Frame roof: device of rafter system, calculation and installation of a design

Frame format stands out among a number of types of roofing. It can be done in a rather different way, but in any case, you will need to calculate the rafters and install them according to all the rules. With proper knowledge of the problem, you can solve it on your own without recourse to specialists.

Features and forms of roofing

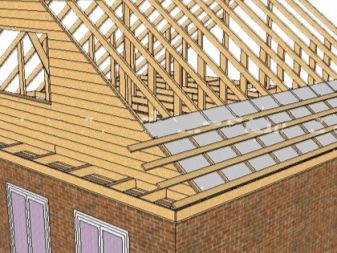

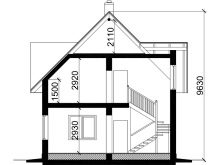

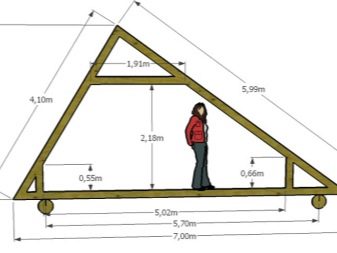

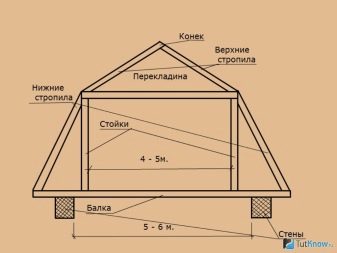

The frame roof can be installed only with spans no longer than 1220 cm, and the gap from one truss to another is maximum 0.6 m. The dimensions of the fragments of the frame are determined by the distances of the spans and the calculated snow load. Rafters can be both freely installed, and taking the load from the attic elements.In the case of a broken roof, it is possible to ensure a ceiling height sufficient for a residential attic, and it will look best on a square structure.

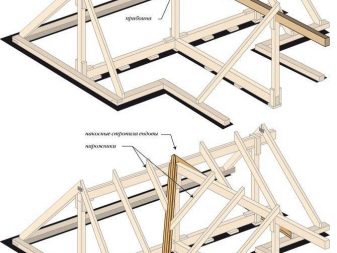

Multi-roof roof is considered the most difficult and hardly accessible variation for amateur builders. A balanced roof system effectively withstands even very high loads, while having excellent “appearance”. Since the slope is steep, the risk of snow retention will be minimal. But at the same time it is necessary to very carefully calculate all the structural elements, and in the process of work a lot of waste will appear. In addition, the valley will have to survive the effects of a significant amount of snow.

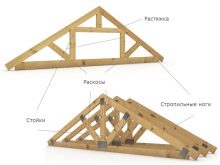

Purpose and types of systems

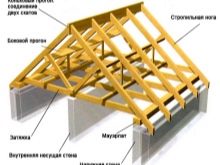

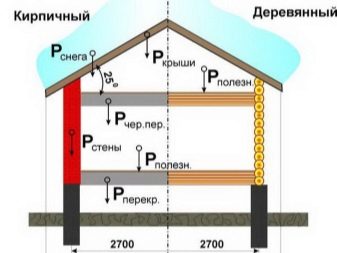

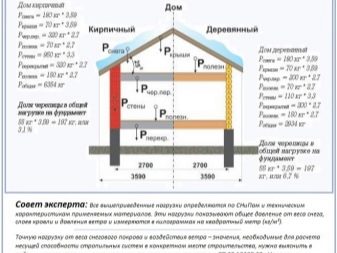

In a variety of systems rafters can be used mauerlat. The mass of the roof of the house varies depending on the area occupied by the slopes, and the materials used. But in any case, the load created is very solid. When there is a ridge on the constructions, it is necessary to envisage a truss frame, with its feet resting against the walls. Power is applied along several vectors at once, and in the cold season, the accumulation of snow only aggravates the problem.

Mauerlat is designed to eliminate this disadvantage and prevent the destruction of the walls. By this word is meant a timber of significant cross section, which can be both wooden and steel. In most cases, they take the same material that was used to form the rafters, but necessarily achieve continuity of the strapping or create durable and especially stable joints. The use of mauerlat is rejected only in houses from a log house or in buildings built using frame technology - and even there they have their own parts that perform a similar task. When it is not possible to make an inseparable block, all fragments must be exactly the same length.

The T-shaped roof is characterized by a tie-in of two wings at a certain angle. Because of this, it is necessary to form a valley. External rafters will rest against the supporting boards. In addition to them, there will also be the main parts directly attached to the wall. In order to make everything fit the end task, wooden elements with a thickness of 3.8 cm are used. The crate is supposed to be made monolithic, the coating is attached to it with clamps every 50 cm. The typical thickness is three times smaller than the bearing wall, and if it is made from steel, you can slightly reduce this figure.

A reinforcing belt is often equipped under the mauerlat. This is especially important if you plan to insulate the roof and provide reliable waterproofing. Such a belt is formed from the same mixture that is used for the construction of the foundation. Completely all formwork is filled with concrete from one reception, the smallest separate layers are inadmissible. In the aerated concrete wall, intermediate bridges are cut down at the upper line of the blocks - and a practical chute appears at once. The attachment of the mauerlat is made either with the help of knitting wire, or with reinforcing bolts (but they will not help with a reinforcing belt), or with building pins.

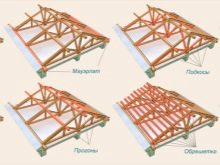

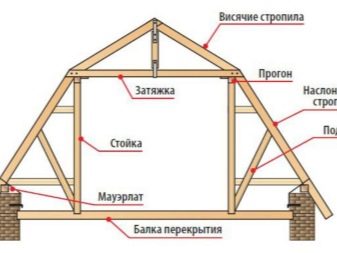

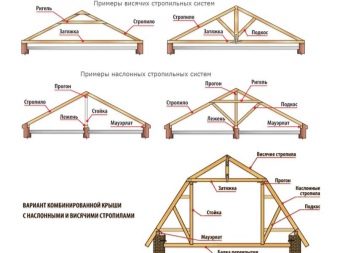

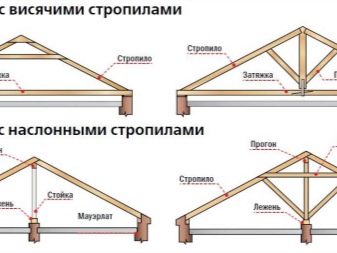

Having dealt with the support for the rafters, you need to figure out what they can be, and what is more appropriate to use for roof support. Hanging rafters are used if there is no capital wall inside the building, their points of support are located exclusively on the external contours.

Such props turned out to be in demand when building:

- houses with one span;

- production facilities;

- various pavilions;

- mansard

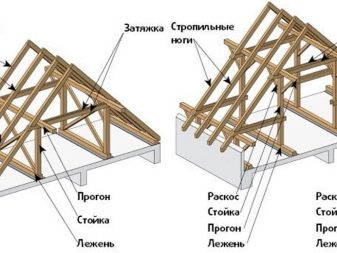

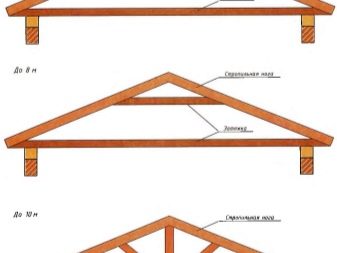

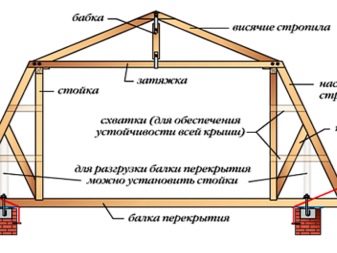

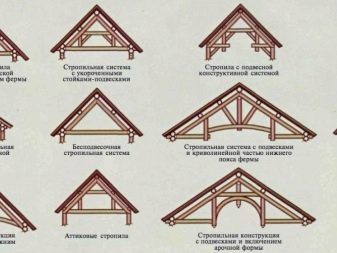

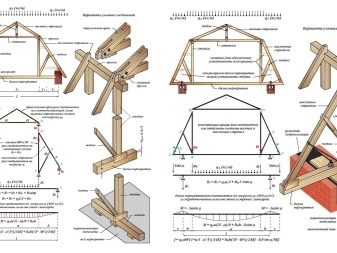

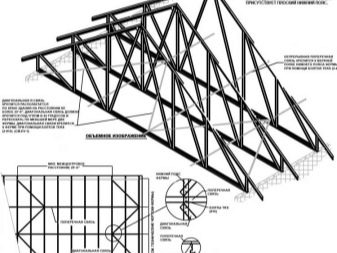

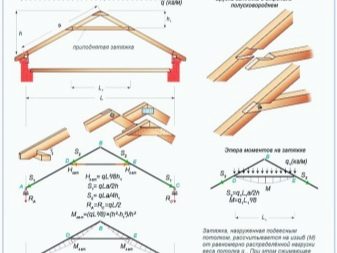

Do not underestimate this option, thanks to engineering developments, suspended rafters can not sag, blocking the spans of 15-17 m.But it is important to understand that they acquire all their capabilities only in close cooperation with other details. We'll have to use and tightening, and grandmothers, and crossbars. The simplest truss is made of two beams connected in the upper position; by configuration, such a device is close to a triangle. The horizontal connection of the frame parts is ensured by tightening (with a beam made of wood or metal profile).

Due to the tightening, the transfer of thrust to the walls is eliminated, and the force applied in the horizontal plane is simultaneously suppressed. The outer walls survive the action of only those forces whose vector is oriented vertically. Builders do not always put a puff at the bottom, often it is exposed at the very ridge. In preparation for the construction of the attic, this element is often put higher than the base of the truss legs. Then you will be able to make a floor, on the ceiling of which you will not have to beat your head in any careless movement.

Hanging rafters for spans longer than 6 m should be reinforced with hangers and braces. In this case, the monolithic tightening is replaced by the one assembled from a pair of connected beams.In the classical scheme (triangular hinged), the lower bases abut in horizontal parts. For the normal functioning of the system requires that the height of the ridge was at least 15% of the span farms. Rafters act on bending, but the tightening does not allow them to move aside. In order for the beams to be bent less, the ridge knots are cut with the expectation of eccentricity (the occurrence of a bending force opposite in the vector).

Attic lofts are built for the most part with the help of triangular arches on three hinges, and puffs are assigned the function of floor beams. Components of tightening bolted by oblique or direct priruba. Elevated tightening can also be used in the construction of rafters under the attic. The higher it rises, the more the ceiling can be raised. But it is important to remember that at the same time the load on all the elements grows. The transfer of forces is carried out on the mauerlat by means of a mobile fastener, extinguishing the change in size from changes in humidity and temperature.

Rafters can be subjected to uneven load, because on the one hand it is higher. This leads to a shift in the same direction of the entire system. To eliminate such an unpleasant effect can, if you take out the rafters for the contour of the walls. The delay in such a decision ceases to be a support, it endures either tensile effects (if the attic is arranged) or stretched-bending (when an attic is constructed). Articulated arches with the inclusion of the bolt differ from the previous version by replacing the slide bearing with an identical in function - hard. Due to the change in the type of supports, the type of stresses that are formed becomes different, the rafter system turns into a spacer.

Tightening is formed in the upper lobe of the arch. Its purpose is to transfer not a stretch, but a compressive force. Additional tightening, reinforcing bolt, needed with a significant load. Arches with suspensions and struts complement the system of arches with "attendants". Such a system is needed for significant spans (from 6 to 14 m). The struts correcting the arising bend need to rest against the grandma. Regardless of the specific type of truss system, it is necessary to carry out all the parts and their bundles among themselves as clearly as possible.

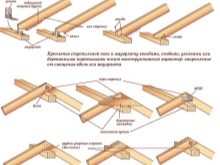

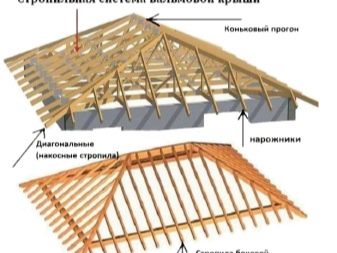

Not always hinged rafters can complete the task.Then pickup elements come to the rescue. This type of rafters is used under hip roofs and under roofs equipped with a valley. Their length is longer than usual. In addition, they become supports for the shorter trussed rafters. Therefore, the load on the rafters accounts for about 50% more than in other structures.

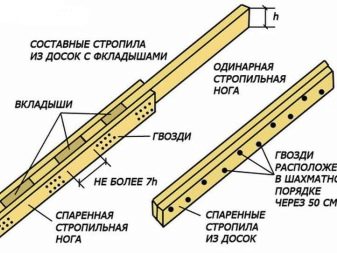

Due to the increased length it is possible:

- resist significant impacts;

- form beams without cuts;

- bring the parts to a uniform size by pairing boards.

To build a hip roof with many spans, diagonal legs are supported. Such supports are made in the form of standard struts or racks of timber, or a pair of connected boards. The support through a lining from a tree and a waterproofing layer is made directly on reinforced concrete overlapping. The struts set at an angle of not less than 45 and not more than 53 degrees, at the bottom of this part rests on the bed. The angle of installation is less important than the possibility of fixing parts of the rafters at a point undergoing the strongest load.

Slanted rafters placed in openings up to 750 cm should be supported by struts only in the upper lobe. With a length of 750 to 900 cm below, a trussed truss or stand is additionally mounted. And if the total length of the span exceeds 9 m, then for maximum reliability in the middle you need to put a rack, no other support will not work. If the chosen overlap is unable to withstand the load, you will have to reinforce it with a beam. The type of support in the ridge is determined by how many intermediate supports are used, what they are, how key napsled rafters are made.

In addition to the type of rafters, you need to clearly understand their material. Both wooden and metal structures can be good, but only each in its place. Even the high strength of the metal does not allow to push the usual wood. For thousands of years the tree has confidently proved its advantages, and now it even increases its popularity due to its excellent ecological characteristics. Boards and timber can be bought at an affordable price, and if something has not been taken into account, it is always easy to cut off the necessary fragment directly on the building site or to increase the detail.

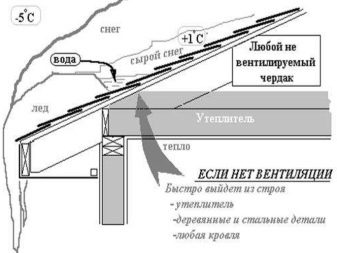

Sometimes there are problems associated with the operation of the created structures. Wooden rafters will have to be carefully treated with antiseptics, as well as means that block the development of mold colonies, eating insects.The combustibility of wood is suppressed due to regular processing, and in addition, for slopes longer than 7 m, it is too difficult to find the necessary components. Prior to installation, walls are laid with a power plate made from a timber frame or on the basis of a block of timber. The thickness of the structures is at least 180 mm, this is the only condition for uniform distribution of loads.

Metal rafters are inevitably heavier than wood with an identical section. Therefore, the walls need to be strengthened, work on their construction becomes more expensive and longer. You will not be able to mount metal blocks manually, you will need cranes. It is impossible or very difficult to adjust the dimensions, the geometry of the rafters, so immediately as accurately as possible have to build walls and eliminate errors during their construction. The slightest mistake can make an expensive unit almost useless in practice.

Metal rafters are tied by welding, and welded joints are inevitably weakened, because corrosion is rapidly developing there. The cost of the work is very high, and in fulfilling them it is necessary to fulfill the fire andelectrical safety. But there is an indisputable advantage, as the ability to support the slope of the roof from 700 cm and longer. If you use a special anti-corrosion paint, the durability of metal structures is fully ensured. All these advantages allow you to quickly and comfortably build industrial buildings with a significant height and length of spans.

How to choose: what to consider?

Trussing system should be selected as correctly and clearly as possible.

When searching for a suitable solution, you need to pay attention to the following points:

- strength;

- the ability to back up ramps and roofing in general, of a certain size and geometry;

- creating a positive aesthetic image of the building as a whole.

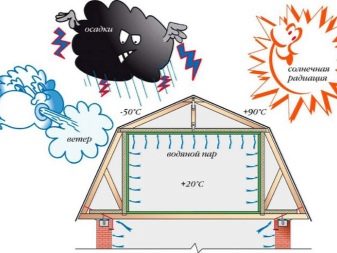

Technical parameters have priority value. Even the most beautiful designs that comply with the principles of design, will not show their positive qualities, if they serve too little. Experienced builders always analyze the average annual and seasonal temperatures, the financial possibilities of developers, the maximum possible rate of wind and the severity of the overlying roof. The future use of the under-roof space, the scale necessary for it, is also taken into account.It is impossible to underestimate wind, snow and rain, since these factors can have a very strong effect on the roof, and through it, also on rafters.

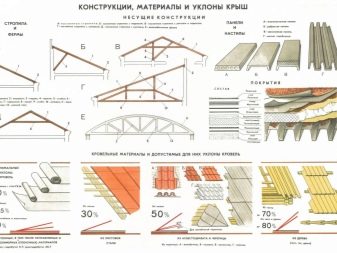

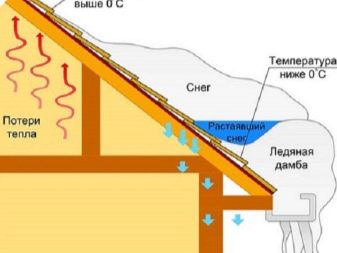

If it is reliably known that a particular terrain is distinguished by heavy snowfalls, the minimum angle of the slope is impractical. This moment is even more relevant when using flat roofs. Under the pressure of accumulating sediments, the frame can rapidly deform or water will pour inwards. Another thing is when a certain region is often subject to the arrival of cyclones and the strong winds they bring. Here, the ramp should be made smaller, then the situation with the breakdown of single structural elements will be practically excluded.

Errors can be avoided if you look at houses that have been built nearby and for a long time. By accurately reproducing the structure of their roof and the truss system interconnected with it, one can best take into account the local specificity. But not everyone follows this path, sometimes the task is to work out an original project only. Then you have to carefully collect the original data, carry out rigorous calculations.In the absence of special knowledge, it is better to attract qualified performers to help.

After analyzing the total load created by wind and snow, it is sometimes possible to find that certain parts of the truss complex need to be selectively reinforced. When assessing the required angle of inclination of the roof, attention is also paid to the type of coating used. Heavy metal tile or corrugated with a very large slope can spontaneously slide down, you have to additionally mount them, complicating their work and the cost of installation. In addition, some materials tend to retain water or soak it, you can only fight this by making the slope cooler. Creating a good roof and truss system that meets such conflicting requirements is not always available to non-specialists.

What is it made of?

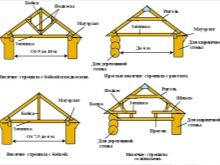

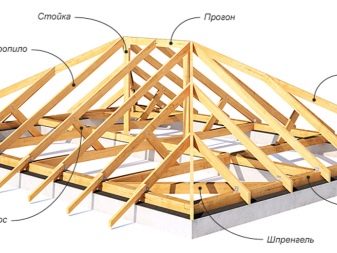

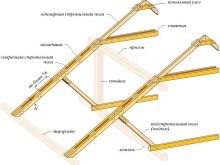

The device trussing system, it is easy to see, is quite complicated and even controversial. Each part of this design has a strictly defined role. Thus, the mauerlat is a long stalk of coniferous wood, and strictly resinous wood is used for work.Such elements are laid out along the external bearing walls, attached to the base with anchors or rods of a special construction (with thread). This detail transmits the load from the roof to the wall.

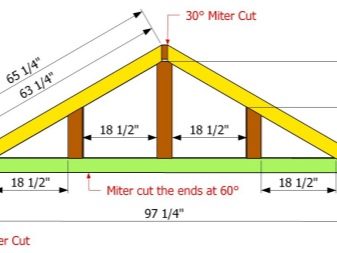

Next comes a device such as a rafter foot. Under this name there is a wooden bar used for the construction of the contour of the slopes. The form of the structure is always triangular, because it helps the roof in the best way to withstand the destructive effects of winds, snow and other atmospheric processes. Rafter legs are placed at uniform distances along the entire roof, a step cannot exceed 120 cm.

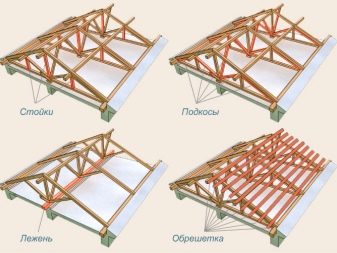

Determined value for the support of the roof and the floor is a wooden bar, replacing the mauerlat in some cases. Lay lie on the inner support walls. They become the basis of the roofing triangle. Thanks to them, the stingrays do not crawl away under their own weight. And it is also worth mentioning about the stands - these are vertical bars with a square section. They perceive the pressure that the ridge knot exerts downward, and transmit it mechanically to the internal carrier plane.Sometimes racks are under the rafter legs.

The struts are designed to strengthen the entire structure of the roof, they bind the legs and legs to one. This detail is shaped like a rhombus. The community formed by puffs and struts, received the name of the farm. In addition to them, you also need a crate, which is a thin board, stuffed at right angles to the feet of the rafters. It helps to keep truss legs as a single system. Absolutely any roof covering is attached to the crate.

Under soft materials, the crate should be made unbreakable, and plywood is considered the best tool. At the very top is the ridge, which logically and physically completes the roof triangle. The connection of a pair of opposed rafters is provided by a square wooden bar, which prevents the destruction of the roof as a whole. And at the very bottom of the pitched roof there is an overhang, which is approximately 0.5 m from the perimeter. Thanks to him, the streams of rain leaving the roof do not flood the outer bearing planes and do not harm them.

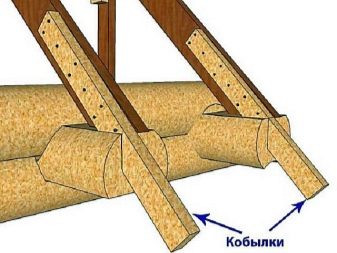

Fillers are used only in the situation when the rafter legs cannot be performed along the length that would allow an overhang. Connecting with reduced-section boards effectively solves this problem.For fastening of wooden elements of rafters it is most often recommended to use collars, brackets. It is undesirable to use nails because the tree punctured by them becomes weak and fragile after a few years. Therefore, if professionals use connections made directly on the construction site, they use bolts.

But even a bolted bond weakens building structures, albeit relatively little. Stronger than all are connections with clamps or metal clips. Only industrial production can maximize the quality of products, since only in strictly standardized and fully controlled conditions deviations from norms and deterioration are excluded. It is possible to assemble a truss structure from completely ready-made farms very quickly, there is no risk in its use. Another thing is that it is necessary to collect information about the required characteristics as accurately as possible and to transfer it to the manufacturer without distortion.

In addition to these elements, the truss system is bordered by the valley. This is the name given to a particular connection of a geometrically complex roof at the points where its trajectory changes.The difference from the ridge is that in such places the roofing parts form a negative angle. The technical essence of the product lies in the fact that the chute helps to divert the liquid aside. The more complex the configuration, the greater the number of such gutters should be.

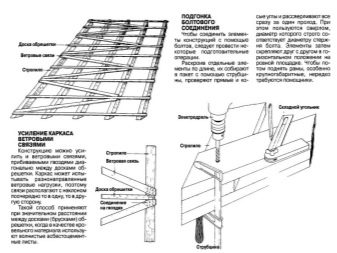

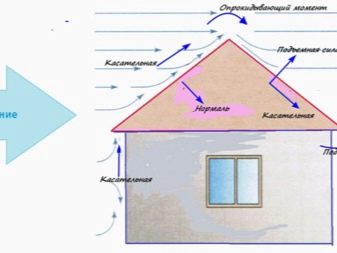

The eaves bar serves for an abutment of a strut into it, the other end of which rests against the frontal plank, while the dripstone is not deformed and its configuration is not distorted. Wind ties are those elements of the truss system that transfer the load created by the wind from roof to foundation. They not only increase the overall stability of the structure, but also help to avoid its overturning in case of instability of individual parts. The roof will retain its spatial rigidity even with very strong winds.

Horizontal wind links are such elements as:

- bracing;

- parabolic tightening;

- sets of conventional puffs;

- farms, supplemented by a cross-shaped lattice.

Vertically, performance is maintained under strong air pressure by wind supports and beams. Sometimes a monolithic reinforcing core is used.Engineers have come up with a lot of other design options for wind communication. It is provided with frames and half frames, pinched props. In small buildings, rigid (resisting compression) or stretched diagonals are used, some span two spans at once. The location of each element is accurately reflected in the project documentation.

Payment

Load

The quality characteristics of roof systems and their composition is not so difficult to understand, if you show care and diligence. But it is equally important to calculate the quantitative parameters of these systems. If you do not do this or make calculations incorrectly, you can either spend too much money, or run into leaks even with the destruction of individual elements.

To accurately calculate everything, you will have to analyze the following:

- roof bends;

- average annual snow mass;

- irregularities in its distribution over the slopes, depending on the steepness of the slope and wind rose;

- wind transfer of already fallen snow;

- the descent of snow and ice masses, the flow of liquid water down;

- aerodynamic characteristics and sail design;

- differences in the impact on individual points.

It is not so easy to calculate everything you need, while simulating realistic situations and putting a reasonable margin of safety into the project. Moreover, it is necessary to pay attention to the addition of various loads, to their cumulative effect. But still, any customer is quite capable of assessing the quality of the work of the designers. The loads applied to the rafter systems are divided into three key groups: main, additional and extreme.

In the main category fall:

- stable factors - the severity of the roof and roof structures, additional elements installed on top of them;

- long-term effects - snow, temperature;

- periodically changing factors - complete calculations of snow and temperature effects, taking into account all the subtleties.

An additional group is the pressure exerted by the wind, builders and repairmen, ice and rain. Extreme category includes all natural and man-made emergencies that may occur in a particular place. Their level is predicted with a margin to ensure the elimination of unpleasant consequences.When calculating the frame roof and the structures under it, the maximum load is taken into account, in the case of application of which the entire structure crumbles. In addition, an indicator or a group of indicators is given, at which achievement various strains inevitably appear.

The snow drift coefficient reflects how much more it will be deposited on the leeward side and in front of the objects (parts) that block air flow. In problem areas, you will have to bring the rafters as close as possible and thoroughly calculate the required thickness of the face material. The most accurate estimate of all parameters can be given only by multiplying any figures obtained by reliability factors. As for the wind, the force developed by him is directed at dropping steep roofs and lifting from the leeward section of the flat roof. We must not forget that the air flow acts simultaneously on the facades and on the slopes of the roofs.

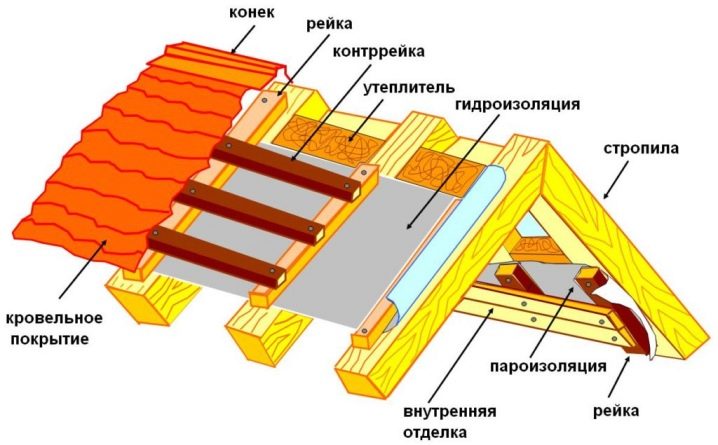

When hitting the facade, the air splits into two waves: one goes down and is of no more interest, and the other tangentially presses on the roof overhang, trying to lift it.The action on the slope takes place at a right angle, this area is pressed inwards. At the same time, a turbulence is formed, which tangentially affects the windward sector of the slope. This vortex bypasses the ridge and begins to create lifting force already in application to the leeward segment. For your information: when calculating the weight of the roof, you must consider the gravity of the rafters, insulation, waterproofing and the vapor barrier.

The standard load per 1 square meter of the roof is up to 50 kg regardless of its size and other significant circumstances. Changing the distance from one roof leg to the other, you can set the actual distribution of loads on them. According to most experts, acceptable values are indicators from 60 to 120 cm. But on the insulated roof you should choose such distances that are equal to one sheet or roll of insulation materials. At the same time, it should be borne in mind that among several suitable variants of placing the rafters, it is preferable to give the optimum effect with the minimum consumption of materials used.

When calculating the loads carried by the rafters, they always look at the fact that they do not exceed the ultimate endurance of the roofing material. After all, there is no point in such an excess.If, with the planned impact, the roof still begins to sag, it is impossible to speak about a solid result. In the calculations, the payload from the structures connected to the trusses of trusses is calculated according to the touch area that is applied to the drawing. Such structures include ventilation chambers, mansard and first floor ceilings, water tanks installed on the roofs. In addition to the amount of pressure on the roof system, calculate the sharpness of the slope of the roof.

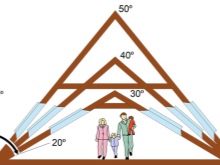

Tilt angle: value

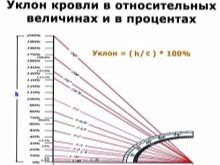

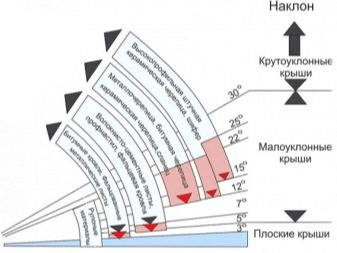

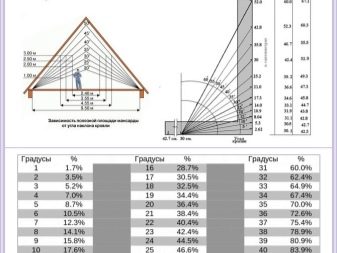

At the forums with the consultations of specialists and in the professional literature one can find references to three units of inclination at once. In addition to the usual and expected degrees, there will be percentages and ratios between the parties. Often they get along together even within the framework of one publication or instruction from the manufacturer of roofing materials. But in fact there is nothing mysterious about it, any consumer can understand the essence. At an angle of inclination of the roof, specialists understand the angle that occurs at the intersection of the horizontal with the roof slope.

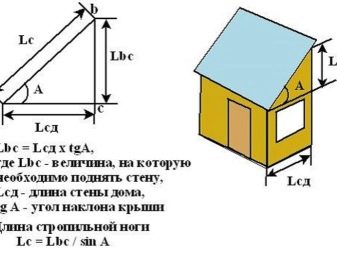

Dumb corners in this case can not be in principle.Moreover, to meet the slope steeper than 50 degrees is possible only in the decorative elements, all kinds of turrets. An exception to the general rule is only the ramps on the lower rows of rafters of the roof roof. In all other cases, the angles range from 0 to 45 degrees. The relative proportions of the sides are calculated as the ratio between the height of the slope and its projection on the horizontal. This figure is equal to evenly designed roof with a pair of ramps half of the span.

On a shed roof, the proportion is equal to one, and in more complex configurations you will still have to do all the calculations and estimations yourself, not starting from ready-made values. The slope angle is usually expressed as a fraction, the numerator and denominator are separated by a colon. But when the resulting figures cannot be rounded to whole numbers, it is recommended to use percentages: they simply divide one by the other and increase by a hundred times. Flat roofs are those that have a slope of no more than 5 degrees; a small slope of 6–30 degrees is recognized, and all other roofs are considered steep. The flat design dramatically increases the usable area and is quite resistant to the wind, but it will be necessary to clean it of snow by hand and to strengthen the waterproofing to the limit.The bias is necessarily consistent with the specific material, and the necessary values can be found in the instructions from the manufacturer. To calculate even the most complex and bizarre configurations of roofs, they are mentally divided into triangles and each one calculates the angle separately.

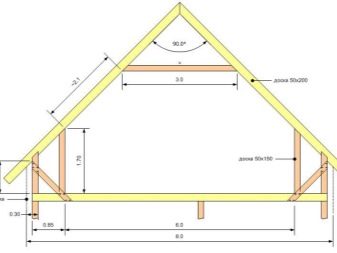

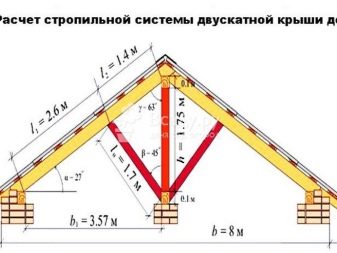

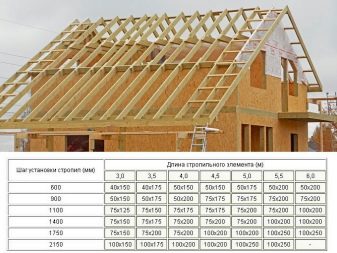

Step, length and cross section of rafters

When it became clear what the length of the slopes, what angles formed by these slopes with a horizontal plane, it is time to do the actual miscalculation of the rafters. If the roof frame is made of 5x15 cm lumber under the metal tile, the installation pitch shakes from 0.6 to 0.8 m. As the steepness of the slope increases, the gap also increases. If the roof is inclined at 45 degrees, you need to put rafters every 800 mm, and for slopes of 75 degrees, you can add another 200 mm.

The next important parameter is the length of the rafters. It is closely connected with the step: if the blocks are made long, they are brought together as closely as possible, and when a single part is shortened, they are moved apart. When calculating the step, the battens are based on the type of tile placed on top and from the fact that an integer number of rows should be laid out on each slope. If you get a fraction, it is better to round, reduce or increase a little figure. Rafter legs under a metal tile, the section of which is 15x5 cm, range from 65 to 95 cm.It is impossible to increase the pitch when cutting the crate of 3x5 cm.

In order to better insulate the insulation, rows of holes with a diameter of 1–1.2 cm are prepared in the area of the upper edge of the rafters. with significant cross-section. The lathing under the corrugated board is assembled from boards with dimensions of 3x10 cm, which are placed with an interval of 0.5 m. The interval should be calculated according to the height and thickness of the materials.

With all the identified deficiencies of slate, it remains widely in demand. Under the slate roof, rafters with a cross section of 5x10–15 cm, 60–80 cm distant from each other, are mounted. The average distance, which is 0.7 m, is most often recommended. In relatively flat areas, reliance on 4 pieces of wood is worthwhile. If the roof is steeper, put 3 bars, separated 63–65 cm.

We must not forget that because of the responsibility of the roof system, it is better to leave a margin of safety than to make an unreasonably weak type of rafter.For their manufacture used timber, dried up to a maximum of 15%. Replacing the timber can serve not edged board of the same dryness. Under ceramic tiles, a crate of 5x5 cm timber is used. In the places designated according to the calculated distance, nails for slate or simple self-tapping screws are used.

Installation: technology

Building a roof involves using a standard range of carpentry tools and an electric drill. If metal structures are used, a grinder is required for precise cutting. Remember that it is impossible to process metal roofing or corrugated board with it, it can lead to material damage. Hip roof without racks is done with the help of puffs that reinforce the structure.

In the hip version it is necessary to strengthen the runs running along the diagonal. They take paired boards and very strong timber. Connection points always have a support (rack), and the main support is placed about a quarter of the length that separates the large rafters from the ridge. Under the gables on the gable roof always make rafters of shorter length. But under the main part of the four-fold design, extremely long parts can be put, even more than 7 m.To keep them securely, they use either a rack, which translates the voltage to the floor, or a sheath.

The first step in creating the rafters under the broken roof is the formation of a supporting complex in the form of a letter P. It rests on the floor joists and is held by the rafter legs. Next, put three or more runs, two of them lead to the corners of the frame, and the rest are in the middle of the overlap. The final step in the trussing is fixing the legs. It is desirable to do rafter systems according to a pattern - to connect two boards that coincide in length with the rafters, and nailed to each other with a nail. Template set edges in the point of attachment truss legs and fix it with a cross member.

An additional template (this time plywood) will help to make a mounting saw. Farms are attached to the power plate, starting with the extreme. In order not to make a mess with the point of attachment of the ridge, the tops of these trusses are tied with a straight rope. The massiveness of puffs as you approach the skate increases. If the truss elements are bolted, it is necessary to use washers or plates. This will prevent the nuts from sinking into the wood.

How to install the rafters with your own hands, see the video below.