Soft roof: types and methods of installation

Soft roofs are not less popular than solid and solid structures. But it is represented by a large number of types, each of which has its own characteristics during installation and operation. Only having understood all these subtleties, you can make the right decision when choosing a material.

Special features

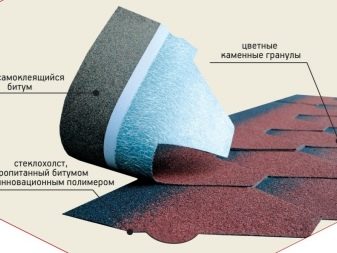

The device of a soft roof is quite simple - it is tiles and glass fabric, impregnated with modified bitumen. To give strength to the coating, it is supplemented with stone chips. The product has a figured edge, it must be laid overlapped on the roof slope. Modern manufacturers have mastered the production of soft roofs of various geometrical configurations - these are ovals, semi-circles, and pentagons. More familiar rectangular blocks can also be found easily.

Under a soft roof, laid on a relatively gently sloping (up to 18 degrees) surface of the slope, a layer of waterproofing should be created only in the least protected areas from water.

These include:

skates;

plots near the pipes;

overhangs;

endovy.

If the total slope is less than 5 degrees, liquid waterproofing materials can be used.

If it is larger, only hard coatings are acceptable. With the exception of atypical design solutions, waterproofing should be carried out in the intervals between the rafters and the crate. Laying is carried out from the eaves to the ridge. Sagging within 2 cm is acceptable because it improves ventilation inside.

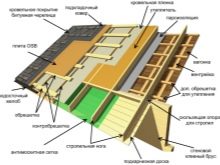

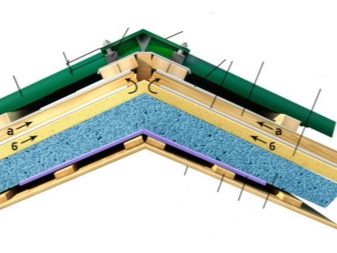

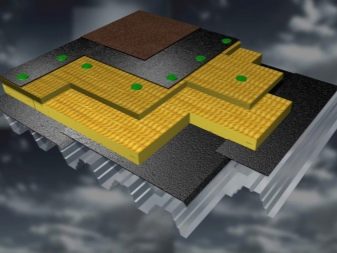

Vapor barrier for soft roofing is almost mandatory., because only this measure prevents the destruction of the batten and the accumulation of condensate. In the case of insulated premises, the vapor barrier material is attached from the inside of the attic directly to the rafter legs. Then an attic surface (made of plywood, board or drywall) is created on top of the membrane. From the outside, a material providing insulation is placed above the vapor barrier. In old or reconstructed houses, one can sometimes find a single-layer display of insulation, but such a scheme is considered outdated and insufficiently effective.

When choosing a modern two-layer variant, the material with the highest thermal stability is placed below, its thickness varies from 70 to 170 mm.

The advantage of this device is that the heat protection has a small mass. But if initially the building is equipped with single-layer thermal insulation, then during the repair or reconstruction of this particular scheme it is better to stick to it again. Otherwise, it will be necessary to drastically recycle the entire scheme of the roofing pie, including reworking the substrate.

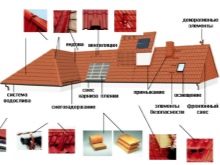

Lightning protection of a soft roof has its own specifics. In most cases, such roofs are equipped with passive means of protection. But the general rule does not always work, and only a trained specialist will be able to properly assess its applicability. Consultation with him will allow you to avoid many mistakes and significant material losses, and sometimes victims. The rods of active receivers are supposed to be lifted at least 2 m above the roof, and still thinking through the construction of the roof you need to think about how the spiers will be fixed.

The grid can only be mounted above the floor, because the internal location increases the risk of fire. Typical cross section of the mesh - 6 mm.Autonomous structures are installed on gable roofs, the grounding of each of them is isolated. The discharge should be distributed in two ways, the distance of movement of the current in each of them trying to make the minimum. Current leads must not be brought closer to the openings of windows and doors.

Advantages and disadvantages

Any building and finishing material has a number of positive and negative sides; This fully applies to the soft roof. It serves a very long time. No other coating is able to work over 70 years; its tightness is much higher than that of corrugated roofs. Elimination of operational defects is relatively simple: you only need to remove single damaged tiles.

In addition, soft roof:

resistant to bad weather conditions;

immune to the action of microflora;

it looks very good throughout the whole operating period and remains solid;

can be mounted even without assistance;

to a large extent suppresses noise arising from heavy rain and even hail.

As for shortcomings, a flexible roof has one weak point - it easily lights up. And for this reason, the material is not suitable for buildings, where the risk of ignition is very high.If there is no such danger, the fee for a soft roof and its installation is fully justified by its characteristics. During operation, the amount of waste is relatively small, and it is possible to build geometrically complex configurations without undue effort.

Ultraviolet rays are not terrible created by the coating, but it weakly retains heat, and the base should be mounted as an inseparable canvas.

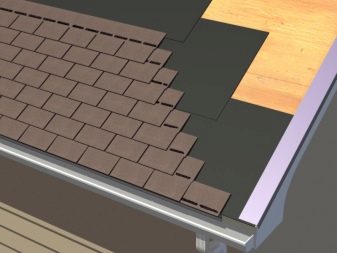

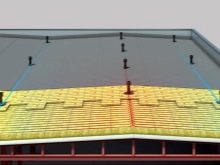

Stages of installation

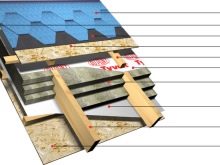

The first step in laying is the preparation of the necessary materials and tools. In accordance with the requirements of the technology, you need to have a very strong foundation that will not sag under load. At the next stage, ventilation is required to cope with the increased humidity and reduce the accumulation of ice in the winter. After finishing the preparation of ventilation, the experts take up the creation of a cushioning layer, which should be located around the perimeter. The material should be protected from precipitation; for this purpose, curtain strips are used (sometimes they are called drippers).

The ends of the structure are equipped with pediment, they are mounted with an overlap of 20 mm. It is necessary to drive nails in increments of 100 mm.Marked where the chimney will be removed. When the installation of the slats is completed, they lay the carpet in the valleys to increase the protection against moisture; this carpet has the same color as the roof itself. Roof tile can be replaced by a private, it will help reduce installation costs.

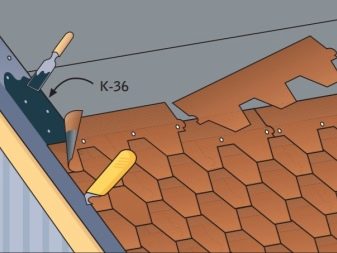

Ordinary tiles are laid, moving from the middle of the roof overhang in both directions. You can remove the protective shell from the shingles only before the installation itself, since only it allows you to fold the material in bundles. It is necessary to fix the shingles with nails (4 pieces are used for one shingle), but with a roof slope of more than 45 degrees, 6 are needed.

The first row is taken away from the ends of the overhang of the eaves by 10-15 mm, the second one is put in the same way, only by covering the notches of the first tier with petals.

The edges are cut along the edge line and glued, leaving a layer of 100 mm. It should be cut by planted plywood, then the lower layer will not suffer. Riddle shingles set, starting with the installation of the stage, then the blocks put an overlap of 50 mm or so. Eaves need to be cut along the lines of perforation - and so the ridge cover is obtained.Minor exits through the roof are organized with the help of rubber insulation, but the heating pipes are different.

The perimeter of the intersection of the pipe and the roof is covered with a triangular rail. Then mounted cushioning carpet, pre-lubricated with glue. The pipe is supposed to be insulated (with a closing of 0.35 m of itself and 0.25 m of a slope). When this is done, you only need to attach the adjacent strips around the perimeter of the pipes, mount the steel apron and seal the joints with a silicone-based mixture.

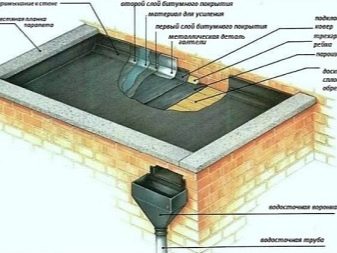

On a flat roof lay mostly rolls of roofing material of the European sample. It is sometimes used on a sloping roof with a slight slope. Roll out the roll, you need to align the folds, stretch the material. One of the sides is heated, waiting for the special indicator to melt. Immediately after this, it is required to glue the side to the substrate and roll out the roll to the next point of attachment.

It is required to weld the ruberoid with overlap of 50 mm, orienting strip helps to control it.

But overheating of the material can deprive it of its ability to adhere to the surface. Qualitative work is expressed in the fact that the surface has no voids, dark areas, and so on.Only strictly observing all the requirements, you can guarantee a long service roofing. The minimum angle of inclination of the roof, on which you can mount any type of soft tile, is 12 degrees.

Subtleties of winter installation

There are no principal reasons for mounting a soft roof during the cold season.

Attaching a soft roof is possible in two main ways. Most often used self-adhesive bitumen layer occupying the lower side of the tile. When the protective film is removed, the bitumen becomes soft and adheres to the substrate. But such material can only be used at a temperature not lower than +5 degrees and low humidity. If these conditions are not met, you will need increased warming up with special installations, therefore the cost of the work will immediately increase.

An alternative is the use of roofing nails with an external zinc layer and wide caps. This technique allows us not to think about the weather conditions - so long as they allow you to safely perform work on the roof. But errors during installation can lead to the destruction of the structure and the occurrence of leaks.SNiP prescribes to install a soft roof on nails only with slopes less than 20 degrees, and the slopes are inclined at angles from 15 to 25 degrees. The higher this value, the more actively the water leaks, so the risk of leakage is reduced.

To cover the roof in winter with ruberoid, you will have to use special heaters.

Even with this condition, the roofing material is supposed to be kept for several hours in a warm room. On the inside, all shingles are equipped with a self-adhesive layer of bitumen, which holds the parts of the structure together. If you only hammer in the nails, but do not warm up the material properly, it will simply disintegrate into its component parts. On the beautiful appearance and reliability in such a situation can not speak.

Roofing carpet superimposed on the eaves overhang and any end 40 cm wide. Joining is performed using large roofing nails, they are driven in 0.2 m from each other. Cover the eaves overhangs necessarily provide and steel strips. For the ends is designed its own type of slats - gable execution. The surface to be treated must be very clean and dry; when laying bituminous material, blocks from different packages should be used to avoid uneven distribution of shades.

The ridge is fixed with roofing nails of great length.

If it is long, you can put a few butt elements. A special ridge tile is placed on top, from which protective films are removed. The treated area is fixed with pairs of nails (left and right). Laying a soft roof on the ridge should be in the opposite direction relative to the prevailing winds, the fragments raid is 30-50 mm.

On the pitched roof, the material is welded and glued first at the lowest points, then climb up the slopes. The maximum allowable installation slope is 25 degrees. If it exceeds 15 degrees, you need to lay a soft roof along the flow of precipitation (at right angles to the feet of the rafters). But this arrangement is quite difficult, and therefore only individual enthusiasts resort to it. Pre-created monolithic obreshetka.

To obtain it you need to use:

oriented plates;

plywood sheets with increased moisture protection;

boards with a maximum humidity of 20%.

Kinds

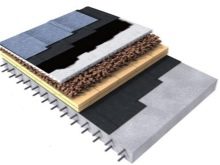

A soft roof is not one thing, it is a whole collection of roofing materials, united only by elasticity. The differences between them are due to the chemical composition, presentation and installation method.The rolled type is different grades of roofing material, roofing felts; it also includes the latest types of membrane products. It is possible to lay the roll relatively quickly, but its appearance can hardly be called attractive to people. Consumption per 1 square. m roll roof (with lining) of at least 500 rubles; they should be used only at an angle of inclination from 12 degrees.

Roofing material is very cheap because it is made of thick cardboard, but such a coating is relatively poor in tolerating temperature extremes.

Fiberglass is easier going through them, the fee for it is justified by increased quality and a long period of use.

Its advantages have shingles, called shingle (or otherwise boxed). These are tiles whose length is 1 m, and the width varies from 0.3 to 0.45 m, laying is overlapped. It will take more time to work than when using membrane solutions, but the self-adhesive layer helps to avoid the enhanced warm-up. The cost of construction is much higher, especially considering the cost of processing the base. It can only be a monolithic crate from moisture-proof chipboard.

The device of a flexible tile according to norms Construction Norms and Regulations includes:

fiberglass;

special modification of bitumen;

reinforcing bedding

Fiberglass - durable and randomly distributed inside the thread. Thanks to them, increased protection against heat, eliminating cracking. If you buy a premium expensive coating, it will be reinforced with polyester, which further enhances the practical qualities of the material. Bitumen is absorbed into the glass fiber with the inclusion of polyester resins and synthetic rubber. Such impregnation allows a soft roof not to get wet, suppresses the occurrence of mold fungi.

Reinforcing material (mineral granules of different colors) makes the surface rough. In most cases, use the crumb of marble, granite or basalt. Mastic (self-leveling) roof is built from expensive materials, but in general its installation work is relatively cheap. Roof works will be partially mechanized. The elimination of seams reduces the vulnerability of the structure to leaks. As for difficulties, it is extremely difficult to form homogeneous and uniform layers, and it is also unacceptable to carry out work with the slightest probability of precipitation.

Finnish roof Katepal has excellent practical characteristics, it can be used to realize a lot of design ideas.

This product has a specific type of bonding, it is very durable and retains heat well. Thanks to flexibility, it will be easy to trim a curved surface, complex curved roof elements. A well-thought-out design makes it possible to perfectly align the blocks with each other, ensuring the integrity of the coating.

As the basis it is possible to apply:

moisture resistant plywood sheet;

grooved board;

edged board.

To obtain the lining layer on the ends, valleys, skates and eaves, it is recommended to use a special proprietary development. Formation of overhangs is made of steel sheets stacked with offset. Begin to work, moving from the middle of the overhang. Before sticking all the elements must be cleaned from the protective film. Strengthen the mount can be due to nails. The installation of skates start in the last turn, using special ridge tiles.

The colors and texture of soft roofs are quite varied., the differences between them appear in texture.There are options that mimic the appearance of a natural tile and even a specially aged version, as if the surface was overgrown with mosses or lichens. If mastic-based solutions are applied, various pigments are added to it. Due to this, you can get the desired effect. Important: the carpet of endovy or galvanized metal should have the same color as the soft roof itself. If this is not the case, the designer dissonance will exclude an attractive appearance.

Bituminous and bitumen-polymer varieties of rolls are applied in four different ways. The addition of hot mastic consisting of bitumen (by itself or mixed with rubber) is time tested. The disadvantage is the need to mechanize the whole process, to involve the whole team of repairmen. You can also glue a soft roof onto cold mastics such as “Vishera”; but this approach is suitable only for materials whose thickness does not exceed 0.28 cm. Mastics in this case are used for lubricating not the substrate, but the coating to be attached.

The option with cold fusing involves the dissolution of bitumen from the inside of the material.

The bottom surfaces of the sheets are treated with kerosene or white spirit, the same substance is applied on the primed surface. The strips are attached with a side overlap of 100–120 mm; at their ends, they are fixed with a 150 mm foray. You can do the work alone, but for this you have to work very quickly. It is necessary to weld rolled material with a clutch of melted or heated back layers of materials treated with bitumen mastics, it is possible with the help of gas burners.

The disadvantages of this approach are obvious:

partial burnout of the roof;

weakening the wear resistance of the coating;

high risk of fire.

It is much better and safer to work with infrared heating systems; this work is done by at least two people. One performer spins the roll and melts the surface of the sheet, and the other with a silicone roller presses it to the surface. Self-adhesive materials can be attached without additional effort only when working with thin insulation. Its thickness does not exceed 0.12 cm, the decorative properties of such a coating are zero. Yes, and the durability of the material is too small, it wears out quickly.

Specifications

The quality of a soft roof is determined both by the technology of preparation of the bases and the quality of fixing the blocks. Manufacturers have made every effort to improve the technical parameters of the coating, and continue to improve their products. Once rolled materials could only protect the roof from getting wet, but now they are attractive in design terms. The flexible shell of the roof of houses is now being delivered in a convenient packaging, and a small width makes it possible to unwind the roll in any direction. Engineers were able to increase the resistance to tearing, and modern rolls can be laid out with little equipment with tools and accessories.

Roofing material of the latest generation allows you to close on 100% of the base of any configuration, even with a very complex geometry.

There is no need to leave the house, because the noise at work is very weak and there is no danger to health. Pie roofing over a warm attic can not be limited to a combination of hard lining and a soft outer layer.

In addition to them, you will need:

waterproofing membrane (laid over rafters);

thermal insulation using basalt or mineral wool;

vapor barrier;

elaborate crate.

The soft roof thanks to the rough layer allows you to abandon the installation of snegozaderzhateley. A lining cake should be made at the bottom if the roof is steeper than 20 degrees. The lining is mounted only on the most vulnerable points. It must necessarily be above the valleys and gutters, at the junctions between the slopes and walls. The rough sheath of a number of materials retains not only snow, but also dirt. Therefore, if you plan to use the roof for leisure and in general often visit it, it is better to use smooth surfaces.

Preparatory work

Soft tiles are mounted differently than metal tiles; sheathing from a bar is not suitable for it, because the material does not have a clear fixation. If a board is placed at the bottom, it is recommended to purchase it in winter, and apply it in the warm season. Then the humidity level will be fully optimal. The best versions of the boards - with a width of about 100 mm, and all elements should have approximately the same size.The roofing carpet next to the skates should have a length of 250 mm, and on the sides of the valleys this distance is 0.5 m.

According to the scheme required to equip the ventilation system; if it does not work efficiently enough, the rafters will quickly collapse with condensate, ice and rot. Be sure to equip airways and air outlets under the eaves. The gap from the tile to the base of the roof also plays a role in airing the inner parts of the roof. This technique also solves the problem of water vapor escaping. Rolled materials are fixed using cold and hot mastics.

Cold mixture is needed for the internal segments of the roof, outside work exclusively with hot substances.

If bitumen is used, it must be supplemented with fillers with pulverized (lime, gypsum or ash) or fibrous structure. The best mastic among professionals are those that contain polymers. Preparation of cold compounds from the components at hand is easy. They take two working containers, one of which is filled with bitumen, and the other with solarium and filler (in a ratio of 2: 2: 1).

The tanks are heated to 180 degrees; After drying the bitumen, you need to mix the prepared substances. Getting hot mastic is achieved somewhat differently: bitumen is heated to 200 degrees and gradually, with care, add to it a filler. In the process of mixing substances should not be cooled to more than 160 degrees. To assess the quality of the resulting composition, it should be cooled to 60 degrees, and then applied to the ramp with an angle of 45 degrees. A decent mastic should not flow from the surface itself, and when it hardens, a smooth surface forms without a single crack.

The base of the structure is made of wood, which is impregnated with a mixture of diesel fuel and bitumen. Then the surface is smeared with mastic, and only after that you can lay asphalt and roofing felt. The sheathing pitch under the ondulin roof, the slope of which exceeds 12 degrees, should be small; its exact value is determined for each specific underlying material. The vapor-waterproofing film under the soft roof is made of polyethylene and polypropylene, it is reinforced with a mesh or cloth. Microscopic perforation protects the coating from moisture, and if it does not, the film will allow steam to pass through.

Equipment for ventilation systems

Installation of ventilation under the polymer roof is quite a complicated matter - aerators, flygarki and airways will be needed. After all, the overlapping of vapor-tight membranes does not allow water to escape from the roofing space. Aerators should be installed even in the case when a completely new roof is being created, covered with liquid rubber. Small flyugarka put on every 60 square meters. m, and large - for every 100 square meters. m roofing space. The gap between close aerators should not exceed 12 m.

The ventilating knot is put most often where plates of heaters are joined. But when using PPU for insulation, there are simply no boundaries, so it is better to consult with experienced engineers. In the course of repairing the old roof, the best solution is the installation of ventilation points where large bubbles and bulges are detected - they show where the vapor exits. Fastening of aerators to roofs and canopies of soft roofing should be carried out on self-tapping screws placed in five or six places along the entire perimeter of the structure.

The necessary points, as indicated by technical regulations, must necessarily have an internal reinforcing layer.

Rules of operation and repair

Dismantling of the roof of bitumen - is not too complicated, but it requires some accuracy and care. If you need to perform work in the overhaul or in a dense development area, it is better to turn to professionals. Self-manipulation cannot be safe and effective enough. But if it is nevertheless decided to do this, special tools will be needed - a wall chaser, a roofing ax. It is required to work only in dry weather and at a temperature of maximum 20 degrees, because with considerable heating bitumen melts and complicates the analysis of the structure.

Of course, before dismantling all the decorative elements, electrical and antenna equipment, lightning conductors must be removed. Problems often arise with chimneys and ventilation, therefore, in the presence of such structures you should not try to repair the roof yourself. Adjacent to the wall of the structure of a soft roof is achieved by various technical solutions. Insufficiently even or partially destroyed brick walls are covered with plaster for a closer approach.It is possible to provide waterproofing of joints only after the final drying of the mastic.

A flat roof should be attached to a reinforced concrete wall only if it is flat and has no cracks or chips. Having noticed such defects, they are eliminated with the help of any suitable sealant. The slightest protrusion behind the contour is immediately removed. Mandatory processing primers. Nails for soft roofing should be special, they are used if the base is made of wood or plywood sheets.

Experienced roofers must have a supply of nails of various lengths and thicknesses in order to cope with a variety of problems.

The approach to repairing a coating depends on its immediate appearance. With minor (up to 40% of the area) deformations, it is permissible to limit to the replacement of single affected areas. In more serious cases, it is impossible to do without removing the entire coating and laying in place of its new layer. The areas where the patches will be laid should be cleaned of dust and degreased.

The area of each applied patch must be 30% or more greater than the defect itself. If the total area of the roof is small, sometimes it turns out just to put a new layer without removing the old one. But you need to thoroughly consider whether security will be ensured at the same time, because it is almost impossible to control the state of the inner layers. When overhauling, it is advisable to inspect all the drainpipes, parapets, ledges and pediments, other elements, and if necessary, change them immediately. To extend the life of a soft roof and reduce the need for its repair, you need to properly operate the coating.

Regular inspection is very important: it is done in spring and autumn, when the air temperature is +5 degrees. Large fragments of garbage must be collected manually, and small contaminants are removed with soft brooms. Be sure to clean the gutters, gutters, remove mosses and lichens, disinfect problem areas. If a layer of snow or frost forms in winter, it is carefully removed with scrapers made of rubber or plastic, taking care not to touch the surface itself. Of course, while strictly adhered to precautions when working at height.

Video lesson on the installation of a soft roof in the video below.