Roofing strips: types and use of elements of a soft roof

Soft tile is used as a roofing material relatively recently. It is made of various substances (bitumen, resins, etc.) that do not pass moisture, and also have considerable flexibility. But the strength and durability of such a roof depends largely on the auxiliary elements. Special attention should be paid to roofing strips.

They are present on almost all types of roofs, so it is important to choose the right ones for a specific modification of the product.

Special features

Soft roofing is a layer of plastic material that is attached to a flat base. With the help of such products it is impossible to obtain a complete waterproofing of the surface.This is especially true of the end elements, as well as places of abutment of several structures to each other.

Solve this problem with roofing strips. This product is a flat part, which is different L-shaped.

Levels for a soft roof solve several basic tasks.

- Waterproofing. Curtain rods and wind strips do not allow rain to penetrate under the base. This extends the life of the rafters and other structural elements. At the same time they are designed in such a way as to direct flows in the right direction. Also, the proper arrangement of ventilation and the use of slats helps prevent the permanent formation of condensate under the roofing coating.

- Wind protection The front strips do not allow winds to penetrate under the roofing material. This protects the base from stalling under high impact. In addition, these additional elements additionally prevent the possibility of rodents or birds getting under the roof.

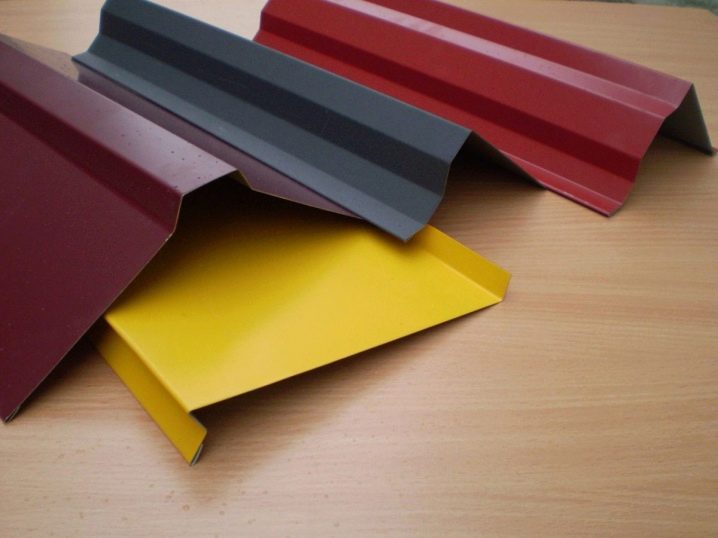

- Decorative design. Roof strips have many colors. This allows you to pick them up under the basic style of the roof.Their use allows you to drastically change the design of the structure.

Species

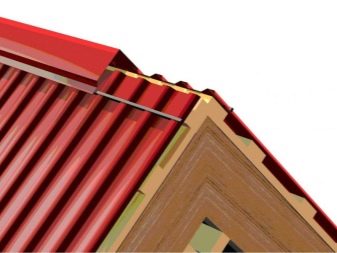

Roofing elements are used only on pitched roofs. This is due to the fact that they all assume the presence of a wooden frame that must be further protected. Conventionally, these products can be divided into several types.

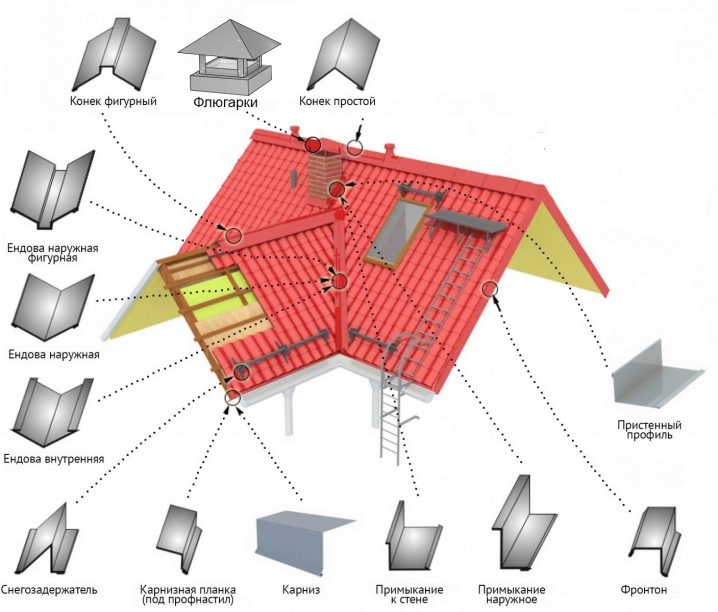

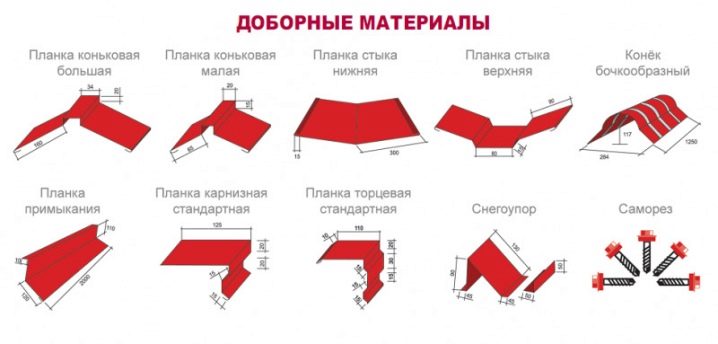

Eaves strips

These fittings in most often attached to the bottom of the roof. The main intent of the droppers is to divert water directly into the drain. Please note that such an additional element is selected depending on the level of the roof slope.

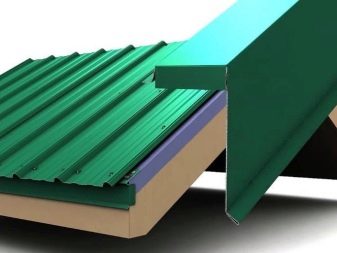

Butt end

Such a structural element is used to protect the web from the effects of wind. Therefore, these strips are often called wind or facade. As a rule, it is a slat that is bent at a right angle. The width of its sides is selected depending on the thickness of the frame for a soft roof.

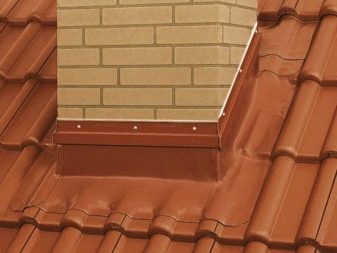

Adjoining

The installation of these strips is carried out at the junction of the roof to vertical surfaces. They are used in the finishing of chimneys, ventilation systems. It should be noted that in most cases such passage elements are bent inward.Technically, this is the same wind strap, but it is turned inside out during installation.

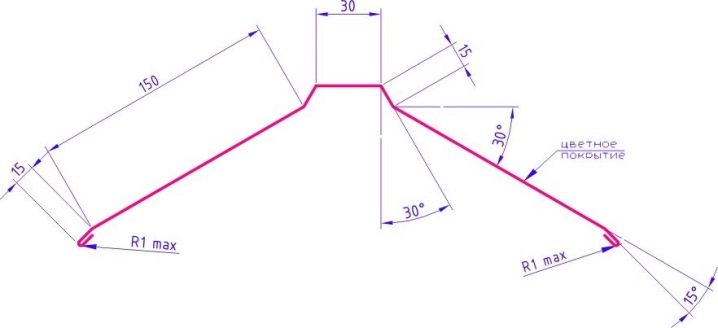

Ridge

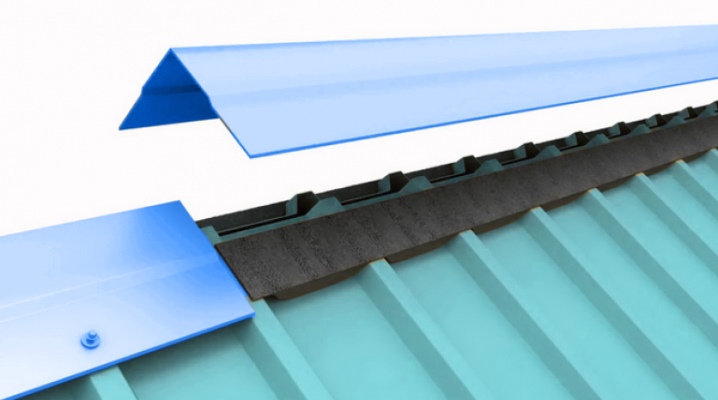

This type of slats is used to protect the joints in the joints of two ramps. Externally, these products are very similar to the previously described modifications. But they can be supplemented with special seals that do not allow water to get under them.

Materials and sizes

The quality of roofing strips depends on several parameters. One of the universal characteristics is the material from which this product is obtained. Today, roofing elements can be divided into several types:

- Metallic. Many companies use galvanized steel as a raw material for production. But by itself, such a product is not able to withstand the effects of moisture, therefore, to protect it, the slats are coated with various polymeric substances. Most often, the protective layer is formed from various types of polyester.

Today on the market are matte and glossy surfaces. The first type is more popular as it is highly resistant to corrosion. The deposited polymer perfectly protects the metal, and also gives the product a unique design.

- Plastic. Polymeric slats are used relatively rarely for soft roofs.This is due to the fact that the products are not distinguished by high strength and flexibility.

Plastic parts are often cheaper than metal. However, they should be chosen as carefully and carefully as possible - parts from low-quality plastic can quickly fail.

An important parameter affecting the strength characteristics of products, are their dimensions. Today, roof strips are characterized by such parameters.

- Length of the product. Today, almost all manufacturers produce materials for which this parameter varies from 2 to 3 m. This allows you to select the required number of products to protect the end elements.

- Thickness. This indicator is often standard. It does not differ depending on the type of strap. Today, products with a thickness of 0.4 to 0.6 mm are increasingly common on the market. These parameters allow them to withstand the roof perfectly wind and physical activity for a long period.

- Side width Almost all types of slats have a similar shape. Standard parameters depend only on the dimensions of the roof frame. The most common modifications of the cornice strip have an aspect ratio of 10x6.5 cm.The width of the end elements can reach 15–20 cm, depending on the modification. Please note that these strips are often supplemented with a kind of bumpers that improve their protective properties.

Mounting technology

Fastening roof strips is no different complexity. This process is carried out in such a sequence.

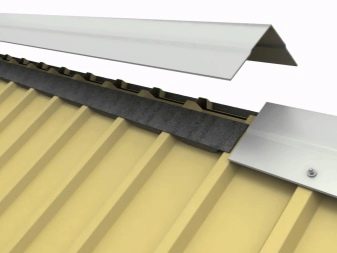

- Installation begins when the frame or lath is ready. Often under the soft roof additionally placed solid sheets of moisture-resistant plywood or OSB. Begin installation work with mounting eaves slats. Fix them directly to the lower bar of the batten or special frontal board. But here it is important, first of all, to attach special hooks under the drain. After that, the bar is nailed or screwed into the groove with screws / nails.

- Installation of adjacent slats. It is carried out when it is necessary to close the vertical elements. Here there are several ways to mount them. But it is important to properly arrange them. Slats should not enter under the bottom of the roofing material. This will lead to the ingress of water and the destruction of the wooden substrate, so these places should be given special attention, checking the tightness and quality of installation.

- The next step is to mount the wind boards.Note that they are mounted when the soft roof is laid. It is located along all the ends of the slope, while carrying out a small overlap of adjacent elements. The overlap should go from top to bottom, as with the installation of any roofing material. This will not allow water to get under the slats.

- All joints between the end strips and roofing material, it is desirable to carefully waterproof. For such purposes, you should apply special formulations that are selected depending on the substance used.

- It is desirable to position all self-tapping screws strictly at right angles to the plane of the plank. This will provide an opportunity to get a quality clamp that affects the strength of the structure.

Recommendations

Installation of roof strips is a necessary step in the construction of all types of pitched roofs.

To get a quality and durable design, you should follow a few simple rules.

- Use only quality products. It is important that the paint does not peel off when cutting material. If this happens, then this material will last for a relatively short time.

- Cutting metal strips is desirable to carry out only with scissors.When using grinders may appear chips, which will be difficult to eliminate. The grinder also heats the polymer, which at the points of contact can simply melt or lose its strength characteristics.

- As fasteners it is better to use special screws. Such products are complemented by a pressure washer and a rubber gasket. The last element will not allow water to get under fasteners, while maintaining the durability of the metal.

Roof strips and soft roofs are integral attributes that are perfectly combined with each other. But if you are planning the arrangement of the roof with their help, then the best solution for this task is to entrust it to a team of experienced professionals. They will not only properly lay the shingles, but also pick up quality auxiliary elements.

To learn how to install roofing strips, see the following video.