Ondulin sheet dimensions: standard parameters and effective area

Ondulin - a popular modern roofing material. Its demand is determined by the ease of installation, as well as the load resistance of the material. The construction name of ondulin is euro slate. Our article is devoted to the size, useful area and other characteristics relating to this material.

Features and purpose of the material

Features ondulin lies in the fact that this material has improved performance in comparison with ordinary sheets. His canvases are as wavy as ordinary slate. As part of the base - compressed cellulose impregnated with bitumen.Improving the characteristics of the material is associated with a special impregnation of thermal oils and minerals. This complex provides enhanced protection from moisture.

Let us examine the material properties in more detail:

- resistance to the adverse effects of the natural environment;

- long service life (manufacturers warranty up to 50 years);

- excellent heat and sound insulation properties;

- visual appeal;

- manufacturers offer a lot of colors, giving the opportunity to choose the perfect combination;

- sheet flexibility;

- leaf susceptibility to fungal and bacterial lesions;

- good moisture resistance.

If we talk about the minuses of the material, then some buyers say that ondulin is melted from the strong heat of the sun, in the heat. In this case, people complain about the unpleasant smell of melted roofing.

Another negative quality of ondulin is the noticeable fading of the coloring pigments over time. When fading, the surface of the sheet is stained with bitumen. Roofing material loses its appeal.

When laying ondulin not necessarily use steam and waterproofing materials.Its properties allow to do without additional barriers. However, for the insulation of the attic, which will be used as a dwelling, it is better to additionally apply the appropriate types of insulation.

Ondulin is used most often in private housing. The material is usually found on the roofs of small houses and cottages. On the two-story luxury buildings used tiles (sheets or piece).

Today, builders began to use ondulin on structures such as schools, clinics, etc. This type of roofing material is incredibly simple to install. In addition, ondulin allowed to lay on top of the old slate. This type of renovation does not require the closure of the institution due to the repair of the roof.

Ondulin can be divided into 2 types, depending on the coverage.

- Matte canvas. Characterized by roughness. This surface contributes to a greater accumulation of small debris on the roof.

- Glossy canvas. The surface is bright, smooth. Snow comes down from such a plane, therefore it is recommended to install snow holders. One of the drawbacks of the glossy ondulin is the fast fading.

Consider the features of maintenance ondulinovogo roof.

- No special care is required for this roofing material. In order to avoid damage to property located in the house, it is sufficient to regularly clean the roof from snow and dirt.

- In order to eliminate the fading of ondulin, it is recommended that the material be coated with a special paint.

The creator of the wavy material is the French company Onduline. Brand products quickly gained popularity abroad due to environmentally friendly material. The appearance of the product compares favorably with traditional slate or asbestos cement.

Not so long ago, the joint Italian-French invention “onduil” appeared on the building materials market. The design perfectly reproduces the look of natural ceramic tiles. At the same time, it is similar in composition to Ondulin.

Purified cellulose is also used for ondovil. The substance is soaked with pigments, then the material is compacted, and upon reaching a thickness of about 3 mm, the substrate is left to dry. After hardening, it acquires a specific waviness. Impregnation with oil bitumen occurs at the final stage of production.Ready sheets are stacked and packed in a special film.

Ondulin always has standard sizes. If there are discrepancies in the width or length of the corrugated sheets, then there is a fake in front of you. Exact dimensions of standard sheets allow you to easily make the necessary calculations.

Options

Consider a few key indicators.

- The main parameter that excites users who plan to equip the roof is the strength of the roofing material. In Ondulin, this figure is more than 1,800 kilopascals. This strength is enough to withstand a significant snow load and the weight of several people. The standard load for Euro-slate is 960 kg per 1 sq. M. coverage meter. With a larger load, the roof system is usually destroyed.

- Manufacturer's warranty is maintained when the material is exposed to temperatures from -50 to +50 degrees. In this case, the manufacturers themselves cite data that the material retains its properties and when exposed to temperatures up to 110 degrees.

- Sound insulation coefficient Euroslate is about forty decibels. This is enough to not hear the falling raindrops.

- The cost of the material varies greatly depending on the country of manufacture (from 200 to 400 rubles). Additional items also have their price, their purchase is required.

- The width of one sheet is 95 cm. This format is considered optimal for creating any roofing configurations.

- The length of the sheet is 200 cm. Such a “round” value noticeably facilitates the necessary calculations.

- Ondulin standard thickness - 3 mm. If there are minor deviations in this parameter, this is allowed and is not considered marriage.

- The weight of one sheet is 6 kg. If we consider the weight of onduvil, then it is 4 kg.

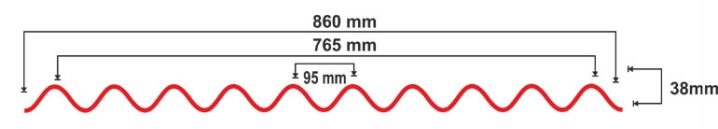

Wave height

The height of the bends of a standard sheet is 36 mm. In one sheet element - 10 bends. Manufacturers allow deviations in dimensions of no more than 2 mm. The nominal step of the wave is 9.5 cm. In the calculations, it should be borne in mind that roofs with complex wave elements will significantly increase the material consumption, since at the junction of each bend it will be necessary to perform overlapping.

Features of the calculation of the required amount

Carrying out the arrangement of complex roofs, do not forget about the inclusion in the cost estimate of additional elements: skates, valleys, tongs and other additions.In any case, for calculations you need to remember the area of one sheet, which is 1.9 square meters. When laying, the useful area of each sheet is taken into account, which is usually smaller and amounts to 1.6 square meters. m. The overlaps of sheets are both horizontal and vertical, it must be considered when calculating.

To find out the required amount of ondulin, you need to calculate the area of the roof slopes and divide it by the usable area of one sheet element. To this value, it is recommended to add about 10 percent of the stock. Additional elements are calculated separately. To get the most accurate calculation, it is recommended to use special computer programs.

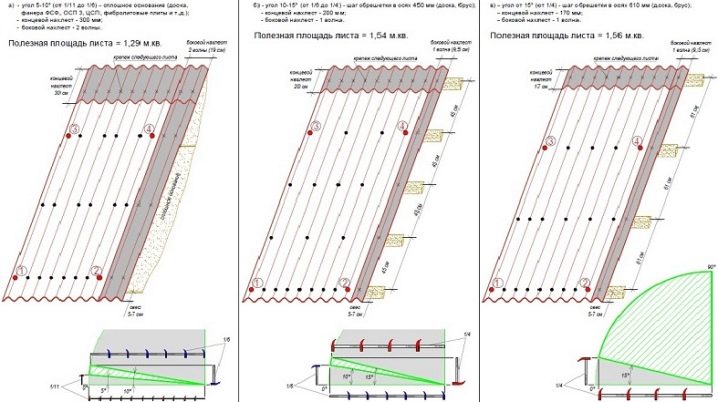

Useful area with overlap

To calculate the number of sheet elements on the roof should take into account the usable area. This is the surface of the material, which is visible, overlaps and interleaving are not considered. Overlaps can be in one bend, and may be more significant.

The vertical overlap of the elements on each other may also differ. It is interrelated with the value of the angle of inclination of the roof. It is believed that the working area of ondulin with steep slopes is approximately 1.3 square meters.m. This is due to the strong bias, in which there is a need for large overlaps on each other. Horizontal overlaps in this case can be not one, but two waves. With the usual slopes of the roof, the useful area of ondulin will be, as already noted, 1.6 square meters. m

The market of building materials is constantly expanding. Today, the usual ondulin is being replaced by a more advanced analogue of it, Smart. This material, unlike its predecessor, is more convenient for installation due to the marking applied on the sheets.

Useful recommendations

A few tips on installing roofing material.

- During the arrangement of the roof, ondulin has to be cut. To lay the material around the chimney it is necessary to cut the sheets into very small fragments. When overlapping experts also recommend to cut the material. For cutting it is strictly not recommended to use an electric jigsaw. Too small teeth of this power tool will get clogged with cellulose.

- For cutting ondulin, it is better to use an ordinary stationery knife. With it, smooth cuts are made, without shredded edges. Cutting is performed starting from the front of the material.Further the sheet is bent on the received line and turns over. The incision is extended further.

If it is necessary to cut a sheet along the length, the incision is made not along the wave, but along the depression between them. Still masters advise to lubricate ondulin sheets with oil. A handsaw with greased cuts will go faster.

- If the sheet is cut to width, then it is better to use a classic hacksaw for wood. Features of the work are mandatory pre-marking. Then the sheet is cut exactly along the line. A chemical marker is used for marking, some masters use wax crayons. To mark the cornice row entirely, it is better to use a cord.

- If a large number of sheets are to be cut, it is better to use a circular saw. With the help of a tool, a beautiful, even cut is made. Sometimes the teeth of the circular saw are clogged with cellulose. For cleaning it is enough to make a one-time cut of a wooden bar.

- Experts recommend caution in using Bulgarian for cutting material. Usually, in this case, melted edges are obtained at the cut points. The temperature of the material increases due to the high revolutions of the working circle.Sometimes melted edges appear due to the fact that the work is carried out in the sun, so it is better to make the cut in the shade or in a cool room.

- Nails with special caps are used to attach the ondulin. They are supplied with plastic plugs. If you use screws or roofing nails, you can break the laying technology. In this case, your claims in the event of an emergency will not accept any manufacturer.

- It is more convenient to hammer in nails with an ordinary hammer. On one sheet should go about 20 nails. First, nails are hammered at the bottom of the cloth, in each wave. Subsequently, the fastener is made through a single wave in a checkerboard pattern.

- Experts advise you to close the caps on the fasteners immediately after fixation, otherwise there may be difficulties during the subsequent work on the roof.

- For lifting ondulin on the roof, you can use a special strong twine. At its edges have hooks. If the roof is low, then the sheets can be delivered manually, without special equipment, as they are light enough.

- Some owners of houses covered with ondulin complain that the material softens over time from frequent rains.To avoid this happening to your roof, it is worth being vigilant when choosing a manufacturer. Some poor-quality companies sell ordinary pressed cardboard, which is coated with coloring substances resembling an undulant coating.

- The original ondulin does not soak, it has the properties of the usual slate. Like slate, it has the peculiarity of breaking. To prevent damage to the material on the roof, you should move on its surface only through special ladders.

The procedure for performing work when covering the roof with ondulin can be represented in several stages.

- Laying crates. It is recommended to use bars with a section of 40x60 cm. The step between the bars is directly related to the slope of the slopes. Usually this value ranges from 45 to 61 cm. For bars, attachments in the form of long screws are needed.

- Evenness of crates for ondulin is not an extremely important characteristic. The material will look great on uneven roofs. Slate under the same conditions can crack.

Bitumen-cellulose coating, due to its elasticity, will correspond to the configuration of the roof. The functional features of the material in this case will remain in force.The roof will lose only visual appeal.

- For marking laying sheets useful pencil and measuring tape. Laying begins on the leeward side. At the same time at the corner junction creates an overlap in three waves. The second row of the coating must begin with ondulin cut into two parts.

- Professional stacking scheme involves the chess order of assembling rows. Vertical seams between the sheets should not be the same. This will provide additional protection. For the same purpose, and useful special waterproofing tape. It must be used in the joints with the end, eaves and other additional elements.

On how to properly roof the ondulin, look in the next video.