Crutches: types and sizes

The final stage of the construction of any house is the construction of the roof. On how well it is mounted, depends on the life of the building and the safety of the people who will live in it. In addition to wooden crates and modern roofing materials with waterproofing properties, the construction uses numerous fasteners that are necessary for reliable fixation of all elements. Nails or screws, as well as roofing crutches are required.

Kinds

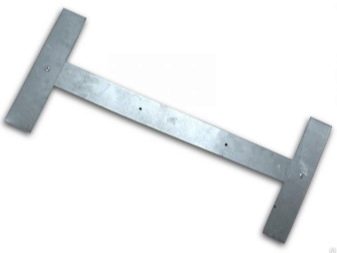

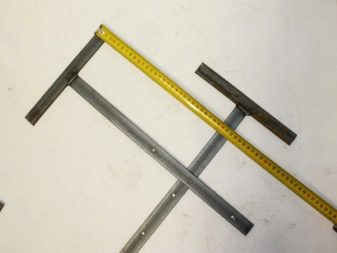

Roofing crutch is a fastening building element used in the installation of roofs of any complexity, mainly metal. It is used to increase roof stiffness, fastening cornices, plums. Made of high quality carbon steel.

Currently in the building stores you can buy several varieties of these parts.

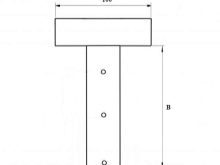

- T-shaped flat. The most popular and therefore the most sought after. It is used when installing roofs of various configurations.

- T-shaped double-sided. Used much less frequently.

- Curved. It is used very rarely, for roofs of increased complexity.

- L-shaped. Maintains a smaller load, with its help those parts of the roof are fastened where it is impossible to use a T-shaped crutch.

Important!

Experienced roofers advise: crutches should be made of the material that is closest in its characteristics to the roofing. For example, if the roof is mounted from galvanized steel sheets, it is best to choose roofing crutches of the same metal.

Sizes and modifications

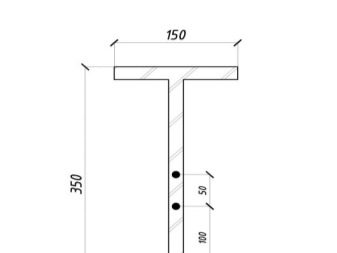

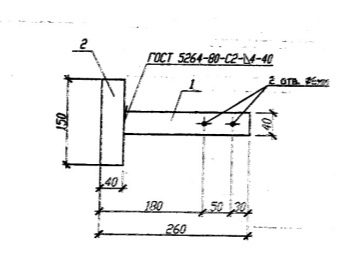

These fasteners are manufactured in accordance with the parameters approved by state standards and building codes. The unified sizes of T-shaped crutches are presented in three versions - 20 cm by 4 cm, 25 cm by 4 cm and 40 cm by 4 cm (4 x 40 x 400 mm). L-shaped models are made by a similar technology and from the same materials.For the production of curved elements using thinner sheets of metal, 2–3 mm thick.

Custom size options

There are situations when none of the modifications presented in the store are suitable for installing any part of the roof.

If necessary, you can make your own mount of the desired length and width, taking into account the specific project.

To work will require:

- strip of high carbon galvanized steel with a thickness of 2 to 4 mm (depending on the severity of the roofing material);

- metal shears (for working with thin products);

- if you need a stronger mount, it is cut out of the metal strip with a chisel and a heavy hammer (sledge hammer);

- thin chalk for marking future details;

- welding machine;

- durable drill bits for steel;

- Countersink is a tool used to clean drilled holes.

Further actions are carried out in the following sequence:

- On the steel sheet using sharply sharpened chalk mark the strip of the desired width and length.

- Cut the required number of long and short segments.

- Cook them in the form of the letter "T".

- On the long side, drill three holes for fasteners (screws or nails), taking into account their diameter. How to do this can be seen in the drawing.

- After all the holes are ready, they must be countersinked, that is, they clean the inner surface of the recess, remove chamfers and barbs, prepare a recess for the bolt head. If this is not done, further difficulties may arise in fixing the fasteners.

- Finished parts to be coated with an anti-corrosion primer, this operation increases the life of the roof, and therefore the entire building.

- After drying, it is possible, on request, to paint with a special polymer paint for metal, which also contributes to protection against corrosion, and, in addition, fastenings take on a more beautiful look.

Mounting technology

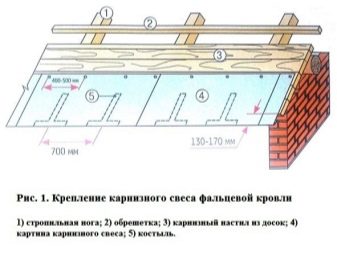

Fastening the crutches to the roof sheathing is carried out as follows:

- apply the part so that the short side protrudes slightly over the edge of the roof;

- through the drilled holes fix galvanized nails or screws;

- then the crutches are installed and assembled along the entire length of the slope, parallel to each other, maintaining the protrusion over the edge and observing the 50–70 cm pitch;

- after all the details are fixed, proceed to covering the roof with roofing material, installing plums, parapets and other elements provided for by the project.

The weight of one roofing crutch is small, about 0.5 kilogram. Therefore, transportation, installation and installation are not very difficult.

The ability to replace one part to another

Those who are just starting to build a house may have different questions. Consider the most common ones.

Is it really necessary roofing crutches in the construction of the roof?

The answer is unequivocal - of course, they are necessary, because a properly mounted and reinforced roof for many years guarantees reliable and safe operation of the building, and is able to withstand any natural disasters. Roof crutches installed at the edges of the roof slope support the part of it that is least protected from external influences.

They take upon themselves the most powerful blows of the elements that can bend and even completely break the roof (heavy snowfalls, icicles that are frozen, torrential rains, hurricane wind).

Is it possible to replace them with simpler and less expensive parts?

Yes, this fastener can be replaced by ordinary steel strips. At first glance, there is an obvious savings, because the steel strip is cheaper than a roofing crutch. However, in fact, it is even possible to increase costs, since it will take considerably more crutches (approximately twice) for the same roof area of the strips. Moreover, in this case, the stiffness coefficient decreases markedly, the roof becomes less protected from natural phenomena.

Application area

The main function of the crutches is to strengthen the roof.

They are often used for other purposes:

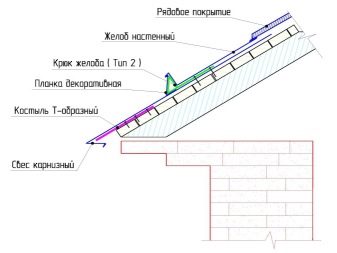

- fastening of eaves and plums (T-shaped models are used);

- installation and support of decorative elements of the roof (in this case, various types of curved crutches are most often used);

- installation of special aprons and drips - devices designed to protect against rain and snow moisture in the joints of the roof and parapet;

- the connection of the roof of the entrance of an apartment building with the wall of the building;

- strengthening of the place of contact of the roofing material with heating pipes and ventilation shafts.

When building a house, it is necessary to take into account all the nuances, strictly observe the production technology. Do not neglect such an important detail as a roofing crutch.

In the video below you will see how the crutches are made.