Chested roof: what it consists of and how it fits?

In recent years, more and more people prefer to use eco-technologies in the construction of private houses and cottages. That is why, in the wake of the popularity of natural materials, more and more consumers prefer a roof made of cement.

Special features

Under the name "tes" there is a usual edged board, obtained as a result of longitudinal cutting of a log on a sawmill and hewn to obtain the same width along the entire length of building materials.

Coniferous wood, as a rule, is usually chosen for mounting a roof. Products are presented in a wide price range: the cheapest boards are made from pine, and the most expensive ones are made from larch.

Pine is a medium-density material; the material is resistant to fungal damage and does not warp or deform when dried. However, it requires regular treatment with antimicrobial and fire resistant compounds.But larch tesses are distinguished by higher quality - this is due to the unique properties of this breed.

Larch boards with their fortress are not inferior to oak. The material has almost no knots, is characterized by a decorative texture and a wide range of shades. Larch is considered a plant that is not subject to rotting, due to the high resin and the special composition of this resin. The roof shows healing properties, as it emits special antioxidants - substances that prevent aging, which strengthen the immune system and help a person to fight against various diseases.

Spruce wood is also used for manufacturing - it is a material similar to pine in its technical parameters and cost. Cedar is more popular among users - it is cheaper than larch, but it has bactericidal properties, is characterized by resistance to negative natural influences and has an attractive appearance.

Speaking about the parameters of the bisque roof, it is worth highlighting the following:

- the roof from tesa differs in considerable weight - 1 sq.m weighs from 21 to 30 kg;

- The length of the tesa is performed in the range from 4 to 6.5 m;

- the thickness of the cut timber is 19-45 m;

- board width is 160-200 mm.

Advantages and disadvantages

The advantages of a wooden roof are obvious.

- Wood is an environmentally safe material, its use as the main roofing material contributes to the creation of a favorable indoor microclimate. Tes under the influence of ultraviolet does not emit harmful and toxic substances, making your stay in the house healthy and safe.

- Coniferous woods have good thermal conductivity, so the boards do not allow the room to overheat in hot summer, and in winter they do not release warm air outside. In such houses it is warm in winter and cool in summer.

- The material has good noise absorption. Reliable sound insulation keeps the sound of rain, hail and wind, so the inhabitants of the house can enjoy peace and quiet.

- Installation of a roofing roof does not require special skills of construction work, it can be done by hand without the involvement of expensive specialists from the outside.

- Roofing from a tree needs care, however, it comes down to periodic renewal of the coating, it does not require a lot of effort, money and time.

- The cost of a speck roof is much lower than the prices of other types of roofing materials.

- Houses with a wooden roof look very stylish and original.

As with any other type of coating, teskov roofs have their disadvantages.

- the design is rather heavy - it creates a large load on the floors, bearing pillars and the foundation of the building;

- wood is a material that is prone to burning, therefore, requires a mandatory coating of fire-resistant compounds every 3-5 years;

- logs are subject to the damaging effects of natural factors, in addition, the tree is a favorite place of residence for bark beetles, which leads to the need for regular dyeing and impregnation of protective components.

Construction planning

There is an opinion that during the preparation of products for the installation of the roof, only three sides of the trimmed lumber should be planted. This is a common misconception - the product must necessarily be cut from all four sides.

This is due to the fact that before the start of roofing all wood materials should be treated with solutions of fungicides, as well as flame retardants, which increase the fire resistance of the surface.Unplanned surfaces are much more difficult to process, and it is necessary to apply protective components several times.

However, if the roof is mounted as a temporary structure, then it is possible and not to cut at all - such works will be much cheaper.

On the one hand of the edged sawn timber, it is necessary to make small longitudinal grooves - they ensure timely run-off of water and protect the structure from rotting.

Before starting roofing work it is extremely important to correctly calculate the required amount of materials.

This operation is performed in the following scheme:

- first you need to clarify the number of boards in each row - for this, the total width of the slope is divided by the same parameter tesa;

- then you need to calculate the number of rows - for this purpose, the length of the slope is divided by the length of the timber;

- then the number of tes in one row is multiplied by the number of rows;

- to complete the calculations, the resulting value is multiplied by 4 (since the technology involves mounting the roof in two rows);

- This number is multiplied by the volume of one tool and we get the required number of boards in cubic meters - it is this parameter that serves as the base in hardware stores.

It is important: if the roof is four-sided, then it makes sense to carry out calculations for each slope separately, and sum up the obtained values among themselves.

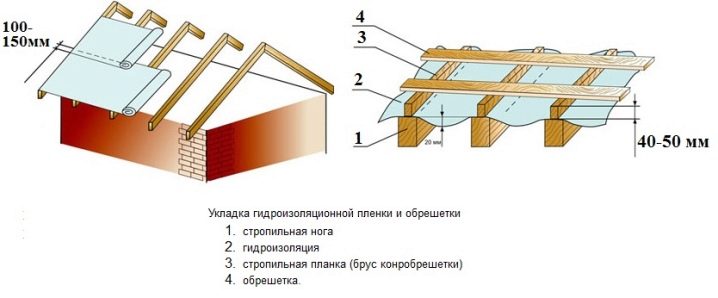

All waterproofing materials should not be laid directly under the boards., as is the case with other types of roofing pie. An air gap of at least 5 cm in depth must be created between the film and the boards - this will ensure the necessary degree of ventilation in the under-roofing layer.

Installation

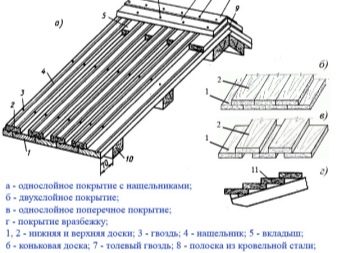

Installation of tesov roofs can be carried out both transversely and longitudinally. Longitudinal masonry is considered the most practical and therefore more common than transverse.

In general, the scheme of installation works as follows:

- the obreshetka is established, wooden bars 50 * 50 are suitable for this purpose;

- then the first layer of the first row is fastened end-to-end; nails are used in fixation of cuts, which are hammered in 50-60 cm steps;

- by the same principle, the subsequent rows of the slope are laid;

- then the second row of wooden roof is mounted so that the lumber overlaps the joints of the underlying layer - that is, the material is applied in a checkerboard pattern.

It is important to remember that the cores of the annual rings of wood in the first row must necessarily be located upwards, and in the second - downwards. This allows for maximum density of the structure.

At the final stage, the cornice is hemmed with a board, for example, clapboard.

In most cases, transverse masonry is used for temporary buildings, so the step of forming the batten is passed. This method of laying assumes that the boards of the upper row overlap the webs of the lower layer by several centimeters, and each of their intersections is also fixed by nails.

The device and visual process of installation of a teskovy roof look further.

Examples

Everything new is well forgotten old. That is why the roof of a tesa is so popular in Europe.

Summer kitchens, gazebos and summer houses are often covered with a wood roof.

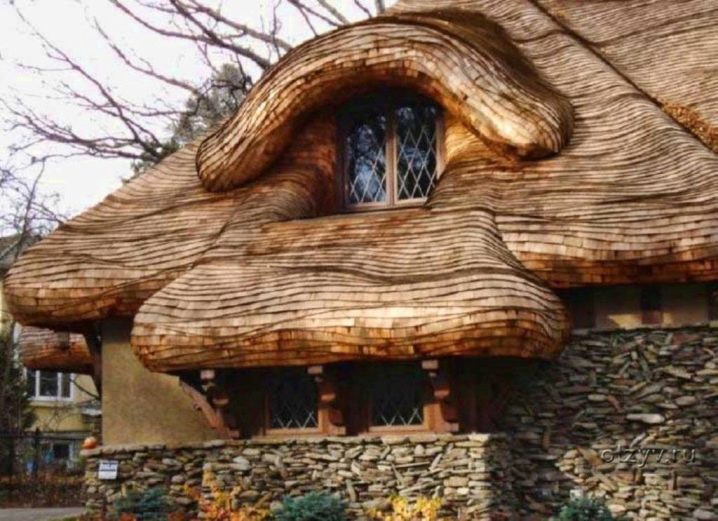

It is very fashionable to equip a speck roof in large mansions and residences.

Well, some craftsmen with the help of such a roof make their buildings into real fabulous houses.