Metal roof: types, device and installation

A few decades ago, galvanized roofs shared a palm with asbestos-cement slate in the post-Soviet space. The introduction of the latest in processing technologies and the use of polymeric coatings allowed metal products to break out far ahead. Metal roofs significantly added to wear resistance and aesthetics, and the color palette and forms meet the requirements of the most demanding customer.

Special features

Metal roofs are used for industrial buildings, residential buildings, farm buildings and small architecture objects: gazebos, sheds. In the classical form, building material is sheets, some of which are coated with a polymer layer or paint.Sheet iron is produced from alloys or non-ferrous metals: copper, aluminum, titanium-zinc, steel. The parameters of one sheet vary depending on the manufacturer. On average, the length is 2500 mm, width - 1250 mm, thickness - 26-29 mm. For a faltsevy roof, products are produced with special locks (pictures), which, when assembled, form a standing double seam - a fold.

By type of processing, the following types are distinguished:

- cold rolled;

- rolled;

- thin sheet;

- the black;

- galvanized.

The most popular are stamped versions that have a relief surface, which is profiled. The wave enhances the rigidity and strength of the metal-profile construction. A modern coating can imitate asphalt, ceramic tiles or wooden shingles. For each type there are special technologies laying. The release of a modern metal roof implies a complete set for the arrangement of the roof. The roofing set includes the plates themselves of various sizes and shapes, as well as fasteners, additional elements and other parts necessary for high-quality installation. The high price of coverage is compensated by the quality,long service life and ease of maintenance.

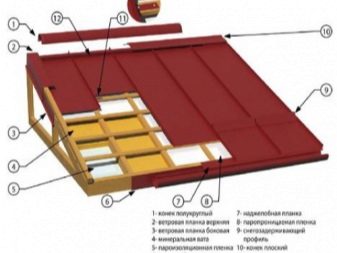

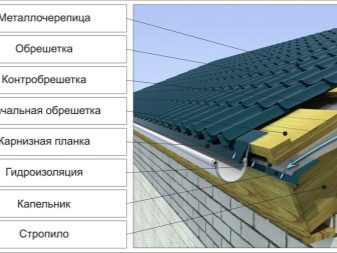

Types of metal-coated roofs are varied and generally have no restrictions on the complexity of the forms. Installation does not require complex equipment. In each case, the weight is simply taken into account, sometimes requiring reinforcement of the framework nodes, the plasticity of the source material, as well as the compatibility requirements. Metal tile and professional sheet do not tolerate contact with bitumen: corrosion appears on the inner surfaces. Installation is made on a solid base with insulating materials. Truss construction has rather small distances between the parts of the batten. For a faltsevy roof the distance between levels makes no more than 250 mm. The recommended slope of the slopes is from 16 to 30 degrees.

Advantages and disadvantages

Advantages of materials are largely determined by the type of finish, which is different from tiles and sheet iron. But they have common indicators with metal profiles, which allow to evaluate the entire group.

There are several advantages of metal roofing.

- Durability - average service life with proper installation and operation of about 50 years.

- Environmentally friendly - the metal does not contain harmful substances, does not have a negative impact on people and animals.

- Lightness - the coating weighs much less compared to ceramic tiles and some other roofing materials.

- Fire resistance - does not ignite and does not burn.

- The rafter system, as a rule, does not need to be reinforced, so you can use the old frame.

- Smooth coating and the absence of horizontal types of beams contribute to the rapid sliding of snow in winter, which makes them indispensable for roofs with a small angle of inclination.

Among the shortcomings worth highlighting several major.

- The roof produces a considerable noise during precipitation, therefore additional materials are required to reduce it.

- The metal quickly heats up and cools, which affects the temperature conditions at home. This means that when arranging the roof, it is necessary to provide for an increase in the heat-insulation layer.

- Metal is vulnerable to lightning. To avoid electrical discharge, all homes are equipped with protective devices with grounding.

- When snowfalls, gliding becomes a disadvantage: snow can fall on peoplelumpy To prevent injuries and block the path of the avalanche, special pegs are installed on the roof. Thanks to the pins, the layers under the weight of their own weight are broken into minor elements and cease to be dangerous.

Species

The concept of "roof" implies a protective outer roof covering, which protects against all sorts of atmospheric phenomena. Very often, analyzing the properties and characteristics of roofing materials, they also consider their influence on the roof system, as well as additional details and the principle of fastening to the batten.

According to the basic material, the roofing iron can be:

- pure metal - copper, aluminum;

- alloys - titanium-zinc, steel;

- with a protective coating (polymers, paint).

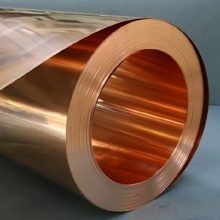

Popular metals and alloys

Copper is the most expensive type of roofing from its group; it has plasticity, resistance to temperature changes, and is suitable for covering even complex forms of roofs. Available in rolls and sheets, including folded. Initially it has a characteristic reddish or pink shade. After 15–20 years, it begins to be covered with a noble patina, which serves as a natural protection against corrosion and the effects of atmospheric phenomena. The oxidation rate is 6 μm / year.

Acquired shade depends on the chemical composition of precipitation and the climate in the region. The whole process of transformation takes from 80 to 100 years - from bright and shiny as a polished copper coin, to brown, black, and then malachite. The average lifespan is 150 years, and the recorded record is 700 years.

Surface decoration may be the following:

- seamless smooth;

- with seam seams;

- imitation of "scales".

Aluminum is the lightest type of coating. (about 2 kg / m²), which has 40 types of shades of gray: metallic silver, light bronze, old copper and others. It is not subject to corrosion, plastic, the color does not tarnish with time and does not change. Aluminum is recommended for coating complex shapes. The advantages include immunity to different types of precipitation. Unlike many other species, it is ideal for decorating roofs in houses by the sea.

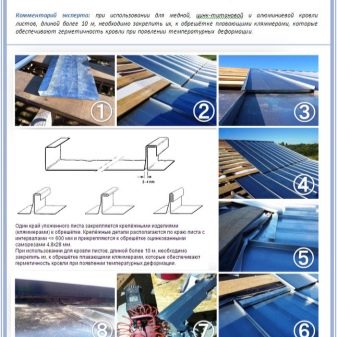

However, when heating and cooling it changes its size, which must be taken into account during installation: special clamps are used for fasteners. This feature does not affect the tightness of the roof. Aluminum can be produced plates of large sizes with paintings. Warranty operation up to 100-150 years.

Zinc-titanium or D-zinc is a separate category of alloys. It is available in rolls and square sheets, often with a folding lock, which ensures the integrity of the entire coating. There are also shingles in the form of rhombuses, designed to decorate part of the roof with a complex geometry, as well as a large angle of inclination - from 35 degrees.

As a percentage, each component accounts for:

- pure zinc - 99.5–99.9;

- titanium - 0.02–0.17;

- copper - 0.03–0.12.

By plasticity, the material resembles copper, but at low temperatures less than + 5 ° C, this property is significantly weakened. Thermal expansion is significant, therefore, as is the case with aluminum, a sliding system of fasteners is used to install the titanium-zinc coating. To carry out the work, a tool intended specifically for this material (without sharp edges) is needed, marking is carried out only with a pencil or marker.

On sale such an iron roof is gray-blue or dark gray. Like copper, it is subject to a process of patina, which begins after 4 or 5 years. Over time, the material does not change its characteristics and does not require maintenance. In the event of mechanical damage easily soldered. Operation is designed for 170 years.

Steel is available in galvanized form, the protective layer prevents the appearance of rust and increases the period of use up to 120 years. This is the most common type of roofing in Russia. This is due to ease of installation, ease of material and the ability to cover even the most complex parts of the structure. The recommended slope angle of the slope is 14–20 degrees.

Roofing iron in the form of black steel is produced from soft rolled carbon alloy by cold rolling. Produce double-sided options by the hot method, the thickness of the foil layer in the finished form - not less than 20 microns. The higher the value, the more durable the material. Due to the properties of zinc, small cracks and damage can be tightened without outside help.

Average lifetimes are as follows:

- black steel - 20–25 years (after 10–15 repair is required);

- "Galvanized" - 25-30 years.

The parameters of the sheet are represented by the following indicators:

- average thickness - 0.45–0.55 mm - for roofing;

- reinforced thickness - 0.63–0.7 mm - for overhangs, wall gutters, drainpipes;

- width - from 510 to 1250 mm;

- length - from 710 to 3000 mm;

- weight - from 4.5 to 7 kg / m².

The disadvantages of steel sheets include a short lifespan and a nondescript appearance - a dull gray color.The resistance of the zinc layer is small: it is damaged by mechanical action, so care must be taken when transporting and laying. From time to time such a roof should be cleaned of rust and painted.

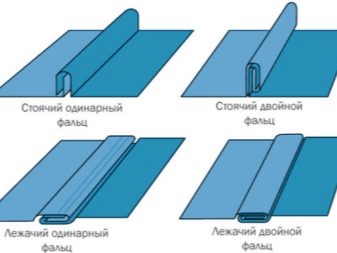

Types of textures and methods of installation

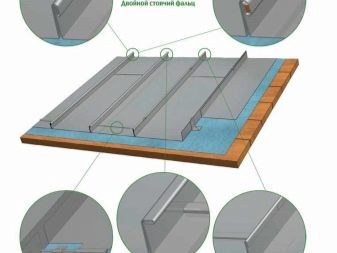

Flat or faltsevoy roof consists of metal strips or sheets, assembled with the help of special clamps, which form on the floor of a peculiar vertical hem - standing seams. They create a rhythm of design and provide tightness, which is extremely difficult to break. The most reliable have roofs, collected by roll technology. On the sheet there are still horizontal - recumbent seam. Sometimes a special tool is needed for fastening, but there are variations with self-locking locks. For such a system, the lightest materials are used, which makes it possible to erect a truss system without additional supports, even with a large coverage area.

Variety fold

It is necessary to adhere to some of the nuances of installation.

- At small angles of inclination of the roof, continuous crate is used. On the slopes of 14 degrees can be installed in increments close to the width of the paintings.

The picture can be of different sizes:

- min - in two sheets;

- max - the entire roof slope.

- The metal is fastened to the base with the help of clamps, one of the ends of which is rolled into the fold, and the other is nailed to the crate.

- Fold depending on the model is single and double. The second is recommended when facing structures with a slight bias.

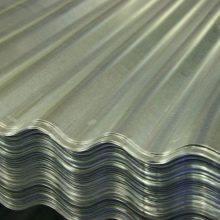

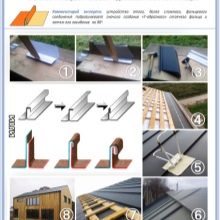

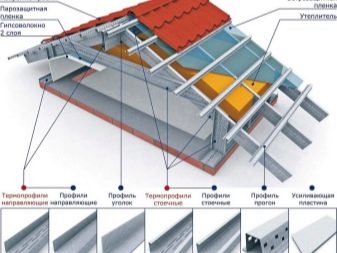

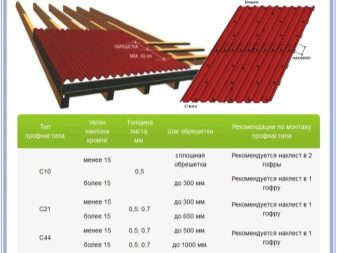

The professional leaf or roofing corrugation is the formed material with a vertical wave of different height and length. Corrugation gives the roof additional rigidity and strength. The higher the amplitude, the more stiffer the ribs. At the base - sheet metal roofing types. The coating is lightweight, corrosion resistance and long service life (50 years). Laying profile roof overlap on one wave. Truss system and crate do not require any reinforcement.

Advanced options in the factory cover with insulating foam, on top of which a polymer layer is applied up to 1.2 mm. In this case, you do not need to spend money on an additional layer of thermal insulation made from conventional materials, for example, mineral wool.Most products come with a protective layer that contains coloring pigments. The color palette of a professional sheet is various and has no style restrictions.

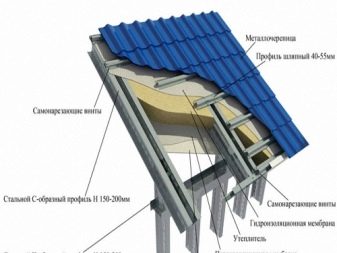

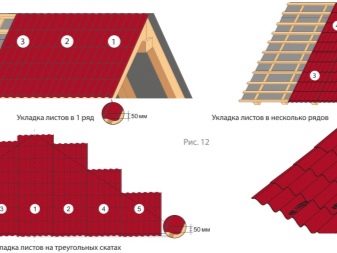

The metal tile is made of profiled sheet (metal profile with a thickness of at least 0.5 mm), having a longitudinal and transverse molding, which exactly copies the types of traditional ceramic tiles: waves, scales, steps and others. The length of the finished sheet depends on the manufacturer and ranges from 50 to 800 mm. At the bottom of the canvas there is an anticapillary groove through which accumulated condensate or sediment should drain from the roof.

Installation is carried out on a simple truss construction. The only restriction is that the slope of the slope should be more than 14 degrees. Between the sheets are joined tightly overlap. The roof is attached to the crate in places of bending with hexagonal screws with a rubber gasket (EPDM). The tile has the widest color scale which is provided by a polymeric protective film. The warranty period depends on its quality and properties. So, it is 15 years old with foil covering from pural.For greater imitation of ceramic sheets covered with powder of quartz sand or basalt crumb. The production technology allows to increase the service life up to 30 years.

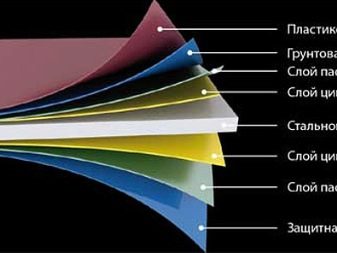

Protective layer

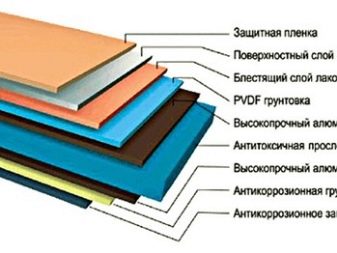

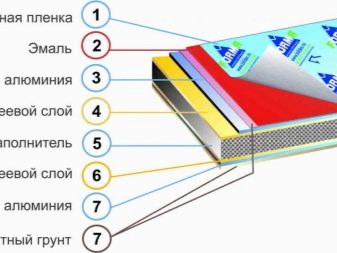

Polymer film is applied only on the outer part of the sheets. Resistance to damage and durability of the material depends on their quality, which, in turn, affects the pricing. The basis is aluminum or high-strength steel. The coating has several layers and each of them protects the previous one.

Steel cake

Aluminum composite

Polyester (glossy PE) is based on polyester. Layer thickness is 25 microns. It refers to the economy class, although it is well characterized for its color fastness, plasticity and resistance to corrosion. Microcracks under the influence of atmospheric phenomena will not appear, but the material is susceptible to mechanical damage, it is easy to scratch it. Transport and installation must be carried out with care. PE is represented by a wide range of colors. Metal roofing with such a coating is most often purchased for summer houses and garden houses.

Polyester (Matte MPE) has a thickness of 35 microns.In contrast to the smooth, it has a pleasant velvety surface. The roof is flexible, the amount of bending does not affect the quality and properties. The material is immune to mechanical damage, well imitates natural textures and does not fade in the sun, but the palette itself is scarce.

Plastisol (PVC200) - 175–200 microns, composition based on PVC (polyvinyl chloride) with the inclusion of various plasticizers. Much more plastic than previous members of the group, it can not scratch the branches of trees. It is recommended for drainage elements, but impractical for roofs in the southern regions: it burns out and is capricious to temperature fluctuations. With the right choice of color, it is ideal for industrial areas and sea coasts, as it is resistant to chemical attack. Most often serves as a coating for stamped embossed products, imitates leather, wood, looks beautiful with a decorative notch.

Pural (PU) - It is a modified polyurethane, which is often presented in combination with polyamide. Thickness is 50 microns. It is used to cover metal tiles; it has excellent characteristics: it is immune to mechanical damage and stress, and is not afraid of sudden changes in temperature. Bright, non-fading colors are another plus in the PU money box.The price is very high, but it justifies itself by durability and the lack of repair of the roof over a large interval of operation.

Polydifluorite (PVF2) - is a mixture of polydifluoride with another polymer - acrylic. It is glossy and matte with a characteristic metallic luster. Thickness is 25–35 microns. The coating has absolute characteristics in all available indicators of resistance: to UV, atmospheric phenomena, mold, chemicals and mechanical damage. In addition, it has the ability to repel dirt, so after a rain the roof will always look like new. The cost of PVF2 is the highest of all polymers.

How to choose?

Galvanized sheets in stores are sold in packages or in rolls wrapped with sheet steel and tightened with thin steel tape. Weight depends on the method of loading. It is 80 kg for manual carrying and up to 5 tons for an automatic (loader).

It should follow the advice of experts when choosing sheets.

- At the time of purchase, you should try to inspect all the sheets. They should have a uniform coating, without cracks, scratches and delaminations.Any violation of the integrity of the surface, the presence of roughness on the gloss will lead to a quick repair and reduce the life of the roof.

- It is necessary to carefully examine the quality of galvanizing. The layer should not have blisters or smudges, the declared thickness is in the range of 250–320 g / m. In the same way it is worth exploring for defects in polymer coatings.

- Sheet thickness depends on the destination, but not less than 0.5 mm. For auxiliary elements, such as overhangs or gouging, metal is chosen from 0.6 mm. Do not confuse roofing iron with wall, it is thicker and has slightly different characteristics.

- The size and calculation of the required amount, for example, metal profile or copper, is determined based on the shape of the roof, its structure and the estimated area. Today, there is no need to calculate manually, many manufacturers and sellers have electronic calculators on these sites. The main thing is to correctly make the measurements of the structure necessary for the calculations. A percentage should be provided for unavoidable waste.

- Experts recommend to acquire basic and additional elements, fasteners from one manufacturer, then the roof will assemble without problems, and the guarantee will not cause unnecessary questions.

- You need to beware of fakes.If you can not distinguish the paint layer from the polymer, it is better to seek help from a specialist or take an experienced builder with you. The difference in price and quality of such products is very great to take risks. Usually paintwork and polymer outer layer are painted in different colors. Even in the store is to determine where one of them is located. This will avoid annoying mistakes.

- With rare exceptions, metal roofing must be protected during transportation and protected from moisture until the installation work is completed.

Installation

At first glance, laying metal seems simple. To cover the roof of a residential building without the appropriate knowledge and skills of working with metal is not worth it. It is better to hire professional roofers who specialize in tin constructions. But on small outbuildings you can cover your own hands, especially if we are talking about a folded roof.

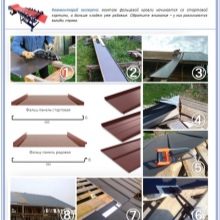

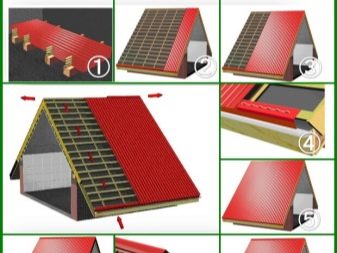

Step by step instruction includes the following steps:

- Cover start to cook more on the ground or in the workshop. In accordance with the drawings and calculations, the pictures for the slopes and additional details are cut out: overhangs, gutters.If the steel is not rolled, but sheet steel, then the fragments are fastened together with the aid of recumbent seams;

- for complex areas that have sharp drops in heights, all quantities are additionally specified, their consistency with the cut parts of the main coating is checked;

- so that the chimney does not leak water under the coating, a special collar is cut that matches the parameters of the pipe. For these purposes, the so-called collar is made, its profile depends on the profile of the pipe;

- the resulting longitudinal elements of the roof are collected in one general picture of the entire slope;

- prepare the folds - bend the edges of the metal on the sides;

- Collected workpieces are lifted upwards, laid from the ridge on the trusses and checked for strict adherence to the vertical position so that there are no distortions. If everything is in order, gradually fix on the crate clamps. Fixation first occurs at the ridge, and only then along the entire length of the picture;

- the protrusions of the roof in the area of the ridge on the side of each of the slopes must be of different sizes. For example, with one - 60 mm, and with another - no more than 30 mm;

- when fastening material properties are considered.For example, the profile is fastened to the laths of the battens with self-tapping screws through a rubber seal to avoid moisture leaks;

- then form longitudinal standing folds, driving the free part of the cleat into the seam of the lock;

- For connection of difficult cuts of a covering use standing or inclined folds. Sometimes for these purposes, especially in cases of bonding corrugated sheets, additional elements are necessary;

- when the entire “designer” is assembled, they proceed to sealing the joints using a hammer and a special metal strip.

Finishing work after the assembly is necessary only for black or galvanized steel. The primer is obligatory before applying paints and varnishes, since zinc has practically no adhesion. Painting recommended in two layers. Cosmetic and major repairs for such roofs should be carried out regularly. The polymer coating does not require increased protection after laying for many years.

Useful recommendations

Should follow a few useful recommendations from experts.

- When choosing insulation materials, it must be remembered that thermal insulation also reduces noise.

- Before the start of the manufacture of folds, before installation, the grease is removed from the sheets of black steel and painted over with linseed oil. If, after drying, badly treated areas are noticeable, the procedure is repeated.

- When working with iron, it is important not to damage the protective coating, so not only special tools, but also components are used. For cutting advised to use a hacksaw for metal or roofing "rodents". A compact electric saw with teeth made of hard alloys will be suitable for cutting the bevel. It is contraindicated to use grinding machines with abrasive nozzles, they burn zinc film, because of which the process of corrosion begins at the sites of processing.

- It is worth paying attention to the guarantee of fasteners, it should coincide with the similar indicators of the main roofing material. For metal screws, better to buy expensive brands. There are models with a lifetime of 50 years and the ability to apply a zinc coating on a technical hole during tightening.

- Sheets of metal must be cleaned from drilling or cutting waste.

- If there are scratches on the profile or tile, they must be carefully cleaned of rust and applied special repair paint to the damaged place.

- To avoid leakage, the roof is regularly inspected, its cleanliness is monitored, cleansing from foreign objects, dust and dirt. It is forbidden to use hard brushes and aggressive chemicals for washing.

- For ease of use and repair when you purchase should be purchased complete with iron transition bridges and special stairs.

Interesting examples

Molded copper can become an accent and a trend setter for the entire private ownership ensemble.

Small structural details on the metal roof give good humor to deliberately restrained forms.

A successful combination of a faltsevy roof with a similar wall decision and furnish by a tree.

Seam roof perfectly combines with wood and panoramic windows. The roofs of all extensions are similarly covered.

Metal tiles are the perfect decoration for a country house.

The form of a professional flooring of noble gray color stylishly looks.

How to mount a roof from a professional flooring, look in the following video.