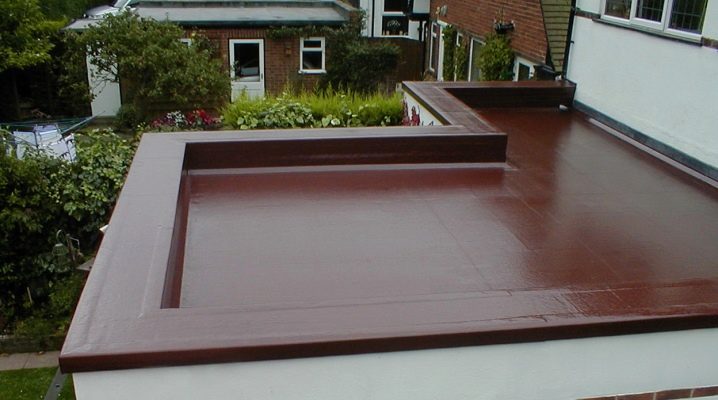

Membrane roof: device design and installation details

Each person during the arrangement of his country house pays special attention to the roof. Today, in the building materials market, consumers can find a variety of materials for this design.

What it is?

Membrane roofing is a roll coating made on the basis of bitumen. It is worth noting that this type of material differs from the rest with special technical characteristics. It is these parameters that make such a roof much better and more reliable compared to other varieties.

Experts give an exact description of this roof: it has the form of a film web consisting of polymer components.Often, manufacturers in the manufacture of such material additional components (fiberglass, converted bitumen), which give the product strength and hardness. The device of such a roof allows the laying of the coating without seams.

Specifications

Roof membrane structures have many important positive properties and characteristics.

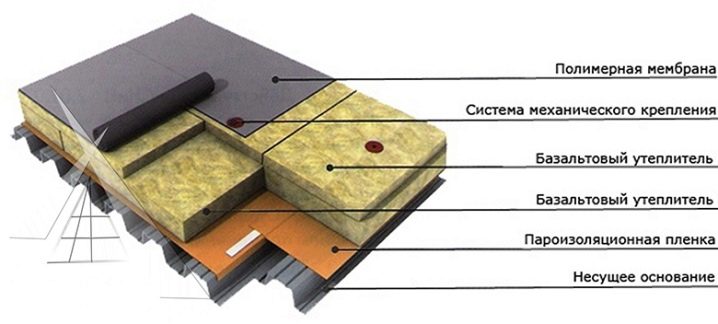

- High level of vapor barrier. This property does not allow moisture to penetrate into the insulation.

- Good thermal insulation. Membrane roofs do not need to be treated with additional materials for insulation.

- Fire prevention Before use, the membrane is carefully treated with special solutions that counteract the fire.

- Environmental safety material. The membrane base is a non-toxic, clean product. Therefore, the roof made of it, never harm human health.

- Long service life. Such roofing material will be able to serve their owners for more than 30-40 years.

- Moisture resistance. The roof, made of a membrane, is particularly resistant to the harmful effects of water.When hit, the roof is not deformed and does not undergo destructive corrosion.

- UV protection. The material of this roof is not subject to the harmful effects of sunlight.

- Flexibility. Often, membrane roof cover structures of complex geometric shapes.

- Aesthetic look. The roof, made of a membrane, has a beautiful appearance. It is also worth noting that this material allows the installation to be performed almost seamlessly - this makes it even more aesthetic and neat.

- High resistance to sudden temperature changes. This type of roof will not collapse or deform even with strong temperature fluctuations. It should also be noted that the installation of this material can also be carried out under different climatic conditions.

- A light weight. This property greatly simplifies installation work on the installation of such a material.

Despite such a rather big list of important positive properties, the membrane roof has a number of negative characteristics:

- High price. Many professionals and consumers note that the device of the roof of the membrane base will be affordable for not every person.However, some buyers say that the quality of such products is fully consistent with its value.

- Low chemical resistance. Some types of membrane coatings are strongly destroyed by contact with chemicals (building solvents, bituminous compounds, organic oils). Many people, to avoid this, cover the material with an additional protective layer.

- Color is quickly lost. The roof of the membrane in the manufacture of coated with special coloring pigments. Under the influence of ultraviolet rays, they begin to quickly burn out, and the whole structure loses its beautiful, original appearance.

- Destroyed by contact with petroleum products. If you cover the roof with membrane material, you will have to make sure that no fuel or lubricants get onto it, otherwise the coating will simply lose its appearance and deform.

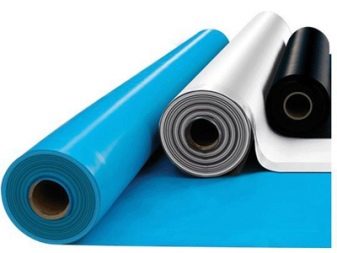

Kinds

Today, the variety of membrane roofing structures is represented on the building materials market.

The most popular types include the following models:

- TPO;

- EPDM;

- PVC;

Roof TPO

The soft built-up roof of TPO is created from special thermoplasticmembranes with reinforcement - this particular sample is considered the most modern and practical types of such materials. In the manufacture of such a model, various types of olefin are used: polypropylene, ethylene-propylene rubber and other varieties.

It should be noted that the presence of stabilizers and antioxidants in this material allows the structure to remain strong for many decades. It is also important to remember that the TPO roofing sample is absolutely eco-friendly and has the longest operational period compared to other types of membrane coatings.

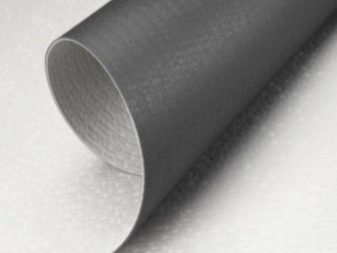

Roof EPDM

Another common type is flat membrane roofing EPDM. Make it from special artificial rubber. When creating this design using a special reinforced polymer mesh. It is needed in order to give the material strength, hardness and increase the service life. In addition, the composition of this model includes additional polyester additives.

Sample EPDM differs from other types of membrane roofs with special waterproofing characteristics.But it is worth noting that the price of such material will be rather big. However, the overwhelming majority of specialists are sure that the quality and high service life fully correspond to the cost of these products.

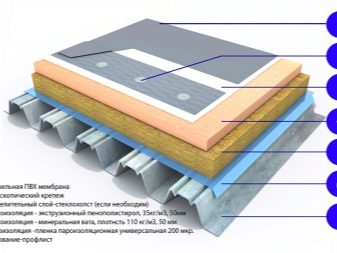

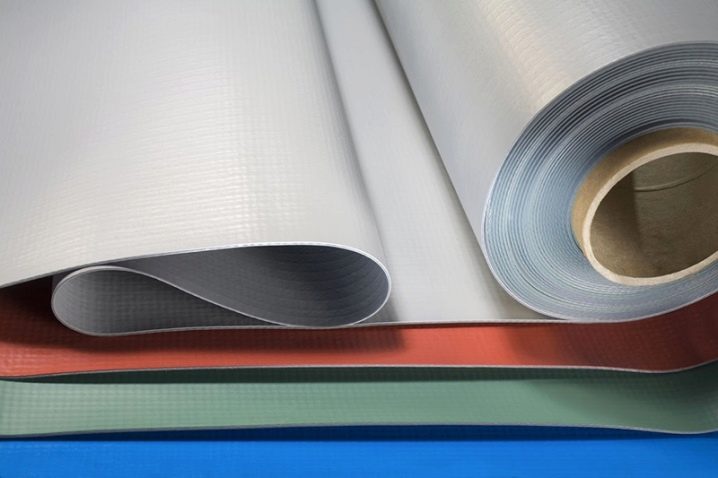

PVC roofing

This model of membrane roof is the most popular among buyers. It is made of polyvinyl chloride. To increase the strength and reliability of the material, additional plasticizers are also added to it. It is important to note that the PVC sample boasts the highest rates of fire resistance compared to other types of membrane structures.

It should be noted that the sample of the PVC roof, as well as the single-layer model of TPO, has a special reinforced polyester mesh, which gives the product additional elasticity and resilience. This type of coating is used in the construction of roofs of complex geometric shape - they can sheathe even the minimum and maximum slopes of the structure, because, thanks to a special degree of flexibility, it fits perfectly to almost any form of the structure.

Choice of laying technology

Many experts note that the membrane types of roofing can be installed in various ways. Before starting installation work, it is imperative that you thoroughly clean the entire surface on which the material will be installed. In addition, it is necessary to carry out accurate calculations of the amount of coverage that will be required for the structure.

Often people when installing this type of roof used a mechanical method. It will definitely require the installation of a special funnel or telescopic fastener. Such a part consists of an anchor element and a load balancer. It is important to choose a part of such thickness that it was significantly less than the thickness of the insulation. Having fixed these components, you can proceed to the direct laying of the coating using an automatic apparatus.

There is also a type of installation of a membrane roof by conventional adhesive bonding - this is the most common installation technology. With this type of installation sealing joints carried out with a special adhesive composition. In this case, it should be applied immediately to both sides of the seam.

Another way to manufacture a membrane roof is heat-welded technology. According to most experts, this type of installation, without a doubt, can be called the most reliable. For installation, you need to heat the welding machine to a temperature of 500 C. Then all the equipment must be placed on the surface of the future coating.

After that, it is necessary to hold the device along the seam, while the mechanism will affect the material with hot air. We must not forget that the reverse side of the surface must immediately be rolled on with a special silicone roller.

Often the membrane coating stack ballast method. But it should be remembered that such a technology can be applied only when a structure with a slight bias is drawn up. Installation with this option can be both mechanical and heat-welded.

But it is important to note that the ballast method implies the presence of a special geotextile, which is intended for the separation function. After laying this layer you need to install the ballast itself. You can use various products: paving slabs, gravel and other similar materials.Only then should the surface be covered with a finishing roofing foundation.

Most experts note that regardless of the installation method, special attention should be paid to some details.

For example, when constructing any roof, it is imperative to make a cake with a razuklonka.

It is a sequence of layers of the future structure, which includes material that gives a certain slope to the coating. This angle is necessary to ensure the drainage mechanism, since without any inclination, precipitation will remain on the roof surface and accumulate there.

Instructions for working with the material

As a rule, all products for the roof, made of a membrane, are issued with a special instruction that greatly simplifies the installation of the roof. It contains all the necessary instructions in order to properly perform the necessary work for laying such a material from the membrane.

Each instruction contains information about the roof assemblies for the structure. It indicates which node to make for a specific type of roof and how to properly perform it.Such elements are different: parapet, curved, endovyh nodes. For each specific membrane there is a specific node.

In addition, in any such instructions, you can find information about which method of technology is best for a particular type of material. It is worth remembering that for many membrane coatings you can use different methods of installation. Detailed installation instructions are also given in the instructions.

The instructions should also pay attention to the conditions under which installation of the roofing material from the membrane is possible. Despite the fact that most of these coatings are not exposed to the harmful effects of temperature fluctuations and moisture, it is still necessary to familiarize yourself with the installation instructions, because there are membranes that begin to deteriorate or deform if they are laid during sharp temperature variations.

There are no special requirements for the material, because it has a unique elasticity, elasticity and durability, which makes it easy to work with it, without fear of tearing and damage. Transportation and loading of the material also does not require special conditions, as it is produced in convenient rolls that are hard to damage.

Manufacturers

Today, a considerable number of manufacturers of membrane roofs can be found on the building materials market.

The most popular is "TechnoNIKOL". This construction company specializes, as a rule, on PVC models. But this company also has a series with samples of TVET and EPDM.

TechnoNIKOL manufactures membrane coatings of several classes: SUPER PREMIUM, PREMIUM and BUSINESS. In addition to these varieties, the company also produces a waterproofing roof for tunnels, bridges, foundations and decorative cladding. According to most experts, the roof of the material from this manufacturer has a special fire and vapor barrier properties.

Another popular manufacturer is Ecoplast. It manufactures its products from high-quality polyvinyl chloride. Roofs from this manufacturer are distinguished by a high level of waterproofing and resistance to ultraviolet radiation.

In addition, the surface of the material Ecoplast in the manufacture of coated with a special anti-slip coating, which greatly simplifies the movement of builders during installation.Also, many consumers separately note the high quality, strength and flexibility of the product. The products of this company are made together with reinforced mesh.

The products of the Swiss company Sikaplan are in considerable demand. It is produced using the latest technology of polyvinyl chloride with internal reinforcement. Designed such a roof for waterproofing structures. In addition, it is the materials of this company that can withstand considerable loads and not be deformed at all. In the company's product range, you can also find coatings of modified membranes, which are used for waterproofing swimming pools and baths, protecting against groundwater. Such products can boast a high level of vapor barrier, durability with strong stretching and special durability. Most often for such roofs used ballast installation method.

Useful tips from professionals

Today, some experts leave many different recommendations for laying membrane roofing structures. For example, many strongly advise installing snow-holding mechanisms along with the roof itself.Especially these elements are needed near the entrance to the house and the entrance to the garage.

These parts do not allow a large amount of snow to fall from the roof.

To avoid the accumulation of ordinary water, you can make a small slope of the structure - then all the excess moisture will drain from the roof without residue on the surface of the coating.

Also, some experts advise to periodically conduct inspections of roof drains and roof funnels, because ice, foliage and other unnecessary items are often clogged in them. This can seriously damage the coating, since all excess moisture will not leave the surface of the material. Therefore, if during heavy precipitation water does not flow from the surface of the structure, then it is worth checking the drains.

Many experts also leave a considerable number of recommendations for the repair of roofing roofs. If the roof is damaged, then it can be easily repaired with a special patch. To do this, you need to cut it out of the base and round off all its edges. Then it is well to warm up the new part and the place of damage. After that, it is recommended to lay the element with a conventional spatula.

Installation of membrane roof, see the following video.