Roof burners: types, characteristics and methods of use

In the process of repairing roofing, it becomes necessary to use hot air or fire, for example, when firing bitumen and other products based on it, melting the inside of roofing material or soldering the edge of a metal sheet. But, accordingly, to do all this, you need a special device.

What it is?

The roofing burner is a specialized gas-air unit that is used to heat, install and dismantle a build-up roof. Due to a certain type of combustible fuel, flame is generated.

Along with the main function it is often used for other purposes:

- quick drying of the surface;

- heating building blocks;

- firing and dismantling of construction paint;

- cutting or soldering metal elements;

- sealing up small cracks;

- heating soft mastic;

- additional fixation and reinforcement of the seam joining.

What are the?

To date, there are several types of burners, the difference of which is mainly in the different used fuels.

Gas

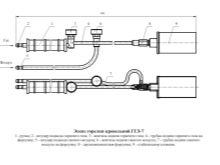

In the process of roofing they are used most often. The system consists of two main elements - a compartment for storing fuel and a torch. They communicate with each other with a hose.

Benefits of use:

- The burner is highly mobile.

- There is no need to constantly monitor the force of the supplied gas.

- Elements regulating the flow of the flame are located on the torch.

Of course, different manufacturers have small differences in design, such as the volume of a gas cylinder, but the principle of work does not change.

Because of the cheap fuel used, the device has gained quite a lot of popularity.However, this is gas equipment, which means that all rules and security measures must be strictly observed.

Propane

Proceeding from the name it is clear that such models work on propane fuel. In fact, they are almost identical to gas models on the principle of operation and in terms of design. But still, they are distinguished as a separate group, since the main and most important difference is the ability to work on standard gas cylinders, which are used in gas welding.

In addition, propane is safer in operation than natural gas, and also forms a stronger and higher temperature flame.

It is necessary to take responsibility for the acquisition of any burner, handicraft devices are not safe, they can lead to accidents.

Diesel

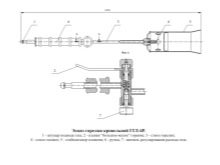

This species is classified as a liquid-fuel class and differs from the previous ones in structure. The torch is equipped with a special nozzle, which regulates the outgoing stream of liquid and simultaneously supplies air. The resulting mixture is ignited, and a flame with an even higher temperature is obtained. The burners are equipped with a powerful blower system, which reduces the amount of soot.

The diesel type is as mobile and efficient as the gas. But at the same time it is safer in work. Of course, the fuel in this case will be much more expensive than gas, but this pays for itself with its economical consumption.

The oil-fuel structure operates on liquid fuel, for example, on diesel fuel. They are very convenient to use a very low ambient temperature due to built-in heating fuel. The burners of this type are safe, have a high-pressure blower system and provide stable and safe ignition.

Fuel models have some differences in design. Liquid fuel under strong pressure first goes into the chamber and then sprayed. At the time of passage and exit from the nozzle, the liquid is ignited, and a stable powerful flame is formed. To preserve the integrity of the system, a special oil and petrol resistant hose is provided.

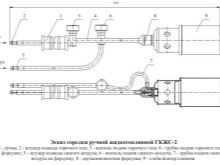

For installation of rolled bitumen roofs use hand-held devices. Usually these are propane burners with a lever design. In operation, they are quite comfortable, the stream of flame can be easily adjusted by pressing the lever mechanism.Also, there is a mode of saving gas consumption.

The valve type of the device is distinguished by its ease of use. The burner is lightweight, easy to repair and is capable of generating a sufficiently powerful flame that does not fade even in very windy weather.

Acetylene devices are also found. If in a conventional burner the fuel consists of a mixture of propane and oxygen, then in this case acetylene and oxygen are used. Most often they are used in gas welding works.

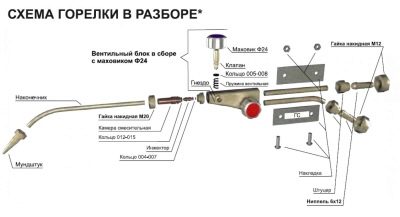

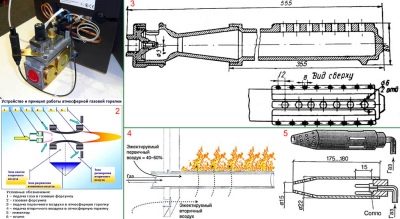

Device

Usually a gas burner is represented by a metal cup with a device for spraying fuel and a handle that is attached to the body. The design of the glass prevents blowing out fire by a strong wind. The gas pipeline channel, consisting of a gas hose, the fuel enters the body part. Depending on the type of device, a valve or a lever is located on the housing. Using the valve, you can adjust the degree of supply and the length of the jet of flame.

The presence of a special gearbox allows you to control the degree of fuel consumption and, consequently, reduce costs. Most devices suck oxygen directly from the atmosphere.To start such a burner, you just need to light it with matches or a lighter.

Many modern models have an additional structural element that is able to regulate the modes of operation. For example, work in standby mode makes it possible to avoid excess fuel consumption during breaks from work.

Due to the fact that the main function of the burner is to heat nearby objects, the material from which it is made must be different in strength and resistance to high temperatures. The handle often has a length of 95 - 100 cm, and the weight of the whole structure does not exceed one and a half kilograms. At the same time, there is no discomfort at work.

To protect the hands of the operator from the heat on the handle is a wooden or plastic holder, which is characterized by low thermal conductivity.

In general, the design of any roof burner depends entirely on the type of fuel used and the area in which it is used. However, if we consider them in general, the devices are identical. The burner consists of a housing that controls the flames of the valve, the fuel is supplied from the attached cylinder through a reducer.

Sometimes the manufacturer may, at its discretion, add elements for additional protection against wind and piezo ignition. Piezo ignition is an additional element that is connected to the nozzles with a thin wire, and when you press the piezoelectric element, it produces high voltage, a spark is formed, and the fuel is ignited.

Manufacturers Overview

In the market you can find a variety of models of roof burners, both domestic and foreign production.

- Among domestic producers, Donmet and Caliber are distinguished. Masters evaluate the products of these manufacturers quite high, noting their quality and safety in operation. These models are not expensive, and with their help perform simple repair operations on the roof. The cost of devices usually reaches 1000 rubles, but it is important to bear in mind that they will only cope with small tasks.

- Burners of foreign production, such companies as "Kemper" and "Poap" characterized by manufacturability, performance and reliability. The devices have an extensive range of operational capabilities, and can even be used in work with structures that require very strong heating.The cost of models will be much higher than the previous ones, ranging from 1000 - 2000 thousand rubles.

When purchasing a burner for your own needs, you need to pay attention to its performance., the presence or absence of additional parts or functions, the type of fuel and the manufacturer. The most common devices have a capacity of 115 KW, and the average gas consumption during operation is about 10 kg / h.

It is not necessary to be conducted on too cheap burners. Such copies in their power are not much different from a soldering iron, and working with it will be very long and inefficient. To achieve the desired effect will have to remove the gearbox, which is fraught with dangerous situations.

Speaking of safety, it is worth noting disposable cans. They need to be no less cautious because of the numerous fakes that can even lead to a fire due to being too close to the fire. This is mainly noted in the so-called "compact" models.

How to make yourself?

It is possible to make a gas burner with your own hands, but still it is not safe. It is best to purchase a ready-made device from a trusted manufacturer with all certificates than to make it yourself.However, if you have confidence in your own abilities, skills and knowledge, you can try to construct a device at home.

It is still necessary to take into account that the burner is a complex device, and for its assembly it is necessary to have certain skills and absolute adherence to numerous rules.

Lovers better to abandon this idea, as it can lead to injuries and cause severe harm to health. After all, work will be conducted with an explosive substance, and the slightest omission in the elaboration of the elements of supply and storage of fuel will lead to accidents.

First of all the torch is made. To do this, take a metal rod and a divider. After the parts are mounted on a wooden heat-resistant handle. To supply the gas, take the hose from the gas welding system, or turn it yourself out of brass.

Of course, the burner will look a little different than the shop counterpart, but at the same time a properly assembled design will be fully functional and will cope with all the main tasks of the burner. However, working with it, it is necessary to be extremely attentive to the slightest gas leaks and any other faults.And if any problem is suddenly discovered, for example, the release of gas or a flame that is too short when the valve is fully opened, you should immediately stop working.

Operating rules

The technique of using the burner is quite simple:

- Click on the lever, which is located on the handle, and fuel begins to flow through the hose.

- At the exit of the glass begins to form a mixture of gas and oxygen, which you just need to ignite. It is important to observe safety precautions.

- And at the end of the flame is regulated by setting the desired length.

Operation of the device still requires some work experience. In general, some basic rules must be observed:

- The work surface must be completely cleaned of debris and dust. This is the preparatory stage at which complete cleanliness of the entire working plane is achieved.

- To facilitate the work with the material, one day before the work begins, it is spread out and left to rest.

- Observing ten-centimeter overlap, you need to spread ruberoid sheets on the roof and make the necessary measurements, after which you need to twist. The edges located on the edge of the roof, immediately fixed with a burner.

- Subjecting the ruberoid to high temperatures, gradually it is necessary to roll it in the desired direction, slightly pressing it to the surface. If bubbles or folds are formed, they should be leveled immediately, for example, with a hand roller.

- Materials of modern manufacture have a special protective film that prevents adhesion of sheets during storage. At the time of laying it should be monitored, and when it is completely melted, the heating is stopped, since the bitumen layer reaches the most optimal temperature.

- The end is the warming up of all seams and gluing to the lower layer of material. To increase the level of strength you can roll the seams with a hand roller.

If the correct and convenient device with a fuel control system is selected, then up to 600 meters of material can be laid in one shift. However, if the ambient temperature falls below 15 degrees, then you need a diesel burner for liquid fuel.

Pro tips

Compliance with safety regulations is an integral part of any job:

- Works with roofing should be carried out in special working clothes made of thick fabric and shoes with non-slipoutsole.

- The insurance system (mounting belt and a thick safety cable) will avoid injuries on pitched roofs.

- Before you start using the burner, a control inspection of the device is carried out. It is important to make sure that everything is working properly.

- In the process of work, additional gas cylinders must be removed from the roof. Also, time to time does not damage the additional inspection of the connection area between the cylinder and the hose.

- Burning the burner, they must leave the nozzle, it is impossible to be directly in front of it.

- Regulating the necessary length of a flame, it is important not to touch people, a hose and a cylinder.

- The guided roofing material must be heated carefully so that it does not catch fire. Indeed, at this moment only the upper layer melts with preservation of the solid base.

- You can straighten only the bottom of the sheet, while not processing the material to the full thickness.

- If a propane burner is selected, the valve opens only half in half before ignition and is left for a couple of seconds to purge. Only then can the fuel be ignited and the flame regulated.

- In no case can not leave the working platform or move through the woods with a functioning roof burner.

- Finishing work, first shut off the gas, and then lower the lock lever.

- When the burner overheats or a back stroke occurs, work is immediately stopped, the gas is shut off, and the device is immersed in cold water for cooling.

How easy it is to make a gas burner, see the video below.