Roofing pie: device and installation features

Any well-executed roof seems to be a solid piece. However, this is not the case, and it receives all the positive properties that such a design has due to its carefully thought-out design. Since a number of layers are hidden inside, the structure was called the “pie”.

Features and Purpose

Roof construction is extremely important.

When creating it, the following factors should be taken into account:

- nuances of the architectural image of the structure;

- ensuring a long period of service of the building;

- cover people and property from atmospheric elements.

Saving money and achieving a rational result is possible only with strict, careful thinking through the smallest nuances. The roofing “pie” is further complicated if below it is a residential attic or simply a warmed attic - in such cases additional insulation and protective layers have to be introduced to ensure success.

The slightest mistake, not only in a separate layer, but also in the order of its location, as well as a violation of tightness, has serious consequences.

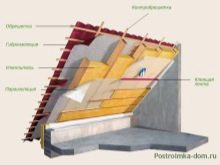

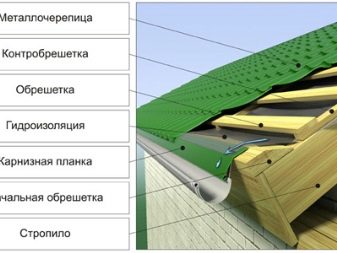

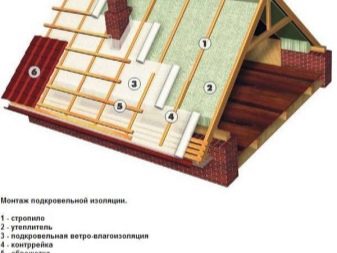

The structure of the typical roof includes:

- air vent clearance;

- finishing material located on the attic or attic ceiling;

- water vapor barrier;

- frame parts;

- warming parts;

- hydraulic barrier;

- front roof composition.

But this does not exhaust the possible set of components. Both the water drain and the system that prevents icing are considered to be “cake”. It is closely connected with walling, with snow retention devices, with decorative additions.

Summing up, we can conclude that the "cake" is all the elements that are mounted above the ceiling, not counting the rafters.Sometimes these or other details may not be, since the type of roof to be mounted and the coating used are of great importance - you should understand them first.

Types of building

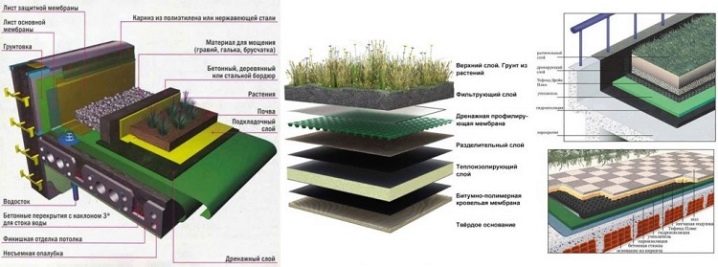

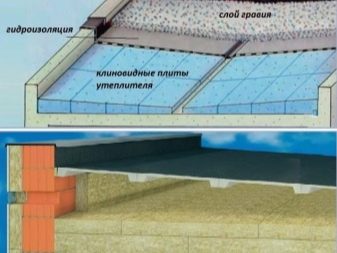

The traditional approach is not always acceptable, and its replacement is inversion roofing.

Its specificity is a change in the order of display materials:

- the basis (for example, from concrete);

- primer;

- geological textiles;

- heat-retaining foam or EPS, thickness of which ranges from 3 to 12 cm;

- new array of geological textiles;

- ballast (gravel of 5 cm or more).

This scheme helps to eliminate a number of weak positions of a flat roof. Geological textiles act as an additional bond between the main parts, and the layout of the insulation under its protection prevents the effects of dampness. In many cases, while eliminating the drawbacks of a classic roof, an inversion “pie” is mounted on top of it. The rolled roof is mounted mainly where the ramps are inclined slightly: from 1 to 12 degrees. It is irrational to use piece goods in such places - they will not look as beautiful as on a steep slope.

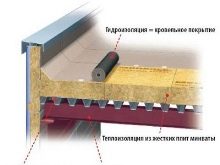

The difference in the layout of the materials under the typesetting and roll roofing does not concern the order of their alternation. First, protection against steam is put, then a heat-insulated unit, covered by a hydraulic barrier, simultaneously performing the functions of decoration and protection against wind. But under the flat roof do not make a monolithic frame, there is no counter-bar there.

The flooring is made without the use of additional wooden parts, if below:

- profile sheet metal;

- screed cement and sand;

- concrete pouring;

- prefabricated concrete or masonry.

More accurately select the number of layers and assess their required thickness, taking into account the warm or cold roofing. When using a metal profile above an unheated attic, you can refuse heat protection. Roofing material or similar material helps to stop the penetration of water.

This solution is intended mainly for seasonal buildings and summer houses - in capital houses, where they live permanently, it is less common. Warm construction is required if you intend to equip the attic, a different living room, or they are already in the house.

Laying principles

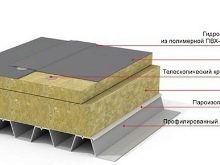

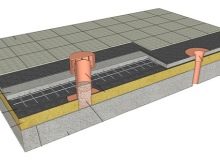

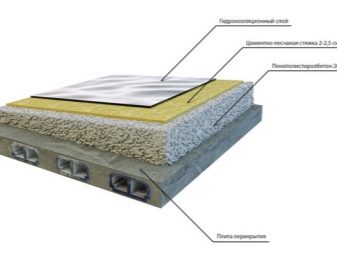

Arrangement of a flat roof, as well as in the presence of a bias, is also produced in the form of a “pie”. Above the base, water vapor barrier, insulation and hydraulic protection are alternately placed. The bottom surface should be leveled and cleaned of any contamination, for sealing the cracks apply sealing compounds based on polyurethane. The seam of the sealant should be 50 mm in width and 3 mm in depth. As a priming reagent, an epoxy-based primer is preferred, which is pre-mixed with a mixer at the lowest speed and diluted with water by 50%.

Primer application involves the use of brushes or rollers. Hardening of the finished surface is made by mastic. The obstacle to steam is made of polyethylene or polypropylene.

Fixing the film is achieved using:

- nails;

- binders;

- assembly adhesives.

The required ventilation channel on a flat roof should be 0.1 m, while ensuring that the heat protection is more tightly pressed against the roof structures, ventilation ducts and any pipes. If the flat roof rests not on concrete, but on a metal profile, the approach to installing the “cake” changes - to contain the vapor, bitumen material or special rolls are used.Heat protection is formed from mineral wool, expanded clay (in pure form or as part of a screed made of cement and sand), sometimes a plate made of expanded polystyrene is used.

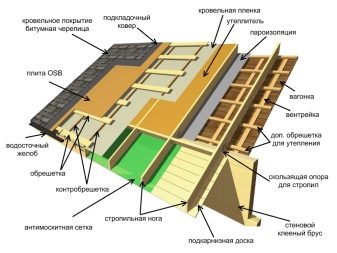

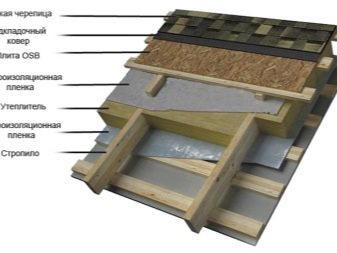

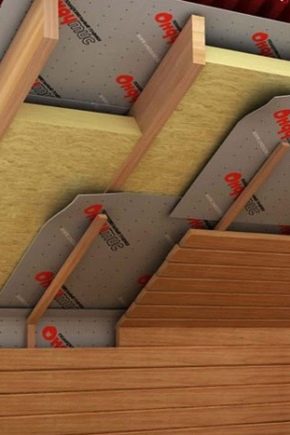

The correct order of insulation of the pitched roof is as follows:

- inside, a vapor retaining membrane is attached to the rafters;

- this material is placed parallel to the overhangs in the form of a series of bands;

- for the formation of a monolithic surface using double-sided tape;

- above the steam protection (also from the inside) a counter-lattice is made, bars are used to form it;

- the pitch of their location is determined by how the attic will be cleaned from the inside (0.4 or 0.6 m for drywall);

- From the outside, in the gaps of the rafter beams, arching parts are introduced that will support the thermal protection blocks;

- the distance between the struts is 20-30 mm less than the height of the planned blocks - this helps the insulation to firmly fix in place;

- the thickness of the thermal barrier is 0.03-0.05 m less than that of the rafters;

- the counter-lattice is nailed back longitudinally to the legs;

- a monolithic skeleton covered with a layer of hydraulic protection is placed on top of it;

- laid soft tile.

But confine heat and cover from moisture penetration ventilation will not work. A very important element of a good roof is lightning protection. The decision in which a lightning-receiving grid on a flat roof is brought under insulation is obsolete, and it has long been recognized that its effectiveness is zero. The approach of the receiver to reinforced concrete reinforcement, supporting profile or just fasteners creates the danger of current transition. In addition, the front part of the roof and equipment installed on it are completely deprived of protection - they can easily be damaged in any discharge.

It is recommended to use a mesh associated with atmospheric electricity receivers raised above the roof covering. The more possible directions for current distribution, the lower the risk that a spark will reach electrical devices or electricity-conducting parts of the building.

The retaining parts must be burdened by the additional load - there is no need to attach them to the bases using self-tapping screws. This rule applies only to flat roofs, but if there is at least a slight slope, then all structures will have to be fixed.You should not try to make protection against thunderstorms with your own hands - in any case, such products are much inferior in reliability to industrial structures.

In addition to the above options for protecting the building from precipitation, a fused structure is gaining increasing popularity. The main part of it is a canvas that is not prone to rotting - it is formed due to the modified bitumen. Under the deposited layer, a cement and sand fastener is necessarily performed, which can be as wide as 0.5 cm. With seams it is divided into squares with a side of 600 cm. , seams are divorced in space to eliminate misunderstandings.

Materials and tools

It is possible to lay a flat roofing “cake” on wooden beams in a cold version without installing steam protection, because in such cases a soft material is usually used that seals the roof itself. It is also important that the laying is performed on profile sheets of metal, slabs of concrete. On top of these structures, expanded clay or pearlitic razuklonka is being prepared, covered with a cement screed.As a result, leaks are absolutely excluded.

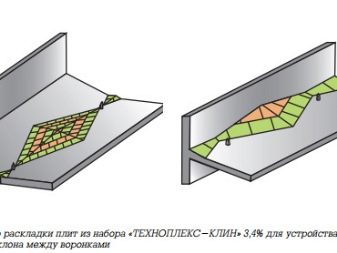

If the roof structure is based on a reinforced concrete slab, then cement and sand for screed are used over the operated attic or attic, a vapor barrier is applied (a build-up is recommended). Then comes the selected insulation, screed, forming a slope, roofing materials and sometimes a terrace covering. The rapid creation of the slope is achieved using a wedge-shaped insulation, such as "TechnoNIKOL wedge". A membrane is placed above it, and only then comes the turn of the facial covering.

To cover the roof of a frame house approach should be somewhat different than when working on a concrete base.

The choice of material in any case is based on the following positions:

- compliance with the geometry of the roof;

- consideration of climate and wind load;

- the proximity of the service life of the front cover and underlying products;

- external aesthetics and availability of financial indicators;

- ease of installation (if you plan to do the work without help).

There are certain standard approaches to the set of tools used.For example, despite the presence of a large number of saws, other cutting and grinding systems, you need to have a carpenter's ax ready. Its mass is about 1.5 kg with a blade length of 0.3-0.45 m.

The fact is that the lighter options will not cope with the work, and the heavier ones are inconvenient to handle. It is also useful to prepare in advance saws, hammers, angle grinders, drill, screwdriver, wrenches, tape measure, marker, plumb, construction level.

How to prepare?

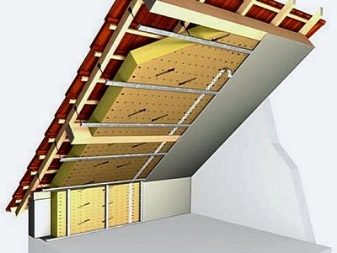

Whichever arrangement scheme is chosen, careful preparation is essential. Let the tile be chosen for the arrangement of the front part of the roof. In this case, drywall sheets must be put above the vapor barrier - they will make the attic room more accurate and become a good, solid base under the insulation.

If a metal tile or profile sheet is used, then it will be necessary to carefully mark the position of each part according to a sketch or pattern, to form a concrete screed, and under heavy materials it is even useful to form columns of concrete.

How to make yourself?

The process of laying and arranging a soft warm roof on the sloping portion of the roof begins with fixing the steam insulation to the rafters. The high cost of special membranes of the modern level is not as terrible as it seems.But it is much more profitable to have a simple plastic film, which differs by its increased size. When attaching steam insulation, each joint is taped with adhesive tape, even if it is a simple clerical, and not specifically designed for construction.

The film is laid on top and bottom, the strip run should be at least 0.1 m. Fixing using a stapler is faster and more reliable, even safer than using nails. The membrane should overlap the chimney.

Then the crate is prepared for the insulation, which is recommended as mineral wool. The distance between the parts of the frame should be a maximum of 0.4 m. If this distance is made larger, the cotton mass can deform and lose its function.

When the insulation is laid out exactly in size, then the wind membrane is used exclusively modern samples. You need to look at which side to attach the material. Then comes the turn of the arrangement of ventilation: no grueling calculations are required if you simply add a trussing system to the truss, the thickness of the slats in which should be 30 mm.After that, a continuous crate is put, a lining layer is prepared to increase flexibility and protection from moisture at the same time. The final step is the installation of curtain strips, end carpet and the transition to the installation of the tile itself.

Professional Tips

When installing the roofing “pie”, a great role is played by its competent docking with the facade covering - this is achieved through the use of additional parts. It is important to know that such elements are mainly used on solid roofs. If the coating is soft and easy to bend, the problem will be solved in a simpler way. Finishing operations are carried out mainly from galvanized steel - their recommended thickness is 0.05-0.07 cm.

If the architectural structure is complex, then the installation is best done by individual order.

In the next video you will find a phased installation of the roof (the necessary elements, the installation of vapor insulation, insulation, hydro-windproof membrane and topcoat).