Choosing nails for roofing

Roofing is a difficult professional job that you need to work hard to get the desired result. It is unacceptable to treat the arrangement of the roof lightly, because even the chosen nails depend on the strength and reliability of the design, as they fix the lining and connect different materials to each other.

Kinds

The construction market is rich in different models of roofing nails. They differ in properties and parameters, which affects their scope and purpose.

- Brushed nails. Indispensable during the installation of the roof of a soft type, characterized by the presence of a tapered head restraint. After clogging, the head restraint is securely fixed in a previously made hole, which results in a very tight fit of the fastener hardware in the perforated overlap.

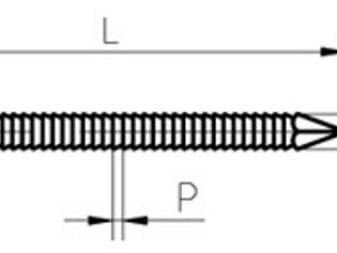

- Screw nails (screws). Popular type of fasteners with a cap used in construction work. The base material is steel wire. The main feature of screw nails lies in their appearance: the leg of the fastener is twisted along its entire length, due to which the fixing part does not fall out of the base of the structure and is securely fixed in it.

- Galvanized nails. Used for fasteners of different types of roofing materials on the construction of wood.

- Hat hardware - this is a special type of galvanized nails with a length of 2.5 to 3.5 cm and a wide cap, used to fix shingles. The length of the nails allows them to easily penetrate into the design of the roof through the flooring, and the wide bonnet prevents them from falling through the surface of the working material.

- Drum nails. They are recognizable due to ring rolling and are designed specifically for use in pneumatic pistols. The length of the products is 1.9-4.5 cm, which allows them to easily fix various roofing materials. Sold in rolls. As a rule, in one such roll is 100 pieces. hardware.

Nails for a soft roof

The list of soft coatings for roofing includes roofing felt and roofing felt. A feature of hardware for such flooring is their appearance - a cap of large diameter. Due to this design feature, the fasteners prevent the tearing of the soft coating by the gusting wind and other negative influences of a mechanical nature. Roofing material is pressed as close as possible to the crate with a cap and remains in the same position for many years.

For fixing roofing, short nails are used, which look like clerical pins. The diameter of the caps of such hardware can vary from 3 to 7 mm.

Since the roofing felt and roofing felt belong to the number of soft flooring, to install them you do not need to put increased physical effort. Fasteners in this case are used from metal alloys and they do not differ in high strength, as they are intended for fixing soft materials. However, in order for the hardware not to destroy corrosion during operation,that will adversely affect the condition of the entire roof covering, you should buy only galvanized or copper nails that do not rust even in conditions of high humidity.

Another soft coating for roofing is shingles. And although it is very similar in its structure to roofing felt, nails for its fixation differ from the above options - the difference concerns size. For the installation of bitumen tiles, fixing hardware is used that is at least 2.5 cm long and with a cap width of 8 mm.

Fasteners for shingles can be made from any metal, however, in order to prevent nails from being exposed to moisture for a long time, they are necessarily galvanized with zinc. Such hardware has excellent anti-corrosion properties.

Nails for ondulin

Ondulin is a roofing material that combines the characteristics of soft roofing material and solid slate at the same time. According to building codes, the mounting of the ondulin to the crate should be as durable as possible, but at the same time the wave, which is inherent in this product, should not be damaged. Hardware for ondulin also have their own characteristics.First of all, they differ from other nails in their appearance, and more precisely, in the possibility of being painted. For this reason, such products may be red, green, there are also brown specimens.

In the process of laying ondulin can be used as ordinary nails, and screws with a gasket made of plastic under the cap-cap. After the hardware is screwed or driven in, the lid is tightly closed, preventing the penetration of fluid under the cap. Wizards with extensive experience to facilitate the installation process, snap the covers on long before the fastener is locked in place.

Due to the irregular shape of the gasket under the bonnet, the fastener reliably and very tightly presses against undulan As a result, the coating is protected from the negative effects of environmental factors.

Manufacturers often manufacture fasteners for ondulin from alloy steel and make notches on the rod that prevent nails from falling out of the wooden crates.

Hardware for pneumatic gun

As a rule, nails in the roof covering are hammered by hand, but it is much easier and faster to do this with special equipment, or more precisely, with an air gun. Fasteners for a pneumatic unit should be short - no more than 4 cm, but at the same time have a wide hat. Quality elements of this type of fasteners are made of stainless steel or galvanized. Steel roofing hardware should be made according to GOST 4030-63.

Fasteners in the gun are in the chamber. At the same time, a few dozen nails attached to each other with wire can be charged into the gun. In appearance, they resemble a machine-gun belt. When the “hammer” touches, a large stream of air passes through the chamber, under the influence of which the hardware nails the roof covering to the crate.

Brushed nails

Ruffled mounting nail got its name due to notches evenly applied to the rod and resembling the needles of a household brush for cleaning bottles. When installing "brushes" are introduced into the wood and "tightly" are fixed in it. Thus, high-quality installation of the roofing material is ensured - all elements of the roof will not move or fall out.

Brushed nails are produced for fixing soft and hard coatings (for example, slate). Asbestos-cement surface fasteners differ from ordinary nails in their size and appearance, since they have a rubberized cap that prevents moisture from entering the mounting recess.

Use nails in the installation of roofing materials should be in full confidence in their abilities or the skill of roofers, because if you have to dismantle the structure, the fastening element can be damaged itself, as well as nail the lining.

About what nails are needed for roofing, see the following video.