Stekloizol "TekhnoNIKOL": technical characteristics and features of the application

Stekloizol from the company "TehnoNIKOL" - soft rolled material used for the arrangement of the roof. Also used as a waterproofing surface and underground structures. Stekloizol is in great demand due to its excellent technical and operational characteristics, as well as affordable cost.

Features and types

The basis of the material is fiberglass or fiberglass. In the manufacturing process, highly oxidized bitumen mass with mineral additives is applied to these surfaces. Next, it is covered with protective components: a polymer film or coarsely fractional dressing.

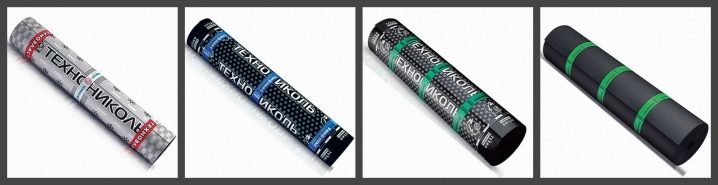

There are several brands of stekloizola.

- HSP. The material is made of fiberglass (X), which has a low tensile strength.On top and bottom applied specialized protective film (PP). Most often used as lining. Reliably protects the roofing base from moisture. It can be used as a waterproofing for underground structures, pipelines.

- Roll roofing CCI. The basis of the material is fiberglass, which has high strength and resistance to mechanical loads. On both sides of the canvas applied low-melting polymer film (PP). Due to this coating, the risks of sticking of the roll during storage and transportation are excluded. Stekloizol TPP is used as a lining under the roofing pie, and also performs the function of waterproofing.

- HKP. The basis of the material - fiberglass (X), covered with coarse shale crumb (K). The surface is trimmed with a protective polymer shell (P). Designed for arranging the top layer of the roof. The material is designed for use for flat types of surfaces with a slight slope. Reliably protects a roof from leakages.

- TKP. For the manufacture of used frame fiberglass (T), coarse shale granulate (K) and a protective polymer film (P).Due to the increased strength, it is recommended to use the canvas for arranging roofs that have a slope of up to 10 degrees.

Depending on the goals and objectives, you can choose the material with the required parameters.

Specifications

Stekloizolu from the company "TehnoNIKOL" prefers the vast majority of builders. The products of this manufacturer have all the necessary supporting documentation: a certificate of conformity and a quality certificate. They describe in detail the technical characteristics of the material.

The main technical parameters of stekloizol include the following:

- tensile strength when stretching from 300 to 400 N;

- heat resistance not less than 80 degrees;

- length in roll from 10 to 15 m;

- water absorption not more than 1%;

- absolute water tightness.

It should be noted that the technical characteristics of different grades of stekloizol vary slightly.

Advantages and disadvantages

Stekloizol has many advantages that distinguish the material from other types of flexible roofing materials.

- Biological resistance. The canvases are “not afraid” of rotting and mold. They are “not interesting” to rodents and insects.

- Resistance to sunlight.

- Environmental Safety. Components of which the stekloizol is made differ in harmlessness. In the course of laying and operation they do not emit harmful substances.

- Easy installation. Decking roll coatings will not require specialized knowledge or skills.

- Excellent insulation properties.

- Resistance to temperature changes.

- Long service life. If the installation rules are followed, the product will last at least 20 years.

- The possibility of laying on any type of base.

- Durability, flexibility and elasticity. Due to such properties, glass insulation is allowed to be laid on roofs with a complex geometry.

- Small roll weight (up to 30 kg).

- Low thermal conductivity, high sound absorption.

Roofing stekloizol no significant drawbacks. The disadvantages include some restrictions on the installation of the coating. For example, its installation cannot be carried out with strong gusts of wind, rain and temperatures below -10 ° C.

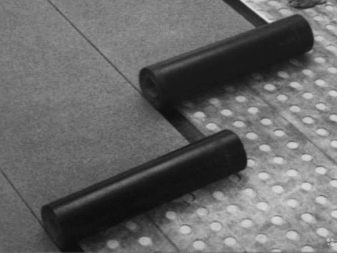

Piling

Decking stekloizola produced in several stages. Before laying the material surface should:

- remove large debris;

- sweep the base with a broom or broom;

- get rid of exfoliated old material;

- to seal up the gaps and potholes using a sand-gravel mixture.

After the work is done, it is necessary to apply the priming composition to the concrete base. If the surface is made of wood, it must be treated with bitumen mastic.

Then you can proceed to cutting the canvas. It is produced on site. When cutting, it is important to take into account the allowance along the length (not more than 0.2 m) and overlap (approximately 10 cm). When laying the first layers, stekloizol grades of PPP or HPP are used.

It is necessary to lay the material from the bottom (in the presence of a slope). For installation do not need to use glue.

To fix the web, its edge should be warmed up with a torch, glued, then slightly roll up the roll and continue heating and gluing. It is also recommended to roll the surface with a roller to remove air bubbles.

For laying the second layer materials are used brands HKP or TCH. The technology of their installation is similar to the installation of stekloizola TPP (HPP). For more on this, see below.

Reviews

Consumers have left a lot of positive feedback on stekloizol. Buyers appreciate the financial availability of the material: this is indicated by the responses of both private craftsmen and heads of construction companies. Consumers say:

- economical consumption of the coating;

- simple and reliable installation;

- the convenience of use.

Buyers also appreciate the prevalence of the material: it can be purchased at almost every building outlet. Due to the numerous positive reviews about the quality and long service life, stekloizol occupies one of the leading places in sales of waterproofing roofing materials.