Shed roofs: design features, types and materials

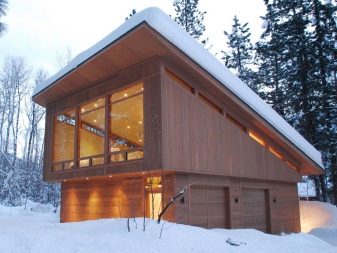

For small buildings, such as a shed or garage, often use a lean-to roof. Simple in the device, it is easily manufactured without the involvement of professional builders and looks very attractive. For the arrangement of residential buildings, such a solution is used less often: the power of tradition and the experience of designing and erecting that is small for our places often work. The time has come to appreciate the benefits of this design.

Features: pros and cons

Shed roof is a rectangular completely flat shape, located at an angle relative to the box of the building. The magnitude of its slope may vary depending on the architectural design, climatic conditions and the surrounding landscape.When using quality materials, it serves at least 20–30 years.

Such a roofing device is considered the most stable., including to external natural influences, if the location of the structure is unmistakable in relation to the wind rose.

Snow falls on the surface evenly, which makes the load uniform and safe.

The sloping sloping shape is better than the gable, although it does not allow for creating a comfortable attic space. But it is simpler with the ventilation system: aerators and a ventilated ridge are simply not needed.

The benefits also include:

- Low load on supporting structures due to relatively low weight.

- The smallest consumption of building materials in comparison with other types of roofs.

- Modest financial costs.

- Simple and fast way to build, do-it-yourself.

- There are no restrictions in the choice of roofing materials and rafters.

- Affordable planning and installation of drainage systems and chimneys.

Harmonious beautiful project requires compliance with many conditions, sometimes to the detriment of functional needs.

There are fewer disadvantages than advantages, but still, they are.

- For the arrangement of residential space in the attic requires a considerable width of the house and a high angle of inclination of the roof.

- Low bevel can cause poor insulation.

- Reinforced gutter construction with a wider diameter pipes, as all the water flows in one direction. Metal systems with fixing brackets at a distance of at least 40 cm are recommended.

- When tilting less than 45 degrees, in order to reduce the load, in winter you will have to constantly clear the roof of snow.

Roofing device

As the structure of any roof, the qualitative composition of the shed elements depends on the finish coating. The number of basic elements is small, but requires attention.

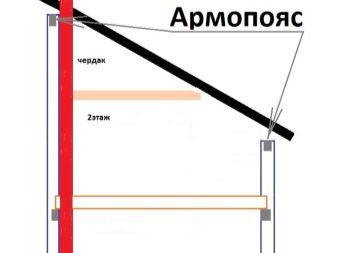

Armopoyas

Reduces tearing load rafters and promotes uniform distribution of the weight of the entire structure. Necessarily required for buildings made of aerated concrete, expanded clay concrete and brick walls, if the construction is carried out in a seismic region.

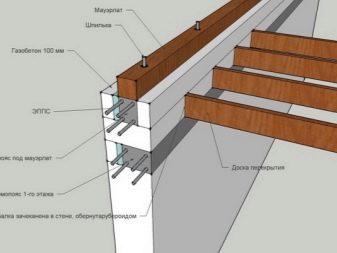

Mauerlat

Located on the upper parts of the walls in the form of bars. It is connected to the armored belt or, in the case of a brick building, it is fastened through anchors already hammered or immured in the walls with a solid wire of at least 6 mm diameter.The anchors themselves must be located at a distance of 30 cm from the end of the wall. If the house is wooden, from a double minibus, then the role of the mauerlat is performed by the upper trim.

Gable

Rarely found in the construction of shed roofs. Its presence is determined by the difference in height between the two bearing walls.

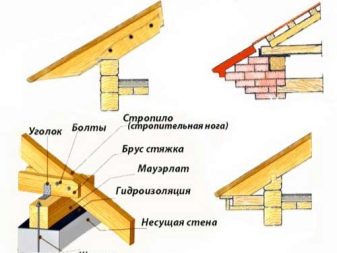

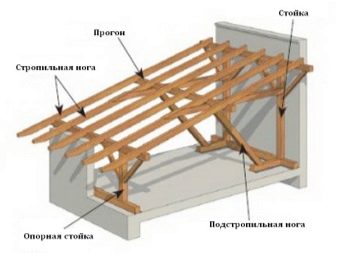

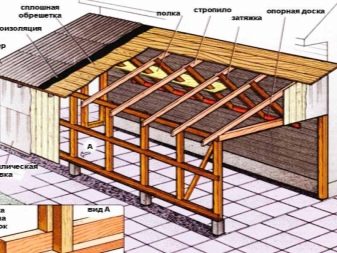

Rafter system

It serves as the basis for laying the roof, it is the main load. It is important to ensure that it is distributed evenly around the perimeter of the upper part of the entire building, and the pressure on the nodes does not exceed the permissible values. To create using wooden beams, the cross section of which depends on the area of the roof and the number of support elements.

Props

They are selected after calculating the weight of the structure and determining the final coating. The number is determined by the angle of inclination and the span length.

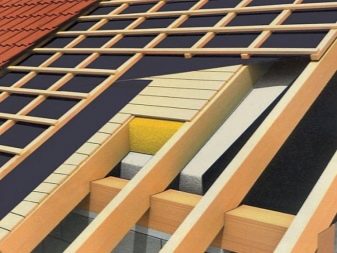

Crate

It is necessary for laying and fixing the roofing and increasing the carrying capacity so that the frame can withstand its own gravity and withstand additional loads: snow, the weight of a person during repair work.

For shingles perform continuous crate. For these purposes boards are used - edged or not edged, MDF panels can be used. The slope can protrude beyond the borders of the gable, forming a visor for the veranda or terrace.

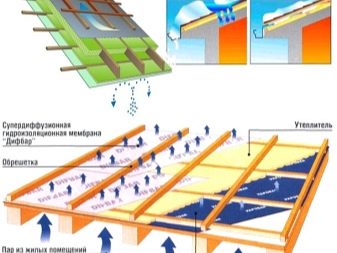

Insulation

Provides protection from moisture and freezing. It is laid on the side of the attic between the rafters and fixed on the crate.

Heater

Consists of rolled tiled materials that are placed on the inside of the crate.

Vapor barrier

Film coatings that are stacked on top of the insulation and fixed with a construction stapler.

Skate board

It serves as a protection for the upper edge of the roof, preventing the ingress of moisture and rotting of the internal elements of the cake.

Fasteners

Rigel

View of the horizontal support for the elements of supporting structures. The element distributes the load of rafters between other beams.

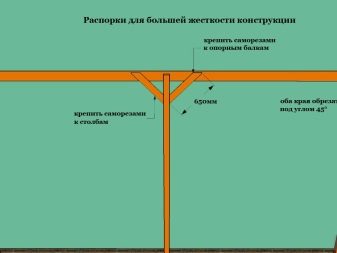

Spacers

Supports that are placed in the spans and increase the stability of the entire frame.

Strut

These are the beams that serve as supports for the truss system.

Kinds

Shed designs are popular in many countries and are used in the construction of both budget and trendy luxury housing.With a high slope of the roof, abandoning the attic, it is possible to optimize the layout. At low - there will be an increase in the volume of residential premises.

The flat roof often acts together with other types, as an element of a multi-level system. This is a great addition for broken, semi-circular and other types of roofs with different slopes.

Beautifully look two-level options "odnoskatok" with different angles of inclination, directed in opposite directions. Simple designs are able to decorate the visors that serve as part of the veranda or protruding attic.

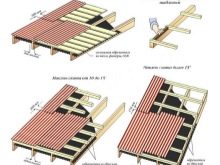

According to the type of ventilation there are 2 types:

- ventilated - bevel from 5 to 20 degrees, the holes are located in the crankshaft;

- not ventilated roofs - an angle of inclination from 3 to 6.

Rafter system

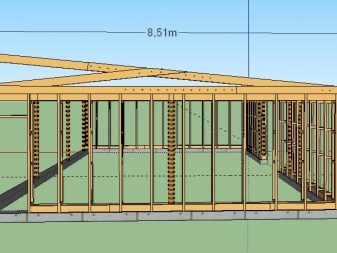

Creating a project and building a system depends on the scale of the building and is determined by:

- climate zone and wind rose;

- linear dimensions of the base - affects the number of rafter legs, the number of additional supports and the distance between them;

- tilt angle - determines the presence of the gable and the method of attachment to the supports;

- type of roofing material - dictates the choice of the characteristics of the building material and the structure of the batten.

The rafters pitch also depends on their length and section:

- with a length of 3 m step - from 1100 to 2150 mm, section - from 80 x 100 to 90 x 160 mm;

- at 6.5 m, the distance is from 1100 to 1400 mm, the cross-section is at least 120 x 220 mm.

Often for large buildings, a beam longer than 7–8 m is needed. To build up, it is stitched, and the joints are strengthened and fastened with planks or metal plates. The larger elements rafters, there is less distance between them.

To ensure the rigidity of the structure are provided:

- racks, bolts and struts with a minimum cross section - 50 x 100 mm;

- Lay and laying of timber - 100 x 150 mm.

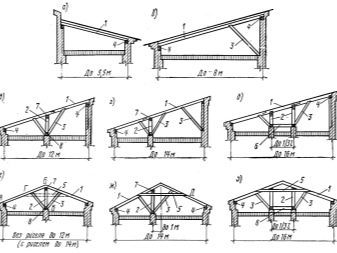

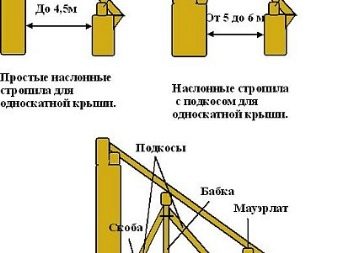

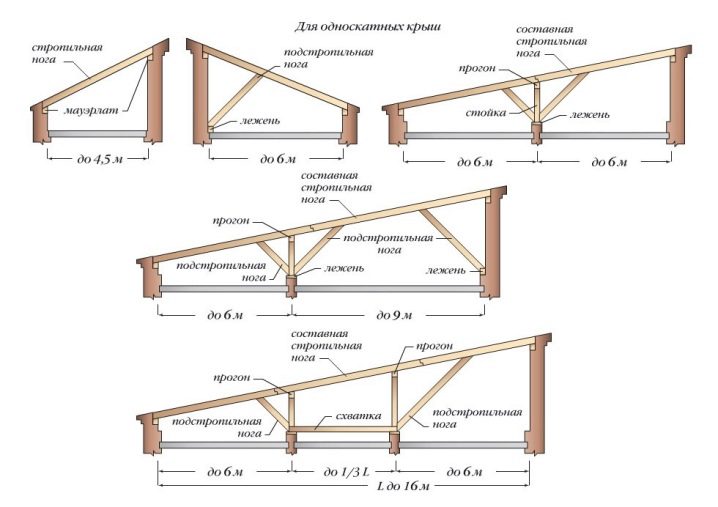

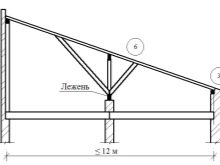

Classification systems in width:

- Up to 4.5 meters. The simplest supporting structures - the roof is fixed on the mauerlate of two logs or boards, which are fixed on the walls.

- From 4.5 to 6 m. The design is enhanced:

- We lie - at the height of the ceiling;

- a subrafter - it serves as a support for the beam in the center of the base; the slope of the foot is determined by the width of the house and the height of the bed above the ceiling.

- From 6 to 9 m. There are two braces that are installed on both sides of the truss foot.

- From 9 to 12 m.Be sure to need another support, which may be part of a protruding inner wall or an additional console-girder structure, which is held by struts.

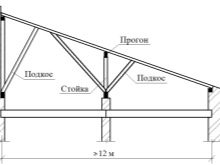

- More than 12 meters. Significantly increases the number of subrafter. The increase to the end of the overhangs of the roof leads to the build-up of beams along the edges with special elements - fillings. Fastening is done with overlays - not less than 60 cm, which are fixed with the help of bolts or nails, sometimes with mounting plates.

In addition, roof systems are distinguished by the type of supports.

Outrageous

A system of struts and struts rests on a mowerlate beam, which is attached to the external walls, and in some cases from the inside. The distance between the rafters - from 600 to 1400 mm. The value depends on the weight of the roof and the characteristics of the wood. Such simple designs are available for tilting the roof up to 26 degrees and a span of up to 5 m. Most often used for outbuildings: barns, workshops, garages.

For exploited roofs, that is, the angle of inclination of which tends to zero, the rafter legs rest against:

- on the one hand - to a higher bearing wall;

- on the other - in the power plate.

Hanging rafters

Used when it is impossible to install additional supports between the side posts. In this case, the designs of any size are collected on the ground or in the workshop, and ready-made farms are gradually delivered to the construction site.

Possible materials:

- metal;

- reinforced concrete;

- wood (pine), with a section for rafters - 50 x 150 mm, for an obreshetka - 50 x 50 mm.

Sliding systems

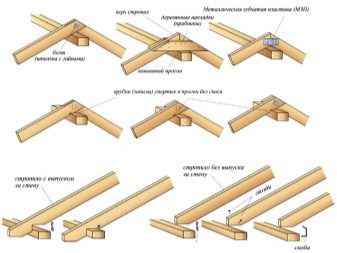

Necessary for the arrangement of the roof in buildings with significant shrinkage during the first time after construction. These include houses built of timber or logs - uneven subsidence of up to 10%. For wooden structures is very important and the method of attachment of rafter legs.

The principles of the device is easy to learn:

- Installation of rafters made on the skate log.

- The joints of the legs can be butt-and-over or overlapped (on nails, bolts and steel plates).

- Step and selection of the thickness of the tree for the rafters is determined by the weight of the roofing. When the thickness of the top layer is 50 mm, an edging board 200 mm wide is selected.

- The mount to the special case is slightly loose, without rigidity. This provides a kind of slip, which allows you to avoid deformation of the roof during shrinkage and reduce the arching load of the walls. Special brackets made of steel, 2 mm thick, with a corner are used as fasteners.

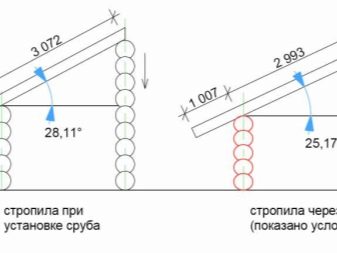

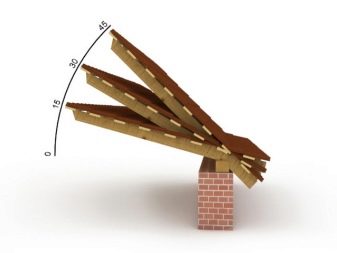

Tilt angle

The greater the angle, the higher the sail. Therefore, the slope of the roof should always be directed towards the most frequent winds. This reduces the load during a big storm. It is important to take into account in the calculations and the climatic zone.

A slight slope can cause large amounts of snow to accumulate. If it is not removed in time, wait for the formation of ice, the roof under its considerable weight will, at best, bend, and at worst - break through.

For central Russia, it is not recommended to build structures of more than 35 degrees.

Natural descent on the roof of precipitation is no less important reason when considering the surface and strength of coating materials. Rough species are better suited for arid regions, smooth - for places famous for abundant rains and snowy winters.

Optimal values for tiles:

- metal, ceramic and cement-sand - not less than 6 degrees;

- bituminous - not less than 12.

Limit values for sheet roofing:

- slate, decking, ondulin - at least 6 degrees;

- copper, galvanized sheets (zinc-titanium) - from 17;

- slabs of asbestos cement - from 27.

When choosing roofing materials worth checking information. Sometimes the declared slope values for the coating, specified by the manufacturer, do not coincide with GOST. It is better to entrust the calculation to professionals, because there are many nuances, especially in overall structures.

After determining the amount of inclination, one of the bearing walls is adjusted to a level that will ensure the implementation of the project.

The necessary calculations to determine the length of the rafters without taking into account the overhangs are produced according to the rules of a right triangle.

To ensure the flow of water and protect the walls from getting wet, the roof is removed by an average of 600 mm. For technical buildings, the minimum for the overhang is - by 20–25, for two-story residential cottages and mansions - up to 1200 mm.

The aesthetics of the whole building is also important. To determine your own preferences, before creating a project, you can use computer programs.This will allow you to see not only the entire roof, but also its harmonious combination with the house.

Materials

The quality of building materials determines the strength and durability of the entire building, so the roofing surfaces should be chosen carefully, taking into account the characteristics of both the building box and the capabilities of the future truss system.

Tree

For the framework, wood of 1-3 grades is selected with a frequency of knots per meter - no more than 3, and their height should not exceed 3 cm. Cracks may be present, but shallow and small length - not exceeding half the length of the board.

General recommendations:

- Bearing beams should have a thickness of 50 mm.

- Board length:

- softwood - up to 650 mm;

- hardwood - up to 450 mm.

- Additional elements - purlins, mauerlat, pillows - are made only of solid hardwood and treated with antiseptic.

Roof

The modern range of roof coatings is very diverse, so it is easy to find the right material for the color, shape, strength and price required.

Ceramic tiles

The material can be of different types: flat tape, groove, single or two-wave.It is well suited for a roof inclination angle of 25 to 60 degrees for houses made of stone, brick or wood. At smaller values of the bevel, it is required to strengthen the ventilation and waterproofing, for large ones, it will be necessary to additionally strengthen the units and install additional fastenings, because the tiles are very heavy material.

The weight of a fragment of 30 x 30 cm can vary from 2 to 4.5 kg, that is, 1 m2 can pull 50 kg. For comparison, a metal tile weighs 10 times less - 5 kg / m2. Therefore, the step rafters for ceramics require a minimum and a wooden crate with small cells. But the tile has excellent sound insulation, beautiful color and texture. The strength of one element is small, but the service life of the entire roof exceeds the average lifespan of a person and reaches 150 years.

Metal tile

These are corrugated galvanized steel sheets that have a polymer coating on the outside. The number of protective layers, as well as the method of fastening elements together, varies depending on the manufacturer. There are both glossy and matte. All sorts of sizes, thickness - from 0.4 mm, weight of 1 m2 - from 3 to 5 kg.

The assembly is made on the crate, fastening with nails or screws, overlapping - in one wave. The recommended slope is from 15 degrees.If it does not exceed 20, then the sediments may run off too slowly, therefore the joints of the floorings are additionally sealed.

In general, the metal roof is quite strong and durable. The warranty period is from 5 to 15 years, but wear of the polymer layer is not always taken into account. Of the shortcomings, only poor sound insulation and a large number of waste.

Soft tile

It is also called bituminous. The material is based on polyester, fiberglass and cellulose. They are applied to the bituminous elements, and are covered with dye on top. Feature is the adhesion, bonding of elements under the influence of sunlight. Available in the form of rectangles or semicircular sheets. The service life of the manufacturers is determined within 15–20 years without taking into account the color fastness.

Options:

- length - 100 mm;

- width - from 300 mm;

- weight per 1 m2 - 8–12 kg.

Universal material with good insulation is equally suitable for residential and farm buildings. The recommended angle of inclination is from 12 degrees. According to the technology, a waterproofing substrate or lining layer is provided. The role of such a carpet can perform the old bitumen coating.Among the shortcomings - flammability, instability to ultraviolet radiation and installation only in the warm season.

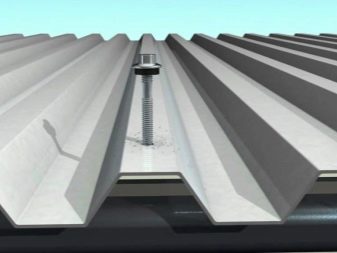

Decking

Available in the form of corrugated galvanized steel sheets of various sizes. The waves provide the coating with rigidity and strength, their height and shape depend on the specific model. There are trapezoidal, sinusoidal or rounded.

Some manufacturers cover the outer side of the resistant polymer film.

To provide a waterproofing, when laying used pergaminovy gasket. Fastening to the crate is made with self-tapping screws, the joints are treated with a bitumen composition. The recommended slope of the roof with corrugated flooring - from 10 degrees.

Like all metal roofs, the material has a small sound insulation, so it is often used for industrial facilities and sheds. Warranty period is 15–20 years.

Ondulin

Universal covering material that can be used even for facing the house. It is based on cellulose, which is impregnated with purified bitumen with the addition of resins and pigments. Color resistant. Standard sheet sizes are 2000 x 950 mm, weight is 6.5 kg / m2, which is 4 times lighter than traditional slate.

Positive properties include:

- ease;

- strength;

- moisture resistance;

- excellent sound insulation;

- high resistance to temperature extremes;

- chemical immunity.

Although the minimum permissible level of slope is 6 degrees, ondulin is not recommended for roofing with a slight bevel: there is no possibility to hold snow for a long time. With higher values and proper operation, the service life will be about half a century, the guarantee of water resistance is 15 years.

Slate

Corrugated sheets of composite material based on Portland cement and asbestos fiber. The shape of the corrugated sheet is always rectangular - 120 x 70 mm, weight - from 10 to 15 kg / m2. The level of inclination of the roof is from 12 to 60 degrees. The installation technology provides for a lining layer of roofing material or glassine.

The slate is attached to the crate overlap with the help of nails through soft hermetic pads.

The timber for the frame is selected:

- for a standard sheet - 50 x 50 mm, the rafter step - from 500 to 550 mm;

- for reinforced - 75 x 75 mm, pitch length - from 750 to 800 mm.

Not recommended for residential buildings. Warranty period - up to 10 years. However, it is worth considering its fragility, which does not always allow the material to withstand hail.

Ruberoid

One of the popular budget options.It is a roofing paper, impregnated and coated with bitumen. To avoid sticking together, coarse powder is applied on the upper part.

Modern variety - euroroofing material, which consists of fiberglass or polyester, impregnated with bitumen. There is a polymer layer on top. This elastic and waterproof material is often covered with small sections of the roof with a complex shape. The main disadvantage is fast flammability; therefore, it is possible to carry out a complete installation only on technical objects.

How to do it yourself?

Before construction, you need to create a project and make all the calculations. Then all the necessary materials are purchased taking into account the additional elements, insulation, ventilation and drainage. The stock depends on the properties of the coating and the quality of the wood. It is worth remembering that for each method there is a technology and instruction.

Preparing tools and equipment:

- saw, hammer, construction knife, ax, plumb line, tape measure, level;

- shropovert;

- construction stapler;

- rafter nails and scotch.

Installation steps include eleven steps.

- According to the drawings, beams and rafters of the required sizes and in the required quantity are prepared. If required, farms are built.

- Armopoyas or Mauerlat are equipped along the perimeter of the upper part of the building.

- According to the schemes and calculated values, beams are gradually established, which are attached to the elements of the power plate. To work properly, the load on the leeward side is taken into account.

- Rafters are attached directly to the beams based on the protruding part of the load-bearing walls. The result should be a right triangle.

- Then carry out the installation of truss legs, laying out one of its ends on the edge of the beam. This structural element will be the basis of the future crates.

- The above activities are step by step applied to all beams and rafters, monitoring the identity and uniformity of the location of nodes.

- After joins the wooden crate.

- On the frame fit the roof. Works begin on the leeward side. The first element is placed near the front canopy, then 2 sheets of cover are attached in the first row. In the next row puts the same amount, then go back to the first row and add another sheet.Following this technique, we overlap the entire roof.

- After fixing the outer cover, for example, a professional sheet, waterproofing from the inside is targeted by a stapler to the crate. For modest buildings like a barn, ordinary plastic wrap will do. It does not stretch and placed with an overlap from the bottom up.

- After that comes the turn of insulation: mineral wool, fiberglass or basalt mats.

- The last line is strengthened by the wind front line - boards or brick masonry.

Examples of beautiful buildings

Private two-storey stone house in a modern style. The lack of a skate allows you to easily build multi-level systems. Clear horizontal lines of the facade perfectly rhyme with a duet of lean-to roofs. The same technique is perfect for the L-shaped base of foam blocks.

Sometimes it is possible to smooth a difficult relief only on a single-roll, the appearance only gains from it.

Sloping roofs fit perfectly into the projects of spacious cottages and small frame buildings of 50 sq. M. m. These Finnish houses in eco-style conquer their comfort and elegance of design.

Shed roofs are harmonious in combination with sloped awnings.This allows you to profitably emphasize some parts of the house, to focus on the design of the entrance group. Stylish look additions in the form of visors, like weightless extensions, awnings with a coating of polycarbonate or corrugated.

The raised bevels provide ample space for external lighting. Built-in lights gently illuminate the area around the building and create the effect of a floating roof. Variations on this topic are manifold.

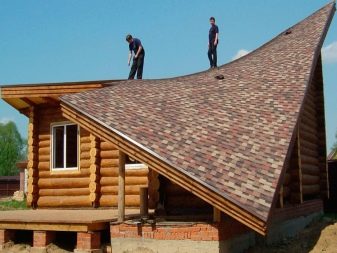

Houses from a bar are quite capricious from the point of view of experiments with style, but they also came up with original solutions for them. The photo shows a shed roof of unusual shape, covered with shingles.

More often one slope is used on chopped baths of narrow forms.

Operated or eco-roofs have a slight slope, reinforced hydro and thermal insulation. Properly selected plant carpet protects against noise. Absorbing water, reduces the load on the stormwater structure.

Mini offers are no less interesting. Garden house with a funny sloping roof and a cozy cottage, with a duet of two-level slopes, have a special charm.

To learn how to build a shed roof with your own hands, see the next video.