Fold roofing: features of the device and installation recommendations

Among the many types of roofing structures, a special place is folded. But most people didn’t have a deep and high-quality idea about him. Deal with the features and nuances of such coverage is extremely important.

What it is?

Fold roof is becoming more and more popular, and the reason is connected with such advantages as:

- stable quality;

- excellent level of protection against external negative factors;

- reliability.

Such roofing material is inextricably linked with Russian classicism in architecture., and this construction is often used in the reconstruction of the original appearance of historical monuments. But the device fold and justified with a completely new construction.Most often it is mounted on the pitched roof. It is difficult to find another solution that would work stably even at an inclination angle of only 3 degrees.

Manufacturing features

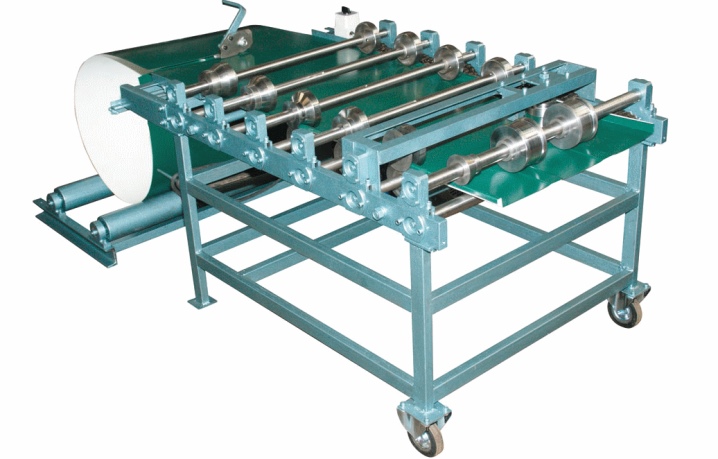

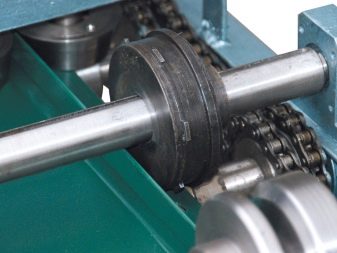

The production of seam roofing materials on their own does not cause any particular difficulties. For this purpose, apply a "frame" (sometimes called "hapami"), such devices will help to create a folded knot in a couple of steps. It is manual machines that help to mount the roof with significant slopes or having an atypical configuration. Semiautomatic systems are placed in the place where the seam is to be passed, and are guided through it with a cable. As a result, immediately prepared fold appears (double, standing).

The speed of work and the quality naturally increase her (after all, the semiautomatic device has very little effect on the plastic outer layer). It is recommended that such systems be used when laying long ramps. Electric devices save a lot of time and effort, almost completely eliminate the risk of error. The work comes down to setting the device in the right place, it is started and monitored for correct manipulation.The market of electric folding machines is highly monopolized, and the best results are given by the devices from Schlebach.

The Flitzer model helps to save material, and a noticeably more expensive Piccolo modification is capable of forming a G-shaped fold, covering arched roofs with material and using additional sets of rolls.

Sheet seam elements that do not have transverse seams, sometimes mounted independently without a specialized tool. The rolls are made entirely on the construction site, for this purpose, the falsetserokatny machine is used. As a result of processing, paintings are created that have a double fold and a randomly selected length.

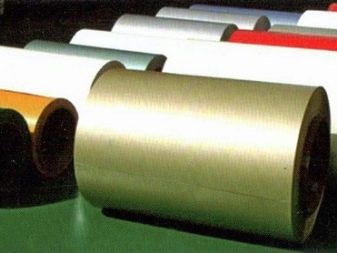

The rolled production technology of a faltsevy roof received such name because roofing pictures are made of the metal rolled into a roll. On a folding machine, a picture of the desired length with a double rebate is formed right at the construction site. The blanks for the final production of the folded structures are produced by Russian, German and Bulgarian enterprises. The choice between them is a largely subjective matter, you need to focus on feedback on the practical use of various designs.

Cost does not always mean high quality products.

Fold roof is formed by durable substances that are well resistant to corrosion. It is completely sealed, because there are no through fasteners.

Even if the bearing elements of the building are deformed, the fixed sheets form a practically indestructible system. Fold technology can be applied on roofs of a very complex configuration, with a very small slope. Even the quadrature is almost unlimited in this case.

But along with these advantages, as well as saving roofing materials, excellent resistance to weather excesses, excellent anti-corrosion properties and lightness, you need to remember about the shortcomings.

It is impossible to achieve anything if there is no training, special installations. The high thermal conductivity of the metal means that it is necessary to thoroughly insulate the roof and arrange the roofing pie according to all the rules.

Steel, aluminum or copper sheet when rain falls and hail is very noisy, and therefore will need to make additional components and increase the level of sound insulation. It is impossible to refuse without mounting snow guards, because only they provide a guarantee that suddenly a miniature “avalanche” will not come down from above.

Classification

Fold roof can have a variety of patterns (textures).The sword has been used on copper roofs for many centuries, it has received special distribution on the buildings of the Christian cult. The square may have sides of 0.5-0.6 m, but in order to give it a volumetric appearance, the sides bend a little. For fixing use clamps.

Its color is very different, and in addition to the classic yellow tone, it can be used:

- oxidized brown;

- tonality of tinned copper;

- malachite color.

Bulk checker is more expensive, because it is more difficult to create it. But the amazing appearance and visual volume justifies all the costs. Diamonds differ from checkers by the inequality of the diagonals. This design step helps to maximize the focus on the vertical orientation of the roof. The size of rhombuses is selected individually.

Volumetric rhombuses (otherwise called plowshares) in the past were used strictly in cult and palace architecture. But the development of technology has made this format accessible to most people. But the texture "scales" is considered very beautiful, although it is very inconvenient to use it - this roof is purely decorative, and it also requires solid knowledge.Much easier for beginners builders texture "brick". Such a design can be applied not only on the roofs, but also on the walls.

According to the materials

In the production of faltsevoy roof can be used quite different types of metal.

This greatly affects the duration of use:

- Galvanized steel structures last a quarter century. The application of the polymer layer increases this time by 5-10 years.

- Copper roof will last 100 years.

- Aluminum roof retains its quality for about 80 years.

- The zinc-titanium version is more difficult to operate than other metal systems. But if the technology is not broken, its shelf life is almost unlimited.

Also the folded roof can be steel with a combination of zinc and enamel layers.

The best indicators are materials with a shell of copper, which is not only very good in its parameters, but also perfectly processed.

Aluminum is slightly worse in practical properties., but also allows you to create an airtight roof, and with an extraordinary design. The combination of titanium and zinc is very expensive, and if galvanized steel is coated with enamel, reliability and service life will be unsatisfactory for the consumer.Therefore, a simple galvanized metal can be considered the best in terms of cost and quality of coating.

If you need to achieve excellent UV protection, prevent ignition and facilitate installation on roofs of any shape, you should use aluminum construction. Ease of material allows to refuse powerful rafters and strengthening of the base. Their cost is relatively small, but the noise when falling rain drops more than when using other materials.

Aluminum is not too strong, and it is undesirable to put a roof out of it if there are some trees higher than the house itself, especially trees.

The ease and durability of galvanized structures allows us to consider them a confident contender for leadership.

Aesthetic properties allow to inscribe such roofs in any landscape and not to think specifically about the choice of architectural styles. It will take several years, and a noble patina will cover the upper part of the building, giving it a chic appearance. If, however, take advantage of certain technological methods, this effect will appear much sooner. Galvanized coating should be stored and transported very carefully so that it does not get moisture. If this is not done, a nasty whitish bloom will appear.

By type of connection

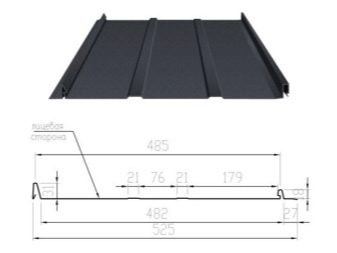

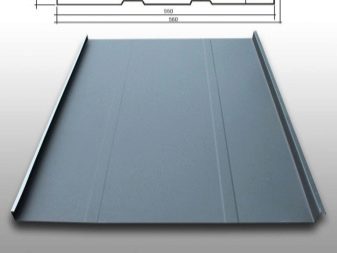

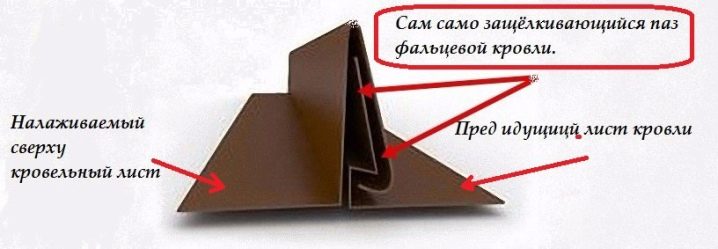

But even if it is clear what type of material is better to choose, the second problem arises - the assessment of various types of compounds. Each seller and manufacturer will convince, naturally, of the advantages of his own decision. The correct answer is simple: a suitable connection is one that allows you to solve a specific problem. Oblong stripes need to be fixed at the joints with a standing seam in the vertical plane and a recumbent - horizontally. Close seam connection can be with their own hands, and with the use of special tools.

In most cases, the roof is mounted using a self-snap view of the fold, it speeds up the installation and makes work easier.

Sheets are fitted with edges that are initially ready for fastening. Double lock is considered the most reliable connection option. Clickfalz is placed without the use of additional tools, the edges of the paintings are connected with a slight pressure. If the slope of the roof is relatively small, it is better to use double-click designs.

All fastening units, in contrast to the professional sheet, are hidden under the coating layer.The overlap places are used for the clutch, while using a cleat that captures the sheet roll with its hook. Single fold can be used only if the roof slope is at least 10 degrees. The double connection is more durable, and besides seaming machines, it can be made by bending machines. To increase the resistance of the structure to the ingress of water, you can use a special tape sealer.

In the form of release

To mount a folded roof is very difficult, and this work requires a significant level of training from the contractor. There are two main methods to do this - roll and sheet. The first type is relatively simple and can be applied in almost any conditions, but you will need to prepare sheets of strictly specified length. It is possible to install a faltsevy roof in such a way in the double mode. Each sheet will need to be customized, while the drawings for laying the material on each roof need to be prepared every time in different ways.

Rolled assembly goes like this:

- rolls refuel in the machine;

- they are rolled and cut;

- the workpiece is put on the crate and put the cleat;

- make out a faltsevy seam.

Dimensions

There is no clear linear dimensions of the folded roof. After all, it is collected and prepared for use directly at the construction site. But at the same time it is worth bearing in mind that the highest quality is achieved if the sheets completely cover each other. The distance from the edge should be 1.5 m, and the laying pitch should be 0.7 m. The main plane of the roof is made of black roofing steel sheets, the thickness of which is usually 0.6 mm.

The choice of the type and size of the lathing is determined by one indispensable condition - the surface should not bend under all the loads placed in the project.

The weight of 1 m2 of a folded roof with a thickness of 0.6 mm is 5.9 kg, and if you choose a material with a thickness of 0.7 mm, the mass already grows to 7.4 kg. These numbers refer to thin rolled steel with a zinc outer layer. If you take the roof covering of the smallest realizable thickness (0.4 mm), the mass of 1 square. m will be reduced to 5 kg. The finished seam picture is a bit harder, because locks are added to the profiling material, but the difference is a few tens of grams, so you should not pay attention to it.

Colors

The colored folded roof is formed by applying special decorative layers,moreover, the polymer coating is much more perfect than powder coating - it does not exfoliate at such an impressive rate. The choice as a polyester coating helps to save on the exterior finish. Such plastic can give the base a variety of colors. If you need a matte surface, most often take Pural, it is smoother, and the layer of this material is thicker - 50 microns.

Due to this property, the wear resistance and mechanical strength increase, but at the same time the total cost increases.

When selecting the tone, they try to focus on the style of the building.

Scandinavian house format is most often covered with a black roof. High-tech style is much better combined with elegant silver tint. There are a number of typical colors, among which are green, cream, blue and others. A more accurate list should be clarified with specific manufacturers. Making a folded roof of atypical color is quite possible, but the fee for it is calculated additionally.

Required tools

Folding machine - a necessary attribute in the preparation and installation of a folded roof.After all, the sheets of metal must be processed carefully and, moreover, very intensively. Other elements will be needed. The material itself is sold in rolls and is initially cut according to the dimensions of the specific structure. During the work with it use both manual, and electric tools.

If it is necessary to process metal on the roof of a large area, electrified machines, capable of automatically forming seam seams, are preferable.

Judging by the operating experience, profitability is achieved when working with seams of 10 m or more. Initially, the fold is folded, then it is finally crimped. If you apply semi-automatic devices, you can increase the speed of work by several times and even increase their quality. Faltsezakatochny systems are used mainly in large-scale construction, when you want to produce a wide range of additional elements in the shortest possible time.

Machines are pre-configured in accordance with the request of the customer (for example, in the valley).

The technique can by itself, without the help of people:

- unwind the roll;

- measure the necessary points and lines;

- make a cut in the longitudinal and transverse planes;

- modify the edges to perfect condition.

You need to mark the roofing pictures with the help of a tape measure, a ruler, a pencil and a square. According to qualified roofers, to roll up the rebate manually will not work if you do not use a mallet. When working in a hard-to-reach place, a seam hammer, recognized by a shortened handle, is of great importance.

All tools worth taking with plastic tips, they manifest themselves much more efficiently than usual options.

You should definitely have a scissors for metal, both left and right.

Manual compression of the seam is achieved using the so-called "frame"Its working length is 220 mm. In addition, it is worthwhile to take an arbor blade and special tongs that facilitate the opening of randomly deformed folds. The pliers, chisel and file will also be included in the home craftsman's kit. Using a drill is not very practical, where the best results at work demonstrate screwdrivers.

Installation procedure

To equip the roof of all the rules, you need to either wait for the temperature of the air to be acceptable, or stretch the awning from above to ensure tightness.But regardless of the season, the very first step, allowing to make a high-quality folded roof, is the collection of the necessary information. You need to know everything about how the structure will be used, how durable this solution should be, what are the aesthetic and practical requirements for the roof. When preparing and calculating the need for a material, you do not need to invent anything - it is enough to focus on the relevant sections of the SNiP.

Fastening of copper faltsev roofs should be made either by inseparable or sparse crate. In the second case, the accuracy of the construction step is of particular importance. If it is broken, the steel sheets can sag, after which the seams are weakened, sometimes completely deformed. Under the self-latching folds and in some other cases, the crate is made of galvanized profiles.

According to the current rules, its complete installation should be carried out in such areas as:

- eaves overhangs;

- bladders;

- points of contiguity to the walls.

It is necessary to use just such a scheme in the case when the roof configuration is very complicated.Fold technology implies first of all the minimum angle of inclination from 14 degrees. If it is smaller, it is necessary to put a double fold on a solid basis. Hard roofs are distinguished by increased requirements for the under-roof space: there must be very strict compliance with humidity and temperature.

Proper formation of the roofing pie helps reduce the risk of condensation by reducing the risk of corrosion processes.

Having dealt with the main points, proceed to the execution of works.

Standard instruction provides for the preparation of paintings directly on the construction site. The marking of metal sheets is carried out manually, even if the subsequent preparation will be carried out by automation. Details with recumbent seam assembled in the picture, the length of which is equal to the length of the slope. Curving the side edges, you can get stand-up folds. At the second stage of the work, the elements are lifted and at the top they connect the sides of the paintings with standing seams.

Next, they are attached to the crate using clamps. One of the ends is inserted into the standing seam where it bends, and the other is attached to the timber.The openings of the inlet and outlet air pipes should be closed with galvanized steel aprons. So in general terms looks traditional technology arrangement folding seam roof.

The roll technique does not require the creation of transverse folds, and therefore the risk of leakage is much less.

When the pictures are connected, the next step is to harden the connection between the parts with silicone sealant. Be sure to require cutting machines, seamers and other specialized equipment. It is advisable to use the rolled method if you need to use steel with a high-quality polymer coating. The tightness of the coating increases, and during operation there is much less noise than usual. Importantly, the roll technique also works on a sloping roof, regardless of the slope of individual ramps, on their size and configuration.

When using panels with self-snapping fold, it is advisable to mount the sheathing of metal.

According to technological requirements, its installation should be preceded by the placement of anti-condensation film on the rafters. For solid reasons, it is recommended to lay out a structural film with a high level.steam diffusion. Thanks to it, the safety of the roof nodes will significantly increase, as well as their service life. Where the cornices are located, the junction to the protrusions of the building and the valley are mounted, a second profile of the sheathing is mounted, which increases the rigidity of the panels.

The places reserved for mounting snow holders are equipped with a pair of hat profiles. The ridge is attached to the upper raised edges of the paintings. Alternatively, you can put it on a perforated Z-shaped plank held by screws on the roof panels. Customers have a choice between flat and semi-circular skates. On this and any other protruding part it is required to put the caps - all work is reduced to bending the sheet aside.

The windows made in the roofs, chimneys and other openings are always blocked by aprons and wall profiles. To correct the discrepancy between the width of the sheets and the size of the roof can be, starting installation on the left side. The final sheet is cut with a turn of the roof of 30 cm. If the distance that is missing for the centering is quite small, they simply leave the bulging parts of the sheets, but lift them up to maintain the contour more clearly.For your information: usually, rails for the installation of wind bars are also put on top of the batten.

Ventilation

The strength and reliability of metal roofs, including folding, turns into a serious problem - the accumulation of condensate. Only high-quality ventilation can cope with this difficulty, and it should be stronger than simple. Very important ventilated obreshetka in which gaps are made. The pitch of the batten under the folded structure should be small, and ideally it is generally preferred to use a solid substrate. If it is obvious that natural ventilation will not be able to cope with their tasks, it is advisable to use aerators or deflectors (at least 2, the exact number is determined by the area).

Repair Tips

No matter how reliable the folded roof was, no matter how carefully they approached its design and construction, over time, repairs become urgently needed.

Make it necessary if:

- there are leaks on the seams;

- tightness at the junction of the chimney and coating is not provided;

- signs of mechanical damage appear;

- visible deflection of the roof;

- many places of slight wear have been noticed.

In all these situations, you must first find out whether a total replacement of the roofing is required or whether it will be sufficient to correct the problems in individual places.

Even if the seams themselves do not cause concern, they still need to be carefully checked. When leakages are detected, they are rolled, further processing with sealants. Best results are achieved with bitumen or butyl rubber based sealing compounds. Problems with the joints of the roof and chimney are eliminated only after assessing the tightness of the profile in these places.

Then the broken parts of the profile are changed, new parts are attached to the dowels and lubricated with sealant. Fighting holes in the roof without a complete replacement of the folded paintings and seal all the seams can be extremely rare. In the best position are the owners of houses that are covered on top with sheets of copper. Its flaws are corrected by means of tinning, then the patches necessarily overlap with a special mixture, which eliminates the visual distinction of the new and old coatings. A more serious problem is the deflection of the roof as a whole.

Here it will be impossible to manage with work with one coating.Be sure to assess the condition of the battens, beams and rafters.

Almost always it is necessary to alter and strengthen the trusses, change their broken elements. The most difficult thing is the complete replacement of the old roof. You can put a new one instead, even without dismantling the existing structure.

Pre-bend with a hammer all the seams, then put a new crate, and already on it is formed of the finished coating. The advantage of this step can be considered the preservation of the beautiful appearance and enhanced sealing of the roofing space. But you need to carefully assess the state of the original elements, and also find out whether the building will withstand the increased load. Before repairing, garbage should be removed from the sheets; to do this, use only brooms or brooms without hard fibers. The remaining dirt is removed with coarse and soft metal brushes.

Inspection of gutters and galls, in which corrosion appears most often, should be given special attention. All places cleaned from rust are additionally painted with exterior paint.Search cracks are in the bright hours, and in pairs, while inspecting the roof from the inside and outside. Having identified the strain, working inside knocking on the roof, and on it note the problem area with chalk. If the sheets are cracked, you will have to put patches on their entire width; only damage to the crest or areas around it can be repaired by local measures.

Holes with a diameter of less than 3 cm can be patched without patches. The hole is cleaned of dirt and traces of corrosion, the same is done in a radius of 3-4 cm around. The problem area is sealed with mastic made from red lead. Then pour the liquid bitumen and put roofing mastic. To close the hole and the inside and outside, otherwise the result will be unreliable.

Also minor flaws can be repaired with a tarpaulin, old bags or other thick fabric.

Matter itself must be whole, dry; cut exactly in size patches for a quarter of an hour kept in oil paint. Then they are removed, wrung out and put on the affected place. To keep the patch on it, use a brush, especially carefully you need to iron it around the edges.Drying takes 5-7 days, then it needs to be painted, only need to remove stray dust.

The process of installation of a folded roof, see the following video.