Types of roofing ruberoid

The roof is one of the most important parts of the house, the quality of which largely determines the degree of comfort in it. If the majority of cottages and mansions are covered with expensive and high-tech materials, then for the arrangement of country houses and small outbuildings, consumers often prefer roofing material.

This inexpensive material has been widely used for many decades and has established itself as a high-quality and cost-effective coating. Its use is particularly relevant in the case when the owner is cramped in cash.

Ruberoid has a low cost, so it is an affordable and budget material. In fairness, we note that the operational resource of roofing material is not inferior to the parameters of many modern coatings.At the same time, how long it will protect the roof from adverse atmospheric manifestations depends largely on the choice of type of coating, as well as on compliance with the technology of its installation.

Special features

At its core, the ruberoid is a construction board impregnated with oil bitumen and coated with refractory materials. On top is a layer of protective dressing, which performs a decorative function, and also protects the material from damage under conditions of constant exposure to UV rays, moisture and mechanical damage. Yes, and in the roll coating does not allow the layers of roofing material to stick together with each other.

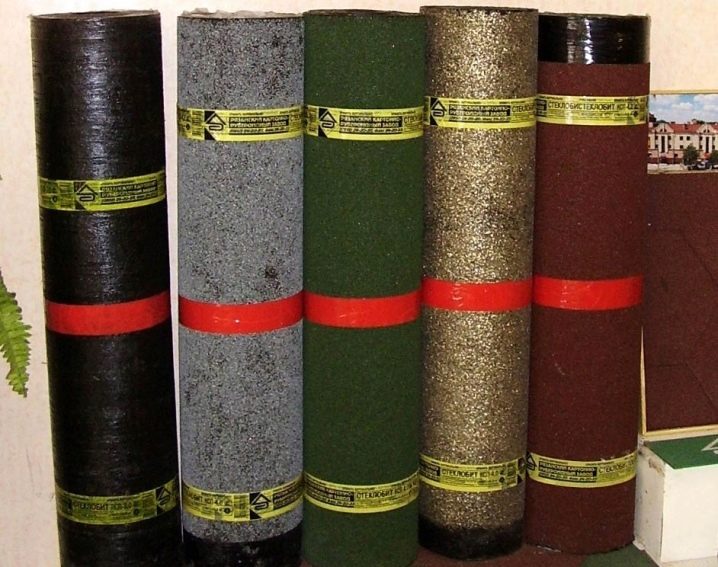

Separately dwell on the types of mineral powders, which are of four types:

- coarse grained;

- fine-grained;

- scaly;

- dusty.

Coarse-grained powders are made from stone chips, usually granite. The coating with this powder is classified as universal, it is suitable for any type of roofing, and also often acts as a waterproofing layer. This coating is not afraid of external loads and mechanical damage.

The fine-grained coating visually resembles a large sandpaper, this is due to the use of quartz sand in its production.This option can also be used as a protection against moisture under a more modern coating or as an independent roofing material.

Scaly powder is made of mica, it has a very attractive appearance, so it is often used for finishing coating.

Dusty compositions are made of chalk and talc, the only purpose of this material is to protect against moisture and waterproofing of attic rooms.

When choosing a suitable variant of roofing material, give preference to paintings with light or colored stripes, they absorb less sunlight and allow you to maintain the optimum temperature level in the summer in the structure.

The composition of the main components used in the production of roofing material, largely determines its physical and technical parameters. As a rule, the material is 100 cm wide, the weight of the package is in the range from 19 to 28 kg, and this amount is enough to cover 10-20 square meters. m roof.

The thickness of the roofing material depends on its scope, for example, for roofing materials, this parameter is 4-5 mm, and for lining materials - 3-3.5 mm.

Despite the fact that the roofing material is positioned by the manufacturers as a reliable and durable material, external influences can lead to cracking of the coating, therefore experts recommend stacking such a roof in several layers, ranging from 2 to 7.

To cover served as long as possible, it is necessary to stop the choice on products with a density of 400 g / sq. m and above. Such materials can last up to 15 years.

Advantages and disadvantages

The main advantage of roofing material in its hygroscopicity - this material is highly moisture resistant and creates excellent waterproofing. In addition, its installation does not require special skills and professional tools, so anyone can cover the roof even without experience in construction.

However, we know that the ideal materials have not yet been invented. Each has its pros and cons, and roofing material in this sense is no exception. That is why we dwell on the advantages and disadvantages of this roofing.

The benefits include:

- low cost and affordability - almost every Russian can afford roofing felt roofing; this is the cheapest kind of roofing materials, while showing fairly good performance characteristics;

- hygroscopicity - roofing material does not allow water and pushes it away from the surface, so you can be absolutely sure that unnecessary moisture does not get inside and does not damage the microclimate of the house;

- high sound insulation - the material absorbs noise perfectly, so no rain and hail will be heard inside the house - in this respect it compares favorably with the metal profile, which is quite noisy;

- tensile strength - the material is very flexible and flexible, it is difficult to break it due to the special structure, so working with it is quite simple and convenient;

- low weight - this greatly facilitates the work with the roofing felt and its delivery from the place of sale to the place of work, it is easy to lift it to the roof and hold it in the right position.

Obviously, for a relatively low price you can get a pretty good roofing option, and its appearance is aesthetically pleasing. But let's not forget about the shortcomings:

- low service life - such a coating can be used for 5-15 years, over time it will have to be repaired or even replaced;

- the installation of the coating requires the installation of a batten, and these are additional expenses of effort, time and money (however, as regards the latter, the low cost of coverage will compensate for everything);

- laying of roofing material is made using bitumen mastic, this substance begins to melt when heated to 50 degrees, as a result if the work is done on a hot day, depressurization and the appearance of cracks are not excluded;

- the material is highly flammable, has a low fire resistance class, so it is still not recommended to cover the places of permanent residence of people.

Kinds

Let us dwell on the types of materials that are traditionally called the general term "roofing material".

Tol

This material won over consumers many decades ago. However, at that time there was no special choice in stores. To date, most manufacturers have refused to release it. The roofing sheet is made from roofing paperboard, which during the treatment is impregnated with tar shale products or coal tar bitumen.

The operational parameters of this coverage are low, so nowadays it is mainly used to cover temporary buildings, which are designed for a short period of use.

Steklomast

It is made of fiberglass fabric with increased strength, less often - a polyester fabric is used as a base material.Coarse powders are used as a coating, all together it gives the material a special strength and plasticity, creates enhanced hygroscopicity and resistance to temperature extremes.

Steklomast can be used for 15 years, while maintaining its consumer characteristics consistently high throughout its life.

Rubemast

This is a certain variation of the usual ruberoid, which is characterized by improved properties and more modern production technology. As a raw material for the production of rubemast used construction paper, impregnated with bitumen and covered with granite chips or quartz sand.

The density of rubemast exceeds the density of the same tol more than 5 times.

Euroruberoid

This is one of the most technologically advanced types of roofing felt. It is made of fiberglass, impregnated with a mixture of bitumen and synthetic rubber. Such components largely cause increased waterproofing performance, coating with euroroofing material is reliable and elastic.

A feature of this coating is its long service life - it is 20-30 years, throughout this period, the material exhibits exceptional resistance to high and low temperatures, as well as to the effects of precipitation.

The upper mineral dressing is made on the basis of stone powder, therefore, performs not only the function of protection against mechanical damage, but also improves the appearance of the coating.

Do not think that euro ruberoid is produced in Europe. Its name speaks not about the country of the manufacturer, but about the quality of the coating itself, which meets the most stringent European standards.

Liquid roofing material

Another type of conventional coating that has a liquid structure. This roofing material is a polymer-bitumen composition, which is applied to wood and concrete surfaces and is used exclusively for waterproofing the roof.

The advantages of such a solution include the fact that as it dries, it forms a perfectly smooth, seamless surface, increasing its hygroscopicity and eliminating any possibility of leakage.

How to choose?

Choose the version of the roofing material that will best meet your goals, you can, based on the adopted labeling of the product. Each roll of coating is distinguished by a specific abbreviation.

P - means that the material is roofing material, this letter always comes first.

The second letter is either K - roofing, or P - lining.

The third letter may also vary:

- K - means that the type of dressing - coarse;

- M - speaks of a fine granular surface;

- H is a scaly structure;

- P - dusting powder.

Then a three-digit number is indicated - it characterizes the density of a substance per 1 square meter. m

As additional marking options are possible:

- C - color product;

- E - highly elastic and more.

The most popular are several models.

RCP 350

Roofing material roofing, dusting dusting. Its density is 350 g / m2. This coating is resistant and resistant to adverse natural factors.

It is realized in rolls, the typical length is 15 m. It has wide application as a waterproofing material, located at the very bottom of the roofing “pie” being created.

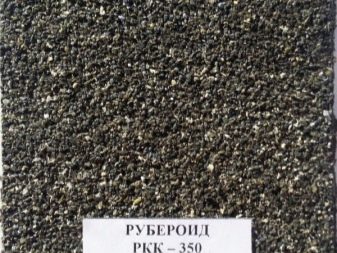

RKK 350

Roofing material roofing with coarse-grained powder. The material is characterized by a density of 350 g / m2. Differs in moisture resistance, it is steady against temperatures to +80 degrees.

It is sold in roll packs of 10 meters. It is widely used for the installation of the outer layers of the roof.

RKK 400

Roofing material roofing with coarse-grained powder. The density is at 400 g / m2. The product has a high moisture resistance and is optimal for arranging the upper layers of the roof. It is realized in rolls, the length of each is 10 meters.

RPP 300

Roofing material lining, dusting powder. Density - 300 g / m2, has a high insulating ability, is used to form the lowest layers of the coating.

Implemented in rolls of 15 m.

RPP 200

Ruberoid lining. Type of coating - powdered. The density is 200 g / m2. Used to create a waterproofing in the lower parts of the roofing "pie". Implemented in rolls of 15 meters.

Separately, we will focus on the fact that each of the listed modifications are not for continuous use. Even if they are stacked as a lining layer under the metal tile or Ondulin, then the period of their operation will be approximately 10-15 years. As a basic roofing material, they will not stand and so much.

That is why the manufacturers have launched RKK 500 roofing material on the market - they are also called armored.

How to fix?

The technology of laying of roofing material does not require special skills in the repair and use of professional equipment.At the same time, it is necessary to know and take into account some of the nuances of working with the material before proceeding to the installation with your own hands.

For a start, rolls should be rolled out and allowed to stay in this condition for at least 24 hours. Otherwise, the coating will curl during operation, which will significantly complicate its installation.

Correctly carry out roofing work in sunny weather with air temperature from 20 degrees and above, in winter conditions installation does not make sense.

Sheets should be laid very evenly and strictly parallel to each other. Separately, draw attention to the places where the material meets the wall - there should not be any, even the smallest gaps.

Roofing material should be applied in several layers, as a rule, from 1 to 5. Their number is largely determined by the parameters of the roof itself.

A five-layer coating is recommended for a flat roof, as in this case the roof must be durable to withstand snow infusions in winter.

Four-layer coating is justified on unexploited roofs with a slight slope of 2-5 degrees. Most often, the RPP-350 is used here, and on top of it you can lay a product of the RKM-350 brand.

Three-layer coating - suitable for roofs with a slope of 5-10 degrees. The last layer can be blocked with RKK-350 roofing material. Two-layer roofing - suitable for roofs with a tilt angle of 10 to 15 degrees.

If the design is more abrupt, then it is necessary to give preference to other types of coatings (metal, slate, professional sheet).

Direct installation can be done in one of three ways.

Mechanical

It involves the use of wooden slats, which determine the strength of pressing of the ruberoid to the base of the roof. In this case, the sheets are laid with an overlap at the edges of 15 cm, and then fixed with a nail or self-tapping screw on the surface.

The work will require a screwdriver and a set of plastic fungi that prevent damage to the roofing material during installation.

Laying on mastic

In this case, you need a special container for melting mastic, as well as a brush for its application. The mixture is applied to the roofing sheet on the entire surface, after which the sheets are mounted on the roof, and for greater adhesion with the base on the surface "pass" the construction roller.

Notice that Molten bitumen is very hot and requires compliance with safety regulations.

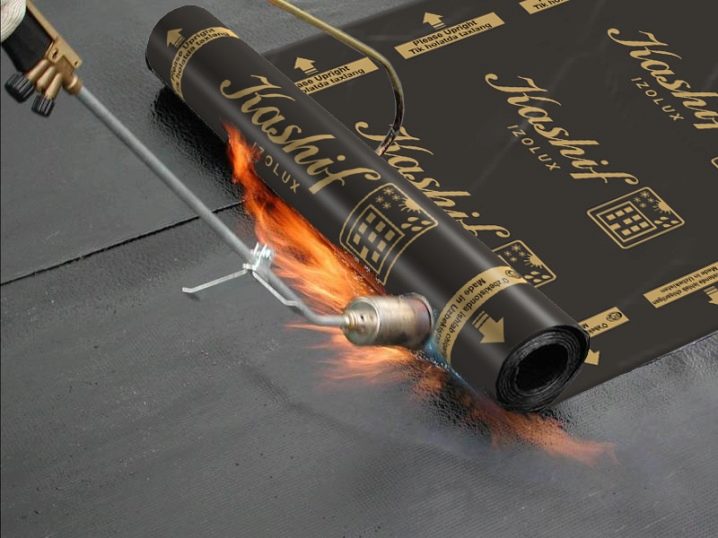

With a gas burner

With this method of roofing the bottom layer of roofing material is melted using a hand torch, in this form it is firmly attached to the roof. A manual roller is also used to prevent condensation.

Tips

To purchase a roofing material of high quality, you should give preference to products manufactured according to state standards. Be sure to pay attention to the indication of standards in certificates and product labeling. If there are none, it is better to refuse to buy in this store.

In addition, you should pay particular attention to certain points.

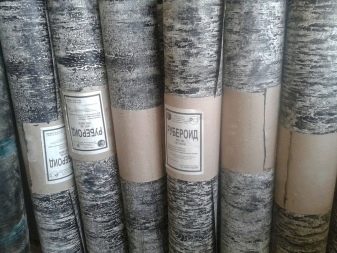

- The state of the roll - the edges of the winding should be perfectly smooth, a deviation of no more than 1.5 cm is allowed. At the same time, the material should be wound firmly, but the layers should not stick together with each other.

- There should not be chips of dressing, its cracks, as well as tears and holes in the structure of the material. According to the requirements of GOST, no more than 2 breaks per full roll are allowed, and the size of the tear should not exceed more than 3 cm.

- Impregnation should be uniform.In the context of the material should not be visible areas not impregnated with mastic.

- Each roll must be packed in paper, all other types of packaging are contrary to existing standards and state standards.

To learn how to install roofing felt, see the next video.