Roof decking: how to choose and put the floor?

Among the wide range of materials for the roof, which are used today, stands profiled. But many consumers are poorly oriented in the intricacies of such a material and evaluate it simply by appearance. That is why very serious mistakes are made.

Special features

Roofing corrugated meets always more stringent requirements than the wall version of this material. But apply it in the most different cases. It's one thing when you need to cover the roof of a solid cottage, another is decorating a private house, and the third is when work is being done on a temporary structure. Always need your approach. In any case, roofing sheeting exceeds many other materials in such parameters as:

- protection against corrosion;

- ease of transportation and installation;

- low weight and versatility in use;

- environmental Safety;

- minimum care requirements.

But users will have to reckon with possible difficulties. Only with the use of reliable noise isolation, it is possible to beat the “volume” of the professional sheet. It is necessary to transport it with great care, because the material is deformed very easily.

Mounting the coating is required carefully and carefully - the slightest defect can devalue all the work. In case of violation of the integrity of the internal parts of the cake will be in contact with water and quickly destroyed.

Options

Choosing a professional flooring, you should first understand the following characteristics:

- type of coverage;

- wave;

- sheet width.

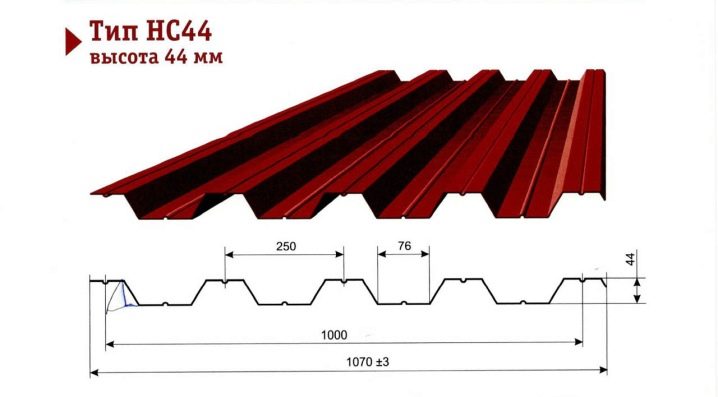

Corrugation for roofing material may have a height of from 1 to 11.4 cm. The type of construction meeting the requirements for height and width is marked with the letters NA. Most often, profiled do in accordance with state standards,as evidenced by the mention at the end of the marking entry. In the absence of such data, the product must comply with some other of the legitimate standards. Letters A, B show which side of the professional sheet is painted (front or reverse).

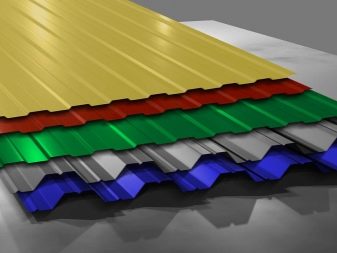

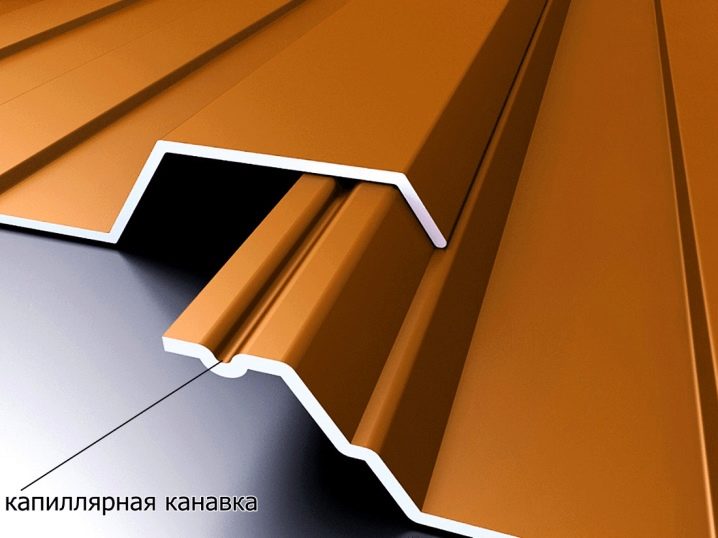

If there is an R in the labeling, this product has a capillary groove. As for the production technology, profiled make the four main types. In addition to the galvanized thin sheet, there is also a thin sheet with an aluminum shell, with a mixture of "aluminum - silicon" or "aluminum - zinc."

Even if two different models are produced in the same installation, they may have dissimilar characteristics: often wall and roofing products are produced in one cycle. Galvanized steel is considered thick with a value of 5-7 mm; thinner products are necessarily covered with a polymer layer.

Depending on the type of polymer used by manufacturers, different options can be distinguished. So, polyester looks beautiful, but almost does not protect against mechanical defects. Peeling and abrasion with time is almost inevitable. Pural is similar in characteristics to polyester, but more accessible.The relatively expensive version of PVDT is both durable and resistant to direct sunlight, it has a rich color gamut.

Metal slate is stronger than asbestos cement sheets and is much better than plastic panels, tolerates strong heating. It differs by applying zinc on two sides of the sheet at once, using a specially selected varnish on the wrong side and adding coloring pigments to the polymer.

The plastic layer helps ensure resistance to ultraviolet rays, liquid and minor mechanical defects. They will remain on the surface and will not grow deep into or in breadth. All these signs make the metal slate one of the main options for decorating the roofs of houses.

Sheet specifications

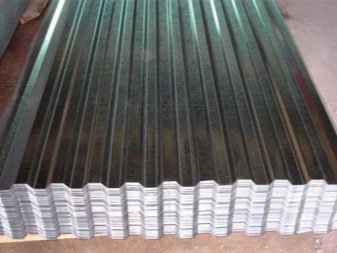

In modern factories make sheet steel with different depths of the zinc layer. The consumption of pure zinc during the operation of production plants can be from 0.1 to 0.3 kg per 1 m2 in the coefficient. The minimum film thickness is always at least 90 microns (that is, from 275 g per 1 sq. M). Such a shell is able to protect the main body of metal from corrosion for 15-20 years even in harsh environments.But due to the development of technology, even this level can no longer be considered an ideal choice.

The galvanized steel sheet has now almost ceased to be used on rooftops, and is used mainly on temporary structures and outbuildings. The high cost of modern varieties of this material is apparent: there the sheet lasts longer, and significantly, and looks much more attractive.

According to the builders, the optimum thickness of corrugated roofing is 0.45-0.5 mm. Increasing the height of the wave compared with the wall analogue already allows you to guarantee the necessary strength.

If in a particular area there are snowy winters, it is better to use metal thicker. According to GOST, the tolerance in thickness of corrugated sheet does not exceed 0.1 mm.

As for the choice of color, then you need to focus not on fashion and not on your own taste, but on the objective requirements of the design. In recent years, professional sheet imitating the appearance of natural wood or other natural coatings has become increasingly popular. But this option is bad on the roof in that it is weakly combined with other decorative elements and can quickly cause disappointment.

Considering the inevitable color distortions when displayed on monitors and in print media, it is worth choosing the tone “a little lighter than the correct color seems”.

Types of construction

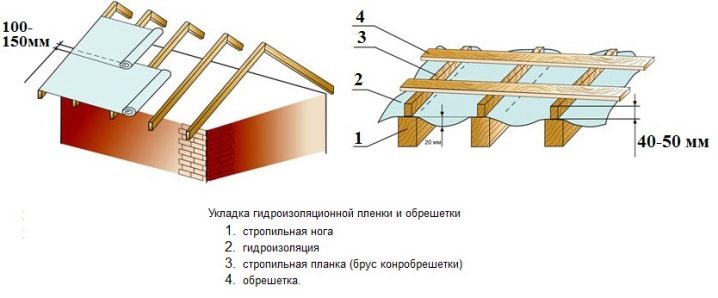

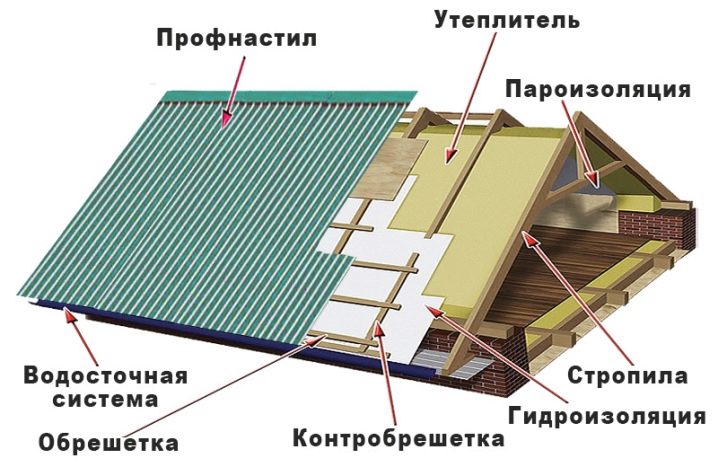

When a professional sheet is chosen according to all the rules, one cannot yet consider ultimate success a guaranteed undertaking. After all, you need to thoroughly understand the intricacies of the created roof and its structure. The cold format of the roof is considered to be the most effective, because an air layer is created in the roofing room, ventilating the roof itself and the rafters. But to do without warming in constantly used residential buildings is impossible. The device of a cold roof from a professional flooring means use:

- rafter legs (from boards with a section of 5х15 cm or metal);

- waterproofing;

- contrabreshetki;

- crates (4x10 boards or 4x4 cm bars) divided or inseparable;

- proper sheeting.

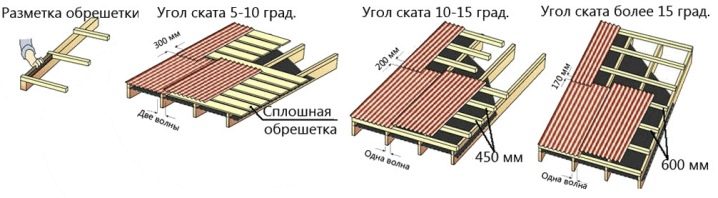

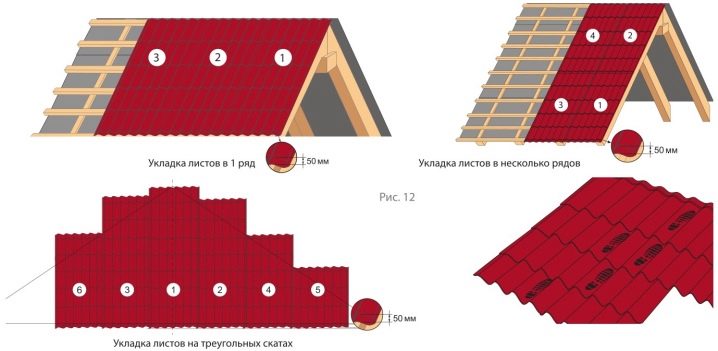

The technology of creating a warm roof made of corrugated board requires the use of thermal insulation in the breaks of rafter legs. These gaps are filled most often with mineral wool, and under the truss system is a membrane that inhibits the flow of steam.Since the roofing material blocks water vapor, it is in this case absolutely unacceptable. Profiled and cold and warm performance is desirable to put only on the slopes of 8 degrees and steeper. If there is insufficient slope, the water will be poured inside horizontal joints and will quickly flow onto the heads of the residents.

If you have to cover the roof with a slope of less than 8 degrees, the sheets lead over each other with an overlap of 20-25 cm. The use of silicone sealant helps minimize the risk of leakage.

For information: the smaller the steepness of the roof, the greater the amount will have to spend on its processing. Even with slopes from 9 to 15 degrees, it is impossible to overlap less than 20 cm, but the use of sealant at the joints is left to the discretion of the builders. Roofs with slopes from 15 to 30 degrees can reduce the overlap to 15-20 cm, and on even steeper sections, this figure drops to 0.1—0.15 m.

Roofs with a small slope of the sheeting should be done on a wooden crate from trimmed lumber or from moisture-resistant plywood. When the steepness increases, the allowable distance between the key nodes of the batten increases.

It is unacceptable to lay a professional sheet on the roof, the slope of which exceeds 60 degrees.

Climatic parameters of the terrain influence recommendations for rational inclination angles. The higher the intensity of precipitation during the year, the sooner they should fall down.

The largest gap from one truss foot to another in any scheme cannot exceed 150 cm. Under a warm roof, this distance is reduced to 1.2 or even 0.6 m in order to simplify the installation of thermal protection. Minimize the number of joints will help the choice of sheets that coincide in length with the slope. But their greatest length is no more than 10 m. If the structure is extended further, it becomes unstable.

The gable roof under the corrugated flooring can be made with hanging rafters, but the ventilated (based on the inner and outer walls to the same extent) is also allowed. It is advisable to attach the sheets with the help of roofing screws, supplemented by a sealant. The washer from a neoprene, flattening, does the received opening as tight as possible.

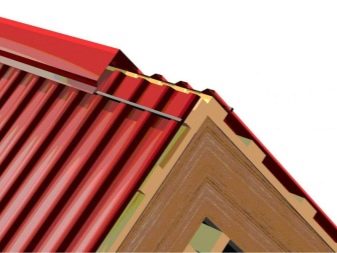

Professionals recommend using shaped parts to form:

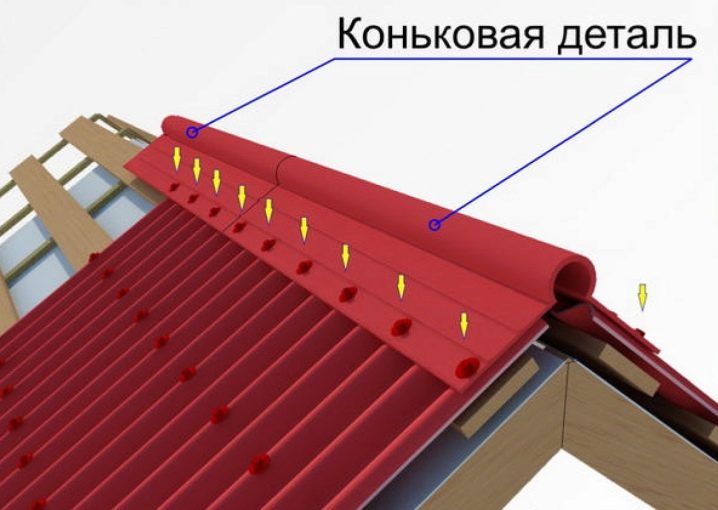

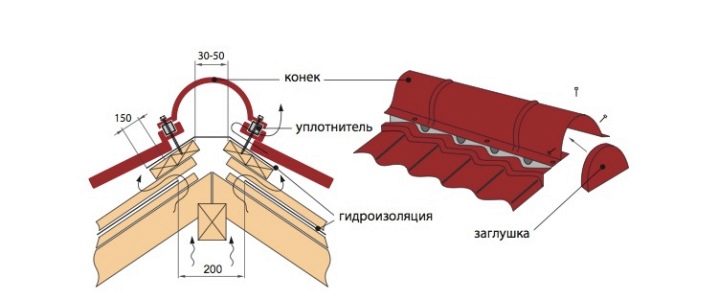

- ice skates;

- pipe exits;

- stingrays connections;

- endovy.

Similar elements can be used on a single-pitch roof, they are painted in the same color as the professional sheet itself. Therefore, the mounted products do not spoil the appearance, it is unlikely that someone will notice them at all. The appearance of the roof, decorated with corrugated board, is different from the options for tile.

A thinner steel is used for metal, although it is obtained by a similar technology (cold rolled steel). Both materials can hardly be called particularly heavy, with an additional tenths of a millimeter in both of them capable of giving the roof a few years of life.

In order for the cake to last longer, and it was not necessary to dismantle the outer shell ahead of time, it is necessary to saturate the crate with fire retardants and antiseptics. Regardless of the tightness of the roofing, water still finds a way inside. And it is better that the lowermost details of the design meet her "fully armed".

When it turns out that the slope is longer than the technically acceptable profile sheet, you need to make an order with the calculation that the fixing point of the transverse joint is above the batten board. The edge of each subsequent stacked sheet should cover the previous capillary drain.

Manufacturers Overview

Roofing for roofing is produced by a large number of manufacturers, but not everyone has the same conscientious approach. Different machines and their modes of operation, different raw materials and applied coating. Judging by the reviews, the best quality professional sheet achieved in Russia - it is made in the Lipetsk region, in Magnitogorsk and Cherepovets. But Turkish, Chinese and Indian materials are many times worse.

Important: the professional sheet with imitation of natural stone, brick and logs is done exclusively in South Korea and nowhere else, everything else is fake.

Among foreign suppliers in the first place are the leading Western European concerns:

- Rautaruukki Group;

- Arcelor Construction;

- Tekla and a number of others.

Tips for choosing

You can not just confine the name and type of profile. The correct selection of the profiled sheet takes into account what area to cover, and how the roof configuration is made, how many ramps it has. It takes into account the average precipitation volume, the difficulty of installation, the complexity of replacing the damaged sheet. For a home, you should choose the material with the highest possible quality, but the sheds can be blocked with cheaper coatings.With an increase in the wave, the mechanical rigidity of the corrugated sheet and the passage of liquid sediments to them increase; at the same time increases the cost.

You can not put on the roof sheet, whose wave is 2 cm or less. The lower part of the wave should be as wide as possible, this facilitates the flow of water. Designs with a high wave on flat roofs are placed with an overlap on one line, and, conversely, a small wave is compensated by a double overlap.

Products with capillary grooves act as an auxiliary barrier that prevents melt water and rain drops from falling under the sheet. The groove also partially protects against condensation, but if the wave height is selected incorrectly, it will not be able to help.

An unpainted professional sheet without a zinc layer rarely serves more than 5 years, and if it is applied, the product's lifetime may increase to a decade and a half. When selecting colors it is worth paying attention that after a while even the most reliable coatings will fade in the sun. The longer the roof is used, the stronger the visual difference is. This can present an unpleasant surprise when replacing single spoiled sheets with goods from the same collections. It is unacceptable to take products with chips and folds, with peeling paint.

Before buying it is recommended to carefully measure all linear dimensions of each element. If they differ from those stated by more than the standard deviation envisages, the product cannot be considered qualitative. You should look for the first waves of the upper sheets to coincide as closely as possible with the closing strips of the underlying profiled sheet. Then the risk of infiltration of sediment inside will be minimal.

The division of corrugated board at large reputable enterprises is carried out with the help of a special machine, the guillotine. It allows you to make the most even cut, will not leave visual chipping. That is why it is not necessary to be afraid that the edge of the professional sheet will suddenly be covered with rust.

If sellers show coloring on round samples, it means that they are trying to overstate the strength of the product, to create a false impression about it. You should always demand to issue a full sheet and put a little effort on it. After this manipulation profiled should quickly return to its original position.

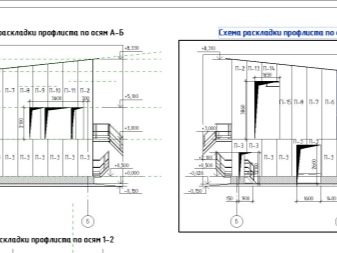

You can not buy a professional sheet, if it is not attached to the detailed specification and layout.This moment is especially important if the geometry of the roof itself differs from the standard variants. Packaging must be safe and sound. Before work begins, it is left in place, but then immediately removed.

You should always require the presentation of certificates, warranty obligations, licenses and technical passports.

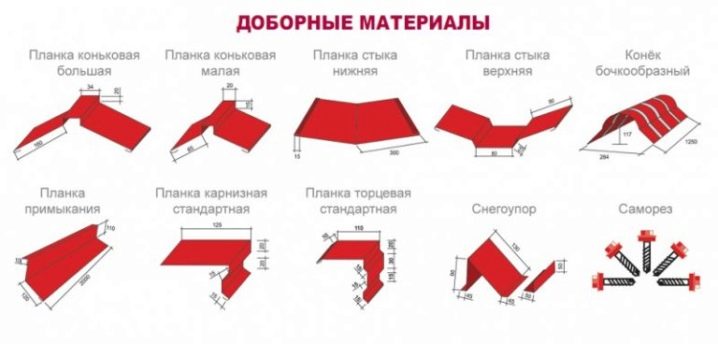

Accessories

Components (auxiliary parts) are just as important as the professional flooring itself. Moreover, they must be selected simultaneously with the coating itself. Only harmoniously combined elements will ensure high-quality styling and long service coverage. Additional elements are designed to complete the stylistic design of the joints and save them from destructive influences. Under the protection you need to take another point of attachment to the walls, windows and gables.

The more complex the roof configuration, the more auxiliary elements are required, including expensive fixtures. End strips are able to block the effect of moisture on the joints.

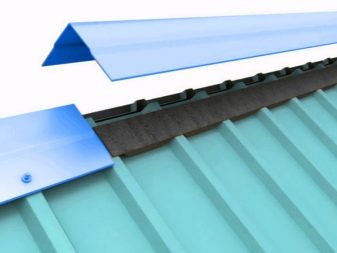

And also thanks to them, the destructive effect of the wind on the coating as a whole is prevented. You can set the slats both in exact dimensions and with overlaps.In both cases, an overlap of the final profile sheets of at least 5 cm is required.

Professional sheet fastening to the base is provided by self-tapping screws: their roofing type helps to attach the end piece to the crate or frontal board. Eaves levels promote the direction of the water leaving from slopes directly to drainpipes. Therefore, their use protects the facade of the house from waterlogging. The plank at the same time becomes the decorative covering of the eaves. You need to put it on the end boards of the batten - and the overlap of overlap is at least 10 cm.

The gutter strap is placed directly under the ridge, masking the ends of the profiles below. Her role is purely decorative, which cannot be said about splatters. The junction bars save roofs with walls, pipes and other vertical planes from getting wet and dusty. Sometimes engineers provide for the presence of strobe in such planks, thanks to which you can go deep into the walls.

All shaped parts need to be mounted only after the arrangement of the roof as a whole.

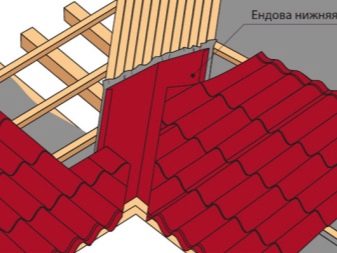

To skates, located at different angles, were one and did not diverge, endows are used. They, on the contrary, put to the calculation of the final coating.Additionally, these elements improve the quality of waterproofing. Upper endova covers the inner corner of the roof joints, and it is this detail that is recognized as the most difficult in engineering terms. And the role of the ridge elements consists in a bundle of fracture lines between the roofs; along with this, they enhance the decorative qualities of the design.

The ridge elements of a simple type are only metal corners, their width is 10-30 cm. In most cases flanging is used, the edges are bent approximately 15 mm. If possible, you should select the most rigid structures, installers appreciate them for their simplicity. In addition to the ease of layout and mounting, the advantage is the resistance to the bending action of a strong wind. The U-shaped element is characterized by an accelerated installation, and initially set the beam, and then the ridge.

Semicircular skates have a flexible geometry, adjustable for individual roofs.

Differences appear in the proportions of the diameter of the ribs. End piece must be used necessarily. For installation, always use sealing tape, placed in the interval from the ridge to corrugated. Using a seal helps to avoid penetration of the pie:

- moisture;

- insects;

- small birds.

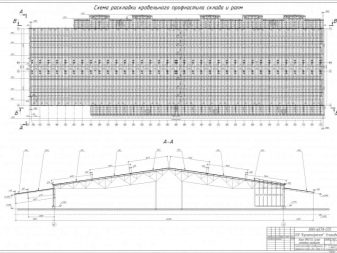

Calculation of the amount of material

Having dealt with the roofing device from the profiled sheet and its general device, you need to find out the need for additional materials. Most accurately calculate the required amount of roofing, taking into account a certain overlap will help specialized programs. They are able to assess the necessary parameters of the roof - both all together and separately.

Such software successfully copes with even the most complex tasks that people have. Alternatively, you can contact the project organization - they not only know how to calculate everything, but also make up professional drawings.

For the most simple roofing options there is no need for sophisticated calculation. All training can be done by the owners themselves. When calculating the area of slopes of a standard form, generally accepted geometric formulas from the school course are used. Then to the result obtained add the calculation of the extreme elements of the roof.

When calculating, they operate not with a common, but only with a useful width of profiled sheeting.

The number of sheets stacked in horizontal rows is calculated by dividing the lengths of skates by the useful widths of profiled sheets. To avoid mistakes and incomplete rounding helps. Standard overlap is taken at the level of 80 mm, but you need to pay attention to how big it is in a particular case. It is extremely important to conduct all calculations in such a way that a one-piece design is created. Additionally, the values of cornice overhangs and additional parts are calculated.

The typical length of the dobors is taken 200 cm. Their number is determined by dividing the length of the slopes by 1.9 (based on the standard overlap). For endov overlap do more, and therefore there must already be divided by 1.7. As in the case with the professional sheet itself, it is required to round the received figures in a big way. On 1 square. m. 7-8 screws are used, additional elements are covered with 8 screws per 1 m2.

Installation Instructions

Installation of corrugated flooring is easier and more convenient to perform if you immediately buy a perfectly sized kit. But this is not always possible technically, and in such cases a special cutting tool comes to the rescue of builders.When fitting, the coating spreads out on a solid, even foundation, most often on clean ground. Among all power tools, a drill with a nozzle in the form of a disk demonstrates the highest efficiency.

When there is no electric machine, you will need to use scissors for metal or a hacksaw with a small tooth.

It is strictly forbidden by technology to cut the professional sheet with abrasive devices. Significant heat generation at work adversely affects the practical properties of the material laid.

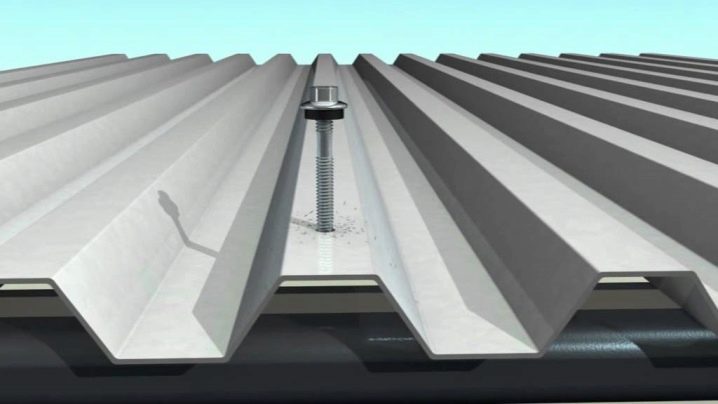

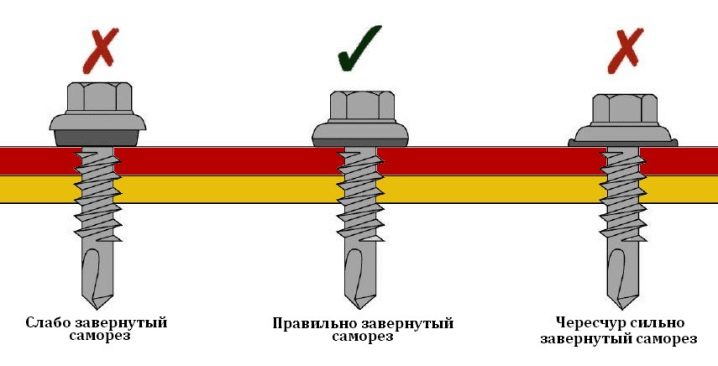

Since the cutting will inevitably break the edge, you will need to think in advance about the paint, which coincides in tone with the main products. To raise the necessary sheets up, use logs - this is the easiest way. The professional sheet is supposed to be mounted on hexagon self-tapping screws 8 cm long with a sealing gasket. It is unacceptable to tighten them all the way, since this may break the waterproofing.

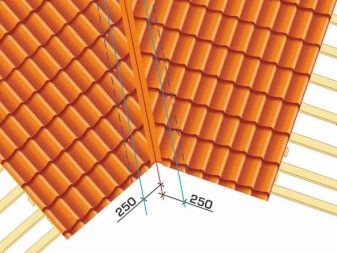

Sheets are attached in the lower lobes of the waves, but for ridge elements and overlaps, the attachments are made in the upper ones. Experienced craftsmen assemble decking, moving from the end of the ramp. The side overlap leads on ½ waves, but on gentle slopes - less than 120 degrees - it is already 1.5 profile waves.

It is very important to equip the gable sections by all the rules, if this is not done, the very first day with strong gusts of wind will be the last for the roof. When the sheet allowance is 5-7 cm, you need a 2.5 x 8 cm wind rail fastened with self-tapping screws.

But in the absence of allowances or their insignificant size, the rail is supplemented with a wind strip that looks like a steel corner. Such a bar is fixed with an interval of 20-30 cm, with a transverse overlap of 10-15 cm. Pressing the slopes to the walls is performed using corner bars. Whatever the junction, connect the materials with screws through every 0.2-0.3 m. The overlap is at least 10 cm.

When repairing or replacing the roof, horses should be fixed from the angle where the impact of wind and precipitation is the least. The snow barrier is especially important at the time of thaws, it allows you to avoid the rapid collapse of miniature avalanches down. This element is placed just below the roof edge across the ramps. For fixing pre-prepared bars. Of course, for any work on the roof is required to comply with safety regulations.

Properly insulate the roof of corrugated will help the combination of mineral wool and a vapor barrier. Nobody forbids taking other seals, but cotton is recognized as the most powerful variety.The choice between the roll and sheet options is not fundamental - they have the same thermal qualities.

You can attach insulation with your own hands in one of three ways:

- holding screws;

- fastening on the thread;

- glue ligament.

In any approach, a balance between the connection density and the minimum compression of the seals is required. After all, blocking the cold is provided not so much by the cotton itself, as by the air contained in it. A vapor barrier is exhibited above the wadding layer to prevent moisture from entering the insulation, which is constantly circulating in the air.

It is unacceptable to insulate 100% of the roof, always leave cold triangles. The site is not covered with cotton, and it will help the normal ventilation of the attic room and the outside world.

It is possible to put a roof from a professional flooring and over existing. The main thing is that its operational parameters are decent, and that the total load is not excessive. Since the profile sheets are relatively fragile, you can not put them on the ground. It is recommended to use coasters from boards approximately 2.5 cm thick, spaced in steps of 0.5 m.

Subsequently, the roof must be cleaned thoroughly at least once every six months; when scratches are found on the professional flooring, the problem areas only overlap with a suitable paint.

You can accelerate the fastening of the material, if you use a screwdriver, and not a simple drill. Joints are handled by riveting manual machines, with which it is easy to put steel rivets.

Rivets made from any other metals and alloys are prohibited. It is recommended to use a special machine for cutting metal. Marking and measurements are carried out with the same tools as for any other construction work.

You can attach a professional sheet strictly using specialized fasteners. Suitable exclusively for metal screws. Mounting belts and safety devices are certainly used, even on the relatively flat roofs of the ground floor in dry, windless weather. If the slope is large, it is required to put special barriers in addition to the profiled sheet. It is possible to move on the already delivered sheets only in soft shoes without sharp protruding parts.

Sometimes it is possible to attach a profiled metal on several sheets of the lower row, while at the same time they retract 35-40 cm from the strip of the cornice. At the same time, fastenings are made for every second wave.Boards at the ends are hemmed with wind corners after the final attachment of all sheets. Only in the last turn mount the junction bar, the outlets of various pipes and the like infrastructure.

Lathing is done after waterproofing. Trapezoidal profile allows the use of three types of bars:

- 30x70 mm;

- 30x100 mm;

- 50x50 mm.

The rafters pitch is 0.9—1.2 m. The most accurate information on the required dimensions can be found in the accompanying documents for profiled sheeting. A sturdy, double-sided flooring of boards, distant by 0.6 m, should be placed under the lathing strap at the level of the batten. Razlelobok of galvanized steel should be mounted with an overlap of at least 200 mm. If the roof is flat, the joints of this element are made using sealing mastics.

Bottom slats of the gouge join initially at the edges (screws are screwed in there), but the final fastening is performed simultaneously with the entire coating. At the moment of laying the sheets, they should be trimmed relative to the overhangs (in any case not along the joints).

Clearing the laid proflista of snow and ice is made using wooden or plastic shovels. Steel tools for this purpose cannot be applied in principle. Observing the basic rules of choice, laying of corrugated flooring and handling it, you can guarantee a long service coverage.

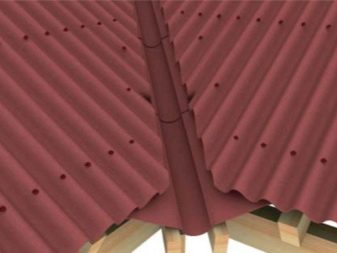

In addition to standard requirements, there are a number of subtleties when laying corrugated flooring on individual types of roofs. When it is placed on the hipped house, one or two corrugations of the panel are superimposed on the placed element.

It is necessary to overlap the longitudinal grooves in the amount that is determined by the angle of inclination of the slopes and the carrying capacity of the material. The calculation is required to take into account how much the corrugation should be placed overlap. Single panels are assembled into a large sheet with the help of short screws that do not penetrate the crate.

The joining of the metal roof as a whole to the crate is made with deepening into the wood, at the same time the fasteners are screwed through the concave sections of the corrugations. All fasteners must have the same color as the cover itself. When working on a hip roof, the central axes of the starting sheets and ramps are initially marked. Then they try everything at once, achieving the alignment of the axes and tracing the lines of cuts.Further sheets need to measure and cut to actual size.

Working with hip roof, the first sheets are mounted, ensuring that the edge coincides with the farthest edge of the right or left posts in the ridge girders. The starting product is not incised along an oblique path, it should be placed on the entire height of the roof. Cut only panels in contact with oblique hip ribs. Tent structures imply the same pattern of cutting sheets on each ramp. In the case of a hip roof, the eaves slopes are covered with material cut according to the “tent” pattern, and the long ones require a small trimming.

The height of the sheets is calculated according to a carefully thought-out scheme, trying to close the hip rib at 100% whenever possible. The layout of the blocks on the triangular slope is from the middle, and on the pentagonal - from the extreme point of the ridge girders.

In any case of work, in any type of roof, you need to strive to limit the number of parts whose width is inferior to the size of the sheet by more than 50%. Each such area is weakened as the number of junction points increases.The height of all profiled panels is increased by the width of the overhangs above the eaves.

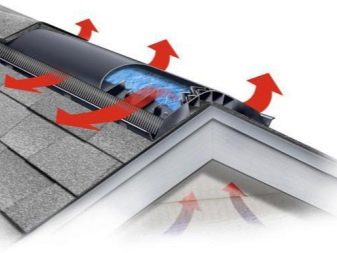

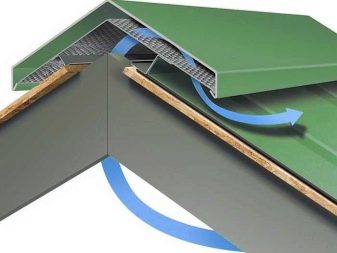

Already at the time of design it is necessary to decide whether the installation of holders of gutters will be carried out before the placement of corrugated flooring or not. The difference is due to the fact that in the first situation, long-length brackets are used, and in the second - shortened hooks. Roof pies under the sheet are made with one or two ventilation circuits. Their number is determined by exactly how the waterproofing is made.

The waterproofing layer under the steel roof with an external polymer layer should not contain bitumen.

The very first circuit is placed in the interval from insulation to waterproofing - provided that water is held back by a polyethylene film or anti-condensate material with a fleecy surface. But there is no need to create a ventilating passage under the diffusion membrane; it will itself discharge excess moisture as soon as mechanical stress occurs. As for the second line of ventilation, which separates the waterproofing from the metal, then there can be no two opinions - it is needed in 100% of cases.

The scale of the ventilation gaps is chosen in proportion to the areas of the slopes.Usually this proportion is about 1%.

If the outflow and the air inlet are separated, the resulting figure can be divided in half. In the case of a gable roof, the resulting values are identical, and for a four-slope roof, the difference is eliminated by the addition of an aerator. Rafters for profiled steel are made from the corners of channels, laths - from square pipes or profiles in the shape of a letter P. When work is being done on a residential house, it is undesirable to use metal truss systems. Much better under the decking fit wooden bases, especially since working with them is much easier.

Reshetinas under profiled are placed at the same distance. Reducing the distance is only necessary where it is necessary to strengthen the structure. This is required along the eaves overhang, the perimeter of which is weakened by further installation of the snow guard, as well as:

- in the valley;

- near the ridge girder roofs;

- at some radius from the roof passage.

The process of installation of the roofing sheeting with their own hands, see the following video.