Additional elements of the roof and facade: what is it and where are they used?

Even a well-built roof can collapse under severe weather conditions. But choosing the necessary additional elements, you can avoid such problems and provide yourself with a reliable roof over your head.

Special features

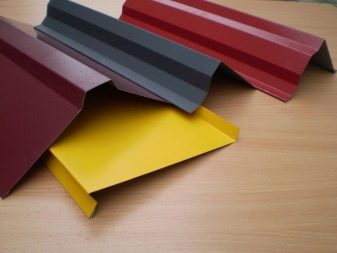

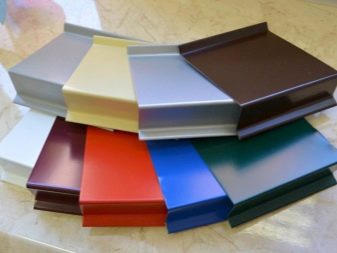

Additional elements are needed as facade cladding; roofing work is unrealistic without them. They play a protective role - they do not allow precipitation to penetrate inside the roof, and prevent heat from escaping. It is very important to know the exact purpose of the elements, methods of their fastening, as well as the sequence of works. All these little details play a very important role. In addition to the protective, they also play a decorative role, since any roof covering without these details will have an unworthy appearance.For the selection of the desired shade using the RAL catalog, which includes a wide variety of color options, as well as standard colors.

Additional elements are divided into three types: roofing, facade, for parapets and fences. Divide them according to the application. But this division is conditional, as some details are used for other types of structures. However, any product is created for certain functions, because of this, the additional elements cannot be called interchangeable. To a person who does not have experience, it will be quite problematic to choose the elements yourself.

Types and their application

Additional elements have different sizes, purpose, names and forms. As a rule, they are all made from different materials.

The following types are available:

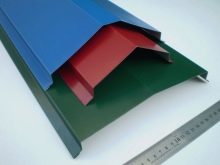

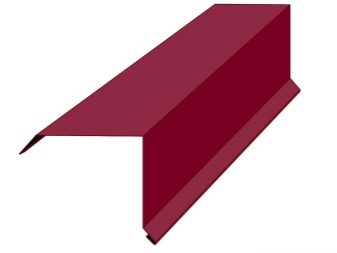

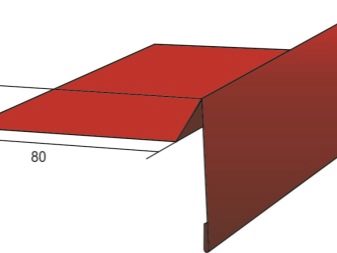

- End plate. This detail is used as protection of the joints of the roofing material from moisture leaking inside. Gable overhangs are also equipped with this part. The overlap of the last sheet of corrugated is 50-100 mm, which does not allow sediments to leak into the interior of the structure. Attach such a bar either on roofing or on ridge screws.

- Scallops. These elements with an internal and external angle are used as protection of the nodes against interfacing of the roofing material with a pipe, wall, as well as against the penetration of precipitation and dust.

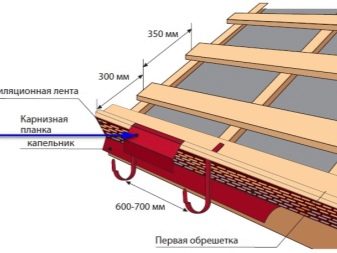

- Eaves plank. Its function is to divert water into the drainage system. Also this level masks the eaves board. This element is installed on the latest rail crates using roofing screws.

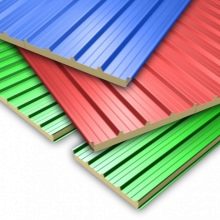

- Sandwich panel. This material has a three-layer structure, which consists of two rigid sheets and an insulating layer. Ondulin sheets are made from cellulose, and from bitumen, and from mineral substances. Such material is durable and very high quality. Usually it is used to cover private buildings or cottages.

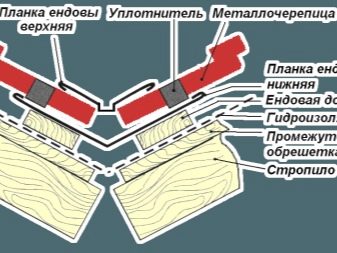

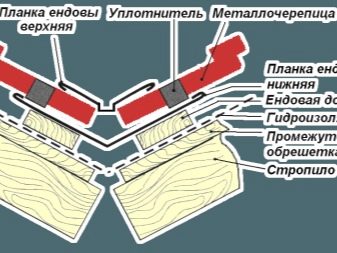

- Endovy. These elements are used to equip joints between adjacent slopes of roofs. On sale are upper and lower endov. The upper ones play a decorative role, while the lower ones perform a waterproofing function.

- Fad. This element is used when equipping the junction of skates at the highest point. Waterproofing and decorative function also performs it. Skating profiles, curtain rods and end strips are more popular.They are used for the construction of not only roofs of complex construction, but also roofs that have a simple structure.

- Eaves plank, able to prevent the ingress of moisture into the frontal board, as well as on its surface. It is a longitudinal part of the roof, the edge of the metal which is summed up. Eaves bar mount before you cover the roof with metal.

- Ridge profile. Ridge profile compared with other shaped products has a large variety of types and shapes. It performs as many as 3 functions in the construction of a professional sheet. Protection against the ingress of water and dust also lies on this profile. In general, it significantly improves the appearance of the roof, air circulation and forms a ventilation gap.

To perform the installation of the ridge profile, use a special seal that copies the profile profile of the roofing material. In addition, this seal is able to protect the ridge from the penetration of precipitation, dust and air currents.

Ridge profiles are divided into 3 types:

- Plain. This is a simple corner made of painted galvanized steel with mounting shelves 100-300 mm in size.Depending on the width of the shelf is determined by the effectiveness of protection against moisture. The greater the width of the product shelves, the better it will protect the joints of the slopes. A simple ridge profile is mounted quite easily, so this work can be done independently.

- U-shaped. This profile can be used for roofs made of profiled sheet with a U-shaped edge between two mounting shelves. But first, an auxiliary wooden beam is attached to this part.

- Semicircular profile. It looks like a semicircle, which gives this profile an unusual look, but its cost is higher than that of other profiles. It is used for roofs with different slopes, which is why it has fastening shelves of various lengths. To protect the ends of the ridge, use plugs, as when installing the ends can be damaged.

It is usually performed in the color of the entire roof covering and even its individual elements. But many emit it in another color tone.

All elements must be installed at the end of the installation of metal throughout the entire roof area.

The eaves level can be of several types:

- End plate. Like others, the end plate protects the roof surface from moisture penetration. In addition, it has the ability to expand the area of roofing space, and also creates an elegant view of the roof. It is made in the form of a bent sheet treated with a special metal product having a flat shape.

- Wind strip. Another type of slats, which is installed at the end of the roof device. Since many consumers use metal roofing as a roofing material, the value of wind strips has slightly increased. Metal tile is a lightweight material that can easily deform under the influence of strong wind gusts. Wind strips are able to prevent such a situation, moreover, they are able to protect the under-roof space from insects, birds, dust and other things.

Also, using this design, a special microclimate is created under the roof, and it does not matter what roofing material is used.

All these elements are necessary to isolate fractures of the roof, eaves, wind ends, and also protect from dust, wind, rain and other precipitations. Many use additional elements as a sealing coating.

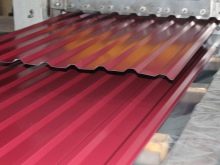

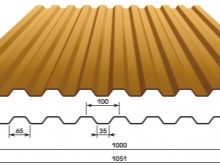

It is worth paying attention to the fact that almost all of the above elements are made of corrugated flooring.

In construction, this material is highly valued due to its impeccable characteristics. It is used both as a coating and as a veneering material.

On corrugated roofs you can often notice some details, namely:

- auxiliary elements;

- ventilation deflector;

- elements of the ridge knot;

- snow holders;

- lower bar;

- end plate.

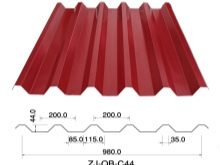

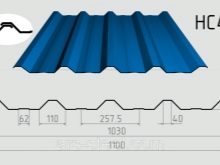

Sheeting in the same way as other materials are divided into types:

- Corrugated roofing without polymer coating. Basically, it is used for fencing equipment or hinged roofs. This material has the appearance of an ordinary cold rolled steel sheet. Probably because of this, he has such a low price.

- Decking, which is based on ferrous metals. The protective coating is absent, therefore, this profiled sheeting is highly susceptible to corrosion, which quickly destroys it. Use it only when making garages.

- Professional flooring from non-ferrous metals. Copper or aluminum is the raw material in the manufacture of this profiled.If copper is used as a raw material, the consumer can be 100% sure of the quality of the product. Appearance also looks quite presentable. Over time, the color becomes a dark color, and the quality still does not change. Serve such material is capable of about 150 years.

- Profiled steel with polymers.

- The sheets of the professional flooring having various forms.

There are also pass-through elements - special devices designed to bring the ventilation lines to the outside, as well as to prevent the ingress of moisture.

Passing elements are divided into:

- designed for cement-sand tiles;

- for ceramic tiles;

- for a faltsevy roof;

- for a soft roof;

- for metal tiles.

These elements are selected according to the diameter of the pipe selected for installation.

We must not forget about the components for additional elements. For example, corrector for repairing scratches. Such correctors are used when working with polymer coatings.

In addition to all these elements, it is worth thinking about the use of drips. Attach them along the bottom edge of the eaves.

An important function, namely the removal of rain from the walls of the building, performs the ebb, departing from the roofs. Pick it up the color of the window frame.

For the roof of different materials

Material that is in great demand - profiled (aka professional sheet) is the best option for arranging any roof, as it produces a reliable coating that can last for many years. Another advantage is easy installation, which can be done independently.

Professional sheet is great for roofs that differ in complex or non-standard forms. But the harder the roof, the more additional elements needed for construction. Skates, valleys or junctions are elements that can give the roof a perfect look, as well as provide the consumer with the durability and strength of the roof to be installed.

Profiled elements have many different options and they are made, as a rule, of various materials:

- Galvanized without a layer of paint. Galvanized steel, which is used to create these elements, is not covered with any painting layer. It is not difficult to damage this material, due to this its cost is low, therefore, the service life is also non-durable.

- Galvanized with a layer of paint. It uses galvanized steel with a coating of high quality paint.The special composition creates an excellent coating that can withstand any weather conditions. For the lack of corrosion on this material meets the paintwork.

- Galvanized elements with polymer coating. The most preferred among consumers option among all the additional elements, as it provides complete protection against moisture, which means that the occurrence of corrosion on such material will not occur exactly. With all the advantages of this element, it is worth noting that its price is quite high, but its useful life is rather big.

- Another more expensive and luxurious option is polyester. It is durable due to the protective coating of polyester, so it is not afraid of low or high temperatures, abundance of precipitation or ultraviolet.

- A more reliable coating than polyester is plastisol. With such a coating, the consumer not only never knows what a roofing is, but also acquires a product that has been serving for decades.

However, standard profiled sheets are used more often than profiled products. This happens because the additional elements of this roof increase the tightness and reliability of the built-up roof.

For the facade

Additional elements for the facade are often called shaped elements.They are part of the facade and form a set of elements that provide connection and protection of problem areas from damage. Even the smallest detail can begin the destruction of the roof or the front part as a result of the intervention of external factors.

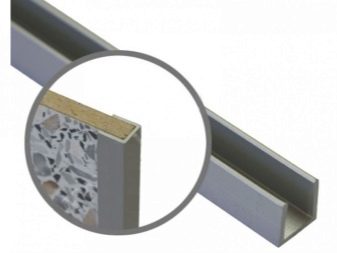

When finishing the facade, the following types of additional elements are used:

- initial and final strips, also known as U-shaped;

- corner bars for arranging the external and internal simple angles;

- corner bars for arranging external and internal complex corners;

- N-shaped and U-shaped doborny laths;

- docking strips;

- additional elements on the junction areas.

How to choose: tips

For the correct choice of additional elements and accessories for them, it is necessary to pay attention to the material taken as a raw material - this determines the price and quality of the product.

You also need a suitable color that can not only emphasize the appearance of the house, giving it elegance, but also spoil it with the wrong combination.

In addition, if you wish to purchase the highest quality product, you should refer to the markings indicated on such material as professional flooring:

- Marking C-21 indicates extreme rigidity, which allows the material to be used not only in the construction of the roof, but also as a facing material.

- C-44. This marking indicates additional stiffeners.

- NS-34 and 44. This view is able to protect the roof from any weather conditions. It was created only for roofing. However, laying such sheets, it is worth taking care of some conditions. One of them is the crate step, which is no more than eighty centimeters.

- RN-20. These sheets have a special groove for water drainage. The crate for such a structure can be laid slightly wider than the previous one, 110 centimeters.

Having carefully studied the marking, you should pay attention to other factors:

- integrity of the purchased goods;

- price;

- polymers used as a protective layer.

Before buying the material is best to know about the protective layer.

In addition to the above, it is worth remembering that the guarantee for roofing materials is valid only if the installation technology was correctly observed. To avoid unnecessary problems, you should contact only the professionals.

It is more reasonable to purchase additional elements from the same company where the roofing material was purchased.as it will allow to pick up elements of one color scale, and also to save on transportation.

When buying additional elements, you need to take care of fastenings to them, since fixing with nails in this case is excluded. Bolts, screws, screws - fasteners that can help get a high-quality and reliable roofing.

How to install?

The end plate is a very functional element, as it protects both roofing elements from moisture and metal roofing from wind.

On the end board is placed waterproofing, and the edge is closed end plate. With the help of screws this strap is fastened from the eaves to the ridge to the end board after about 60 cm. Then it is pressed tightly against the metal tile.

If necessary, the overlap between the slats is cut, but it should be at least 100 mm.

In order to avoid precipitation falling under the metal tile, the end plate is fastened so that it overlaps the upper crest of the wave. Next, the edge of the sheet metal fold up.

Upper endova not only removes water from the inner corner at the junction of two slopes, but also performs a decorative function, giving the joints a graceful appearance.

Upper endova fasten screws. This should be done in such a way that the screws do not pass through the bottom valley, as this can break the waterproofing layer.

A self-expanding gasket is installed between the sheets of metal tile and the upper plate of the valley.

Roof fractures are direct and inverse. When installing the junction bars, it is important to accurately observe the continuity of waterproofing at the fractures of the roof.

In the case of a direct break, crate boards should be as close as possible to each other. Sheet metal, which covers the fracture, it is necessary to push out to close the fracture site. Eaves bar here can be used as a mating element. Then between this element and the tiled sheet is placed a universal seal, available from any manufacturer of the roofing material.

If this is the case with a reverse kink, then a wall junction is used here. This mating element is laid side rolling on the lower slope. It is necessary to bring the crate boards as close as possible to the place of fracture. Next, between the slats and metal install a universal seal.

Then waterproofing is brought to a height of 50 mm.Bring it to the wall - to the penalty. You can use either a universal seal or a profile seal - it all depends on the junction, which can be on the side or on the end.

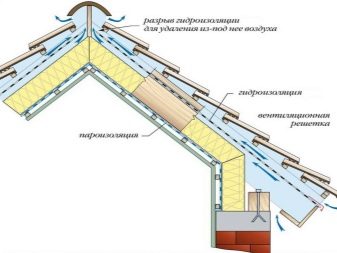

When installing the ridge elements, the waterproofing film must be torn to a width of 200 mm along the entire length of the ridge. If necessary, you can glue it with a metalroll or figarole, which will provide the ridge with additional waterproofing.

Skate fasteners held on both sides with screws. This is done through the upper crest of the waves in the crate. From the ends of the horse is closed with plugs.

To complete the architectural image of the building apply additional elements for the facade. In addition to the decorative function, these elements also perform the function of protecting vulnerable areas.

With the help of facade finishing parts, it is possible to strengthen the building and ensure the masking of the holes left after the finishing works, as well as protect your home from dust, moisture and other sediments.

To install the facade elements, that is, windows, doors, and so on, angular strips are necessary, the number of which must coincide with the sum of the external and internal corners of the house.

Installation of additional work is needed in order to correctly combine the structural elements of the design. These elements are usually made of aluminum or galvanized sheet, plastisol, polyester, pural and other materials. Apply the necessary paint coating can be at the end of the installation. In this case, as in many other previous ones, a competent approach and priority is needed.

To protect the window system from water streams, external window sills are used. They are made in the form of flat profiles, which emphasizes a certain elegance of the building and creates a harmonious look.

Favorable choice of many consumers is ventfasad. The front film is connected to the base of the house. This is done through the installation of the frame. This creates optimal sound insulation and thermoregulation, and also creates an air gap.

If necessary, masking joints and the connection of the roof with the base apply additional elements.

Panels for the facade - this is an excellent analogue of the house trim. Such panels are able to withstand moisture and any weather conditions, in addition, they need special preparation of the walls of the equipped building.Installation of these panels is carried out with the help of brackets, construction nails and screws.

These panels are convenient in that they can be used both when finishing the facade and when stitching decorative elements. And perhaps this is because the installation of these elements can be both vertical and horizontal forms.

Manufacturers

In the production of additional elements, special bending equipment is used, with which it is possible to achieve exact dimensions. For the manufacture of these elements are usually used galvanized or painted sheet steel.

At the moment, there are a huge number of companies that can manufacture non-standard additional elements of the most sophisticated forms and the highest complexity.

One of them is TechnoNIKOL. It is one of the largest manufacturers of building materials. This company is able to skillfully react to any requests from consumers and fulfill any of its desires.

Another major manufacturer is considered a company. Penoplex, which began its activities in 1998. It can rightly be considered a representative of the new generation of building and thermal insulation materials.

Also worth noting is the factory VladMetallProfil, which, as well as the manufacturers listed above, is one of the leading Russian manufacturers. VladMetallProfil It offers its additional elements at producer prices, eliminating unnecessary margins.

Purchase clamping strap designed for fixing waterproofing materials, can be carried out in online stores or from popular manufacturers.

There are three types of pressure plates:

- aluminum edge;

- aluminum clamping;

- steel.

The most important thing when installing and selecting additional materials is a high level of experience. A person who does not have knowledge in this field is able to make many mistakes and waste all his savings. That is why it is best to entrust such a complex and reverent work to professionals who will do everything competently and without mistakes.

See where the additional elements of the roof and facade are used in the next video.