Ventilation pipes: types and features of the application

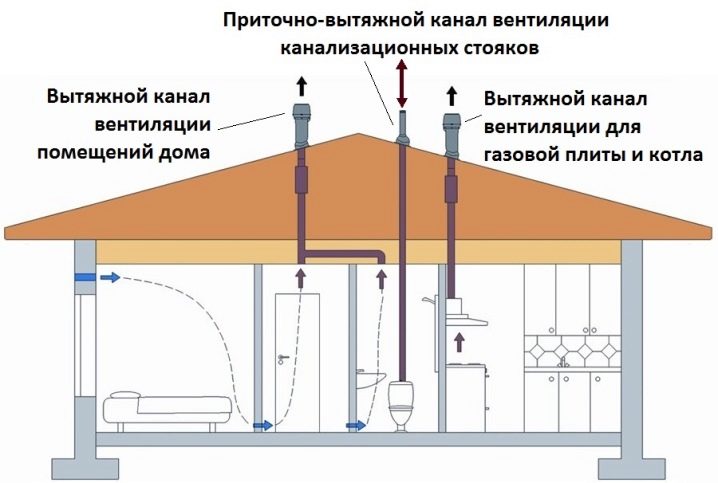

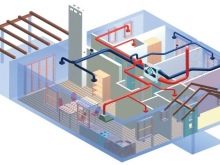

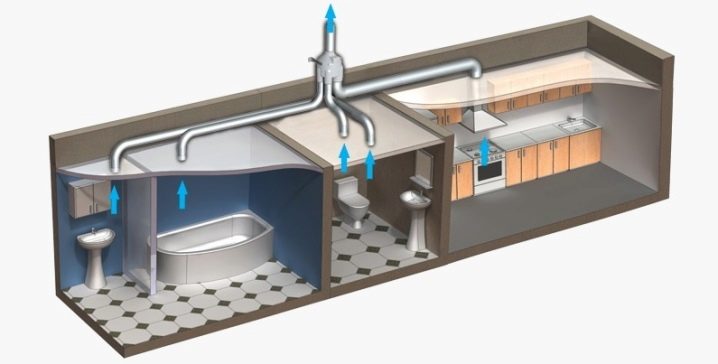

The air outlet to the outside and the supply of clean and fresh air masses must be present in any room. For this reason, each room must have a ventilation system that will be responsible for the entry and exit of air masses. Its integral attribute is the ventilation pipes, which are necessary for the transportation of air masses. It is worth considering what they are, how they are created, what forms and dimensions they have and how to install them yourself.

Description

In order to make a good ventilation or exhaust system, it is necessary that the ventilation pipes to be used in this system are properly selected.

In order to achieve this effect, the following parameters should be considered:

- conditions in which the system will be operated;

- dimensions;

- the material from which everything will be made.

To date, air ducts are made of either aluminum or plastic. Each of the materials has its own characteristics, as well as advantages and disadvantages. As well as exhaust systems differ in their purpose. Some will be designed for the kitchen, others will simply serve as hoods, third models will be industrial. In general, such systems are used literally everywhere and their role is quite difficult to overestimate.

Standards

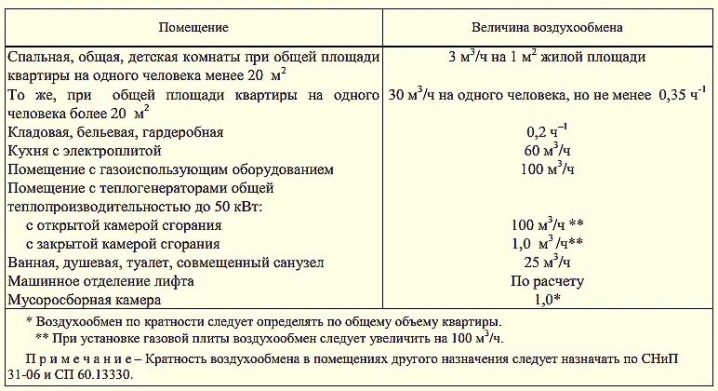

Design, as well as the calculation of ventilation parameters, is an extremely important task that will require the contractor to have an understanding of SNiP 41-01-2003, building codes, and knowledge in the field of air exchange processes. In addition, the features of the region where the building is located, as well as the parameters of the building itself, where the ventilation system will be created, will play a big role in this.

According to the aforementioned standards, the flow of air into a residential area per person should be:

- for rooms with an area of 20 square meters about 30 cubic meters per hour of clean air;

- if the area is less, then 3 cubic meters of air per hour per 1 square meter of area.

A network of ventilation ducts should be established regardless of whether the air flows naturally or by force.

If we talk about the requirements, the ducts must meet the following criteria:

- Be airtight. It is tightness that is necessary in order to maintain cravings, and also not to allow mixing of oncoming exhaust and clean air flows. It is especially necessary to check the system in the area of the connections of the various elements of the ventilation main;

- Make minimal noise. In the ventilation system, the aerodynamic hum should not be above the level allowed by sanitary norms. This is a level of 25 decibels;

- To be as resistant to external factors and corrosion. Through ventilation from the room is the conclusion of air masses, which have different degrees of humidity. For this reason, steam may begin to accumulate on the walls of the ventilation ducts, forming condensate.Subsequently, this may cause rust formation and subsequent deformation and violation of the tightness of the pipeline;

- To weigh a little and not take up much space. If we take the total length of such a system, then it is quite large. And so that the building is not overloaded and does not close the space as much as possible, it is better to take pipes that have a minimum size, which will ensure a clear and effective air circulation;

- Resistant to fire. The material from which the pipe fittings will be made should not be ignited too quickly and should not emit any harmful substances upon ignition.

And also it would be nice if the system will have smooth channels, as well as good thermal insulation properties. It should also be said that the ventilation system and the hood are not the same thing.

The exhaust air duct is not able to provide normal ventilation of the room for the following reasons:

- pipe section is small;

- a number of areas will be blocked by fan blades;

- the height at which the hood is located cannot be lower than 170 centimeters.

All of these points will directly affect the ability to transmit air.Too low located exhaust will not give the opportunity to properly ventilate the space that will be above it. This can cause microclimate disturbances and abnormal conditions. It is for this reason that the installation of the air duct should be carried out with the use of a backflash. This will enable uninterrupted operation of both exhaust and ventilation systems.

Materials

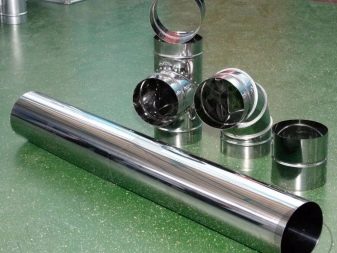

If we talk about the species to the destination, then in a private house on the roof is usually the use of metal pipes. Although in private buildings such pipes are used less frequently. The reason is that they have not very high performance. In addition, galvanized steel, which is most often used in this case, is used in ducts, despite the fact that it is galvanized, is not durable. And when such a pipe begins to corrode, it becomes a source of a specific and not very pleasant smell.

As a vent, you can use a stainless steel duct. Such solutions serve a long time, but their cost will be quite high.Yes, and the resistance to air flow will be higher. For this reason, it is necessary to have a more powerful ventilation unit on hand. In addition, such solutions have a lot of weight, which significantly complicates the installation of such a system as a whole. At the same time, it should be said that the ventilation pipes made of steel are not without advantages.

In comparison with plastic air ducts, of course, they have no advantages. But at the same time, the cross section of plastic pipes is very limited, but the steel makes it possible to create pipes with almost any section. Yes, and stainless steel resists corrosion. Frankly speaking, plastic pipes are the best solution for creating ventilation pipes in small private buildings: in the kitchen or somewhere else. Compared to metal counterparts, such pipes have quite a few advantages.

It is worth telling about them in more detail. The main advantage of such pipes will be one hundred percent corrosion resistance. In addition, such pipes have a low weight, which allows them to be installed quickly and easily. The same applies to fasteners. For steel counterparts usually used clamp, screws, various fasteners, and so on, and for plastic - all this is not necessary.It suffices only a bell that connects the pipes to each other or they are connected with a sealant or sealant. In addition, the technical characteristics of plastic wins much from the metal. And if we talk about strength, then when laying ducts it will not be so important.

Plastic ventilation pipes make it possible to install any air exchange system. And any on complexity, and also for various constructions, after all pipes of various size are presented. Their length varies in the range of 3-12 meters, and if we talk about the diameter - from 1.6 centimeters to 1.6 meters. In addition, the plastic ventilation pipe has a smooth surface inside that facilitates the flow of air. That is, such pipes need less powerful equipment, and they generally do not need to be cleaned. In addition, such pipes can be easily warmed. Enough to wrap them in insulation and everything will be ready. In general, plastic pipes have really excellent characteristics.

And there are also sandwich pipes. They are usually used to create exhaust systems near fireplaces or stoves.These are the warmed pipes which not only bring out combustion products, but also allow to keep heat within the room. Among the advantages of this type of pipe should be noted ease of installation.

And the main disadvantage is that they are short-lived. As a rule, such pipes do not serve for more than 10 years.

If we talk about the characteristics, such pipes differ in the following:

- universality;

- easy installation;

- soot and condensate do not settle on it, as the surface of the chimney is smooth;

- small size, which saves space;

- the use of this type of ventilation makes it possible to bypass roof elements, rafters and other elements;

- the production of such pipes is made of high-quality stainless steel, which is not afraid of exposure due to combustion of fuel;

- such ventilation does not require the installation of the foundation, which greatly simplifies the installation process and makes it possible to save well;

- it is possible to install such chimney without bearing elements.

Species by appointment

If we talk about the types of pipes for the purpose, then the ventilation pipes are different. For example, there are pipes for the kitchen hood.Hood, in general, is one of the most common ways to use ventilation pipes. Another use is to create a ventilation system in the room. It can be created both on the basis of steel pipes, and on the basis of plastic analogues. Everything will depend on what is needed and where such ventilation will be done.

Another interesting type of pipe ventilation plan for the purpose will be a sandwich pipe. Such pipes are usually used for chimneys and hoods, where you need to remove various combustion products. Filters are often installed in such pipes in order to prolong their service life, which is rather small. In addition, there are flexible ventilation pipes for mines. They are designed to supply air to the mine workings.

There are options such as:

- methane gas pipe;

- coal pipe that protects against dust;

- air supply pipe.

Accessories

If we talk about components for this type of pipe, then it should be said that in fact there are not so many of them. For example, you can call the clamp for fastening pipes. Most often, the corrugation requires the use of clamps.And when working with other pipes requires the presence of fasteners, as well as various kinds of bolts. Sometimes there is a need to clearly mark the ventilation entrances, for which appropriate devices are used.

It should be said about several elements that may be in the ventilation unit.

- The heat exchanger is a part of the installation of ventilation, which affects the air temperature in the room. It is thanks to this element that the temperature can be regulated.

- The recuperator is a part of the system that controls the temperature due to the fact that the air energy leaving the room heats the incoming air. Heat transfer occurs, which saves electrical energy.

- The air heater is an element whose main task is to heat the air. This element is usually mounted in installations of supply and exhaust and intake types.

- The cooler is an element whose main task is to cool the supply air. Cooling is carried out in such a way that air flows are slowed down while passing through this element.Usually it is equipped with a drip tray that can draw out condensate and moisture from the air mass, which allows normalization of humidity in the room.

- The filter is a part whose main task is to clean the air. Moreover, the filters purify not only the air that comes into the system, but also the air that comes out of it. Usually they can clean the air from various contaminants - dirt, dust, bacteria, chemicals, allergens, and so on.

Dimensions and shapes

If we talk about air ducts, then they can have a cross section of a different type. A round and rectangular pipe for ventilation is often used in both exhaust and supply versions, and with both natural and with a imposed type of burden. It should be noted that today there are twenty-two standard sections for pipes of round size ranging in size from 100 to 2000 mm. A pipe with a diameter of more than 50 centimeters, already belong to a group of large. Allowed to lay straight sections of highways such pipes length from two and a half to six meters.

If we talk about pipes of rectangular section, then their standard sections are equal from 100x150 mm to 1600x2000 mm. The pitch is 50 millimeters.If a flat pipe is used, then the straight sections of highways cannot have a length of more than two and a half meters. In order to interconnect parts, turns and forks, there are so-called shaped ventilation elements of appropriate shape and size.

Selection of the shape of the section is carried out on the purpose of the room and on how large it is.

In small rooms where the ceilings are low, rectangular flat ventilation pipes will not be as noticeable. Although their aerodynamic properties are significantly lower than those of round ones. This can be explained by the fact that angles allow to increase noise, reduce the speed of transporting air masses and, accordingly, create resistance. It is for this reason, despite the size, pipes of this type in the ventilation of various rooms, especially residential, are always additionally isolated.

Installation

Before you install the duct, you should choose it correctly. The fact is that depending on the material from which it is created, its performance characteristics may vary. The most important points in this matter are the right choice of pipe type and calculation.And the installation itself is usually not difficult. The choice should be made based on the norms of the relevant SNiP, which contains the main recommendations on this issue.

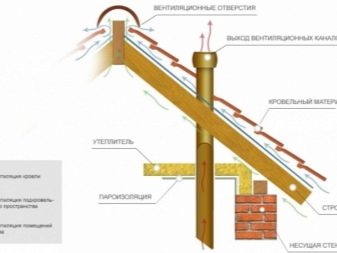

Ventilation shafts can be made of various materials. - brick, stainless steel, galvanized steel, high-strength plastic or aluminum. All of the above materials have both minuses and advantages. But whatever material is chosen, the main thing is that the pipe is reliable and durable, and also works flawlessly. The installation of such a structure on the roof of the house can be done after its construction. First you need to choose a place where this element will be located. In this case, it is necessary to be guided by the norms of the SNiP and the design features of the product itself.

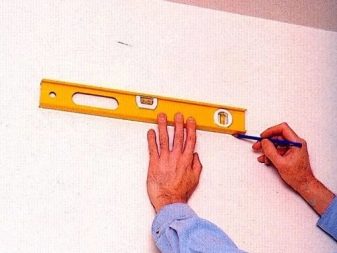

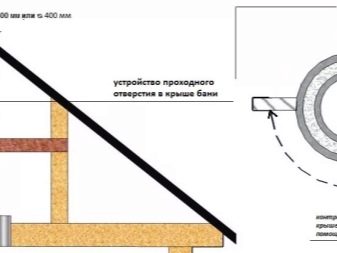

The next step is to mark the wall to understand how the pipe will go inside the house and where it will go. It is best to apply the markup in the form of a pipe section, which will allow you to understand how everything will look in the future at the design stage. After the marking has been applied, it is necessary to cut the opening in the ceiling by marking.This should be done carefully so as not to damage the overlap more than necessary, because then it can take a lot of time to seal the hole. When a hole was made in the ceiling, you can do the same in thermal insulation, waterproofing, as well as in other layers of the roof.

Important: you should not try to cut all layers at once, as this is likely to result in too much deformation, which may even be the reason for their replacement. It is better to work separately with each layer so that everything is done as accurately and accurately as possible.

Now it is necessary to carry out the marking of the passage node. When it is done, it is necessary to fix several holes in which in the future self-tapping screws and screws will be placed, because with their help they will be attached to the wall. The next step is to install a rubber-based gasket. And also it will not be superfluous to lubricate it with a weatherproof type sealant on the back side, which will make it possible to ensure reliable fastening of such a gasket.

It now remains to mount a node on it and make a fixation. It is necessary to insert it into the pipe, previously clearly putting it in a vertical position.This can be easily done if you use the building level. Many use an analogue - rubber cuff. This option is allowed, as it is well protected from the ingress of debris and water, because it is in close contact with the pipe. If there is no desire to break the roof or, in general, there is no need to carry out the ventilation output, then the pipe in the wall can be easily passed through the hole.

To carry out the output through the wall, there is the following algorithm:

- you must first apply the markup on the wall where the pipe will go. The markup must be applied with the calculation, then the diameter of the hole should be slightly larger than the cross section of the duct itself;

- after that, contour cuts are made along the previously outlined line, and the perforator should be exactly horizontal, which will make it possible to avoid various kinds of distortions;

- now the desired part of the wall should be knocked out. It is better not to try to knock out everything at once, but to do it in parts;

- when the hole is ready, insert a pipe into it and fill the space with wall and ventilation with foam;

- when it dries, you should take a clerical knife and remove excess;

- now, to the place where the pipe comes out of the wall, from the outside should be applied a facade-type plaster, and from the inside - starting;

- On both outputs should be attached grating made of plastic. They can be put on screws. Their presence prevent trash, insects and various rodents from entering.

Important: if there is a need to build the pipe to a certain length, then it is best to fix it to the wall using metal clamps. If it is necessary to dismantle it, it will be easy to do it - it will be enough to remove the metal clamps and remove it.

It is worth considering in more detail how to hide the exhaust pipe, because this moment is bothering many. No matter how the pipe is installed, but I want it to not spoil the interior of the room with its not very attractive appearance. As a rule, air ducts, if you look at apartments, are laid above the hanging cabinets or near the ceiling. But you can find more interesting solutions in order to divert attention from them. For example, a ventilation pipe can be made an interesting piece of interior due to the fact that it will be sheathed with plasterboard.It is also possible to insert some small lighting technique into its sheets, which will make it possible to illuminate this area additionally.

To hide the ventilation pipe, it is worth considering another solution. If the kitchen walls are painted with some bright paint, then the ventilation pipe can be painted in the same color. Sometimes, thanks to her, you can emphasize the rich colors of the interior. For example, if the kitchen is made in purple color, then the hood with a pipe can be painted in yellow.

Those to whom this combination seems provocative can be pasted over the pipe with wallpaper or hide it. To do this, you can use, in addition to drywall, a box of plastic.

This option would be a great solution if suspended ceilings are made in the room where such a pipe is located. The plastic box weighs relatively little, so it can be safely attached to the ceiling. It should be said that the installation of a plastic pipe in your own house will be more time consuming than in comparison with the same work in the apartment. But the specifics of installation is quite simple both in the apartment and in a private house. Such work can be performed by any person without resorting to outside help.

Manual

Ventilation-type installations require certain maintenance during operation for the timely solution of various kinds of problems, and also need to be periodically checked.

If we talk about the process of testing fans in industrial systems, you should look at the following points:

- are there any limitations of rotating parts;

- Are all lock nuts in place;

- how much work can be called silent and smooth;

- how well the installation is attached to the base;

- are bearings and electric motors well lubricated;

- what is their temperature;

- are there any drive belts, are they well tense;

- what condition of the vibration bases, protective coating and so on;

- if there is grounding.

Important: if the fan vibrates too much, and also knocks during how it works, its bearings become too hot, then you need to turn off the fan and figure out what's wrong.

And also periodically it is necessary to inspect the condition of the air discharge apparatus in smoke installations and to release air from them. The same applies to irrigation chambers.

Their maintenance should be carried out as follows:

- check and thorough cleaning of the injectors;

- cleaning the surface of the water filter mesh from the inside, the chambers, as well as the plates of the drip catchers;

- checking the device, which is responsible for ensuring that the water level in the pan is on a certain indicator;

- check how tightly the doors are closed.

When checking the ventilation pipes and other elements of the air removal systems from the premises, they should be inspected for the absence of mechanical damage. For example, if the insulation is damaged in some place, the pipes may stop performing certain functions qualitatively. And also you need to check the reliability of fasteners. Throttling devices of such systems should be located as correctly as possible, the indicators of the degree of opening should be in place. Particular attention should be paid to the state of the filters. If they are too worn out, it is better not to try to clean them, but to replace them.

In general, as you can see, today there are a large number of ventilation pipes.that caused the presence of a large number of ventilation systems, which differ significantly from each other in purpose and other characteristics.Selection of pipes, if desired, can be carried out independently for a particular system. But for this it is necessary to have a good knowledge of theoretical knowledge and to understand how the ventilation systems as a whole are arranged.

How to make ventilation in the apartment, see the following video.