Liquid rubber for a roof: features of the choice and installation

Any building needs waterproofing, which is used for the foundation, walls, roof and other elements. That roof requires special protection, for which liquid rubber is increasingly used.

Special features

Liquid rubber is a modern material that has excellent waterproofing characteristics. Such material is created on the basis of latex and bitumen emulsion. Liquid rubber can be used for roofing as a protection or self-covering.

After applying the rubber in a short time begins to harden, turning from a liquid material into a solid, elastic membrane without seams and joints. Such material can be used in various areas and roofs with complex structures.Liquid rubber can not be compared with other types of waterproofing. This can be easily seen by examining its benefits.

Advantages and disadvantages

Roofing liquid rubber has several advantages and disadvantages. Familiarity with this material will not be complete, if you do not study these two sides.

The list of benefits consists of the following points:

- uniformity and solidity of the coating, the absence of seams and joints;

- achieving maximum adhesion characteristics regardless of the coating material: concreted surface, wood or metal;

- filling the liquid material with small surface defects simplifies the preparation stage;

- elasticity allows the coating of liquid rubber to increase in size and return to the original parameters. This advantage becomes relevant when temperature drops and seasons change. On such a coating does not form cracks, which makes it possible to call it durable and hardy;

- The use of a mechanized method of application allows to reduce the installation time and improves the quality of the application. Fast and high-quality installation is particularly relevant when processing convex and complex elements;

- ecological safety and absence of toxic substances in the composition;

- The extensive scope of application includes residential facilities, industrial and commercial complexes;

- the possibility of using a finishing coating and creating a base area that can be used for further operation;

- a large number of shades and textures opens up enormous possibilities for aesthetes and designers;

- Easy repair, requiring a minimum of time and finances. The possibility of repairing a small area without affecting the main area.

The following disadvantages are added to this impressive list of benefits:

- the need to use a special technique for applying liquid rubber on the roof;

- high demands on the surface preparation process;

- the presence of requirements for environmental conditions that must be maintained throughout the installation works;

- the difficulty of dismantling the coating created from liquid rubber.

Species

The market of liquid rubber for roofing is actively developing. Already, there are many varieties of this material, which makes rolled materials irrelevant.

The classification may be based on different principles.

- Single-component material has a liquid consistency, low viscosity. The color palette is diverse, which opens up great opportunities for choice.

- Two-component mastic liquid roof, in addition to the main components, also includes a hardener. Components are mixed immediately before application to the surface.

- The sprayed material is still recognized as the most promising due to high quality and quick installation. Be sure to require the use of special technology.

- Paint rubber is available in a large assortment. It can be liquid and pasty. After hardening it forms a film on the surface. Installation is carried out using hand tools.

- Self-leveling roof is an economical option and is usually used before installing the coating. The material is simply poured onto the prepared surface and leveled with a special hand tool resembling a mop.

- Hot rubber is more suitable for bitumen surface. The seamless surface provides reliable protection for the roof and the building as a whole.

- The cold material in the composition has a solvent, is more mobile and convenient during installation.With such material you can work independently. You need to have gasoline or kerosene on hand, which may be necessary to dilute the rubber.

- Fixed was recently developed by the military-industrial complex. Initially, this material was used exclusively for the military and defense industries, so its characteristics are at a high level. It can be used equally on a flat and sloping roof.

- Liquid rubber can have a different basis, bitumen and polyurethane foam are most often used. The second option is more innovative, durable and durable. Although bitumen is not going to go to the background, because it is a proven, affordable and high-quality option.

How to choose?

At the time of purchase, you must carefully examine the liquid material. Large elements cannot be present in its composition; waterproofing should be uniform, uniform and smooth. Otherwise, when laying the surface will not be smooth and high quality. On the packaging label must be stamped, corresponding to GOST. It is necessary to pay attention to the shelf life and integrity of the package.In the presence of even the slightest doubt, you must refuse to purchase.

Different materials can be applied in various ways. Each manufacturer puts on the packaging recommendations for use and the required thickness at which the material will provide adequate protection. Do not deviate from these recommendations.

To determine which tires are the best, you should study the offers of the market. Preference is better to give well-known companies that have managed to earn the respect and recognition of the consumer.

Manufacturers

Many companies are engaged in the production of liquid rubber. There are among them both domestic and foreign representatives. In this assortment it is easy to get lost, so you should pay attention to the most popular and worthy producers whose products will not be a disappointment.

- It should start with a Russian manufacturer, or rather, with a whole group of companies. Partner-Stroy. It supplies several products to the market at once: Euromast, Euromast Plus and Euromast Color. These products are chosen for high quality, reasonable price and a large range.

- At the production facilities of the company "Climbing" high-quality liquid single-component rubber is produced "Blockade". This material is fully consistent with international standards that apply to waterproofing materials of this type. Pleases acceptable cost, which relegates to the background the products of many manufacturers. The company offers discounts when placing bulk orders.

- Another worthy domestic manufacturer is the company. "LKM USSR". She has been producing a wide range of polymeric protective materials, including liquid rubber. These products are widely used in the construction of the industrial and civil sector of Russia. Waterproofing is produced on the basis of developments that were created for the military-industrial complex of the USSR, and for a long time remained classified. The basis of liquid rubber is bitumen, which is ideally suited for waterproofing protection of surfaces of various types.

- Organization "Synthetic Polymer" part of the company Nippon acewhich is engaged in the production, development, promotion and sale of polymer compounds. These materials are off-season water-displacing compositions that have a wide range of applications.There are no analogues of this product, none of the existing manufacturers have yet produced such material.

Application Equipment

For high-quality material application, it is necessary to use special equipment. As such equipment is mainly used mobile spray. Its preparation is the first stage from which rubber spraying begins. The spray mechanism consists of a dispenser and a mixing device. In most cases, gasoline is used as fuel, not electricity. This feature provides mobility, compactness, autonomy and ease of operation. With this set of features, work is possible even in hard-to-reach places.

Also, the mechanism includes a long hose, the length of which can reach 150 meters. Due to this, in the process of installation there is no need to constantly move the device around the roof. The environmental friendliness of the material allows to do without personal protective equipment even when working indoors.

Instructions for use

When treating the roof with liquid rubber, it is necessary to strictly follow the application technique.

Otherwise, the end result may be disappointing.

- For work you need to choose dry weather with air temperature above +5 degrees.

- The base must be carefully prepared for further work. The essence of this stage is to clean the working surface. There should be no pollution, not to mention the garbage. In the process of purification can be used a powerful pressure of water or burning. The latter method is applicable to greasy and other complex stains.

- Priming is the next stage, the essence of which is to create a waterproofing layer on the prepared surface. The structure of the future roofing directly depends on the quality of priming, therefore it is necessary to approach this stage seriously. The result of this step will be the elimination of the smallest dust particles, imperceptible to the eye pollution and ensuring maximum adhesion between the surface and the liquid rubber.

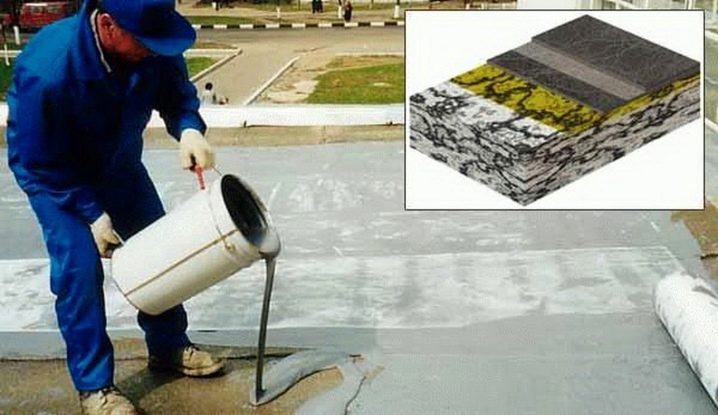

- Installation technology is completed by applying a liquid rubber by spraying. It is necessary to strive for a uniform layer. This will be easy if you observe the right angle between the base and the sprayer.And also you need to adhere to the same distance, which will be maintained between the base and the extreme point of the sprayer.

- Composite materials of the solution are mixed directly by spraying. To do this, the equipment has a special compartment. The width of each strip should be within 1–1.5 m. Transitions should be cross-shaped.

- Several layers are sprayed on flat roofs, their number can reach three.

- Must be present fittings. For this purpose, you can use geotextiles or fiberglass.

The consumption of 1 m² with a layer thickness of 2 mm is 3 liters of liquid rubber. The freezing of the material depends on the external conditions. With an air temperature of +20 degrees and a humidity of no more than 50%, it takes three days to fully set. Liquid droplets may appear on the surface, which is normal. The reason for this phenomenon is the work of the catalyst.

This was described by spraying, but there are materials that require a different method of application. Many stages remain unchanged, and the various methods of installation differ only in some moments. For example, the paint rubber is distributed over the roof with a roller.In this case, the layer of material is thicker, which allows to achieve a durable and resistant coating. But the consumption of rubber will also be more. In addition, you need to make a lot of effort to achieve a uniform distribution of material. Bulk tires poured on the center of the roof and leveled with a spatula. The method is very similar to the installation of painting material.

Useful recommendations

Liquid rubber is a polyfunctional material that can be used not only for the installation of waterproofing systems. With its help, the repair of the roof, which was installed earlier, is successfully performed. There is no need to dismantle the existing coating.

Repair can be done in the following ways:

- at full repair the existing covering is completely covered with rubber;

- in case of a flat (partial), the damaged area is removed and the liquid waterproofing is sprayed on it. This method is applicable to eliminate roof swelling.

When working with flat roofs, it is necessary to consider the following installation features:

- the surface must be smooth and well cleaned, the preparation process is carried out carefully and scrupulously;

- in the presence of irregularities on the surface leveling is done with a tie;

- on a tile covering the consumption of material increases;

- Reinforcement of all joints is necessarily performed on the ground surface.

When choosing a liquid rubber, you need to study reviews from consumers who have already managed to use this material. This information will be very useful.

On the deposition of liquid rubber on the roof, see the following video.