam, or, more simply, polystyrene foam. This material is often used to insulate overlappings of a pitched roof into a frame - in a similar construction it is laid between lags.

The material has high user characteristics:

- Low weight. This is largely due to the gas-filled structure of the material. It is lightness that is considered, perhaps, one of the most important arguments in favor of coverage - it is easy to transport it, lift it to the attic, one person can hold it.

- The material contains a lot of air, so it is bad for both cold and warm.

- It has a high degree of noise absorption - even if the roof is finished with a metal profile, the use of foam absorbs the sounds of rain and hail, making your stay more calm and comfortable in the room.

- It is resistant to high and low temperatures, tolerates changes in them well, without losing its consumer properties.

- Under the influence of moisture does not freeze through, since it has a low thermal conductivity.

- It does not require additional installation of hydro and vapor barrier systems, but, of course, this is permissible only in case of reliable sealing of joints and joints, as well as elimination of gaps between the roof and the foam.

- Easy to fit on the simplest tile adhesive.

- Simply and quickly cut with any tools.

As you know, the ideal materials have not yet been invented, and the foam in this sense is no exception.

Among the disadvantages of this insulation should be noted:

- Strong crumbles.

- Often, mice and rats are turned up in the attics of private houses. Unfortunately, foam plastic is considered an attractive material for rodents.

- Thermal insulation of the roof with foam plastic takes quite a lot of time, because it requires mounting of the batten and further fitting of the plates to the frame dimensions. This not only increases the work time, but also requires a lot of power for the subsequent cleaning of the room and getting rid of the foam balls.

- If the material is used in rooms with high humidity and insufficient ventilation, black mold may appear on the foam. To avoid this, it is necessary to provide a gap of at least 2–3 cm in thickness even during assembly.

- Foam is resistant to burning, in most cases it just melts. However, under the influence of elevated temperatures, the material can emit toxins that poison the human body.

Many users question the environmental safety of insulation, believing that it releases harmful fumes into the environment.For the sake of fairness, we note that such an assertion does not have good reasons, and therefore is considered controversial.

By the way, the foam is often used for the construction of "green roofs" - a reinforced coating, a membrane and geotextiles are installed on the insulation. Then a layer of soil is poured in which the ground cover plants are planted.

The foam does not absorb water vapor, so it can be placed directly on the layer of waterproofing material. The tendency to burning and vapor resistance of the material does not allow it to be used for arranging a soft flat roof.

Similar properties have plate insulation penoplex, which also enjoys consistently high demand among consumers.

Polyurethane foam

For all the good there is always something better. If we are talking about heaters, then under the best should be kept in mind polyurethane foam (polinor). Reviews of the most positive. This is a semi-liquid substance that is sprayed onto the surface to be treated.

Technically, this material is a gas-filled plastic with a solids content of less than 15%.The rest of the volume is occupied by gas bubbles. As a result, the material exhibits exceptionally high thermal insulation properties and is widely used in the construction and decoration of modern private houses and cottages.

Polyurethane foam can be sprayed directly onto the surface, skipping the step of installing the batten, preparing the material and mounting it. The principal difference between polyurethane foam insulation is the absence of any special preparatory work, and the coating layer is very durable, resistant to adverse environmental conditions and retains its operating parameters for many years.

The service life of polyurethane coatings reaches 50-60 years.

Polyurethane foam has a high adhesion, so it is successfully sprayed onto surfaces of various types - metal, plastic, wood. It can be applied both horizontally and vertically.

PUF is distinguished by exceptional hygroscopicity, while the higher the density of a substance, the greater moisture-resistant characteristics it exhibits. By the way, components that contribute to the waterproof material are castor oil, some manufacturers use and derivatives of flaxseed oil.

Insulation refers to flammable compounds due to the introduction of special flame retardants and halogens. PPU ignites only under the influence of an open flame. Under the action of fire, the coating is coked, thereby delaying the spread of fire.

The advantage of PPU is that it fills any cracks and crevices as fully as possible.

Polyurethane foam has a rather low thermal conductivity coefficient (less than 0.035W / m * K), so the insulation layer can be reduced, which significantly reduces the load on the overall structure.

And a few more advantages:

- frost and icicles are not formed on the roof insulated with polyurethane foam;

- rodents do not "settle" in polyurethane foam;

- it does not reproduce mold and does not form a fungus;

- the covering turns out seamless, "cold bridges" are absent;

- the product is watertight, the total moisture absorption rate is no more than 3% of the total precipitation;

- possesses good adhesion, therefore firmly rests on the surface of all types;

- does not contain harmful and toxic substances;

- differs in resistance to burning;

- rust resistant;

- not subject to the ravages of chemicals.

Among the shortcomings worth noting the following:

- quite high prices for coverage;

- the need to use professional technical equipment for application;

- destruction by direct ultraviolet rays.

Note that the recommended coating layer is 5 cm. If it is thinner, the insulating effect will not be achieved.

The material does not have good vapor permeability, and therefore requires the installation of additional film coatings. Otherwise, condensate will accumulate and liquid will form on the inside of the rafter.

Regarding the destruction under the influence of sunlight - this deficiency is correctable, it is only necessary to cover the insulation with paints or mastics, since UV rays do not have the ability to penetrate into the substance and have a harmful effect no more than 1-2 mm wide.

It is obvious that the positive characteristics of PPU are much more than negative, so the material is considered one of the best today.

Polyurethane foam allows the roof to provide practical and effective roof insulation, prolong the life of the entire roofing system, and also contribute to the creation of a favorable microclimate in the house.

The subtleties of working with the roof

Regardless of what type of roof structure is insulated, the basic principles of working with a roof are:

- Insulation made of cotton wool is mounted so that it does not come into contact with the layer of waterproofing, hesitate and remains undeformed, and at the end of laying it is imperative to lie down.

- When using foam and other sheet materials, it is necessary to seal all the gaps at the joints with conventional foam.

- In the case when thermal insulation materials are placed in several layers, it is very important that their joints do not coincide with each other; for this, each subsequent layer is fixed perpendicular to the previous one.

- When using liquid polyurethane foam, it is applied to the rafters and all the space inside between them, and it must be sprayed strictly onto completely dried surfaces.

- Upon completion of work with mineral wool, a vapor barrier is laid on all rafters without fail, then finishing is performed. If foam and polyurethane foam is used, vapor barrier is not so necessary, but experts recommend not to neglect it, especially if we are talking about attic floors.

As for the installation technique of insulation, it all depends on the type of roof, so let's dwell on the insulation of all types of roofs: pitched and flat.

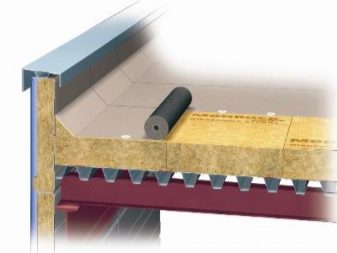

For pitched

Traditionally, pitched roofs suggest an unheated, unheated attic - such rooms are quite difficult to convert into residential areas, so their insulation is not given due attention and the insulation is laid on the attic floor. And if we are talking about penthouses, then we cannot do without reliable thermal insulation.

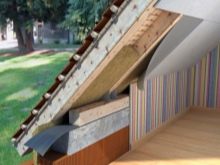

Features of the pitched roof are that it is a durable wooden frame-type construction, which serves as the basis for creating a roofing "pie".

In the context of its thickness is not less than 15 cm and in a simplified version includes:

- outer coating;

- insulation layer;

- waterproofing materials;

- lathing of wooden boards;

- directly roofing material.

As the optimal insulation in the attic can use any material. However, mineral wool with a density of 35-45 kg / m2 is considered the best. In order for the main joints to fit well together, it is necessary to cut the layers of cotton wool as tightly as possible with a mandatory tolerance of 8-10 mm.The coating is put a little pressing it into the space between the rafters, work begins from the center and lead towards the periphery. In situations where the rafters are low, it is necessary to hammer in the counter-grilles - wooden additional bars, and lay the mineral wool with the second layer.

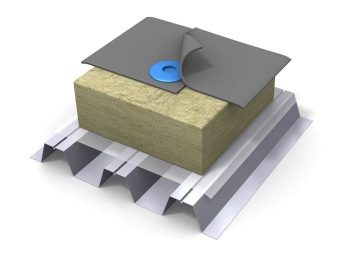

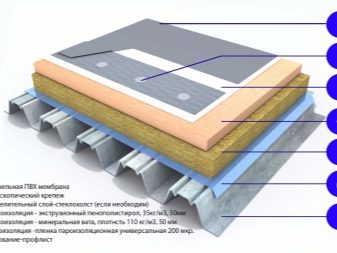

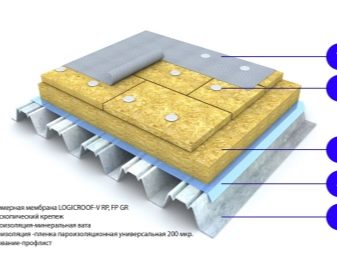

For flat

Flat roof is rarely equipped with the construction of residential buildings. It is most common when equipping gazebos, garden kitchens, sheds and other types of outbuildings in the country. The principal difference in the system of insulation of such a roof is that the insulation layer is necessarily outside, which is why the entire roofing “pie” looks a little different than in the case of pitched structures.

Traditionally, the base layer is the overlap of concrete, however, with the equipment of ready-made roofs, this is likely to be a professional sheet.

Stages of work is approximately as follows:

- To begin with, make a cement screed over the entire ceiling. It is treated with mastic based on bitumen over the entire surface, and then a vapor-permeable film is placed on the prepared coating.

- Above a layer of insulation materials mount insulation.it is very important to leave a gap of 4-5 mm between it and the walls. The joints between the plates are covered with foam, and on top they are covered with another waterproofing layer.

- On the dry bitumen base they spread fine gravel and trample down very carefully.

Experts recommend basalt wool or polystyrene for flat roof equipment. By the way, the latter makes it possible to build an “inversion roof”. This is such a coating, the layers in which are concentrated in the reverse order: the overlap - the waterproofing layer - the insulation - the vapor barrier - the gravel. This design is necessary to ensure that the heated bitumen coating does not crack under the action of direct sunlight.

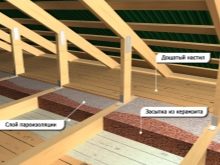

Walls and attic floor

In insulating the attic, an important role is played by the thermal insulation of its floor and walls, as it has a big role on the durability of the rafter system and the roofing material itself.

Condensate from the interior of the premises actively diffuses into the under-roof space and flows down to the rafters, as a result, wooden and metal elements begin to break down, and the insulation itself is effective only if it is completely dry.To do this, the insulation is protected from all sides by vapor barrier films.

To drain the insulating coating and remove unnecessary moisture from the attic, use the creation of a ventilation system through the airways: ridge, slotted and dormer windows. To achieve maximum ventilation efficiency, the total area of such openings should be approximately 0.3-0.5% of the total size of the attic floor.

Work on the insulation of the floor in the attic is always carried out from the attic and never from the dwelling. First you need to prepare space for work. At this stage, you should carefully examine all the elements of the roof structure, make sure that there are no cracks in the rafters and gables and also make sure that the floors have a functional look. If the materials are subject to decay, mold has formed on them, and corrosion has appeared on metal parts, spoiled beams should be replaced, all wooden floors should be impregnated with moisture-resistant solutions and treated with an antiseptic to prevent the appearance of dangerous microorganisms.

It makes sense to additionally process all the wooden and steel components of the roofing system with compounds that increase the fire resistance of the material.

Additionally, you should check the condition of the old insulation. If it has not lost its functional characteristics, then new insulation materials can be laid on the existing ones. For example, if the floor is insulated with sawdust with clay, then a frame can be installed directly on top of them and laid with mineral wool. If the quality of the old insulation does not meet the standards, then it is necessary to remove it, and lay more modern practical materials on top.

Before direct installation of insulation a layer of vapor barrier material is attached. As a rule, the film is nailed by a construction stapler.

When weatheting a concrete floor, high density materials should be used - from 160 kg / m2. Such coatings include mineral wool mats, foam or expanded clay.

Arrangement of wooden floor involves laying insulation material between the lags. Here it is necessary to give preference to mineral wool with a density of less than 50 kg / m2.

One of the most popular materials for attic insulation fromfloor is considered to be expanded clay. It is a natural material with high operational efficiency. At the same time it has a lot of weight and can create an additional load on the floor, so its use is justified only in houses, finished with monolithic polystyrene concrete.

According to the current standards and GOST, an area of 100 m2 of expanded clay is laid with a layer thickness of 60 cm, while its total weight is 30 tons.

If non-residential buildings are insulated, the thickness may be less. There is enough 20-35 cm, but even in this case, the attic floor can simply not sustain such a weight.

Warming of a garret floor with expanded clay has some more features. This is a porous material, it absorbs very well and retains moisture inside it, therefore, not only steam but also waterproofing should be laid under the expanded clay. Most often in this quality they use the simplest polyethylene film or roofing felt, which is covered with a whole cloth. A vapor-tight membrane is also placed on top of the expanded clay.

Expanded clay - non-combustible material, and exhibits extremely high thermal insulation properties, so many fill it with a thin layer, and the top is covered with mineral wool or ecowool.In this case, claydite can retain heat without danger of collapsing the entire building as a whole.

Another well-known method of warming the floor and walls of the attic came to us from ancient times - even our grandparents in the villages used sawdust with clay to improve the indoor climate, to make it warmer and more comfortable. The undoubted advantage of this warming is that it costs the owners of the premises practically free of charge.

So, to prepare a heat-insulating mixture, you need:

- dilute the clay to the consistency of cream;

- introduce sawdust into the solution in such a quantity that it can be freely moved; purely visually, such a composition will resemble sawdust smeared with sawdust;

- Apply the mixture on the floor with a layer of 10-15 cm, thoroughly tamp.

This coating is different density. If it is a little springy, you can put another layer of 5 cm and ram it again.

Such heat insulation allows keeping heat well, besides, it “breathes”, contributing to the formation of a favorable microclimate in the room. Sawdust with clay are natural materials, they do not contain harmful and toxic compounds, do not emit radiation.

The same solution can be treated attic walls.For greater adhesion, it must be thoroughly rubbed using a construction spatula.

Options for mounting waterproofing

Waterproofing is one of the cornerstone issues in arranging an effective durable roof. It creates protection of the wooden part of the roofing structure from snow, rain and spring melt water, prevents the detrimental effects of condensate, contributes to high-quality ventilation. And most importantly - protects insulation from soaking.

A nice bonus is the protection from the wind, which also lies on the waterproofing. By the way, this allows you to significantly reduce the cost of maintaining a residential home, because the penetration of cold wind increases the cost of its heating.

To date, the building stores presented a wide selection of waterproofing coatings.

Traditionally, two are considered the most popular:

- ruberoid;

- polyethylene hydrobarrier.

Roofing material as a waterproofing layer has been used for many years and even decades. It is a construction board impregnated with bitumen, which is fixed on wooden rafters overlapping 10-13 cm canvases.The joints are additionally treated with molten bitumen-based mastic to protect the joints from water ingress. The material is attached to the crate with special nails. A wavy slate is applied over it. It is due to the curvilinearness that the materials are ventilated, which significantly reduces the risk of moisture accumulation.

This method of waterproofing is quite simple, and given that the price of roofing felt is quite low, it is also affordable for the majority of our compatriots.

At the same time, waterproofing with roofing material has disadvantages. First, the ruberoid is based on a paper base. This significantly reduces the period of use of the coating - extremely rarely the material remains consistently functional for more than 10-15 years. In most cases, already after 4-5 years, the joints of the bands crack and begin to leak moisture. This is due to the physical and technical aging of bitumen, as a result of which its molecular bonds collapse. Secondly, the ruberoid during laying is often torn, so its use is justified only in cases with temporary buildings. Installation of roofing material is carried out on the deposited technology.

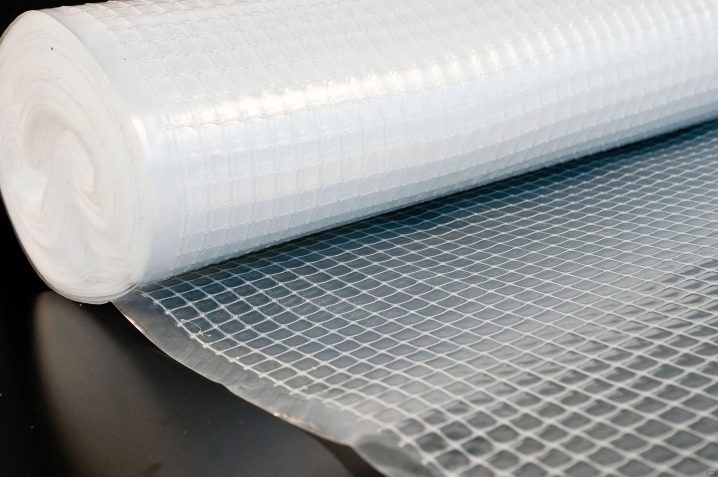

More modern material is reinforced polyethylene. It is often called a film. However, this comparison is not quite true, because the coating has small holes for ventilation. Such a product can be attributed to the membranes. Despite this, it is distinguished by its lightness, durability and a good vapor barrier component.

Such a film is mounted on the wooden girders of the part that does not contain inscriptions. All these instructions are set out in the instructions, which necessarily comes with the membrane. If the material is put in the wrong way, the condensate will penetrate through the vapor barrier and get onto the insulation. In this case, it will lose its operational properties in a rather short time.

Laying hydrobarrier begin at the bottom of the roof. For this roll is rolled perpendicular to the rafters and fixed to them with a stapler or nails. The second and subsequent strips overlap by 10–20 cm, and a wide rubber tape is glued in at the junction of the two sheets.

There are some features of mounting waterproofing in the attic. Here put the slats in increments of 50 cm.All wooden elements are pre-treated with fungicides that protect the wood from fungus and insects. Installation of corrugated board produce after attaching the rails.

It is very important to pay special attention to the insulation near chimneys, pipes and ventilation systems. In accordance with the installation technology, the film should be glued to the elements of engineering communications so that neither the precipitation from the outside, nor the internal condensate could get under the roof. Experts recommend using butyl rubber tape instead of the main adhesive tool.

Important about vapor barrier

It is very important when planning a roof system (regardless of the base material - metal tile or profiled sheet) to be confused with the issues of vapor barrier. The modern construction market offers a wide variety of coatings with similar consumer characteristics. Beginner builders and homemade craftsmen are quite problematic to distinguish between different versions of the film, which are characterized by varying degrees of vapor permeability.

The vapor barrier on the roof protects the insulation from the damaging effects of steam. But where does he come from? It's simple.In construction terminology there is such a thing as “moisture transfer”.

Steam can result from:

- human breathing;

- cooking;

- hygiene procedures (bath or shower);

- effects of artificial humidifiers.

Since school, we all know that the heated air rises, and his ability to carry water is much higher than that of cold. This means that he carries with him and moisture. On the way he meets concrete floors and facing finishing materials. Part of the steam settles on them, but part reaches the roofing "pie." If the design does not contain a vapor barrier, then moist air gets straight into the insulation.

So, the answer to the question of why we need a vapor barrier is obvious - it serves as protection of the insulation from moisture ingress into it.

For this purpose, a variety of materials can be used. The most common is polyethylene.

Note that plastic films are perforated and non-perforated. The first ones have high vapor permeability, therefore they cannot be used in roofing “pie”. This point is important to consider when buying a suitable coverage.

We specifically mention the types of films that are covered with aluminum foil. They are distinguished by a rather high resistance to steam, which is much higher than the required level, therefore such coatings are widely used for arranging baths and saunas, but there is no sense to use them in ordinary residential premises.

Such coatings are durable and resistant to sunlight. In order to create a more accurate picture of the material, we say that such films can successfully protect open rafters throughout the year.

Modern technologies keep pace with the times and constantly bring new products to the market with additional functionality. These include, for example, films with antioxidant effect. They have a very attractive appearance due to the viscose coating with cellulose. In addition to the decorative function, this structure effectively protects the material from the damaging effects of moisture - it simply absorbs it and holds it for quite a long time. When installing such a film, it is of fundamental importance to observe the technology of laying the antioxidant layer must always be turned downwards relative to the insulation.

Regardless of what type of vapor barrier was chosen, its installation has its own characteristics and nuances.

- Vapor barrier is installed only on top of the insulation.

- The material can be applied horizontally and vertically. With horizontal installation, which is made transversely to the rafters, work begins from the topmost row in the direction from top to bottom. Films are mounted on the frame with a construction stapler or galvanized nails with wide caps. Joints are fixed with one-way and double-sided tapes. The first ones are necessary for sealing the seams from the outside, and the two-sided ones are used for fixing the inner strips of vapor barrier material.

- If a vertical vapor barrier is made, then the joint should certainly fall on the wooden bars of the batten. Otherwise, the coating may tear, and even the use of adhesive tape will not protect it from damage.

- Where the film is in contact with the windows, use a special apron or paste a special tape. This applies to mansard roofs.

- On top of the laid insulation mount addition bars. They help to increase the overall vapor barrier of the roof and the formation of a node passage ventilation. This design promotes air circulation.

- The film should be mounted in tight, try to avoid sagging.

Among consumers, izospan, which has high hydro- and vapor-insulating parameters, is very popular.

Recommendations

The choice of insulation for the roof is great, however, in order for the insulation to fulfill its protective function 100%, give preference to products from proven manufacturers whose products have been pleasing consumers for many years with the highest quality and durability.

Let us dwell on the most popular manufacturers of thermal insulation materials.

Ursa

Products of this brand are made from the highest quality raw materials on advanced equipment using the most modern technologies.

The product line includes:

- Insulation from staple fiberglass. This material is of high quality, practicality and low weight. It is suitable for insulation of all types of premises, is simple to fasten and practically does not form waste.

- Styrofoam. Expanded polystyrene of this brand has a closed cellular structure, which provides the highest thermal insulation characteristics of the material, as well as contributes to its hygroscopicity and resistance to compression.

TechnoNIKOL

The company is engaged in the production of hydrophobized plates, which are made of mineral bas basalt.

The advantages of the material are undeniable:

- neutrality when interacting with concrete or metals;

- high degree of strength;

- excellent noise insulation;

- biostability;

- insignificant water absorption;

- preservation of heat-insulating properties at temperatures from -60 to +200 degrees.

The product is widely used for insulation of the roof, as well as for insulation of the walls of the attic.

Paroc

Under this brand, basalt insulation is produced, which is commonly purchased for decorating mansards, roofing “pies”, as well as facades and partitions.

The material has a number of useful physical and technical properties:

- is a dielectric;

- does not pass moisture;

- characterized by environmental and fire safety;

- exhibits noise absorbing properties;

- retains its properties at temperatures from -260 to +900 degrees;

- resistant to acid-base solutions and mechanical damage;

- has low thermal conductivity.

Knauf

This is a world famous brand, one of the leaders in the market of building finishing materials.This company brought to the market insulation that can be used for all types of coatings: floor, walls and ceiling. The product line of the concern includes mineral wool, foam plastic and glass wool.

The advantages of the products include:

- ease of use;

- good sound absorption;

- high thermal insulation properties;

- the absence of any smell;

- small weight;

- environmental friendliness.

On the technology of insulation of the roof of a country house, see the following video.